- Hardware & Machines

- CNC Machines

- Milling Machines

- Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

29 Dec 2025 18:03 #340667

by workshop54

Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT) was created by workshop54

Hi all,

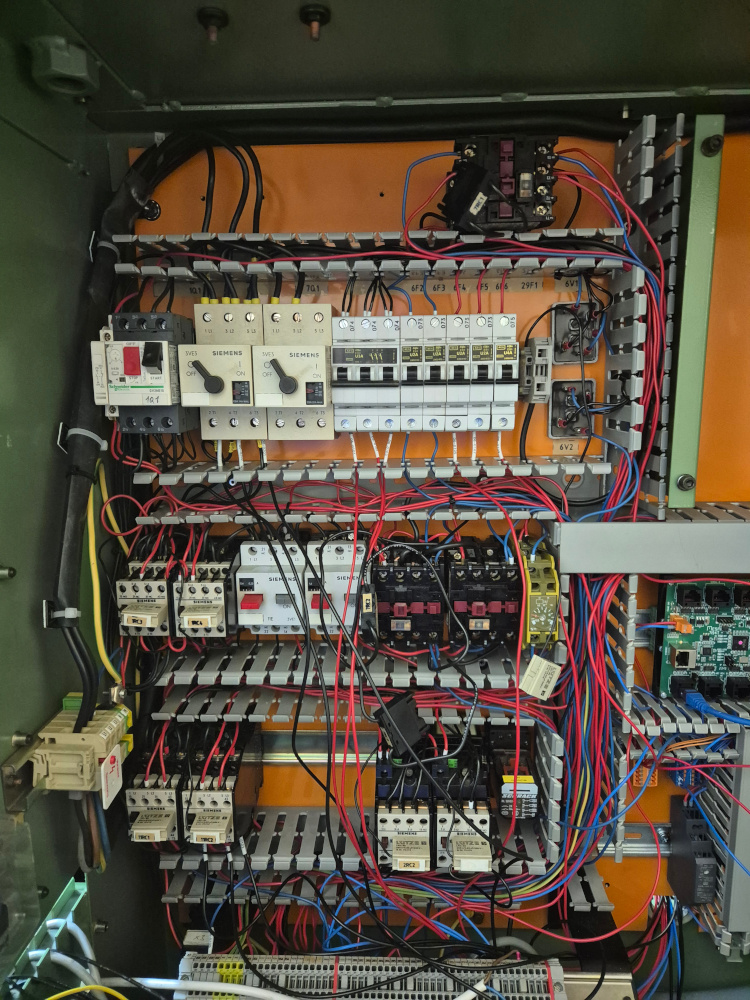

I've been working on a design for the control cabinet of my Maho MH400E.

I initially planned a relatively simple retrofit using Mesa cards, but after running into issues with the servo motors and spending quite some time trying to understand what was going wrong, the scope of the project gradually grew.

Along the way I ran into a few challenges:

This isn't meant as an endorsement, just my personal experience.

At this point the SWE license has expired and I want to move on to the actual build, once the remaining mechanical designs (servo motor mounts in particular) are finished.

Given my limited experience, I'm reasonably happy with the result so far, while fully expecting that there are still issues and blind spots.

What I ended up with:

I'm not looking to optimize for cost or replace major components at this point, but I am very interested in feedback on correctness, robustness, and failure modes — especially regarding EtherCAT behavior under LinuxCNC.

Due to forum size limits the attached PDF is a flattened version without internal cross-references. I do have a fully cross-referenced version available and can share it privately if someone wants to take a deeper look.

I've been working on a design for the control cabinet of my Maho MH400E.

I initially planned a relatively simple retrofit using Mesa cards, but after running into issues with the servo motors and spending quite some time trying to understand what was going wrong, the scope of the project gradually grew.

Along the way I ran into a few challenges:

- I'm not an electrical engineer, so there was (and still is) a lot to learn.

