- Configuring LinuxCNC

- Advanced Configuration

- (Solved) Index signal for Orient, G33.1, M19 with proximity sensor

(Solved) Index signal for Orient, G33.1, M19 with proximity sensor

- anton610

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 7

24 Dec 2021 15:23 #229895

by anton610

Replied by anton610 on topic Index signal for Orient, G33.1, M19 with proximity sensor

Hi, thanks!

I'll try.

Is it a problem that i use a NC sensor? Or should i use a NO sensor?

BR

Anton

I'll try.

Is it a problem that i use a NC sensor? Or should i use a NO sensor?

BR

Anton

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17568

- Thank you received: 5140

24 Dec 2021 16:05 #229899

by PCW

Replied by PCW on topic Index signal for Orient, G33.1, M19 with proximity sensor

Either will work, the firmware senses the edge of index

so the polarity (NC or NO) only changes which edge

of the index pulse is detected.

so the polarity (NC or NO) only changes which edge

of the index pulse is detected.

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

24 Dec 2021 16:26 #229901

by Henk

Replied by Henk on topic Index signal for Orient, G33.1, M19 with proximity sensor

In this case, your 0v from your proxy voltage decider circuit and the 0v of the mesa card must be connected.

Please Log in or Create an account to join the conversation.

- anton610

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 7

25 Dec 2021 11:58 #229955

by anton610

Replied by anton610 on topic Index signal for Orient, G33.1, M19 with proximity sensor

Hello,

many thanks for the inputs.

I've connected the signal correct (ttl, 0v to GND), measuring gives me also the values (0v, 4,08v)

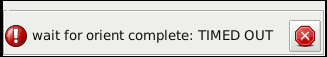

when i run the command M19 R15 Q4 i get the error:

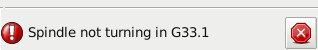

when i run G33.1 Z10 K2 i get the error:

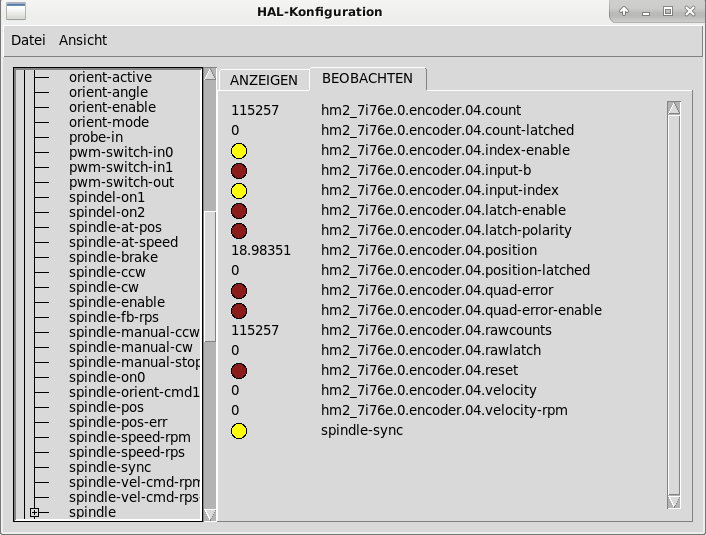

when the spindle is stopped my halshow is:

