Spindle Motor Advice

- BeagleBrainz

-

Topic Author

Topic Author

- Visitor

-

15 Aug 2020 23:25 #178333

by BeagleBrainz

Spindle Motor Advice was created by BeagleBrainz

I've just ordered a belt drive kit for my BF20L (G0704 to those across the pond) and am looking to replace the stock motor.

Please don't suggest a treadmill motor, coming from the repair\service industry for exercise equipment I don't want to deal with one nor the controller.

I have been looking at a brushless DC motor here:

www.emppl.com.au/collections/brushless-d...1000w-3500rpm-m090-l

or the 750w option

www.emppl.com.au/collections/brushless-d...-750w-3500rpm-m090-m

Along with their recommended controller, on the surface it looks expensive but the supplier is in Australia, so should have a saving on delivery costs.

Or would an AC servo motor be an option such as:

dmm-store-shopify.myshopify.com/products...-75kw-ac-servo-motor

What other options are there ?

Keep in mind that almost all my milling projects have been in steel so far. If possible I would like something with a 14mm shaft

Please don't suggest a treadmill motor, coming from the repair\service industry for exercise equipment I don't want to deal with one nor the controller.

I have been looking at a brushless DC motor here:

www.emppl.com.au/collections/brushless-d...1000w-3500rpm-m090-l

or the 750w option

www.emppl.com.au/collections/brushless-d...-750w-3500rpm-m090-m

Along with their recommended controller, on the surface it looks expensive but the supplier is in Australia, so should have a saving on delivery costs.

Or would an AC servo motor be an option such as:

dmm-store-shopify.myshopify.com/products...-75kw-ac-servo-motor

What other options are there ?

Keep in mind that almost all my milling projects have been in steel so far. If possible I would like something with a 14mm shaft

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

16 Aug 2020 08:28 #178367

by rodw

Replied by rodw on topic Spindle Motor Advice

a 3 phase motor with a VFD would be the cheapest option if you can get one the right form factor.

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

Topic Author

Topic Author

- Visitor

-

16 Aug 2020 08:34 #178369

by BeagleBrainz

Replied by BeagleBrainz on topic Spindle Motor Advice

I though of that Rod,I have one for the Myford ML7\Super 7 I'm putting together, but it weighs a ton and I'd have to upgrade the Z axis motor & drive to cope.

I'll give emppl a shout Monday and see what they reckon.

I'll give emppl a shout Monday and see what they reckon.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

17 Aug 2020 22:53 #178544

by JohnnyCNC

Replied by JohnnyCNC on topic Spindle Motor Advice

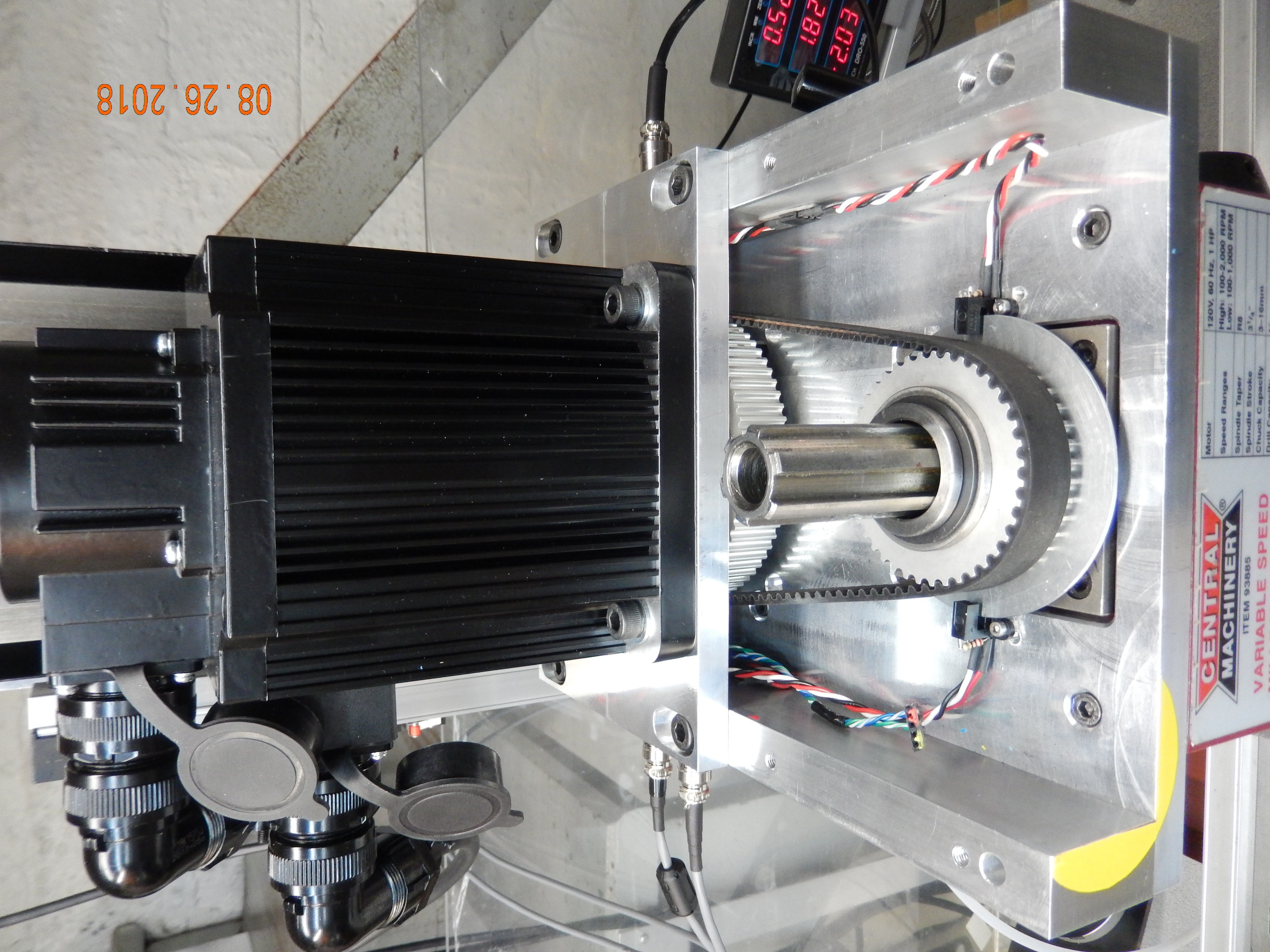

I used this one on a Sieg X3 which is very similar to a G0704. It drives the spindle via a toothed belt geared 1:1.8 so I get 5400 rpm at the spindle. My goal was higher spindle speed and being able to do rigid tapping. Both were achieved.

DMM-DYN4 1.8kw

DMM-DYN4 1.8kw

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

Topic Author

Topic Author

- Visitor

-

18 Aug 2020 06:14 #178569

by BeagleBrainz

Replied by BeagleBrainz on topic Spindle Motor Advice

I opted for the 750 watt from DMM, the local supplier never got back to me, could be something to do with the hipsters in Melbourne and the beverage plague.