- Cost: this kind of hardware isn't cheap. Given the scope of the project, I deliberately chose components from vendors with strong documentation and long-term availability, to reduce risk during commissioning and future maintenance.

- Time — or perhaps more accurately: patience.

This isn't meant as an endorsement, just my personal experience.

At this point the SWE license has expired and I want to move on to the actual build, once the remaining mechanical designs (servo motor mounts in particular) are finished.

Given my limited experience, I'm reasonably happy with the result so far, while fully expecting that there are still issues and blind spots.

What I ended up with:

- An EtherCAT-based setup using Beckhoff I/O modules

- Delta servo drives and a VFD with EtherCAT support

- Replacing the original Heidenhain 1 Vpp → TTL encoder cards with Beckhoff 1 Vpp encoder modules

- Schneider Electric and Phoenix Contact components for relays, power supplies, circuit breakers, etc.

- Reuse of the original 400 V → 110 V transformer, the cabinet itself (with heat exchanger), the hydraulics pump and the lubrication pump

- Control cabinet layout

- Mechanical design for the servo motor mounts

I'm not looking to optimize for cost or replace major components at this point, but I am very interested in feedback on correctness, robustness, and failure modes — especially regarding EtherCAT behavior under LinuxCNC.

Due to forum size limits the attached PDF is a flattened version without internal cross-references. I do have a fully cross-referenced version available and can share it privately if someone wants to take a deeper look.

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- Cooped-Up

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 4

29 Dec 2025 20:14 #340674

by Cooped-Up

Replied by Cooped-Up on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

this is awesome. I am currently nearing the finish line on a MH800e retrofit. i used mesa cards and followed in the footsteps of rotarysmp and his documentation. this was a huge boost in feasibility as he had already done it. As the machine currently sits I could run a program but shift gears manually as I am still integrating auto shifting into the mix.

what issues did you have with the indramat?

what issues did you have with the indramat?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1549

- Thank you received: 572

29 Dec 2025 21:34 - 29 Dec 2025 21:49 #340680

by RotarySMP

Replied by RotarySMP on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Very nicely laid out. My only advice would be to provision 20% extra terminals, especially grounds and 24VDC than you calculate you need.

I don't see a pendant. I am not familiar with that layout style from Solidworks, but you will certainly want a pendant.

And a fourth axis.

Cheers,

Mark

I don't see a pendant. I am not familiar with that layout style from Solidworks, but you will certainly want a pendant.

And a fourth axis.

Cheers,

Mark

Last edit: 29 Dec 2025 21:49 by RotarySMP.

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

30 Dec 2025 12:12 #340708

by workshop54

Replied by workshop54 on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

I'm not sure what the underlying issues were with the Indramat, but some of the symptoms were:

- One of the servomotors didn't run at all

- One of the servomotors did run, but stopped at random places

- The last servomotor sometimes just started to run, without giving it a command, and when I did give it a command it didn't run at all.

After debugging for weeks I figured the "easy" way would be to just do a complete redisign. And boy, whas I wrong.

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

30 Dec 2025 12:15 #340709

by workshop54

Replied by workshop54 on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Thanks, Mark.

I did not include the pendant yet because I had to be aware of scope creep. I also didn't include things like coolant/Fogbuster valve control and a touch-off probe.

I did not include the pendant yet because I had to be aware of scope creep. I also didn't include things like coolant/Fogbuster valve control and a touch-off probe.

