LinuxCNC cutting corners while staright line GCode

- gaeldk

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 1

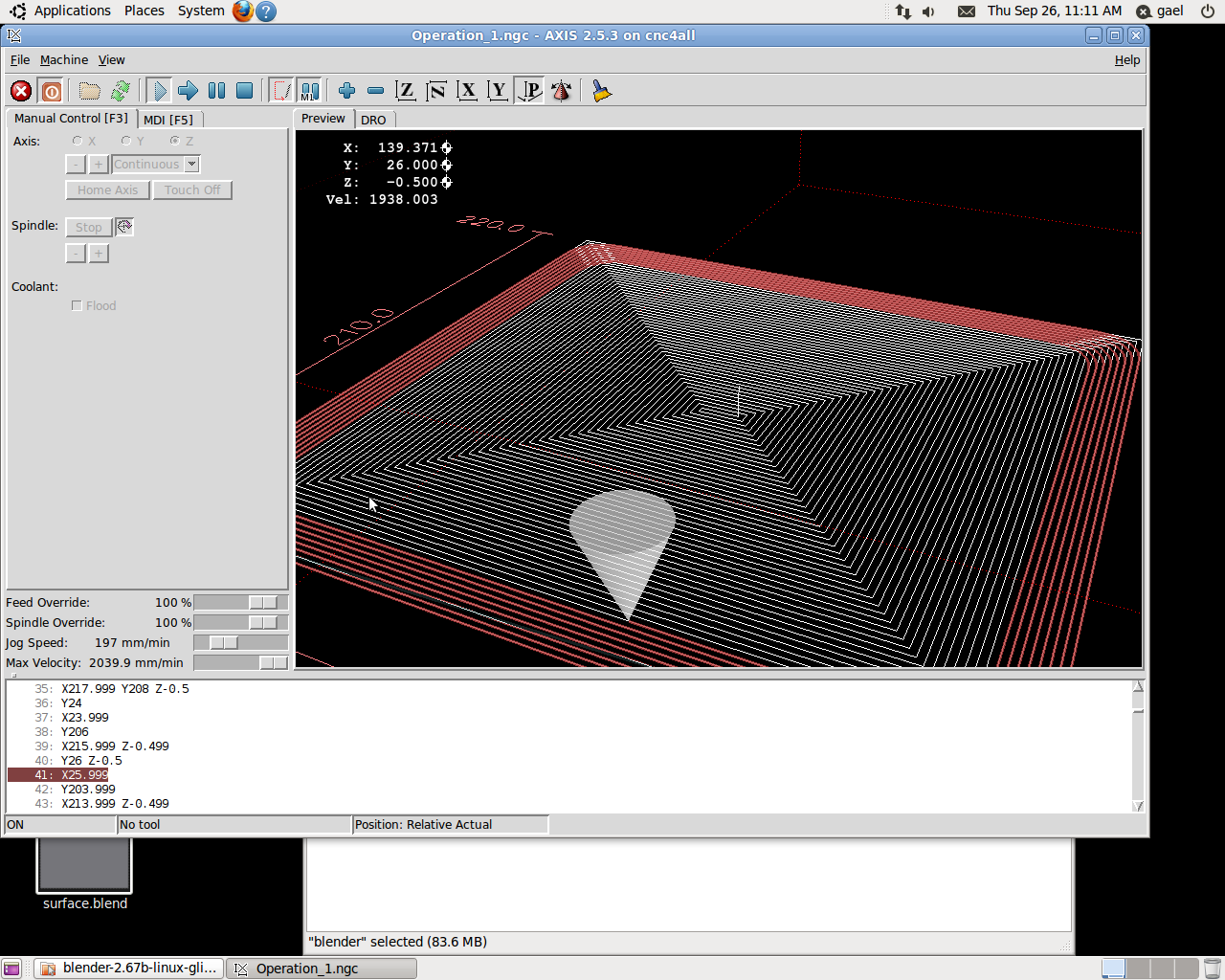

I started an operation to level my table and generated some simple GCODE that basically moves the cutter above the entire surface.

As you can see from the attached screenshot, the GCODE in white is showing straight lines in the corners while the machine is rounding corners as shown in red...

Why is that ?

Thanks

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

- Posts: 27

- Thank you received: 114

www.linuxcnc.org/docs/2.4/html/gcode_mai...#sub:G61,-G61.1,-G64:

Your program probably has G64 set

G64 without P means to keep the best speed possible, no matter how far away from the programmed point you end up.

try adding the line

G64 p.001 q.001Rick G

Please Log in or Create an account to join the conversation.

- gaeldk

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 1

There is no G64 is my program, adding G61 did fix the issue.

How can I tell LinuxCNC to operate with G61 by default without having to manually add it to each program ?

Thanks

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

- Posts: 27

- Thank you received: 114

www.linuxcnc.org/docs/devel/html/config/...b_rs274ngc_section_a

Depending on what you are doing you may not always want to use G61 as very short lines can cause slow stop and go motion,

There is no G64 is my program

It is normal for it to be the default.

Rick G

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Have you tried much higher acceleration? How did you determine the accel limits?

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

- Posts: 3990

- Thank you received: 994

Thank you Rick.

There is no G64 is my program, adding G61 did fix the issue.

How can I tell LinuxCNC to operate with G61 by default without having to manually add it to each program ?

Thanks

It is good practice to not assume the state of your machine when you run a G code file. A preamble line that sets the environment is normal. You can never tell what state the last G code program left your machine in.

gnipsel.com/linuxcnc/g-code/gen01.html

Also please read and understand what M2 does.

linuxcnc.org/docs/html/gcode/m-code.html#sec:M2-M30

JT

Please Log in or Create an account to join the conversation.

- gaeldk

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 1

Have no idea how this has been calculated by the provider of my router (cnc4all)

Will look at how to calculate acceleration...

Please Log in or Create an account to join the conversation.

- gaeldk

- Offline

- Senior Member

-

- Posts: 47

- Thank you received: 1

So between 60 and 1000 I have no idea whatsoever what a good acceleration value is...

All I know about the steppers is 1,7 Nm 4A ... 1600 steps/rev

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

- Posts: 27

- Thank you received: 114

You do need to error on the cautious side to avoid missing steps, especially when actually cutting or under load.

Rick G

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

I played with the stepconf configuration and my machine can take up to 1000 mm s2

?? Of course then the movements are very brutal...

So between 60 and 1000 I have no idea whatsoever what a good acceleration value is...

Somewhere between where you get the path-following you want and where the machine either loses steps or shakes itself apart.

Accel numbers tend to be 10x to 20x the velocity number. But it is a compromise and depends on the machine.

Please Log in or Create an account to join the conversation.