Was going to go thru one major US supplier but they were $110 USD more for delivery than DMM.

Was going to go thru one major US supplier but they were $110 USD more for delivery than DMM.

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

Topic Author

Topic Author

- Visitor

-

18 Aug 2020 11:25 #178595

by BeagleBrainz

Replied by BeagleBrainz on topic Spindle Motor Advice

Johnny have you any tips for setting up the DYN4 as a spindle.

I'd guess I'll also need a 7i83 for the analogue voltage to control the DNY4.

I'd guess I'll also need a 7i83 for the analogue voltage to control the DNY4.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

20 Aug 2020 03:14 - 20 Aug 2020 03:15 #178790

by JohnnyCNC

Replied by JohnnyCNC on topic Spindle Motor Advice

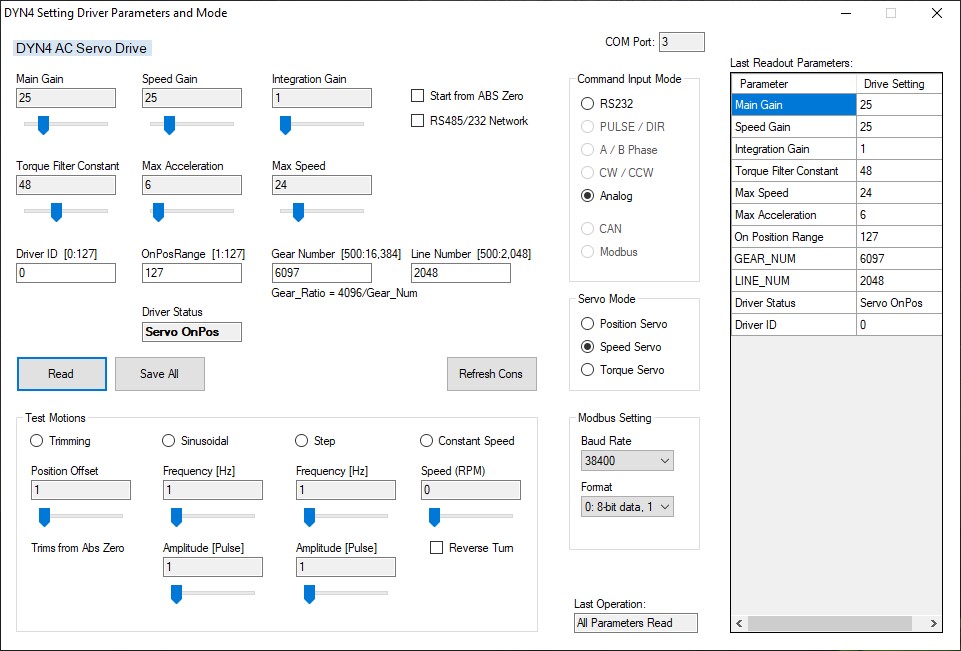

I'm using a 6l25+7i76 and I did add a 7i83 for the 0-10v interface. I used the AB encoder signals sent out by the DMM drive and I added a slot type optical sensor on the spindle for the Z signal. I had to do that because of the 1:1.8 toothed belt gearing. You can probably use 1:1 gearing since the max speed on the 750 watt is 5000 rpm. On the 1.8kw it is only 3000 rpm and I could afford to trade some torque for speed.

The other thing that the docs or the tech warned about (can't remember which) was not to do quick power cycles like off then right back on again. I think I put something in the HAL to prevent that from happening but I would have to look.

This was some advice I got from DMM Tech support:

For use as spindle motor, set Integration Gain to "1" and keep it at "1". Then increase Main Gain and Speed Gain until the motion is rigid and suitable. Keep Main Gain and Speed Gain at the same value.

Make sure to install a regenerative resistor on the drive to help absorb deceleration energy from the motor. Also install a transformer or AC line reactor on the AC power input to smooth and filter the power coming into the drive.

We have a large regenerative resistor for $62 with attached specifications. The line reactor you can use something like this unit: www.automationdirect.com/adc/Shopping/Ca...ine_Reactors/LR-23P0

These are the settings I ended up with:

The other thing that the docs or the tech warned about (can't remember which) was not to do quick power cycles like off then right back on again. I think I put something in the HAL to prevent that from happening but I would have to look.

This was some advice I got from DMM Tech support:

For use as spindle motor, set Integration Gain to "1" and keep it at "1". Then increase Main Gain and Speed Gain until the motion is rigid and suitable. Keep Main Gain and Speed Gain at the same value.

Make sure to install a regenerative resistor on the drive to help absorb deceleration energy from the motor. Also install a transformer or AC line reactor on the AC power input to smooth and filter the power coming into the drive.

We have a large regenerative resistor for $62 with attached specifications. The line reactor you can use something like this unit: www.automationdirect.com/adc/Shopping/Ca...ine_Reactors/LR-23P0

These are the settings I ended up with:

Attachments:

Last edit: 20 Aug 2020 03:15 by JohnnyCNC.

Please Log in or Create an account to join the conversation.

- BeagleBrainz

-

Topic Author

Topic Author

- Visitor

-

28 Aug 2020 07:42 #179792

by BeagleBrainz

Replied by BeagleBrainz on topic Spindle Motor Advice

Cheers mate, sorry I missed your reply. Just received my servo & driver package this week, had a bit of a play around on the bench using the DMM software.

Have a 7i74 & 7i83 on order as well as some noise filters. Just need to get a contactor with a 24v DC coil and a line reactor. The joys of living Down & Under, throw the covid thing in and it's almost impossible to buy stuff. "Stock is due in but........."

Good info on the on\off power cycles.

High speed gearing with the kit I got is 1:1 so max speed should be about 5k less whatever losses in the system. The lower gear is 1:0.647. Most of the stuff I work with is mild steel so the lower speeds should be good.

This weekend's plan is to make a replacement motor plate as the one I was supplied with the belt drive kit is for the std g0704 motor.

If it's ok I may ask about your HAL setup for the spindle just to have a base to start with.

Have a 7i74 & 7i83 on order as well as some noise filters. Just need to get a contactor with a 24v DC coil and a line reactor. The joys of living Down & Under, throw the covid thing in and it's almost impossible to buy stuff. "Stock is due in but........."

Good info on the on\off power cycles.

High speed gearing with the kit I got is 1:1 so max speed should be about 5k less whatever losses in the system. The lower gear is 1:0.647. Most of the stuff I work with is mild steel so the lower speeds should be good.

This weekend's plan is to make a replacement motor plate as the one I was supplied with the belt drive kit is for the std g0704 motor.

If it's ok I may ask about your HAL setup for the spindle just to have a base to start with.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

30 Aug 2020 00:14 #179985

by JohnnyCNC

Replied by JohnnyCNC on topic Spindle Motor Advice

Attached are all of my .ini & .hal files that involve the spindle operation.

vc-p4s.hal

vc-posthui.hal

Warning: Spoiler!

