Need a programmer for help with custom machine/interface

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

27 Jun 2019 23:07 #138044

by blazini36

Need a programmer for help with custom machine/interface was created by blazini36

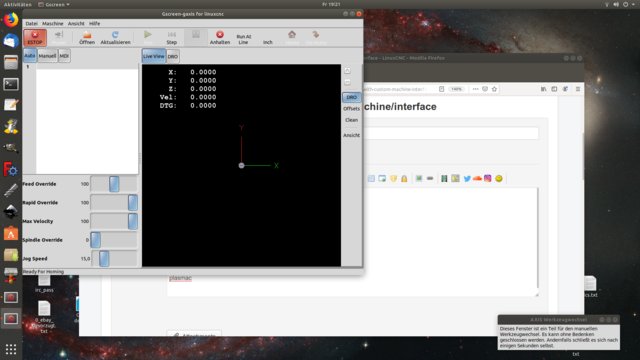

Been working on a machine for some time now, biggest thing holding me up has been the custom programming. Had a friend helping me out for some time but he no longer has time for it. All the major things are reasonably well sorted, just some python bugs and minor things that need to be added yet. It's a dedicated machine with a dedicated purpose running a GUI that I built. The nuances of LinuxCNC and machine control make it difficult for me to find reasonable help with this. There's some coin involved if anyone is looking for a project.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21207

- Thank you received: 7242

28 Jun 2019 00:53 #138067

by tommylight

Replied by tommylight on topic Need a programmer for help with custom machine/interface

If you really want any help, start by uploading what you already have, and aproximately what you are trying to achieve.

No need for coin.

No need for coin.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

28 Jun 2019 01:18 #138072

by blazini36

Replied by blazini36 on topic Need a programmer for help with custom machine/interface

If I need help with my mill I do as you suggested in the appropriate section of the forum. This is a bit different than that, I'm not looking for suggestions on how I can fix small portions of the code when I'm not a programmer. Looking to work with 1 person that knows what they're doing to get this finished up in a solid manner.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21207

- Thank you received: 7242

28 Jun 2019 10:25 #138107

by tommylight

Replied by tommylight on topic Need a programmer for help with custom machine/interface

This brings back memories of "Blender style GUI for Linuxcnc " or something simmilar, it's very short glory and it's inevitable and monumental demise.

What a pitty !

What a pitty !

Please Log in or Create an account to join the conversation.

- fixer

- Offline

- Premium Member

-

Less

More

- Posts: 132

- Thank you received: 27

28 Jun 2019 16:09 - 28 Jun 2019 18:38 #138123

by fixer

Replied by fixer on topic Need a programmer for help with custom machine/interface

I can help. See mail.

Last edit: 28 Jun 2019 18:38 by fixer.

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

28 Jun 2019 17:27 #138124

by pl7i92

Replied by pl7i92 on topic Need a programmer for help with custom machine/interface

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

28 Jun 2019 21:49 #138136

by blazini36

What on earth are you talking about? You have really got the wrong idea bud.

Replied by blazini36 on topic Need a programmer for help with custom machine/interface

This brings back memories of "Blender style GUI for Linuxcnc " or something simmilar, it's very short glory and it's inevitable and monumental demise.

What a pitty !

What on earth are you talking about? You have really got the wrong idea bud.

Please Log in or Create an account to join the conversation.

- Grotius

-

- Offline

- Platinum Member

-

Less

More

- Posts: 2419

- Thank you received: 2345

28 Jun 2019 22:26 #138138

by Grotius

Replied by Grotius on topic Need a programmer for help with custom machine/interface

First of all it's normal to ask someone for help to provide a custom user interface.

Some of us are not good coders, or have no skills for this and just want a working custom designed machine interface.

In the past i was new to linux and linuxcnc, I had no clue about coding, so i understand the question related to Blazini36.

Making your own gui and understand the linuxcnc code can take about 1 to 2 years.

