Low budget plasma setup, what do I need?

27 Jun 2019 02:33 #137950

by phillc54

Cheers, Phill.

Replied by phillc54 on topic Low budget plasma setup, what do I need?

Tom, I like the way you wrote PlasmaC instead of plasmac, I think I will change it to that it looks kinda neat...Use PlasmaC built in feature to generate ArcOK signal, dealing with plasma cutter guts is not healthy, it does not forgive mistakes.

It should work properly with some fine adjustment, in about 2 to 5 minutes of your time.

Cheers, Phill.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

27 Jun 2019 10:34 #137983

by pl7i92

Replied by pl7i92 on topic Low budget plasma setup, what do I need?

depending on Y length i thik the wrong Side of the Y bar used will bend as it is made for Wx WY use and in this setup i see it is the Force in Wz of the bar so not the best way to go

is it a 45x90mm bar we taking in Y or smaller and what is the max width between the X fix rails

to get a calculation on

if a Mechanical touch off is used i think it wil ltroubel

is it a 45x90mm bar we taking in Y or smaller and what is the max width between the X fix rails

to get a calculation on

if a Mechanical touch off is used i think it wil ltroubel

Please Log in or Create an account to join the conversation.

27 Jun 2019 11:28 #137990

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

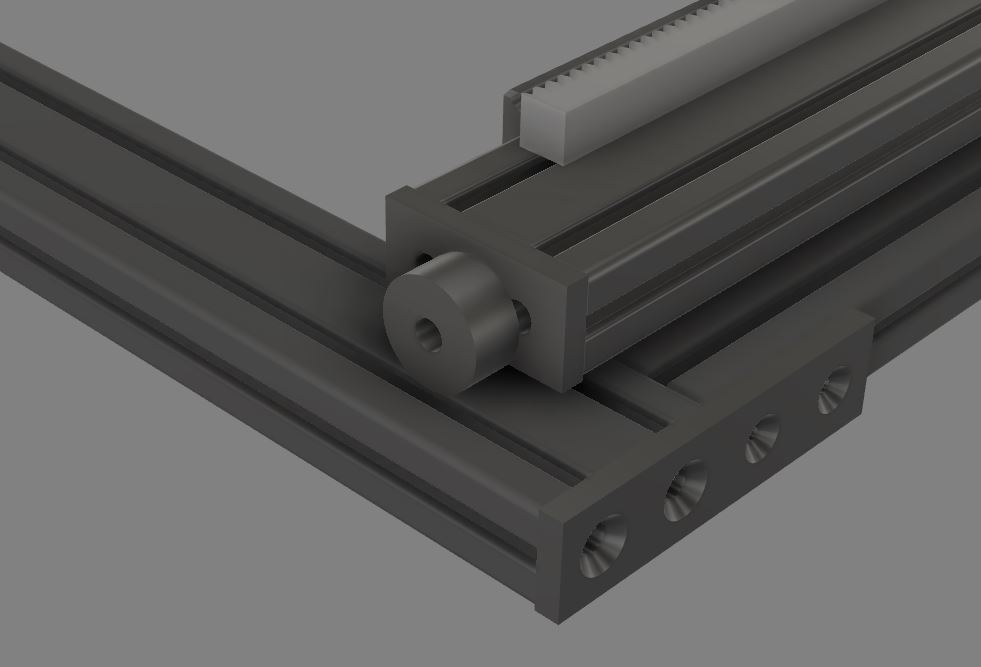

Profiles are thick wall 80 x 40 1400mm long + 800mm so the opening is 1240 by 800

This will give me plenty space to cut 1000 x 500 plates

Linear rails are 35mm for R1651 linear guides

The *arm* is 800mm long and supported with ball bearing so X is only with one rail.

So you are worried about torsion force on this arm, I can make the open arm to ride on two bearing well apart to counteract this if needed. I am not particularly worried about this as the load is not so high.

A secondary linear rail is easily fixed if needed on the other side but for now it will have to do with only one side.