# Generated by PNCconf at Sun Jan 12 16:23:57 2020

# Using LinuxCNC version: UNAVAILABLE

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = SiegX3

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

#EMBED_TAB_NAME = GladeVCP

#EMBED_TAB_COMMAND = halcmd loadusr -Wn gladevcp gladevcp -c gladevcp -H gvcp_call_list.hal -x {XID} gvcp-panel.ui

PYVCP = pyvcp-panel.xml

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/john/linuxcnc/nc_files

PYVCP = pyvcp-panel.xml

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 4.000000

MIN_LINEAR_VELOCITY = 0.016670

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

CARD0=hm2_5i25.0

[HAL]

HALUI = halui

HALFILE = SiegX3.hal

HALFILE = custom.hal

HALFILE = vc-p4s.hal

POSTGUI_HALFILE = postgui_call_list.hal

POSTGUI_HALGUI = vc-postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

MDI_COMMAND=G28

MDI_COMMAND=M7

MDI_COMMAND=M9

MDI_COMMAND=o100 call

MDI_COMMAND=o100 call

MDI_COMMAND=.

MDI_COMMAND=.

MDI_COMMAND=.

MDI_COMMAND=G10 L20 P1 X0

MDI_COMMAND=G10 L20 P1 Y0

MDI_COMMAND=G10 L20 P1 Z0

MDI_COMMAND=G0 X0

MDI_COMMAND=G0 Y0

MDI_COMMAND=G0 Z0

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 0.5

MAX_LINEAR_VELOCITY = 4.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_QUILL_UP = 1

#******************************************

[AXIS_X]

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

MIN_LIMIT = -0.001

MAX_LIMIT = 19.7

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

HOME_SEQUENCE=1

HOME_SEARCH_VEL = -2.0000

HOME_LATCH_VEL = .10000

BACKLASH = 0.000

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.20

STEPGEN_MAXACCEL = 27.20

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 200

DIRHOLD = 200

STEPLEN = 1000

STEPSPACE = 2000

STEP_SCALE = 10160.000

MIN_LIMIT = -0.001

MAX_LIMIT = 19.7

HOME_OFFSET = 0.6

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

MIN_LIMIT = -0.001

MAX_LIMIT = 6.92

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

HOME_SEQUENCE=1

HOME_SEARCH_VEL = -1.00000

HOME_LATCH_VEL = .10000

BACKLASH = 0.0016

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.2

STEPGEN_MAXACCEL = 27.2

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 200

DIRHOLD = 200

STEPLEN = 1000

STEPSPACE = 2000

STEP_SCALE = 10160.000

MIN_LIMIT = -0.001

MAX_LIMIT = 6.92

HOME_OFFSET = 1.02

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 2.6

MAX_ACCELERATION = 10.0

MIN_LIMIT = -12.5

MAX_LIMIT = 0.001

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 2.6

MAX_ACCELERATION = 10.0

HOME_SEQUENCE=0

HOME_SEARCH_VEL = 1.00000

HOME_LATCH_VEL = .10000

BACKLASH=0.0084

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 3.25

STEPGEN_MAXACCEL = 20

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 200

DIRHOLD = 200

STEPLEN = 1000

STEPSPACE = 2000

STEP_SCALE = 13062.0

MIN_LIMIT = -12.5

MAX_LIMIT = 0.001

HOME_OFFSET = 0.1

#******************************************

[SPINDLE_0]

P = 2.0

I = 4.0

D = 0.0

FF0 = 1.08

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

OUTPUT_MIN_LIMIT = -5400.0

OUTPUT_MAX_LIMIT = 5400.0

OUTPUT_SCALE = -10800

ENCODER_SCALE = 4551.111111

#((2048 * 4) / 1.8) = 4551.111111

# Using LinuxCNC version: UNAVAILABLE

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = SiegX3

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = axis

#EMBED_TAB_NAME = GladeVCP

#EMBED_TAB_COMMAND = halcmd loadusr -Wn gladevcp gladevcp -c gladevcp -H gvcp_call_list.hal -x {XID} gvcp-panel.ui

PYVCP = pyvcp-panel.xml

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_OVERRIDE = 1.000000

MIN_SPINDLE_OVERRIDE = 0.500000

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/john/linuxcnc/nc_files

PYVCP = pyvcp-panel.xml

INCREMENTS = .1in .05in .01in .005in .001in .0005in .0001in

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 0.250000

MAX_LINEAR_VELOCITY = 4.000000

MIN_LINEAR_VELOCITY = 0.016670

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

# **** This is for info only ****

# DRIVER0=hm2_pci

# BOARD0=5i25

CARD0=hm2_5i25.0

[HAL]

HALUI = halui

HALFILE = SiegX3.hal

HALFILE = custom.hal

HALFILE = vc-p4s.hal

POSTGUI_HALFILE = postgui_call_list.hal

POSTGUI_HALGUI = vc-postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

MDI_COMMAND=G28

MDI_COMMAND=M7

MDI_COMMAND=M9

MDI_COMMAND=o100 call

MDI_COMMAND=o100 call

MDI_COMMAND=.

MDI_COMMAND=.

MDI_COMMAND=.

MDI_COMMAND=G10 L20 P1 X0

MDI_COMMAND=G10 L20 P1 Y0

MDI_COMMAND=G10 L20 P1 Z0

MDI_COMMAND=G0 X0

MDI_COMMAND=G0 Y0

MDI_COMMAND=G0 Z0

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = inch

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 0.5

MAX_LINEAR_VELOCITY = 4.00

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

TOOL_CHANGE_QUILL_UP = 1

#******************************************

[AXIS_X]

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

MIN_LIMIT = -0.001

MAX_LIMIT = 19.7

[JOINT_0]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

HOME_SEQUENCE=1

HOME_SEARCH_VEL = -2.0000

HOME_LATCH_VEL = .10000

BACKLASH = 0.000

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.20

STEPGEN_MAXACCEL = 27.20

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 200

DIRHOLD = 200

STEPLEN = 1000

STEPSPACE = 2000

STEP_SCALE = 10160.000

MIN_LIMIT = -0.001

MAX_LIMIT = 19.7

HOME_OFFSET = 0.6

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

MIN_LIMIT = -0.001

MAX_LIMIT = 6.92

[JOINT_1]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 4.0

MAX_ACCELERATION = 16.0

HOME_SEQUENCE=1

HOME_SEARCH_VEL = -1.00000

HOME_LATCH_VEL = .10000

BACKLASH = 0.0016

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 4.2

STEPGEN_MAXACCEL = 27.2

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 200

DIRHOLD = 200

STEPLEN = 1000

STEPSPACE = 2000

STEP_SCALE = 10160.000

MIN_LIMIT = -0.001

MAX_LIMIT = 6.92

HOME_OFFSET = 1.02

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 2.6

MAX_ACCELERATION = 10.0

MIN_LIMIT = -12.5

MAX_LIMIT = 0.001

[JOINT_2]

TYPE = LINEAR

HOME = 0.0

FERROR = 0.5

MIN_FERROR = 0.05

MAX_VELOCITY = 2.6

MAX_ACCELERATION = 10.0

HOME_SEQUENCE=0

HOME_SEARCH_VEL = 1.00000

HOME_LATCH_VEL = .10000

BACKLASH=0.0084

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 3.25

STEPGEN_MAXACCEL = 20

P = 1000.0

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 1.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 0.0

# these are in nanoseconds

DIRSETUP = 200

DIRHOLD = 200

STEPLEN = 1000

STEPSPACE = 2000

STEP_SCALE = 13062.0

MIN_LIMIT = -12.5

MAX_LIMIT = 0.001

HOME_OFFSET = 0.1

#******************************************

[SPINDLE_0]

P = 2.0

I = 4.0

D = 0.0

FF0 = 1.08

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

OUTPUT_MIN_LIMIT = -5400.0

OUTPUT_MAX_LIMIT = 5400.0

OUTPUT_SCALE = -10800

ENCODER_SCALE = 4551.111111

#((2048 * 4) / 1.8) = 4551.111111

Warning: Spoiler!

