wedm con ejes xyuv

- darito78

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

16 Apr 2022 01:47 #240362

by darito78

wedm con ejes xyuv was created by darito78

hola a todos quiero poner linuxcnc en una cortadora de hilo de molibdeno de 4 ejes xyuv, hay un modo de hilo caliente pero el problema que tengo es que los ejes uv estan montados al marco o sea se mueve la mesa para x e y pero el problema es cuando quero usar los 4 ejes no se como deberia configurar los ejes uv ya que si quisiera hacer un cono los ejes uv deberian moverse solo en la diferencia entre X y U y entre Y e V. muchas gracias a todos.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4594

19 Apr 2022 22:34 #240697

by andypugh

Replied by andypugh on topic wedm con ejes xyuv

I am not fully understanding the description of the machine.

You might need a modified kinematics file if the U and V are mounted on the X and Y. But it should be a very simple one.

You might need a modified kinematics file if the U and V are mounted on the X and Y. But it should be a very simple one.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21150

- Thank you received: 7222

19 Apr 2022 23:27 #240703

by tommylight

Replied by tommylight on topic wedm con ejes xyuv

There is a sim config for foam cutting included with LinuxCNC that has the same geometry and axis, i think.

It is aptly named "foam" under sim/axis/

It is aptly named "foam" under sim/axis/

Please Log in or Create an account to join the conversation.

- darito78

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

05 May 2022 18:23 #242057

by darito78

Replied by darito78 on topic wedm con ejes xyuv

hello tommylight thanks for answering, the configuration for foam does not work for me, I have a 4-axis commercial wire machine in this the table moves. the axes U and Y are mounted on the bridge, so when I make figures in 2d it works, the problem is when I make 3d in axis it is configured for 2d that they move together X, u and Y, v but in the machine I have for 2d it only needs to move in X and Y so u and v don't have to move

Please Log in or Create an account to join the conversation.

- darito78

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

05 May 2022 18:28 #242058

by darito78

Replied by darito78 on topic wedm con ejes xyuv

hello andypugh thanks for answering, of course it is difficult to explain in this machine the table moves like in a milling machine and the u and y axes are assembled in the z head for explaining it in some way and what I should do I think that the u and y axes should move by themselves in difference between x and u and between y and v but I really don't know how to do this

