Lathe Macros

As my lathe is set up as metric then if I put "1.25" in the box I get a 1.25 mm pitch thread.Is the threading function TPI only or is there a way to enter a metric pitch.

If your lathe is set up for imperial then you will get a 1.25" pitch.

However, if you put in the feature in post 48403 further up the page then you can type "25tpi" and it will automatically change to "1.016" and then if you type "mm" it will change to "0.04"

The cycles all start from where the machine is when the "go" button is pressed, so if I decide to interrupt the sequence I just jog to a suitable starting point and press the button again.Also, is there a way to recover the original setting if the code was stopped midway? If not how would you do it in practise

Please Log in or Create an account to join the conversation.

- Zahnrad Kopf

- Offline

- Elite Member

-

- Posts: 218

- Thank you received: 3

However, if you put in the feature in post 48403 further up the page then you can type "25tpi" and it will automatically change to "1.016" and then if you type "mm" it will change to "0.04"

Andy,

Speaking as someone that has been living with the same way of things for years and years, THAT is pretty darn nifty! Nice work. I'll definitely look at implementing that once this one is up and running. Thank you.

Please Log in or Create an account to join the conversation.

As my lathe is set up as metric then if I put "1.25" in the box I get a 1.25 mm pitch thread.

If your lathe is set up for imperial then you will get a 1.25" pitch.

My lathe is set up for metric. I am not clever enough to work in imperial

It looks like I did exactly as you would but the results are not the same.

I will implement the feature you mentioned. Will this feature be included in production (2.6.x) at any stage or will I have to make sure that I apply a fix after any update?

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

However, if you put in the feature in post 48403 further up the page then you can type "25tpi" and it will automatically change to "1.016" and then if you type "mm" it will change to "0.04"

Magic Stuff man. If I had paid attention to this I might have saved my threading tool.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

If I use the spinbox feature and enter 1.25mm it converts it to 0.0492 but then I get an error " In G76 K must be greater than J" You have J set at 0.2 so how does K get greater?

Must I modify the sub to use this in any way?

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

I think a radio button for metric/imperial will be required unless you have a better idea ( I hope ).

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

If I use the spinbox feature and enter 1.25mm it converts it to 0.0492 but then I get an error " In G76 K must be greater than J" You have J set at 0.2 so how does K get greater?

Must I modify the sub to use this in any way?

I am a bit confused by your problem. If your lathe is set up in mm, and all the other numbers are mm, then the thread pitch should be mm. (ie, 1.25 in the box is correct for a 1.25mm pitch thread)

I think that the subs include a G21, but perhaps they don't. Is your lathe accidentally in Imperial mode?

Please Log in or Create an account to join the conversation.

If you are confused by my problem then you must know how I am feeling already.

I spent many hours trying all kinds of things but it just remains the same.

The lathe is setup in mm - G21 present

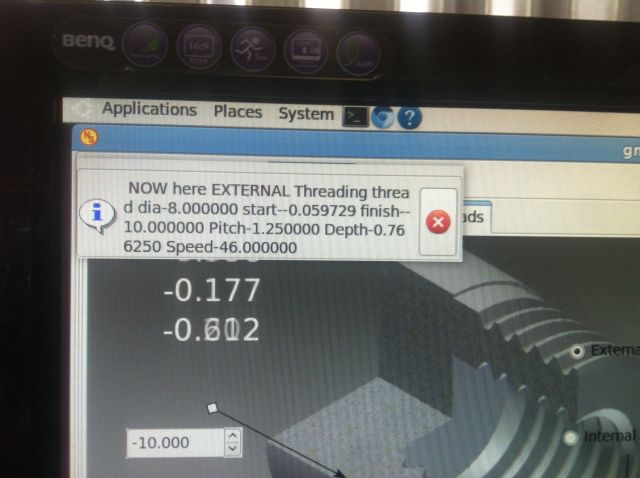

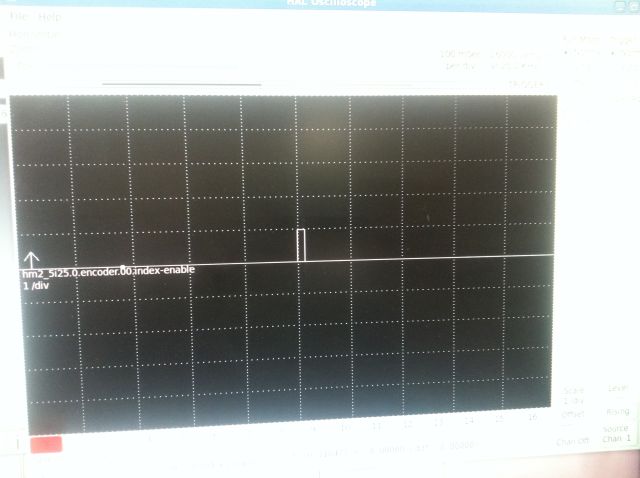

There seem to be an index enable pulse that occurs every revelution of the chuck.

Have a gander at the pics included.

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.

The lathe is setup in mm - G21 present

There seem to be an index enable pulse that occurs every revelution of the chuck.

How much does the value of motion.spindle-revs increase for a single rotation of the chuck?

I should count complete revolutions, and increase by 1 for each revolution.

Please Log in or Create an account to join the conversation.

What I just noticed is that the feedrate remains the same no matter what spindle speed I select. Surely that does not seem right?

Regards

Marius

www.bluearccnc.com

Please Log in or Create an account to join the conversation.