#DYN4 1.8K Servo Spindle with encoder.

# Generated by PNCconf at Sun Jan 12 16:23:57 2020

# Using LinuxCNC version: 2.8Pre

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=1 num_pwmgens=0 num_stepgens=4 sserial_port_0=00xxxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt estop_latch count=2

addf estop-latch.0 servo-thread

addf estop-latch.1 servo-thread

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt encoder

#add scale and lowpass, these will be used in custom_postgui.hal

loadrt scale count=1

loadrt lowpass count=1

loadrt abs count=1

loadrt near count=1

#loadrt not names=not.halui.spindle-stop

addf scale.0 servo-thread

addf lowpass.0 servo-thread

addf abs.0 servo-thread

addf near.0 servo-thread

#addf not.halui.spindle-stop servo-thread

#loadrt and2 names=and2.vc,and2.ena,and2.spindle-moving

loadrt and2 names=and2.vc,and2.ena

addf and2.vc servo-thread #Used by pendant

addf and2.ena servo-thread

#addf and2.spindle-moving servo-thread

loadrt or2 names=or2.spindleStart,or2.spindleStop

addf or2.spindleStart servo-thread

addf or2.spindleStop servo-thread

#limits debounce to stop false triggers

loadrt debounce cfg=2,1 #change to the number you want

setp debounce.0.delay 100 #this sets the delay 100 iterations of the servo-thread

addf debounce.0 servo-thread

#48Volt power on.

setp debounce.1.delay 125 #this sets the delay 100 iterations of the servo-thread

addf debounce.1 servo-thread

net deb-probe-in debounce.0.0.in <= hm2_5i25.0.7i76.0.0.input-05-not

net probe-in debounce.0.0.out

net probe-in => motion.probe-input

net run-touch-btn <= hm2_5i25.0.7i76.0.0.input-06 => halui.mdi-command-04

#Time delay to prevent quick enable/disable of DYN4 drive.

loadrt timedelay count=1

setp timedelay.0.on-delay .5 #float in (default: 0.5) #The time, in seconds, for which in must be true before out becomes true

setp timedelay.0.off-delay .5 #float in (default: 0.5) #The time, in seconds, for which in must be false before out becomes false

addf timedelay.0 servo-thread #Delay between command and DYN4 enable.

#// hm2_5i25.0.encoder.00

#// Parameters

setp hm2_5i25.0.encoder.00.counter-mode false

setp hm2_5i25.0.encoder.00.filter false

setp hm2_5i25.0.encoder.00.index-invert false

setp hm2_5i25.0.encoder.00.index-mask false

setp hm2_5i25.0.encoder.00.index-mask-invert false

setp hm2_5i25.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

net x-home-sw <= hm2_5i25.0.7i76.0.0.input-23-not

net x-neg-limit <= hm2_5i25.0.7i76.0.0.input-24-not

net x-pos-limit <= hm2_5i25.0.7i76.0.0.input-25-not

net y-home-sw <= hm2_5i25.0.7i76.0.0.input-26-not

net y-pos-limit <= hm2_5i25.0.7i76.0.0.input-27-not

net y-neg-limit <= hm2_5i25.0.7i76.0.0.input-28-not

net z-home-sw <= hm2_5i25.0.7i76.0.0.input-29-not

net z-pos-limit <= hm2_5i25.0.7i76.0.0.input-30-not

net z-neg-limit <= hm2_5i25.0.7i76.0.0.input-31-not

net coolant-mist => hm2_5i25.0.7i76.0.0.output-00

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_5i25.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_5i25.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_5i25.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_5i25.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_5i25.0.stepgen.00.step_type 0

setp hm2_5i25.0.stepgen.00.control-type 1

setp hm2_5i25.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output <= hm2_5i25.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_5i25.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_5i25.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

setp pid.y.maxerror .0005

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_5i25.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_5i25.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_5i25.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_5i25.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_5i25.0.stepgen.01.step_type 0

setp hm2_5i25.0.stepgen.01.control-type 1

setp hm2_5i25.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output <= hm2_5i25.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_5i25.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

#setp pid.z.maxerror .0005

setp pid.z.maxerror .0

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_5i25.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_5i25.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_5i25.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_5i25.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_5i25.0.stepgen.02.step_type 0

setp hm2_5i25.0.stepgen.02.control-type 1

setp hm2_5i25.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output <= hm2_5i25.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_5i25.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_5i25.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]OUTPUT_MAX_LIMIT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable hm2_5i25.0.encoder.00.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---Analog output signals/setup---

setp hm2_5i25.0.7i83.0.1.analogout5-scalemax [SPINDLE_0]OUTPUT_SCALE

setp hm2_5i25.0.7i83.0.1.analogout5-minlim [SPINDLE_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i83.0.1.analogout5-maxlim [SPINDLE_0]OUTPUT_MAX_LIMIT

net spindle-output => hm2_5i25.0.7i83.0.1.analogout5

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on and2.ena.in0 estop-latch.1.reset

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => hm2_5i25.0.encoder.00.position spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

net spindle-lockout-db estop-latch.1.ok-out => and2.ena.in1

net spindle-OK and2.ena.out => timedelay.0.in

net DYN-enable timedelay.0.out => hm2_5i25.0.7i76.0.0.output-03 hm2_5i25.0.7i83.0.1.analogena5

net spindle-Lockout hm2_5i25.0.7i76.0.0.input-07-not => estop-latch.1.fault-in

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rpm-abs => near.0.in1

net spindle-fb-rpm-abs => near.0.in2

net spindle-at-speed spindle.0.at-speed <= near.0.out

setp near.0.scale 1.04

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.0.gain 60

setp lowpass.0.gain .007

setp lowpass.0.load false

net spindle-vel-fb-rps hm2_5i25.0.encoder.00.velocity => scale.0.in

net spindle-fb-rpm scale.0.out => abs.0.in

net spindle-fb-rpm-abs abs.0.out => lowpass.0.in

net spindle-fb-rpm-abs-filtered lowpass.0.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

#net jog-x-pos halui.jog.0.plus

#net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.axis.x.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

#net jog-y-pos halui.jog.1.plus

#net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.axis.y.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