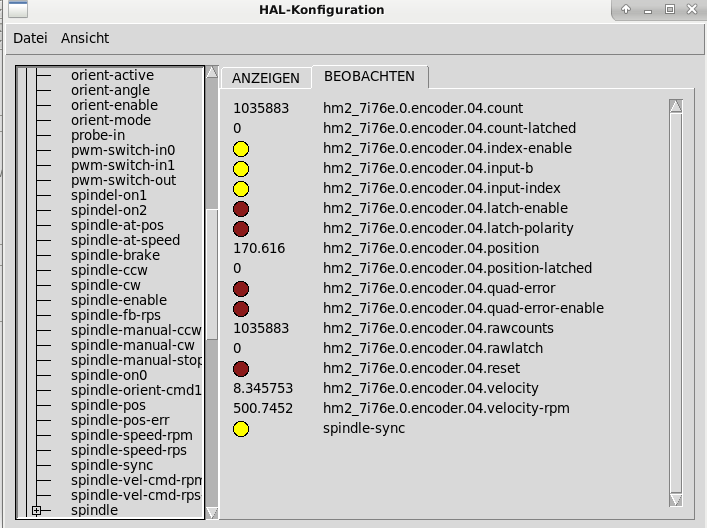

when the sindle is at 500rpm:

maybe the hal or ini is fault...

maybe someone can give ma a hint, where to look.

Many thanks!

BR Anton

many thanks for the inputs.

I've connected the signal correct (ttl, 0v to GND), measuring gives me also the values (0v, 4,08v)

when i run the command M19 R15 Q4 i get the error:

when i run G33.1 Z10 K2 i get the error:

when the spindle is stopped my halshow is:

when the sindle is at 500rpm:

maybe the hal or ini is fault...

maybe someone can give ma a hint, where to look.

Many thanks!

BR Anton

Attachments:

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

25 Dec 2021 15:34 - 26 Dec 2021 03:32 #229962

by Henk

Replied by Henk on topic Index signal for Orient, G33.1, M19 with proximity sensor

ok, lets verify a couple of things first.

look at the pin spindle.0.revs in hal configuration. rotate the spindle by hand. this should go from 0 to 1, then reset back to 0 as you rotate. 0...>>...1 must equal exactly one rotation of your spindle...***edit: checked this on my machine, it counts up and down, does not stay between 0 and 1 as described above.

now, in MDI start the spindle with M3 S500, followed by G91 g33.1 z-20 k1 (assuming metric machine and G21 active) make sure that there is at enough space below the spindle to allow a -20mm move in Z direction.

if the spindle starts and runs, but no tapping action happens, your index signal is not detected, or the encoder direction is incorrect. for the latter you can swop A and B wiring, or you can set the encoder scale to -6071.428571428571 (negative) in your INI file.

It seems that your spindle is set up as a step/dir spindle. does it run? What functions are available in the drive? Position control mode selectable by an input signal to the drive?

I dont have any experiance with step/dir spindle setup. In your case, with the encoder on the motor and not on the spindle, you probably cannot use the drive orientation function and you should use Linuxcnc's orientation component, which seems to be the case looking at your hal file. Check the orientation mode, it needs to be set as either 0 or 1

henk

look at the pin spindle.0.revs in hal configuration. rotate the spindle by hand. this should go from 0 to 1, then reset back to 0 as you rotate. 0...>>...1 must equal exactly one rotation of your spindle...***edit: checked this on my machine, it counts up and down, does not stay between 0 and 1 as described above.

now, in MDI start the spindle with M3 S500, followed by G91 g33.1 z-20 k1 (assuming metric machine and G21 active) make sure that there is at enough space below the spindle to allow a -20mm move in Z direction.

if the spindle starts and runs, but no tapping action happens, your index signal is not detected, or the encoder direction is incorrect. for the latter you can swop A and B wiring, or you can set the encoder scale to -6071.428571428571 (negative) in your INI file.

It seems that your spindle is set up as a step/dir spindle. does it run? What functions are available in the drive? Position control mode selectable by an input signal to the drive?

I dont have any experiance with step/dir spindle setup. In your case, with the encoder on the motor and not on the spindle, you probably cannot use the drive orientation function and you should use Linuxcnc's orientation component, which seems to be the case looking at your hal file. Check the orientation mode, it needs to be set as either 0 or 1

henk

Last edit: 26 Dec 2021 03:32 by Henk.

Please Log in or Create an account to join the conversation.

