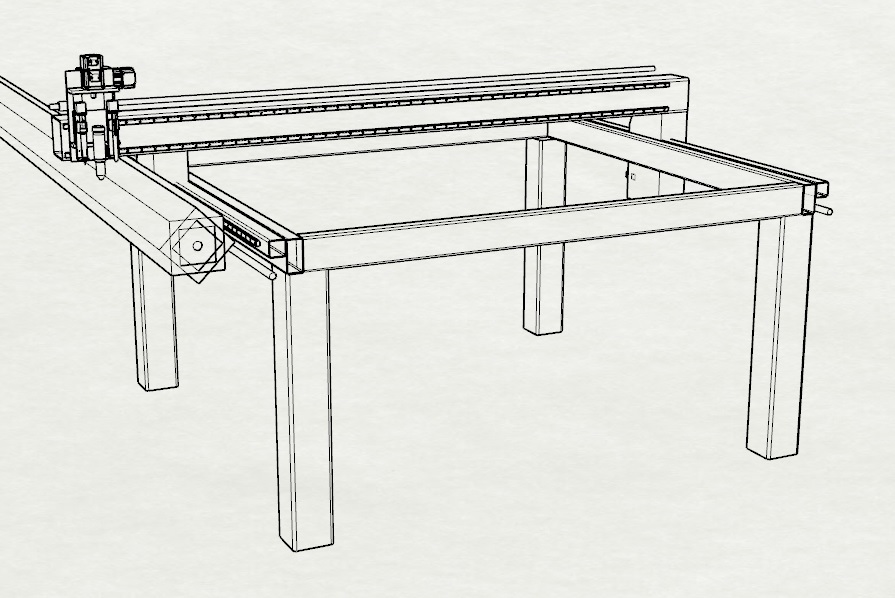

Plasma table + 4th axis

- chrisfischer

- Offline

- Junior Member

-

- Posts: 37

- Thank you received: 9

-5x5 table

-4th axis on the side big enough for 6x6 square tube (so far)

-I havent drawn this but I plan on indexing a full size tube for cutting every 5 feet so I can process a whole tube in one setup.

-scribe, sharpie, crosshair green laser, and hyperthem mini torch on the z axis (I plan to add a bolt on 20w diode laser someday... maybe)

-4 to 6 inches of z travel (going back and forth... probably 6)

-hypertherm 45xp with finecut consumables and shop air

-rotating ball nuts on x and y

-carbon fiber tubes for linear bearing on the z axis (provided I can get the od more precise using an od grinder... total experiment)

-chicago scribe and retractable sharpie deployed by steppers (as opposed to stuffmadehere's pneumatic example)

-torch collision detection

-designed for 2g acceleration (this is arbitrarily high and I am pretty loosely estimating things other than mass - like friction)

-mesa 7i96, thcad torch height control, thcad ohmic sensing, stmbl drives, 60ST-M01930 servo motors

-QTPlasmaC, touch screen monitor, sheetcam

-$6k budget

This machine will help me take on job shop work as well as prototype designs for a business I am building to manufacture motion simulators.

Attachments:

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

I have about 10 seconds of post flow on all plasma sources, so not an issue really, but shuting down the plasma while it is still wet is not good as it stops the air drying the torch.

Just leave it on untill the post flow stops.

Please Log in or Create an account to join the conversation.

- chrisfischer

- Offline

- Junior Member

-

- Posts: 37

- Thank you received: 9

I made an attempt at making commodity carbon tubes into linear rails lasts night. In the end, it was more trouble than its worth.

The tubes i bought were 1.5mm wall 25mm od tubes off amazon. My hope was to bairly scratch the surface to true in any change in diameter so I could slide an igus bearing on it smoothly. I already purchased 25mm igus bearings and they slid with slight changes in friction along the length.

I figured since they are made on a mandrel the id would be concentric but it was pretty out - like .4mm. This meant that I would have to drop the tube down to the next igus bearing size of 24mm. Of course that meant I could grind off a good amount of carbon. The grinder handled this really well. With coolant the wheel didnt load up at all.

Unfortunately the layers under the top are all pulltruded layers rather than a weave. I should have guessed this would be the case. Since there was only pulltruded fibers they were fraying in places rendering this tube useless.

The way to do this right is lay up your own tube with plenty of carbon past where you will grind it back to - all with a weave fabric. This doesn't sound appealing to me so Im changing the z bearings to linear rails.

Attachments:

Please Log in or Create an account to join the conversation.

- CarterKraft

- Offline

- Senior Member

-

- Posts: 46

- Thank you received: 7

Please Log in or Create an account to join the conversation.

I do, but not always. When using the machine every day i fill the table above the material about 1-3 cm, it is a nice showcase, less metal dust and less ultraviolet radiation. Does not last long though as it evaporates quickly if used all day in about two days it gets under the material level.

Tommy,

Do you have any issues with excessive dross, since the sheets are underwater?

I watched a video with Jim Colt who said cut quality can be better if the water level is slightly below the bottom of sheet.

I was also wondering if the water level affects the THC readings in your experience?

Thanks!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

No, and the dross that gets left is easier to remove when cut with water touching the plate or under water, it cools down much faster so has no time to stick to the rest of material.Do you have any issues with excessive dross, since the sheets are underwater?

In general, no amount of videos will help with cut quality, been there done that, the only thing that really helps is testing and more testing and writing the results.

Get some scrap sheets, set the plasma to say 50A, set the feed rate to 1500mm/m for say 3mm thick plate, check the air is sufficient and do 500mm cuts in a straight line, then do 1600, 1700, etc.

Look under it, get a small hammer and smack the dross see where there is the least dross and comes off easiest, write those settings.

Never ever change 2 or 3 parameters at the same time, that always leads to bigger mess than stared with!

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

Not in any noticeable way or form. The current is way to big for the minuscule amount of current that passes through water to cause issues.I was also wondering if the water level affects the THC readings in your experience?

Please Log in or Create an account to join the conversation.

Why not plumb a float-valve to the table? (And an overflow pipe in case that fails)

Does not last long though as it evaporates quickly if used all day in about two days it gets under the material level.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

I like to suffer!

Why not plumb a float-valve to the table? (And an overflow pipe in case that fails)Does not last long though as it evaporates quickly if used all day in about two days it gets under the material level.

That is easy to add, but never though of it, thank you.

Please Log in or Create an account to join the conversation.

- Dah-Lih Llama

- Offline

- New Member

-

- Posts: 7

- Thank you received: 0

So, ever make it anywhere past design stage?

Please Log in or Create an account to join the conversation.