#net jog-z-pos halui.jog.2.plus

#net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.axis.z.analog

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

#net spindle-manual-stop halui.spindle.stop

#net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

net extermal-spindle-Start hm2_5i25.0.7i76.0.0.input-08 or2.spindleStart.in1

net startSpindle or2.spindleStart.out halui.spindle.0.start

net extermal-spindle-Stop hm2_5i25.0.7i76.0.0.input-09 or2.spindleStop.in1

net stopSpindle or2.spindleStop.out halui.spindle.0.stop

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net machine-is-enabled <= motion.motion-enabled

# ---estop signals---

net estop-loopout iocontrol.0.emc-enable-in <= estop-latch.0.ok-out

net estop-loopin iocontrol.0.user-enable-out => estop-latch.0.ok-in

net estop-reset iocontrol.0.user-request-enable => estop-latch.0.reset

net remote-estop estop-latch.0.fault-in <= hm2_5i25.0.7i76.0.0.input-04-not

#net estop-is-activated => hm2_5i25.0.7i76.0.0.output-02

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

# Generated by PNCconf at Sun Jan 12 16:23:57 2020

# Using LinuxCNC version: 2.8Pre

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_pci config=" num_encoders=1 num_pwmgens=0 num_stepgens=4 sserial_port_0=00xxxx"

setp hm2_5i25.0.watchdog.timeout_ns 5000000

loadrt estop_latch count=2

addf estop-latch.0 servo-thread

addf estop-latch.1 servo-thread

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt encoder

#add scale and lowpass, these will be used in custom_postgui.hal

loadrt scale count=1

loadrt lowpass count=1

loadrt abs count=1

loadrt near count=1

#loadrt not names=not.halui.spindle-stop

addf scale.0 servo-thread

addf lowpass.0 servo-thread

addf abs.0 servo-thread

addf near.0 servo-thread

#addf not.halui.spindle-stop servo-thread

#loadrt and2 names=and2.vc,and2.ena,and2.spindle-moving

loadrt and2 names=and2.vc,and2.ena

addf and2.vc servo-thread #Used by pendant

addf and2.ena servo-thread

#addf and2.spindle-moving servo-thread

loadrt or2 names=or2.spindleStart,or2.spindleStop

addf or2.spindleStart servo-thread

addf or2.spindleStop servo-thread

#limits debounce to stop false triggers

loadrt debounce cfg=2,1 #change to the number you want

setp debounce.0.delay 100 #this sets the delay 100 iterations of the servo-thread

addf debounce.0 servo-thread

#48Volt power on.

setp debounce.1.delay 125 #this sets the delay 100 iterations of the servo-thread

addf debounce.1 servo-thread

net deb-probe-in debounce.0.0.in <= hm2_5i25.0.7i76.0.0.input-05-not

net probe-in debounce.0.0.out

net probe-in => motion.probe-input

net run-touch-btn <= hm2_5i25.0.7i76.0.0.input-06 => halui.mdi-command-04

#Time delay to prevent quick enable/disable of DYN4 drive.

loadrt timedelay count=1

setp timedelay.0.on-delay .5 #float in (default: 0.5) #The time, in seconds, for which in must be true before out becomes true

setp timedelay.0.off-delay .5 #float in (default: 0.5) #The time, in seconds, for which in must be false before out becomes false

addf timedelay.0 servo-thread #Delay between command and DYN4 enable.

#// hm2_5i25.0.encoder.00

#// Parameters

setp hm2_5i25.0.encoder.00.counter-mode false

setp hm2_5i25.0.encoder.00.filter false

setp hm2_5i25.0.encoder.00.index-invert false

setp hm2_5i25.0.encoder.00.index-mask false

setp hm2_5i25.0.encoder.00.index-mask-invert false

setp hm2_5i25.0.encoder.00.scale [SPINDLE_0]ENCODER_SCALE

addf hm2_5i25.0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf hm2_5i25.0.write servo-thread

# external output signals

net x-home-sw <= hm2_5i25.0.7i76.0.0.input-23-not

net x-neg-limit <= hm2_5i25.0.7i76.0.0.input-24-not

net x-pos-limit <= hm2_5i25.0.7i76.0.0.input-25-not

net y-home-sw <= hm2_5i25.0.7i76.0.0.input-26-not

net y-pos-limit <= hm2_5i25.0.7i76.0.0.input-27-not

net y-neg-limit <= hm2_5i25.0.7i76.0.0.input-28-not

net z-home-sw <= hm2_5i25.0.7i76.0.0.input-29-not

net z-pos-limit <= hm2_5i25.0.7i76.0.0.input-30-not

net z-neg-limit <= hm2_5i25.0.7i76.0.0.input-31-not

net coolant-mist => hm2_5i25.0.7i76.0.0.output-00

#*******************

# AXIS X

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

setp pid.x.maxerror .0005

net x-index-enable <=> pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-vel-cmd => pid.x.command-deriv

net x-pos-fb => pid.x.feedback

net x-output => pid.x.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_5i25.0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_5i25.0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_5i25.0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_5i25.0.stepgen.00.position-scale [JOINT_0]STEP_SCALE

setp hm2_5i25.0.stepgen.00.step_type 0

setp hm2_5i25.0.stepgen.00.control-type 1

setp hm2_5i25.0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output <= hm2_5i25.0.stepgen.00.velocity-cmd

net x-pos-fb <= hm2_5i25.0.stepgen.00.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => hm2_5i25.0.stepgen.00.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

setp pid.y.maxerror .0005

net y-index-enable <=> pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-vel-cmd => pid.y.command-deriv

net y-pos-fb => pid.y.feedback

net y-output => pid.y.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_5i25.0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_5i25.0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_5i25.0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_5i25.0.stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp hm2_5i25.0.stepgen.01.step_type 0

setp hm2_5i25.0.stepgen.01.control-type 1

setp hm2_5i25.0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output <= hm2_5i25.0.stepgen.01.velocity-cmd

net y-pos-fb <= hm2_5i25.0.stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => hm2_5i25.0.stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

#setp pid.z.maxerror .0005

setp pid.z.maxerror .0

net z-index-enable <=> pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-vel-cmd => pid.z.command-deriv

net z-pos-fb => pid.z.feedback

net z-output => pid.z.output

# Step Gen signals/setup

setp hm2_5i25.0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_5i25.0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_5i25.0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_5i25.0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_5i25.0.stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp hm2_5i25.0.stepgen.02.step_type 0

setp hm2_5i25.0.stepgen.02.control-type 1

setp hm2_5i25.0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp hm2_5i25.0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output <= hm2_5i25.0.stepgen.02.velocity-cmd

net z-pos-fb <= hm2_5i25.0.stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => hm2_5i25.0.stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE S

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

setp pid.s.maxoutput [SPINDLE_0]OUTPUT_MAX_LIMIT

setp pid.s.error-previous-target true

net spindle-index-enable <=> pid.s.index-enable hm2_5i25.0.encoder.00.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm => pid.s.command

net spindle-fb-rpm => pid.s.feedback

net spindle-output <= pid.s.output

# ---Analog output signals/setup---

setp hm2_5i25.0.7i83.0.1.analogout5-scalemax [SPINDLE_0]OUTPUT_SCALE

setp hm2_5i25.0.7i83.0.1.analogout5-minlim [SPINDLE_0]OUTPUT_MIN_LIMIT

setp hm2_5i25.0.7i83.0.1.analogout5-maxlim [SPINDLE_0]OUTPUT_MAX_LIMIT

net spindle-output => hm2_5i25.0.7i83.0.1.analogout5

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on and2.ena.in0 estop-latch.1.reset