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

31 Dec 2025 10:39 #340764

by workshop54

Replied by workshop54 on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

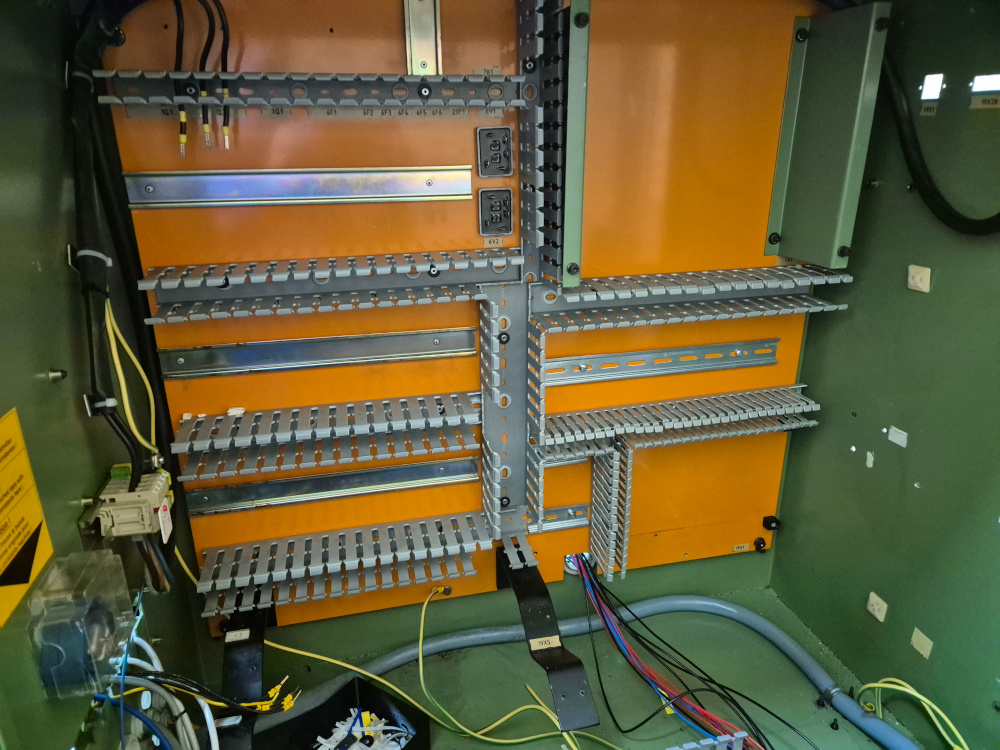

Honestly one of the most terryfying things I have ever done to a machine. Point of no return reached. (Even thought I labeled all the componentens and still have the drawings of the original setup, so I could technically put everything back)

Now I can start to layout the new components in the control cabinet (with cartboard cutouts)

Now I can start to layout the new components in the control cabinet (with cartboard cutouts)

Attachments:

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- Cooped-Up

- Offline

- Senior Member

-

Less

More

- Posts: 71

- Thank you received: 4

31 Dec 2025 14:30 #340771

by Cooped-Up

Replied by Cooped-Up on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Oh man! I will definitely follow this project, it will be interesting to see the changes! when you trouble shot the indramat did you try switching the motors with there respective "channels" to see if it was a motor or drive issue? I guess it doesnt really matter now that the cabinet is empty haha. I know a guy that might need an indramat drive lol

Please Log in or Create an account to join the conversation.

- Surmetall

-

- Offline

- Junior Member

-

Less

More

- Posts: 34

- Thank you received: 21

31 Dec 2025 14:47 #340773

by Surmetall

Replied by Surmetall on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

That’s not the point of no return, it’s the point of no concern!

Getting rid of thw oldsh** drivers is one of the best things you can do.

I love old machines and mechanics, but 1980s servo controllers and PCs can drive you crazy after 45 years.I retrofitted an old DECKEL FP3NC with LinuxCNC and new AC Servos a few years ago. It runs like charm.Today I would use EtherCAT Delta Servos and the cabinet would be about the size of a shoebox.

Getting rid of thw old

I love old machines and mechanics, but 1980s servo controllers and PCs can drive you crazy after 45 years.I retrofitted an old DECKEL FP3NC with LinuxCNC and new AC Servos a few years ago. It runs like charm.Today I would use EtherCAT Delta Servos and the cabinet would be about the size of a shoebox.

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

31 Dec 2025 15:15 #340774

by workshop54

Replied by workshop54 on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

I was never able to figure out if it was the drive or the motors, I just kept getting weird results. I also know a guy who might need an Indramat drive and I already sent him a message.

