Servo tuning f-error spikes

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17628

- Thank you received: 5157

06 Jan 2022 17:37 #230966

by PCW

Replied by PCW on topic Servo tuning f-error spikes

If X is much worse than Y or Z with similar LinuxCNC PID settings

it may be analog drive tuning related. You might try some small drive

setting changes (marking the original POT settings first) to see their

effect on the error plot.

it may be analog drive tuning related. You might try some small drive

setting changes (marking the original POT settings first) to see their

effect on the error plot.

The following user(s) said Thank You: Wieser

Please Log in or Create an account to join the conversation.

- aleksamc

-

- Offline

- Platinum Member

-

Less

More

- Posts: 568

- Thank you received: 67

08 Jan 2022 09:16 #231098

by aleksamc

Replied by aleksamc on topic Servo tuning f-error spikes

Also, I had problem with one channel of analogue control on MESA. PCW advised me to make some re-soldering of Chanel. That was very similar problems as yours.

Try to change channel to another one.

Problem with encoder could be but you can check it by osciloscope (in linuxcnc) and look that channels where encoders are connected.

Try to change channel to another one.

Problem with encoder could be but you can check it by osciloscope (in linuxcnc) and look that channels where encoders are connected.

Please Log in or Create an account to join the conversation.

- joekline9

-

- Offline

- Senior Member

-

Less

More

- Posts: 59

- Thank you received: 9

08 Jan 2022 20:54 #231171

by joekline9

Replied by joekline9 on topic Servo tuning f-error spikes

Acceleration might be too fast.

Try cutting it in half or even 1/10 of what it is now.

Try cutting it in half or even 1/10 of what it is now.

Please Log in or Create an account to join the conversation.

- Wieser

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 1

09 Jan 2022 10:14 #231230

by Wieser

Replied by Wieser on topic Servo tuning f-error spikes

Thanks to all of you!