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21150

- Thank you received: 7222

05 May 2022 21:15 #242072

by tommylight

Replied by tommylight on topic wedm con ejes xyuv

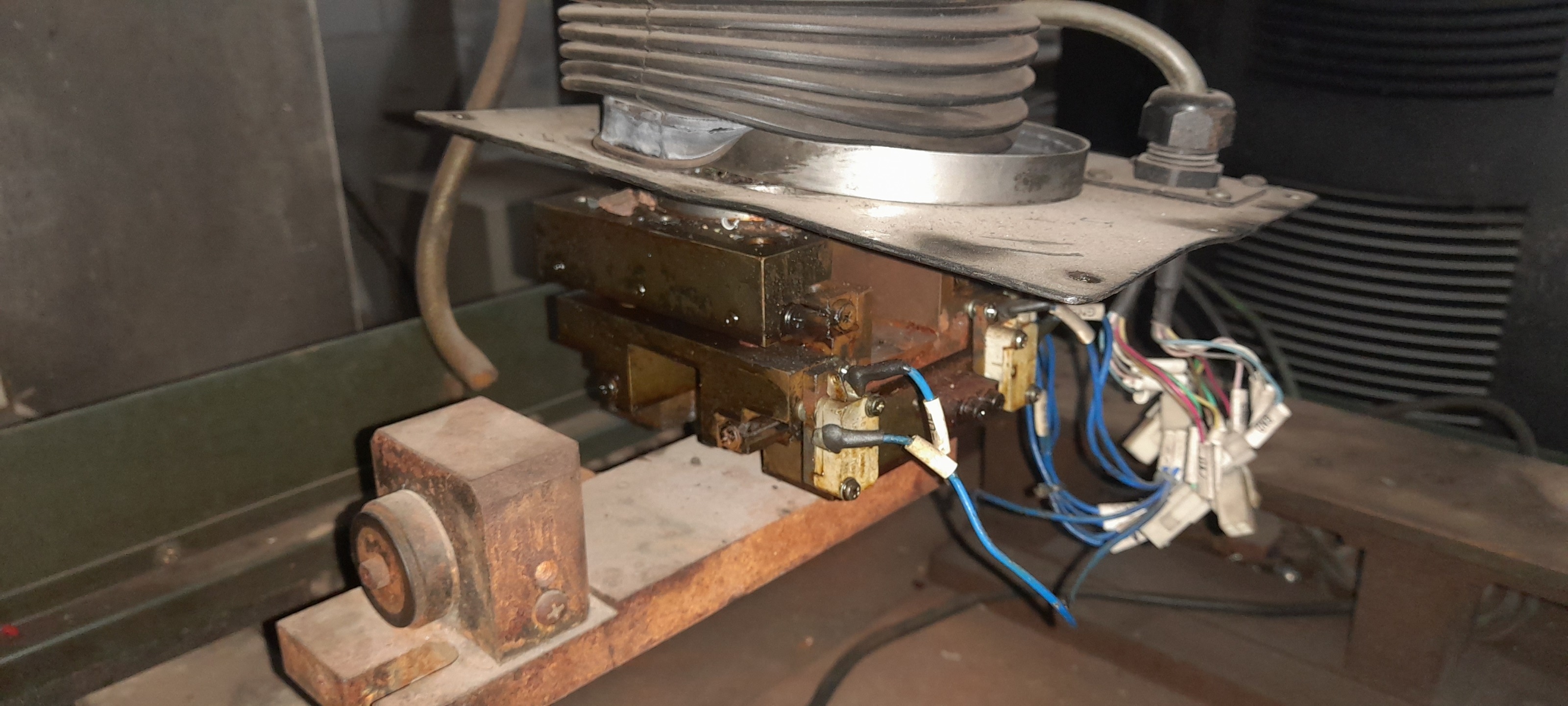

Pictures? Videos?

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

05 May 2022 21:31 #242073

by Henk

Replied by Henk on topic wedm con ejes xyuv

I have a similar wedm machine that I started retrofitting but have not got to the point where I started playing with the u and v axes.

Basically, the u and v axes move relative to the bottom wire guide and that determines the angle between the wire and the xy plane. The angle is also affected by the distance between the upper and lower wire guides.

I think it would help to know how these machines were programmed originally.

For example, if you want to produce a cone shaped hole that is say 20mm in the bottom and 30mm Dia at the top, and the guides touch the work surfaces (not possible, but just to make the point) ....then the gcode would be something like this

Starting at x10 y0 and u5 v0

G3 i-15. (For xy)

But the u and v axis should then follow a similar circular path, but with a radius of 5. And I don't think it is possible to program that in one line,which I believe is the problem described above.

Maybe there is a simpler way?

BTW. How are you dealing with the spark generator?

G3 i-15

Basically, the u and v axes move relative to the bottom wire guide and that determines the angle between the wire and the xy plane. The angle is also affected by the distance between the upper and lower wire guides.

I think it would help to know how these machines were programmed originally.

For example, if you want to produce a cone shaped hole that is say 20mm in the bottom and 30mm Dia at the top, and the guides touch the work surfaces (not possible, but just to make the point) ....then the gcode would be something like this

Starting at x10 y0 and u5 v0

G3 i-15. (For xy)

But the u and v axis should then follow a similar circular path, but with a radius of 5. And I don't think it is possible to program that in one line,which I believe is the problem described above.

Maybe there is a simpler way?

BTW. How are you dealing with the spark generator?

G3 i-15

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21150

- Thank you received: 7222

05 May 2022 22:44 #242079

by tommylight

Still waiting on eye candy ...

Replied by tommylight on topic wedm con ejes xyuv

10 ?But the u and v axis should then follow a similar circular path, but with a radius of 5.

Still waiting on eye candy ...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19770

- Thank you received: 4594

06 May 2022 19:26 #242166

by andypugh

Replied by andypugh on topic wedm con ejes xyuv

I think that the foam config probably can work.

You can treat XY and UV as independent, and use conventional G-code (possibly even from foam-cutting software)

Then, either use a custom kinematics which subtracts X from U and Y from V, or do exactly the same thing in the HAL layer.

If it was my machine I would experiment with which worked best in terms of homing (especially) and limit switches.

You can treat XY and UV as independent, and use conventional G-code (possibly even from foam-cutting software)

Then, either use a custom kinematics which subtracts X from U and Y from V, or do exactly the same thing in the HAL layer.

If it was my machine I would experiment with which worked best in terms of homing (especially) and limit switches.

Please Log in or Create an account to join the conversation.

- darito78

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

07 May 2022 21:07 #242257

by darito78

Replied by darito78 on topic wedm con ejes xyuv

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.320 seconds