Please Log in or Create an account to join the conversation.

- workshop54

- Offline

- Junior Member

-

Less

More

- Posts: 39

- Thank you received: 8

31 Dec 2025 18:45 - 31 Dec 2025 18:48 #340787

by workshop54

Replied by workshop54 on topic Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

@suremetall Yeah, that's what my thoughts are exactly. I could keep messing around with the original hardware, waiting for one thing after another to fail, but once this retrofit is done I should be able to run it for years to come.

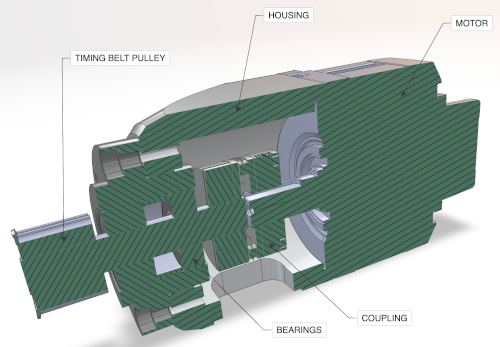

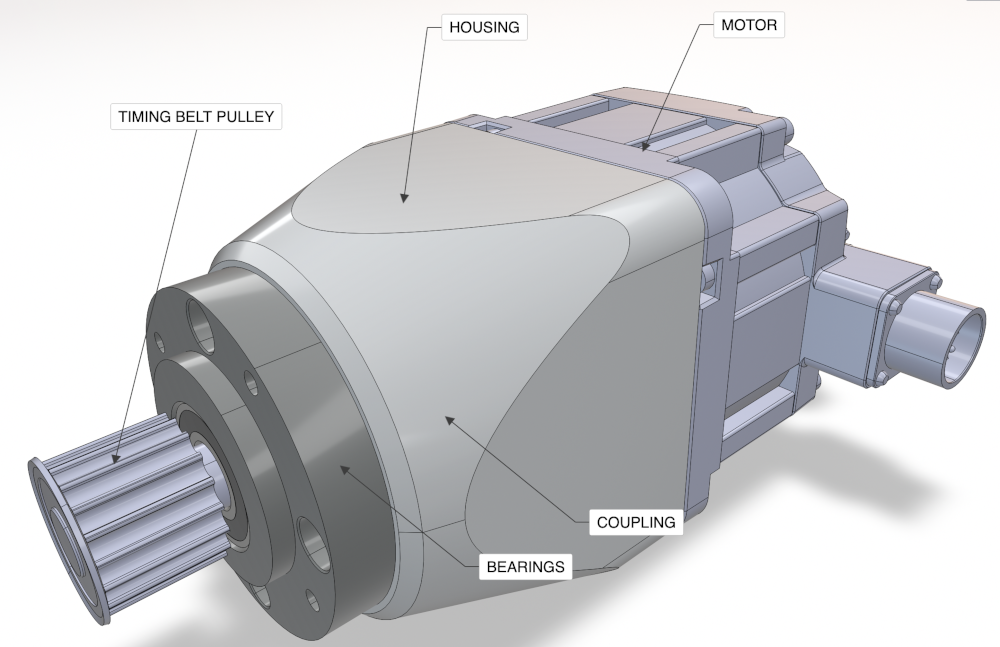

The biggest challenge for me at this moment is the motor adapter for the z-axis (ram), which doesn't have a lot of space.

I already created a design, but I'm having some issues with the tolerances and manufacturability I can't really get my head around.

The biggest challenge for me at this moment is the motor adapter for the z-axis (ram), which doesn't have a lot of space.

I already created a design, but I'm having some issues with the tolerances and manufacturability I can't really get my head around.

Attachments:

Last edit: 31 Dec 2025 18:48 by workshop54.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- Escalation of a Maho MH400E Retrofit (LinuxCNC + EtherCAT)

Time to create page: 0.604 seconds