This will give me plenty space to cut 1000 x 500 plates

Linear rails are 35mm for R1651 linear guides

The *arm* is 800mm long and supported with ball bearing so X is only with one rail.

So you are worried about torsion force on this arm, I can make the open arm to ride on two bearing well apart to counteract this if needed. I am not particularly worried about this as the load is not so high.

A secondary linear rail is easily fixed if needed on the other side but for now it will have to do with only one side.

Attachments:

Please Log in or Create an account to join the conversation.

09 Jul 2019 10:27 #138940

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

I have a question regarding consumables to P80 torch.

On Aliexpress there is 3 varieties of consumables = pro / std / diy

What is the difference on these, need only 1.1mm and 1.3mm

On Aliexpress there is 3 varieties of consumables = pro / std / diy

What is the difference on these, need only 1.1mm and 1.3mm

Please Log in or Create an account to join the conversation.

11 Jul 2019 05:12 #139059

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Anybody out there that can give me some advice on the consumables?

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

Less

More

- Posts: 1130

- Thank you received: 531

11 Jul 2019 05:16 #139061

by thefabricator03

Replied by thefabricator03 on topic Low budget plasma setup, what do I need?

Maybe ask the seller? Sorry I do not have any experience with those, only Hypertherm,

Maybe buy a small amount of all three and test each on the material you are going to be using.

Maybe buy a small amount of all three and test each on the material you are going to be using.

Please Log in or Create an account to join the conversation.

11 Jul 2019 05:25 #139062

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

www.aliexpress.com/item/32823645689.html

Asking seller? Most likely as good as asking my wall at home

I think I will go for the premium type.

Asking seller? Most likely as good as asking my wall at home

I think I will go for the premium type.

Please Log in or Create an account to join the conversation.

- thefabricator03

- Offline

- Platinum Member

-

Less

More

- Posts: 1130

- Thank you received: 531

11 Jul 2019 05:51 #139064

by thefabricator03

Replied by thefabricator03 on topic Low budget plasma setup, what do I need?

Those prices are not to bad,

My hypertherm consumables cost me $7.58 AUD for a single 45amp nozzle and you have to buy them in packs of 5. I mostly use the 125 amp nozzles and they are $14.85 each.

My hypertherm consumables cost me $7.58 AUD for a single 45amp nozzle and you have to buy them in packs of 5. I mostly use the 125 amp nozzles and they are $14.85 each.

Please Log in or Create an account to join the conversation.

11 Jul 2019 05:57 #139065

by tecno

Replied by tecno on topic Low budget plasma setup, what do I need?

Ouch that is costly.

Just ordered one pack each 1.1 + 1.3mm (20 nozzles total) Premium for ~50AUD

Just ordered one pack each 1.1 + 1.3mm (20 nozzles total) Premium for ~50AUD

Please Log in or Create an account to join the conversation.

- islander261

- Offline

- Platinum Member

-

Less

More

- Posts: 757

- Thank you received: 216

11 Jul 2019 14:27 #139105

by islander261

Replied by islander261 on topic Low budget plasma setup, what do I need?

We pay HT and TD (ESAB) for all their R&D spending every time we buy equipment/supplies. What we get in return are good cut tables and relatively reliable equipment. With a Chinacom plasma you have to be your own R&D department.

'03

Yes you pay more in Oz than we do here for HT consumables, about 33% more without factoring in exchange rates. I find that the HT consumable life is so good that their cost per cut unit distance is quite low. I also buy the 25 packs of nozzles and electrodes because a big part of my cost is shipping because there is no welding shop here.

John

'03

Yes you pay more in Oz than we do here for HT consumables, about 33% more without factoring in exchange rates. I find that the HT consumable life is so good that their cost per cut unit distance is quite low. I also buy the 25 packs of nozzles and electrodes because a big part of my cost is shipping because there is no welding shop here.

John

The following user(s) said Thank You: thefabricator03

Please Log in or Create an account to join the conversation.

Moderators: snowgoer540

Time to create page: 0.190 seconds