My advise to Blazini36 is the following :

1. You have a almost working gui, open source, provide your code and we can help to solve error's.

2. You can search for coders. I don't know Fixer, but if he can help you. Why not....

3. Don't be afraid to provide your code. In the end, everything will be open source.

Some of us are not good coders, or have no skills for this and just want a working custom designed machine interface.

In the past i was new to linux and linuxcnc, I had no clue about coding, so i understand the question related to Blazini36.

Making your own gui and understand the linuxcnc code can take about 1 to 2 years.

My advise to Blazini36 is the following :

1. You have a almost working gui, open source, provide your code and we can help to solve error's.

2. You can search for coders. I don't know Fixer, but if he can help you. Why not....

3. Don't be afraid to provide your code. In the end, everything will be open source.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

28 Jun 2019 22:30 #138139

by blazini36

Replied by blazini36 on topic Need a programmer for help with custom machine/interface

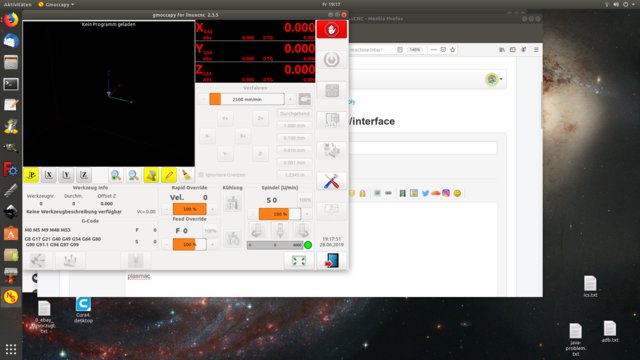

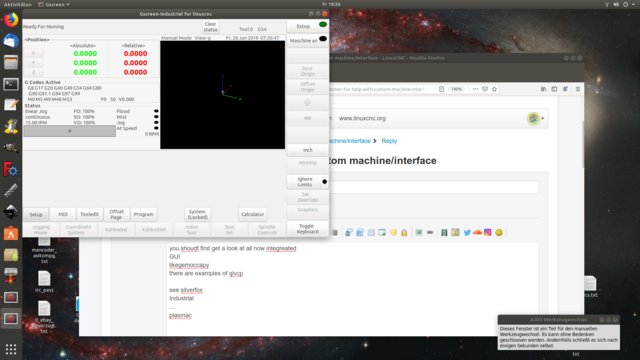

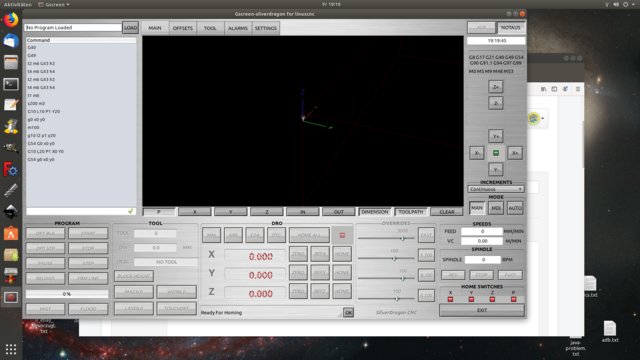

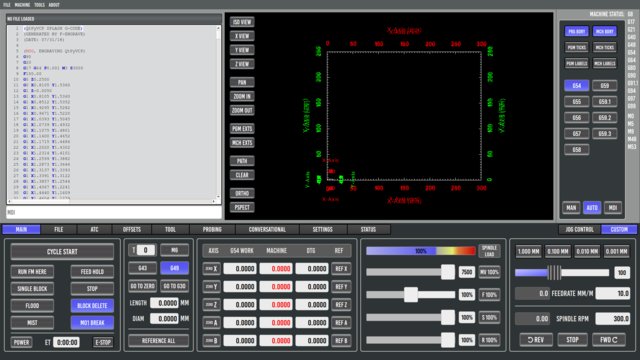

you shoudt first get a look at all now integreated

GUI

likegemoccapy

there are examples of qivcp

see silverdragon

Industrial

gaxis

....

plasmac

I run gmoccapy on my mill and I've tweaked it some with auto probing and buttons to control the "spindle-monitor" component that we added to the repo. The machine and it's UI are fully functional, there's just a couple of unfinished things that need attention. These aren't functions that are used in anything that people building a LinuxCNC machine are using so regardless of how customizeable a UI is, the programming behind it doesn't exist.

