Problem loading PlasmaC for the first time

I seem to have a problem with torch on. Looking in Hallshow at torch_enable it triggers with the Torch-enable button but the torch on LED does not come on.

Also the Ark OK is on all the time.

I have tried putting M3 &0 S1 in the MDI and M3 S1

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

Please Log in or Create an account to join the conversation.

It seems a lot of your problems were caused from the [TRAJ]LINEAR_UNITS = metric line in your original .ini file. "metric" is invalid, it should be "mm". linuxcnc.org/docs/devel/html/config/ini-...g.html#_traj_sectionPhill Well spotted with the [RS274NGC] re the probing It was running so slow I could not see it I had to change the speed in the motion tab.

Torch Enable won't fire the torch, is only enables it to be be fired. It is basically to start your machine in a safe mode.I seem to have a problem with torch on. Looking in Hallshow at torch_enable it triggers with the Torch-enable button but the torch on LED does not come on.

Torch Pulse will fire the torch if it is enabled.

You cannot fire the torch from MDI because the probing and move to pierce height sequence has not been completed.

As Tom said, you need to have the OK High Volts and OK Low Volts set correctly.Also the Ark OK is on all the time.

Please Log in or Create an account to join the conversation.

.

.It seems a lot of your problems were caused from the [TRAJ]LINEAR_UNITS = metric line in your original .ini file. "metric" is invalid, it should be "mm". linuxcnc.org/docs/devel/html/config/ini-...g.html#_traj_section

I can't be certain but I am pretty sure I did not put metric in that line . I do know that it can only be mm. That is why I commented it out and had to change it to be able to run.

On looking at my original ini file (before the your configurator) I see metric is in there as well. This was built with JT's configurator for the 7i96 back in September. I will check that out when I get the time. This was never used with any hardware so it got missed.

Did I read somewhere that you have some test code for the spanner that I could use?

Please Log in or Create an account to join the conversation.

The spanner/wrench is in nc_files/plasmac

Please Log in or Create an account to join the conversation.

It is a steep learning curve.

The spanner/wrench is in nc_files/plasmac

Yes I am getting there

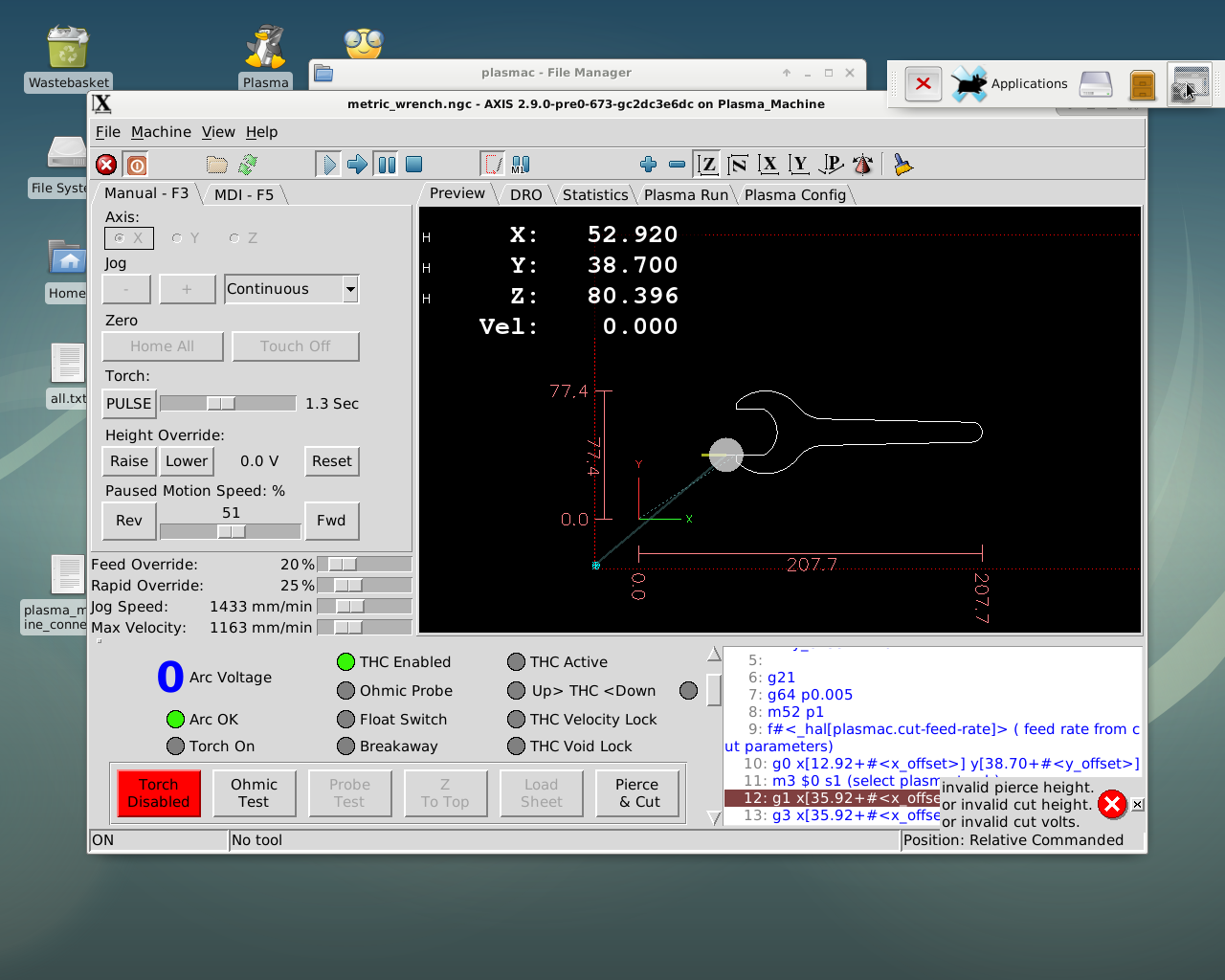

Is it possible to do a dry run without the the plasma cutter connected to check if the probing is working as expected at the moment it errors out.

I can now fire the torch on relay. but I don't have the slats in the table yet

Attachments:

Please Log in or Create an account to join the conversation.

That error message is saying one of the cut parameters in the Run Panel is invalid.

Please Log in or Create an account to join the conversation.

Yes, if you run while the torch is disabled it will do a dry run, which is everything except torch and THC.

That error message is saying one of the cut parameters in the Run Panel is invalid.

Success, at last have had it simulating cutting the spanner at 9mr/min with no errors.

Next job is to try and calibrate the the THC-10 not sure how to do this yet. I have tons on this but my brain exploded

I am using a cut40 scratch start cutter and wired the THC inputs to each terminal via a 1 meg R very close to the terminals.

The output from the THC via a cat5 to the 7i96 encoder.

I have tested the torch on with the cut40 connected to verify the torch firing via the pulse

Is this all correct?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 19011

- Thank you received: 6371

Now comes the hard part of somehow making it actually start an arc?

Is the floating switch working?

Please Log in or Create an account to join the conversation.

Yes.

Now comes the hard part of somehow making it actually start an arc?

Is the floating switch working?

Yes I have a floating switch and breakaway on different inputs

So you can educate me. That's the hard part

Please Log in or Create an account to join the conversation.