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => hm2_5i25.0.encoder.00.position spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

net spindle-lockout-db estop-latch.1.ok-out => and2.ena.in1

net spindle-OK and2.ena.out => timedelay.0.in

net DYN-enable timedelay.0.out => hm2_5i25.0.7i76.0.0.output-03 hm2_5i25.0.7i83.0.1.analogena5

net spindle-Lockout hm2_5i25.0.7i76.0.0.input-07-not => estop-latch.1.fault-in

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rpm-abs => near.0.in1

net spindle-fb-rpm-abs => near.0.in2

net spindle-at-speed spindle.0.at-speed <= near.0.out

setp near.0.scale 1.04

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.0.gain 60

setp lowpass.0.gain .007

setp lowpass.0.load false

net spindle-vel-fb-rps hm2_5i25.0.encoder.00.velocity => scale.0.in

net spindle-fb-rpm scale.0.out => abs.0.in

net spindle-fb-rpm-abs abs.0.out => lowpass.0.in

net spindle-fb-rpm-abs-filtered lowpass.0.out

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net joint-select-a halui.joint.0.select

net x-is-homed halui.joint.0.is-homed

#net jog-x-pos halui.jog.0.plus

#net jog-x-neg halui.jog.0.minus

net jog-x-analog halui.axis.x.analog

net joint-select-b halui.joint.1.select

net y-is-homed halui.joint.1.is-homed

#net jog-y-pos halui.jog.1.plus

#net jog-y-neg halui.jog.1.minus

net jog-y-analog halui.axis.y.analog

net joint-select-c halui.joint.2.select

net z-is-homed halui.joint.2.is-homed

#net jog-z-pos halui.jog.2.plus

#net jog-z-neg halui.jog.2.minus

net jog-z-analog halui.axis.z.analog

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

#net spindle-manual-stop halui.spindle.stop

#net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

net extermal-spindle-Start hm2_5i25.0.7i76.0.0.input-08 or2.spindleStart.in1

net startSpindle or2.spindleStart.out halui.spindle.0.start

net extermal-spindle-Stop hm2_5i25.0.7i76.0.0.input-09 or2.spindleStop.in1

net stopSpindle or2.spindleStop.out halui.spindle.0.stop

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net machine-is-enabled <= motion.motion-enabled

# ---estop signals---

net estop-loopout iocontrol.0.emc-enable-in <= estop-latch.0.ok-out

net estop-loopin iocontrol.0.user-enable-out => estop-latch.0.ok-in

net estop-reset iocontrol.0.user-request-enable => estop-latch.0.reset

net remote-estop estop-latch.0.fault-in <= hm2_5i25.0.7i76.0.0.input-04-not

#net estop-is-activated => hm2_5i25.0.7i76.0.0.output-02

# ---manual tool change signals---

loadusr -W hal_manualtoolchange

net tool-change-request iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-change-confirmed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

vc-p4s.hal

Warning: Spoiler!

# 0---vc-p4s Control Pendant

loadusr -W vc-p4s

#loadrt and2 names=and2.vc

#addf and2.vc servo-thread

# 1---LCD reletive Coordinates

net axis.0.pos-relative halui.axis.x.pos-relative => vc-p4s.axis.0.pos-relative

net axis.1.pos-relative halui.axis.y.pos-relative => vc-p4s.axis.1.pos-relative

net axis.2.pos-relative halui.axis.z.pos-relative => vc-p4s.axis.2.pos-relative

#net axis.3.pos-relative halui.axis.a.pos-relative => vc-p4s.axis.3.pos-relative

#net axis.4.pos-relative halui.axis.b.pos-relative => vc-p4s.axis.4.pos-relative

#net axis.5.pos-relative halui.axis.c.pos-relative => vc-p4s.axis.5.pos-relative

# 2---JOG

net axis.0.jog-en vc-p4s.axis.0.jog-enable => axis.x.jog-enable joint.0.jog-enable

net axis.1.jog-en vc-p4s.axis.1.jog-enable => axis.y.jog-enable joint.1.jog-enable

net axis.2.jog-en vc-p4s.axis.2.jog-enable => axis.z.jog-enable joint.2.jog-enable

net jog-scale vc-p4s.jog-scale => joint.0.jog-scale axis.x.jog-scale

net jog-scale vc-p4s.jog-scale => joint.1.jog-scale axis.y.jog-scale

net jog-scale vc-p4s.jog-scale => joint.2.jog-scale axis.z.jog-scale

net jog-counts vc-p4s.jog-counts => joint.0.jog-counts axis.x.jog-counts

net jog-counts vc-p4s.jog-counts => joint.1.jog-counts axis.y.jog-counts

net jog-counts vc-p4s.jog-counts => joint.2.jog-counts axis.z.jog-counts

net jog.0.cont-plus vc-p4s.jog.0.plus => halui.axis.x.plus halui.joint.0.plus

net jog.0.cont-minus vc-p4s.jog.0.minus => halui.axis.x.minus halui.joint.0.minus

net jog.1.cont-plus vc-p4s.jog.1.plus => halui.axis.y.plus halui.joint.1.plus

net jog.1.cont-minus vc-p4s.jog.1.minus => halui.axis.y.minus halui.joint.1.minus

net jog.2.cont-plus vc-p4s.jog.2.plus => halui.axis.z.plus halui.joint.2.plus

net jog.2.cont-mimus vc-p4s.jog.2.minus => halui.axis.z.minus halui.joint.2.minus

net jog-speed vc-p4s.jog.velocity => halui.axis.jog-speed halui.joint.jog-speed

net motion-in-position motion.in-position => vc-p4s.is-moving

setp axis_0_max_velocity [JOINT_0]MAX_VELOCITY

setp axis_1_max_velocity [JOINT_1]MAX_VELOCITY

setp axis_2_max_velocity [JOINT_2]MAX_VELOCITY

# 3---FOR 4TH AXIS, REMOVE # FROM THE FOLLOWING LINES

#net axis.3.jog-en vc-p4s.axis.3.jog-enable => axis.a.jog-enable joint.3.jog-enable

#net jog-scale vc-p4s.jog-scale => joint.3.jog-scale axis.a.jog-scale

#net jog-counts vc-p4s.jog-counts => joint.3.jog-counts axis.a.jog-counts

#net jog.3.cont-plus vc-p4s.jog.3.plus => halui.axis.a.plus halui.joint.3.plus

#net jog.3.cont-mimus vc-p4s.jog.3.minus => halui.axis.a.minus halui.joint.3.minus

#setp axis_3_max_velocity [JOINT_3]MAX_VELOCITY

# 4---FOR 5TH AXIS, REMOVE # FROM THE FOLLOWING LINES

#net axis.4.jog-en vc-p4s.axis.4.jog-enable => axis.a.jog-enable joint.4.jog-enable