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

Less

More

- Posts: 972

- Thank you received: 167

29 Jun 2019 16:52 - 29 Jun 2019 16:55 #138180

by blazini36

I think I've seen a post or 2 of some of one of your machines or UI's I recall it being a pretty serious looking machine. I recall it being a very large plasma cutter or router or something. There's one fundamental difference between anything you do for that machine and things you open source that you've started. Those types of machines are built on the same principals that almost all machines LinuxCNC runs is built on. Almost anything you could open source would be useful to plenty of people and could get some traction by people who want to build something similar, and that only helps your use case. Judging by the quality of the machine I recall seeing I'd assume maybe you sell them. If that were the case for me I'd do the same, the GUI that comes with the machine is just a cool bonus it's the machine that is the thing you might be actually interested in selling.

Personally The GUI in and of itself has been done for a long time, I made that as well as a GTK3 version I probably won't ever be able to use as it seems to have been abandoned. There's alot of Python programming well beyond the GUI that really has not much at all to do with LinuxCNC. I did respond to Fixer, as that's what I'm looking for so I'll see how that goes.

I catch flack sometimes for the non-opensourcyness of my little project almost everytime I post something about it. I kind of understand that but at the same time it's not actually justified. I build a not too large machine that's fairly neat with only the nuances being complex. It's based solely on a specific niche industry and it's movements simple but positioning is fairly complicated just because of the situations it serves. The GUI is solely based on machine vision cameras and serving it's display. It's a system that's been done 100 times in this industry but this is my take on it. I use LinuxCNC as a backend for machine control, there's several thousand lines of code that actually run everything else. You couldn't even start the program without satisfying the camera requirements, it needs to see them. I don't sell anything, I just keep in the back of my mind that one day maybe I can.

If I dumped the entire program on the internet as "open source" what do I achieve? Some company can have a damn near ready made solution for doing exactly what this machine does. The fundamental issue with open source is that people use and improve upon what they are interested in and want to use. I sincerely doubt that anyone would just fix the little Python things specific to my machine. If anything they'd just pull the camera handling stuff and "virtual axis" thing I have going on out and play with that......but that's all sorted since that's fundamental to the basics of the machine. I don't know enough about actual programming to just pop portions of it out and open source it and I wouldn't just dump the whole code for reasons I just explained.

However that sounds is how it sounds, the thing is is that if someone were like "hey, If I can take a look at that specific portion of code I'll pack it up and open source it" I really wouldn't have a problem with that but obviously that person has to make certain promises.