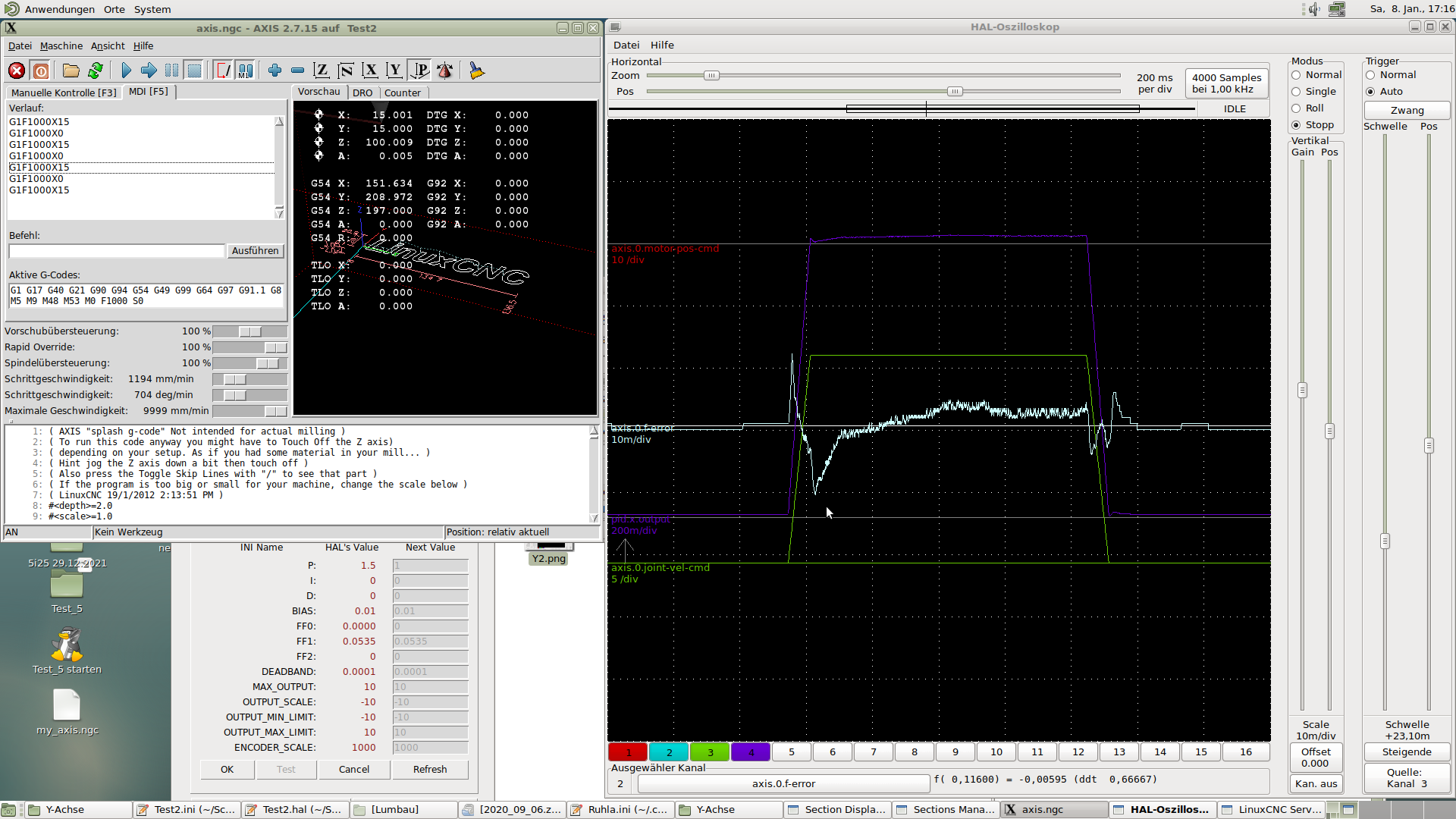

The Problem was related to the Tuning of the Simodrive.

The "T" parameter had a similar effect as FF1 and "Kp" is similar to P.

A quarter turn cw of Kp and a reduction of "TN" helped in the end. Increasing kp without adjusting TN led to high frequency oscillations of the motor.

Then I could increase P in linuxcnc from 1 to 3.

This is the result (I also increased the acceleration from 500 to 700):