#net jog-scale vc-p4s.jog-scale => joint.4.jog-scale axis.b.jog-scale

#net jog-counts vc-p4s.jog-counts => joint.4.jog-counts axis.b.jog-counts

#net jog.4.cont-plus vc-p4s.jog.4.plus => halui.axis.b.plus halui.joint.4.plus

#net jog.4.cont-mimus vc-p4s.jog.4.minus => halui.axis.b.minus halui.joint.4.minus

#setp axis_4_max_velocity [JOINT_4]MAX_VELOCITY

# 5--FOR 6TH AXIS, REMOVE # FROM THE FOLLOWING LINES

#net axis.5.jog-en vc-p4s.axis.5.jog-enable => axis.c.jog-enable joint.5.jog-enable

#net jog-scale vc-p4s.jog-scale => joint.5.jog-scale axis.c.jog-scale

#net jog-counts vc-p4s.jog-counts => joint.5.jog-counts axis.c.jog-counts

#net jog.5.cont-plus vc-p4s.jog.5.plus => halui.axis.c.plus halui.joint.5.plus

#net jog.5.cont-mimus vc-p4s.jog.5.minus => halui.axis.c.minus halui.joint.5.minus

#setp axis_5_max_velocity [JOINT_5]MAX_VELOCITY

# 6---FEED OVERRIDE

setp halui.feed-override.scale 0.001

net feed-enable vc-p4s.feed-override.count.enable => halui.feed-override.count-enable

net feedrate-counts vc-p4s.feedrate-counts => halui.feed-override.counts

net feed.value halui.feed-override.value => vc-p4s.feed-override.value

# 7---RAPID OVERRIDE

setp halui.rapid-override.scale 0.001

net rapid-enable vc-p4s.rapid-override.count.enable => halui.rapid-override.count-enable

net rapid-counts vc-p4s.rapid-counts => halui.rapid-override.counts

net rapid.value halui.rapid-override.value => vc-p4s.rapid-override.value

# 8---MAX VELOCITY

setp halui.max-velocity.scale 0.001

net max-enable vc-p4s.max-velocity.count.enable => halui.max-velocity.count-enable

net max-counts vc-p4s.max-counts => halui.max-velocity.counts

net max.value halui.max-velocity.value => vc-p4s.max-velocity.value

# 9---SPINDLE OVERRIDE

setp halui.spindle.0.override.scale 0.001

net spindle-enable-vc vc-p4s.spindle-override.count.enable => halui.spindle.0.override.count-enable

net spindle-counts vc-p4s.spindle-counts => halui.spindle.0.override.counts

net spindle.value halui.spindle.0.override.value => vc-p4s.spindle-override.value

# 10---PROGRAM

net program.is-idle halui.program.is-idle => vc-p4s.program.is-idle

net program.is-paused halui.program.is-paused => vc-p4s.program.is-paused

net program.is-running halui.program.is-running => vc-p4s.program.is-running

net program-start-btn halui.mode.auto and2.vc.in0 <= vc-p4s.program.run

net program-run-ok and2.vc.in1 <= halui.mode.is-auto

net remote-program-run halui.program.run <= and2.vc.out

net program.pause vc-p4s.program.pause => halui.program.pause

net program.resume vc-p4s.program.resume => halui.program.resume

net program.stop vc-p4s.program.stop => halui.program.stop

# 11---ZERO

net zero-x vc-p4s.zero-x => halui.mdi-command-05

net zero-y vc-p4s.zero-y => halui.mdi-command-06

net zero-z vc-p4s.zero-z => halui.mdi-command-07

net x-go-to-zero vc-p4s.x-go-to-zero => halui.mdi-command-08

net y-go-to-zero vc-p4s.y-go-to-zero => halui.mdi-command-09

net z-go-to-zero vc-p4s.z-go-to-zero => halui.mdi-command-10

# 12---SPINDLE

#net spindle.is-on halui.spindle.0.is-on => vc-p4s.spindle.is-on

#net spindle.start-p vc-p4s.spindle.start => halui.spindle.0.start

#net spindle.stop-p vc-p4s.spindle.stop => halui.spindle.0.stop

net spindle.is-on halui.spindle.0.is-on => vc-p4s.spindle.is-on

##net spindle.start vc-p4s.spindle.start => halui.spindle.start

net spindle.start-p vc-p4s.spindle.start or2.spindleStart.in0

##net spindle.stop vc-p4s.spindle.stop => halui.spindle.stop

net spindle.stop-p vc-p4s.spindle.stop or2.spindleStop.in0

# 13---E-STOP

net estop vc-p4s.estop.activate => halui.estop.activate

net reset vc-p4s.estop.reset => halui.estop.reset

net estop-is-activated halui.estop.is-activated => vc-p4s.estop.is-activated

# 14---MACHINE

net machine-on vc-p4s.machine.on => halui.machine.on

net machine-off vc-p4s.machine.off => halui.machine.off

#This stops the relay that controls the 48volts from briefly clicking on while LCNC is starting.

net machine-ison halui.machine.is-on => vc-p4s.machine.ison debounce.1.0.in

net mach-on debounce.1.0.out => hm2_5i25.0.7i76.0.0.output-02 #SSR 48Volt

net DYN4-Power hm2_5i25.0.7i76.0.0.output-04 hm2_5i25.0.7i76.0.0.input-16-not #DYN4 Power

##### P4-S PENDANT SETTINGS #####

# 15---STEP SIZE, SET 0 TO SKIP

setp stepsize-1 0.0001

# DEFAULT

setp stepsize-2 0.001

setp stepsize-3 0.01

setp stepsize-4 0.1

setp stepsize-5 1

setp stepsize-6 0

setp stepsize-7 0

setp stepsize-8 0

setp stepsize-9 0

loadusr -W vc-p4s

#loadrt and2 names=and2.vc

#addf and2.vc servo-thread

# 1---LCD reletive Coordinates

net axis.0.pos-relative halui.axis.x.pos-relative => vc-p4s.axis.0.pos-relative

net axis.1.pos-relative halui.axis.y.pos-relative => vc-p4s.axis.1.pos-relative

net axis.2.pos-relative halui.axis.z.pos-relative => vc-p4s.axis.2.pos-relative

#net axis.3.pos-relative halui.axis.a.pos-relative => vc-p4s.axis.3.pos-relative

#net axis.4.pos-relative halui.axis.b.pos-relative => vc-p4s.axis.4.pos-relative

#net axis.5.pos-relative halui.axis.c.pos-relative => vc-p4s.axis.5.pos-relative

# 2---JOG

net axis.0.jog-en vc-p4s.axis.0.jog-enable => axis.x.jog-enable joint.0.jog-enable

net axis.1.jog-en vc-p4s.axis.1.jog-enable => axis.y.jog-enable joint.1.jog-enable

net axis.2.jog-en vc-p4s.axis.2.jog-enable => axis.z.jog-enable joint.2.jog-enable