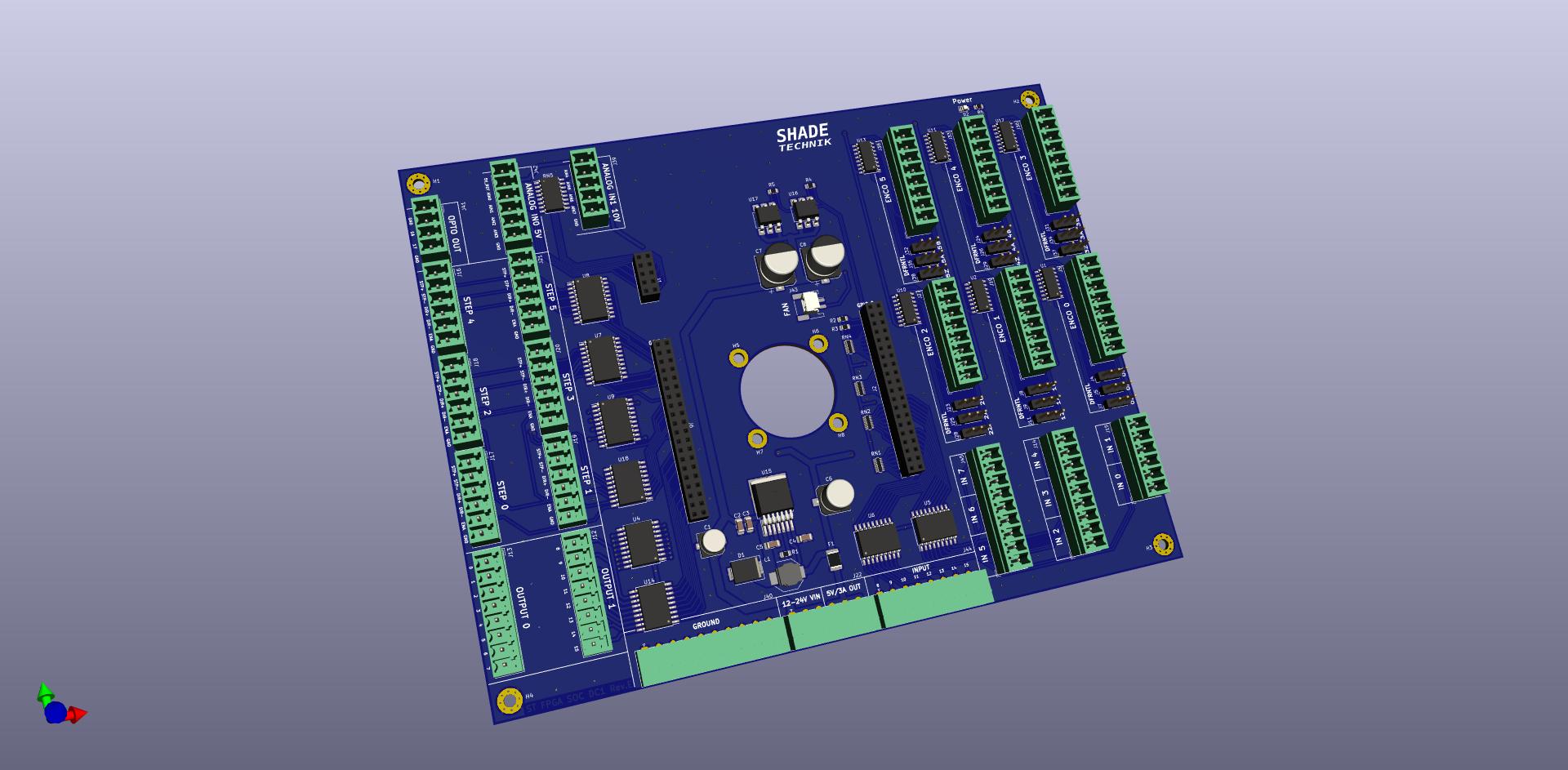

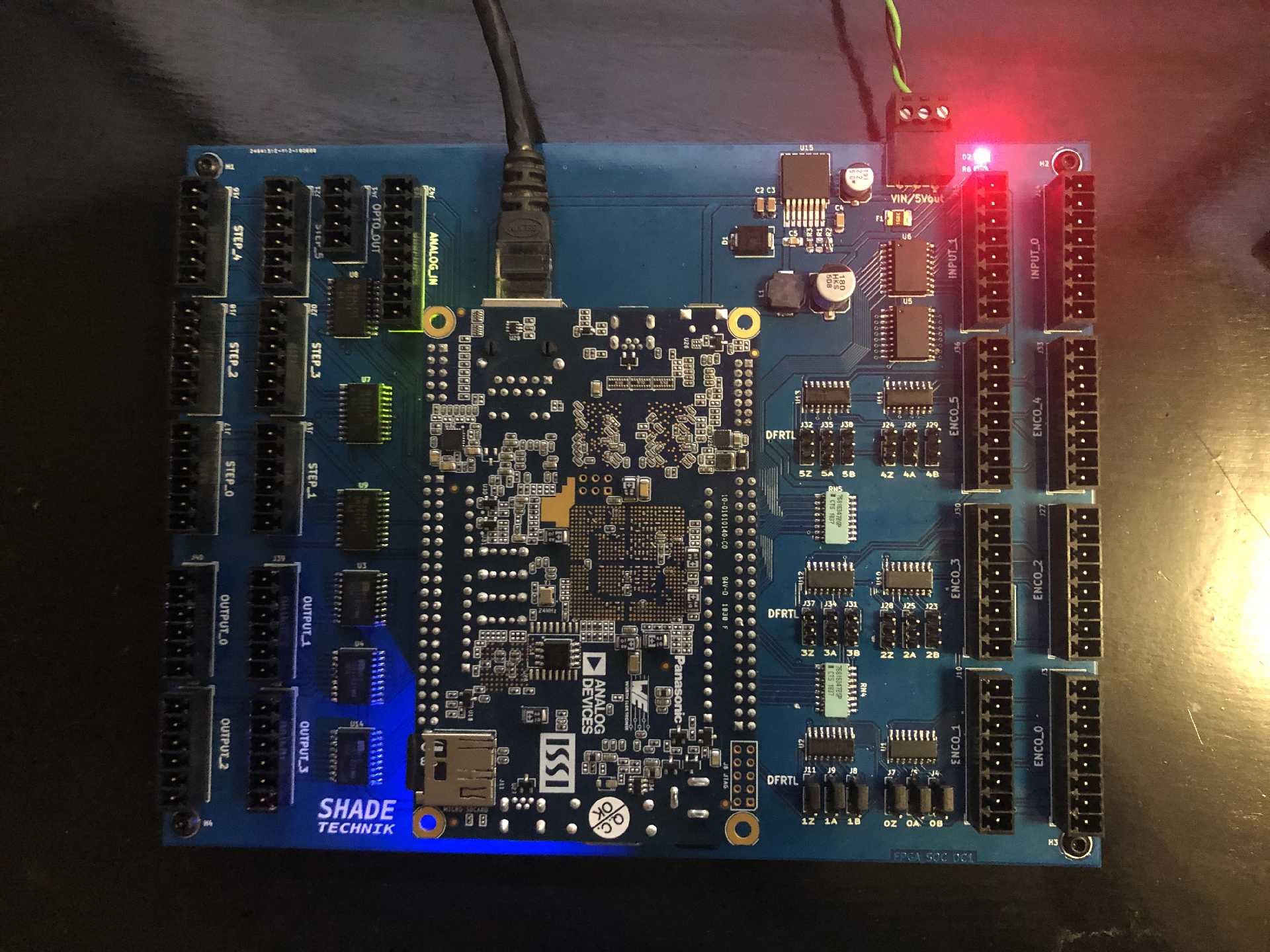

I don't write programs but I certainly do open source things as we're all part of that community. I've been dabbling in PCB design .....mostly for this machine. I see some neat opportunities in MachineKit's work of FPGA's with hard ARM processors. Porting Mesa hm2 to SOCs is brilliant, you can run the whole RT layer on ARM cores that only do that. So as a side project I picked up a DE10 nano, problem there is there's very little I/O hardware options. That's OK I can't program but I can do a PCB, so I whipped up a daughtercard for it. after a couple of revs and circuits that work as expected I'll have something to mess with. Now this board is suited for my machine, but all of the circuits and a more generic maybe cheaper PCB deign, I'll open source. And I don't have a problem with that because it's a component of what I'm doing, not the secret sauce. Those MachineKit guys helped me out alot with all my idiot firmware questions so maybe somebody would use that board and I would be more than glad to open source that. That said I'd love to see LinuxCNC get up on some of these FPGA SOC things.

I'm big on open source, 90% of all of my PC's and everything I use is something open source. The thing that gets me is when the open source community thinks everybody should open source everything, I just don't agree with that. That's the "free software" movement, not really the open source idea.

Some version of this will OS

Replied by blazini36 on topic Need a programmer for help with custom machine/interface

First of all it's normal to ask someone for help to provide a custom user interface.

Some of us are not good coders, or have no skills for this and just want a working custom designed machine interface.