- anton610

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 7

25 Dec 2021 15:56 #229965

by anton610

Replied by anton610 on topic Index signal for Orient, G33.1, M19 with proximity sensor

Hello Henk!

Thanks for your time and quick reply!

spindle.0.revs is counting to plus and minus as i turn the spindle. it does not reset to 0. (maybe thats the problem)

I have is enough space to go -20 in Z, spindle is on the top position.

Spindle is not starting get the error: "spindle is not turning in G31"

When i turn the spindle, the encoder counts to plus in clock direction and to minus counter clock direction.

The spindle runs CW and CCW normally. I can set the speed by S command without a problem.

I run the spindle in position mode, velocity mode (0-10V) and torqe mode are also available.

BR Anton

Thanks for your time and quick reply!

spindle.0.revs is counting to plus and minus as i turn the spindle. it does not reset to 0. (maybe thats the problem)

I have is enough space to go -20 in Z, spindle is on the top position.

Spindle is not starting get the error: "spindle is not turning in G31"

When i turn the spindle, the encoder counts to plus in clock direction and to minus counter clock direction.

The spindle runs CW and CCW normally. I can set the speed by S command without a problem.

I run the spindle in position mode, velocity mode (0-10V) and torqe mode are also available.

BR Anton

Please Log in or Create an account to join the conversation.

- Henk

- Offline

- Platinum Member

-

Less

More

- Posts: 404

- Thank you received: 92

25 Dec 2021 16:22 - 26 Dec 2021 03:33 #229966

by Henk

Replied by Henk on topic Index signal for Orient, G33.1, M19 with proximity sensor

The spindle pos does not seem to be correct. And you need to get the spindle to run using M3/4.

**edit. spindle.0.revs counts up and down, doesnt stay between 0 and 1, this is correct, checked on my machine.

**edit. spindle.0.revs counts up and down, doesnt stay between 0 and 1, this is correct, checked on my machine.

Last edit: 26 Dec 2021 03:33 by Henk.

The following user(s) said Thank You: anton610

Please Log in or Create an account to join the conversation.

- anton610

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 7

25 Dec 2021 16:29 #229968

by anton610

Replied by anton610 on topic Index signal for Orient, G33.1, M19 with proximity sensor

Hi,

Yes M3, M4 with S command works.

With "spindle pos" you mean the encoder direction?

Yes M3, M4 with S command works.

With "spindle pos" you mean the encoder direction?

Please Log in or Create an account to join the conversation.

- anton610

- Offline

- Senior Member

-

Less

More

- Posts: 40

- Thank you received: 7

25 Dec 2021 17:22 - 25 Dec 2021 19:33 #229972

by anton610

Replied by anton610 on topic Index signal for Orient, G33.1, M19 with proximity sensor

Hi,

I think i have a wireing problem. Now when i measure the input for the encoder (proxy sensor) idx+, I have 4v and triggered 4,9v.

When i disconect the sensor from the encoder input and i measure i have 0v and triggered 4,08v

Thats bad...

I think i have a wireing problem. Now when i measure the input for the encoder (proxy sensor) idx+, I have 4v and triggered 4,9v.

When i disconect the sensor from the encoder input and i measure i have 0v and triggered 4,08v

Thats bad...

Last edit: 25 Dec 2021 19:33 by anton610.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17568

- Thank you received: 5140

25 Dec 2021 20:40 #229983

by PCW

Replied by PCW on topic Index signal for Orient, G33.1, M19 with proximity sensor

The encoder inputs have a 2K Ohm pullip resistor to +5V so if you use a

resistive divider it needs to have a quite low resistance, say 220 Ohms on the

low side and 1K Ohms on the high side

resistive divider it needs to have a quite low resistance, say 220 Ohms on the

low side and 1K Ohms on the high side

The following user(s) said Thank You: anton610

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Advanced Configuration

- (Solved) Index signal for Orient, G33.1, M19 with proximity sensor

Time to create page: 0.206 seconds