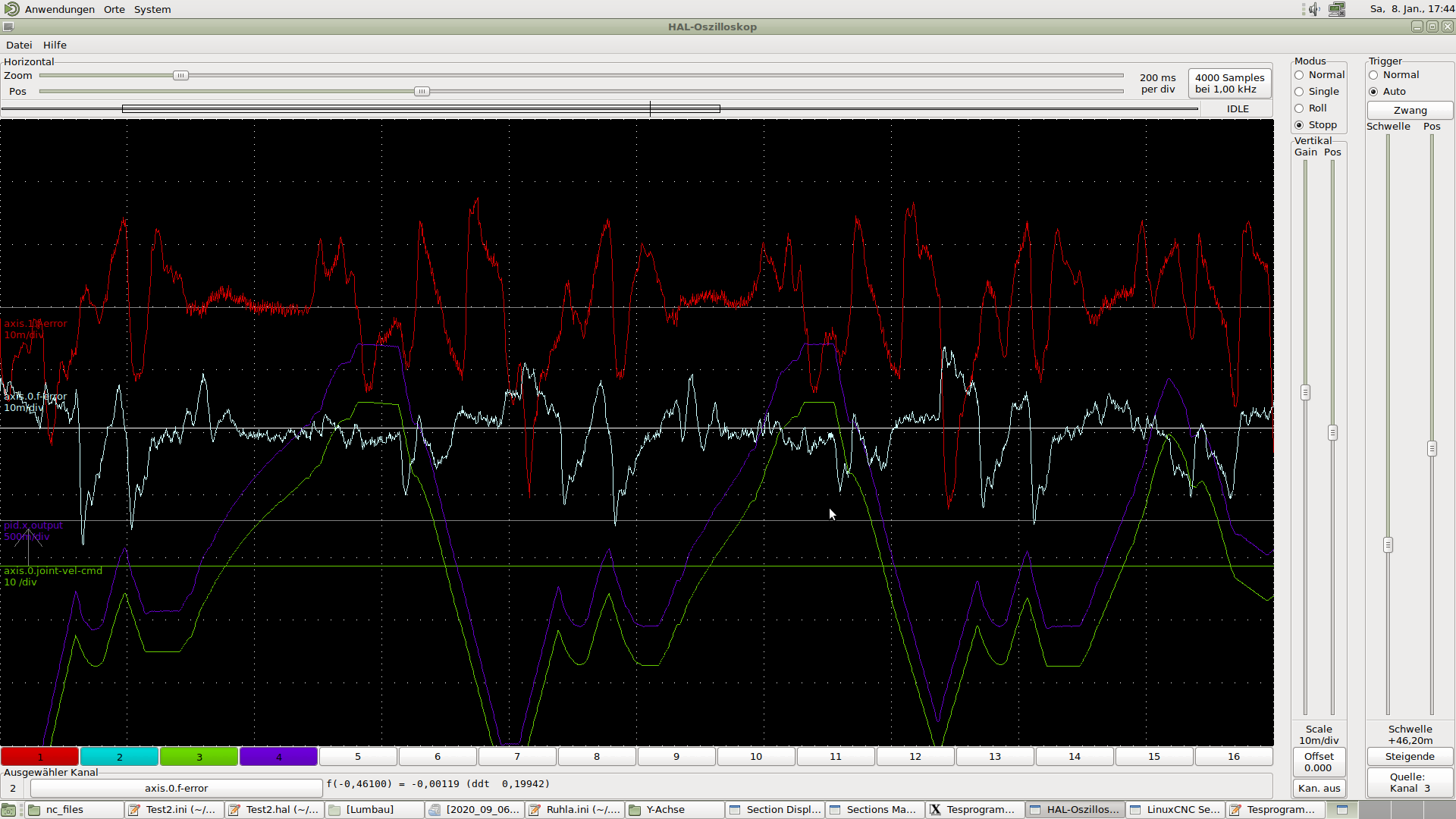

The next picture is during some violent Fusion 360 adaptive code running. Programmed feedrate of F3000.

I am pretty happy with that result. (red is f-error of Y, white is X). During helical G2/ moves f-error is below 0.005mm.

Just out of curiosity:

What are appropriate FERROR and MIN_FERROR values for such a machine? I tend to set them high (0.1) to avoid f-error during milling operations. Picture of machine on first page of this thread.

But during a crash the f-error warning has saved once me from destroying an 800€ shell mill i borrowed from work (on the Siemens control).

So there a small FERROR would be advantageous.

The Problem was related to the Tuning of the Simodrive.

The "T" parameter had a similar effect as FF1 and "Kp" is similar to P.

A quarter turn cw of Kp and a reduction of "TN" helped in the end. Increasing kp without adjusting TN led to high frequency oscillations of the motor.

Then I could increase P in linuxcnc from 1 to 3.

This is the result (I also increased the acceleration from 500 to 700):

The next picture is during some violent Fusion 360 adaptive code running. Programmed feedrate of F3000.

I am pretty happy with that result. (red is f-error of Y, white is X). During helical G2/ moves f-error is below 0.005mm.

Just out of curiosity:

What are appropriate FERROR and MIN_FERROR values for such a machine? I tend to set them high (0.1) to avoid f-error during milling operations. Picture of machine on first page of this thread.

But during a crash the f-error warning has saved once me from destroying an 800€ shell mill i borrowed from work (on the Siemens control).

So there a small FERROR would be advantageous.

Attachments:

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

10 Jan 2022 13:50 #231305

by Todd Zuercher

Replied by Todd Zuercher on topic Servo tuning f-error spikes

The ideal f-error settings will very from machine to machine. What f-error setting does your Siemans control like?

If I were setting up the machine, to start with I'd set the MIN_FERROR to be about double the error you measure in Halscope when you were tuning the drive, then set the FERROR to about double what MIN_FERROR is. If those numbers feel like they are acceptable for the accuracy tolerance I would expect from the machine. Another good option for setting the FERROR limit is to set it equal to the distance required to saturate your PID output.

In Linuxcnc MIN_FERROR and FERROR set a range of error values where Linuxcnc fill fault with a following error alarm. MIN_FERROR will be the falt limit when the axis is stopped, and FERROR will be the limit when moving at maximum velocity. At velocities between the error limit will be linearly interpolated between the two values.

If I were setting up the machine, to start with I'd set the MIN_FERROR to be about double the error you measure in Halscope when you were tuning the drive, then set the FERROR to about double what MIN_FERROR is. If those numbers feel like they are acceptable for the accuracy tolerance I would expect from the machine. Another good option for setting the FERROR limit is to set it equal to the distance required to saturate your PID output.

In Linuxcnc MIN_FERROR and FERROR set a range of error values where Linuxcnc fill fault with a following error alarm. MIN_FERROR will be the falt limit when the axis is stopped, and FERROR will be the limit when moving at maximum velocity. At velocities between the error limit will be linearly interpolated between the two values.

The following user(s) said Thank You: Wieser

Please Log in or Create an account to join the conversation.

- Wieser

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 1

10 Jan 2022 18:28 #231326

by Wieser

Replied by Wieser on topic Servo tuning f-error spikes

Thanks Todd!

I will set the FERROR accordingly and see if i get unexpected f-error warnings in some test programms.

I think i will set MIN_FERROR to 0.025 and FEROR to 0.050.

The FERROR Parameter of the Siemens is 0.01 (0.04 at G0). But I am prettty sure it only triggers a f-error warning if the error occurs for a longer time period.

I will set the FERROR accordingly and see if i get unexpected f-error warnings in some test programms.

I think i will set MIN_FERROR to 0.025 and FEROR to 0.050.

The FERROR Parameter of the Siemens is 0.01 (0.04 at G0). But I am prettty sure it only triggers a f-error warning if the error occurs for a longer time period.

Please Log in or Create an account to join the conversation.

Time to create page: 0.127 seconds