In the past i was new to linux and linuxcnc, I had no clue about coding, so i understand the question related to Blazini36.

Making your own gui and understand the linuxcnc code can take about 1 to 2 years.

My advise to Blazini36 is the following :

1. You have a almost working gui, open source, provide your code and we can help to solve error's.

2. You can search for coders. I don't know Fixer, but if he can help you. Why not....

3. Don't be afraid to provide your code. In the end, everything will be open source.

I think I've seen a post or 2 of some of one of your machines or UI's I recall it being a pretty serious looking machine. I recall it being a very large plasma cutter or router or something. There's one fundamental difference between anything you do for that machine and things you open source that you've started. Those types of machines are built on the same principals that almost all machines LinuxCNC runs is built on. Almost anything you could open source would be useful to plenty of people and could get some traction by people who want to build something similar, and that only helps your use case. Judging by the quality of the machine I recall seeing I'd assume maybe you sell them. If that were the case for me I'd do the same, the GUI that comes with the machine is just a cool bonus it's the machine that is the thing you might be actually interested in selling.

Personally The GUI in and of itself has been done for a long time, I made that as well as a GTK3 version I probably won't ever be able to use as it seems to have been abandoned. There's alot of Python programming well beyond the GUI that really has not much at all to do with LinuxCNC. I did respond to Fixer, as that's what I'm looking for so I'll see how that goes.

I catch flack sometimes for the non-opensourcyness of my little project almost everytime I post something about it. I kind of understand that but at the same time it's not actually justified. I build a not too large machine that's fairly neat with only the nuances being complex. It's based solely on a specific niche industry and it's movements simple but positioning is fairly complicated just because of the situations it serves. The GUI is solely based on machine vision cameras and serving it's display. It's a system that's been done 100 times in this industry but this is my take on it. I use LinuxCNC as a backend for machine control, there's several thousand lines of code that actually run everything else. You couldn't even start the program without satisfying the camera requirements, it needs to see them. I don't sell anything, I just keep in the back of my mind that one day maybe I can.

If I dumped the entire program on the internet as "open source" what do I achieve? Some company can have a damn near ready made solution for doing exactly what this machine does. The fundamental issue with open source is that people use and improve upon what they are interested in and want to use. I sincerely doubt that anyone would just fix the little Python things specific to my machine. If anything they'd just pull the camera handling stuff and "virtual axis" thing I have going on out and play with that......but that's all sorted since that's fundamental to the basics of the machine. I don't know enough about actual programming to just pop portions of it out and open source it and I wouldn't just dump the whole code for reasons I just explained.

However that sounds is how it sounds, the thing is is that if someone were like "hey, If I can take a look at that specific portion of code I'll pack it up and open source it" I really wouldn't have a problem with that but obviously that person has to make certain promises.

I don't write programs but I certainly do open source things as we're all part of that community. I've been dabbling in PCB design .....mostly for this machine. I see some neat opportunities in MachineKit's work of FPGA's with hard ARM processors. Porting Mesa hm2 to SOCs is brilliant, you can run the whole RT layer on ARM cores that only do that. So as a side project I picked up a DE10 nano, problem there is there's very little I/O hardware options. That's OK I can't program but I can do a PCB, so I whipped up a daughtercard for it. after a couple of revs and circuits that work as expected I'll have something to mess with. Now this board is suited for my machine, but all of the circuits and a more generic maybe cheaper PCB deign, I'll open source. And I don't have a problem with that because it's a component of what I'm doing, not the secret sauce. Those MachineKit guys helped me out alot with all my idiot firmware questions so maybe somebody would use that board and I would be more than glad to open source that. That said I'd love to see LinuxCNC get up on some of these FPGA SOC things.

I'm big on open source, 90% of all of my PC's and everything I use is something open source. The thing that gets me is when the open source community thinks everybody should open source everything, I just don't agree with that. That's the "free software" movement, not really the open source idea.

Some version of this will OS

Last edit: 29 Jun 2019 16:55 by blazini36.

Please Log in or Create an account to join the conversation.

Time to create page: 0.332 seconds