net jog-scale vc-p4s.jog-scale => joint.0.jog-scale axis.x.jog-scale

net jog-scale vc-p4s.jog-scale => joint.1.jog-scale axis.y.jog-scale

net jog-scale vc-p4s.jog-scale => joint.2.jog-scale axis.z.jog-scale

net jog-counts vc-p4s.jog-counts => joint.0.jog-counts axis.x.jog-counts

net jog-counts vc-p4s.jog-counts => joint.1.jog-counts axis.y.jog-counts

net jog-counts vc-p4s.jog-counts => joint.2.jog-counts axis.z.jog-counts

net jog.0.cont-plus vc-p4s.jog.0.plus => halui.axis.x.plus halui.joint.0.plus

net jog.0.cont-minus vc-p4s.jog.0.minus => halui.axis.x.minus halui.joint.0.minus

net jog.1.cont-plus vc-p4s.jog.1.plus => halui.axis.y.plus halui.joint.1.plus

net jog.1.cont-minus vc-p4s.jog.1.minus => halui.axis.y.minus halui.joint.1.minus

net jog.2.cont-plus vc-p4s.jog.2.plus => halui.axis.z.plus halui.joint.2.plus

net jog.2.cont-mimus vc-p4s.jog.2.minus => halui.axis.z.minus halui.joint.2.minus

net jog-speed vc-p4s.jog.velocity => halui.axis.jog-speed halui.joint.jog-speed

net motion-in-position motion.in-position => vc-p4s.is-moving

setp axis_0_max_velocity [JOINT_0]MAX_VELOCITY

setp axis_1_max_velocity [JOINT_1]MAX_VELOCITY

setp axis_2_max_velocity [JOINT_2]MAX_VELOCITY

# 3---FOR 4TH AXIS, REMOVE # FROM THE FOLLOWING LINES

#net axis.3.jog-en vc-p4s.axis.3.jog-enable => axis.a.jog-enable joint.3.jog-enable

#net jog-scale vc-p4s.jog-scale => joint.3.jog-scale axis.a.jog-scale

#net jog-counts vc-p4s.jog-counts => joint.3.jog-counts axis.a.jog-counts

#net jog.3.cont-plus vc-p4s.jog.3.plus => halui.axis.a.plus halui.joint.3.plus

#net jog.3.cont-mimus vc-p4s.jog.3.minus => halui.axis.a.minus halui.joint.3.minus

#setp axis_3_max_velocity [JOINT_3]MAX_VELOCITY

# 4---FOR 5TH AXIS, REMOVE # FROM THE FOLLOWING LINES

#net axis.4.jog-en vc-p4s.axis.4.jog-enable => axis.a.jog-enable joint.4.jog-enable

#net jog-scale vc-p4s.jog-scale => joint.4.jog-scale axis.b.jog-scale

#net jog-counts vc-p4s.jog-counts => joint.4.jog-counts axis.b.jog-counts

#net jog.4.cont-plus vc-p4s.jog.4.plus => halui.axis.b.plus halui.joint.4.plus

#net jog.4.cont-mimus vc-p4s.jog.4.minus => halui.axis.b.minus halui.joint.4.minus

#setp axis_4_max_velocity [JOINT_4]MAX_VELOCITY

# 5--FOR 6TH AXIS, REMOVE # FROM THE FOLLOWING LINES

#net axis.5.jog-en vc-p4s.axis.5.jog-enable => axis.c.jog-enable joint.5.jog-enable

#net jog-scale vc-p4s.jog-scale => joint.5.jog-scale axis.c.jog-scale

#net jog-counts vc-p4s.jog-counts => joint.5.jog-counts axis.c.jog-counts

#net jog.5.cont-plus vc-p4s.jog.5.plus => halui.axis.c.plus halui.joint.5.plus

#net jog.5.cont-mimus vc-p4s.jog.5.minus => halui.axis.c.minus halui.joint.5.minus

#setp axis_5_max_velocity [JOINT_5]MAX_VELOCITY

# 6---FEED OVERRIDE

setp halui.feed-override.scale 0.001

net feed-enable vc-p4s.feed-override.count.enable => halui.feed-override.count-enable

net feedrate-counts vc-p4s.feedrate-counts => halui.feed-override.counts

net feed.value halui.feed-override.value => vc-p4s.feed-override.value

# 7---RAPID OVERRIDE

setp halui.rapid-override.scale 0.001

net rapid-enable vc-p4s.rapid-override.count.enable => halui.rapid-override.count-enable

net rapid-counts vc-p4s.rapid-counts => halui.rapid-override.counts

net rapid.value halui.rapid-override.value => vc-p4s.rapid-override.value

# 8---MAX VELOCITY

setp halui.max-velocity.scale 0.001

net max-enable vc-p4s.max-velocity.count.enable => halui.max-velocity.count-enable

net max-counts vc-p4s.max-counts => halui.max-velocity.counts

net max.value halui.max-velocity.value => vc-p4s.max-velocity.value

# 9---SPINDLE OVERRIDE

setp halui.spindle.0.override.scale 0.001

net spindle-enable-vc vc-p4s.spindle-override.count.enable => halui.spindle.0.override.count-enable

net spindle-counts vc-p4s.spindle-counts => halui.spindle.0.override.counts

net spindle.value halui.spindle.0.override.value => vc-p4s.spindle-override.value

# 10---PROGRAM

net program.is-idle halui.program.is-idle => vc-p4s.program.is-idle

net program.is-paused halui.program.is-paused => vc-p4s.program.is-paused

net program.is-running halui.program.is-running => vc-p4s.program.is-running

net program-start-btn halui.mode.auto and2.vc.in0 <= vc-p4s.program.run

net program-run-ok and2.vc.in1 <= halui.mode.is-auto

net remote-program-run halui.program.run <= and2.vc.out

net program.pause vc-p4s.program.pause => halui.program.pause

net program.resume vc-p4s.program.resume => halui.program.resume

net program.stop vc-p4s.program.stop => halui.program.stop

# 11---ZERO

net zero-x vc-p4s.zero-x => halui.mdi-command-05

net zero-y vc-p4s.zero-y => halui.mdi-command-06

net zero-z vc-p4s.zero-z => halui.mdi-command-07

net x-go-to-zero vc-p4s.x-go-to-zero => halui.mdi-command-08

net y-go-to-zero vc-p4s.y-go-to-zero => halui.mdi-command-09

net z-go-to-zero vc-p4s.z-go-to-zero => halui.mdi-command-10

# 12---SPINDLE

#net spindle.is-on halui.spindle.0.is-on => vc-p4s.spindle.is-on

#net spindle.start-p vc-p4s.spindle.start => halui.spindle.0.start

#net spindle.stop-p vc-p4s.spindle.stop => halui.spindle.0.stop

net spindle.is-on halui.spindle.0.is-on => vc-p4s.spindle.is-on

##net spindle.start vc-p4s.spindle.start => halui.spindle.start

net spindle.start-p vc-p4s.spindle.start or2.spindleStart.in0

##net spindle.stop vc-p4s.spindle.stop => halui.spindle.stop

net spindle.stop-p vc-p4s.spindle.stop or2.spindleStop.in0

# 13---E-STOP

net estop vc-p4s.estop.activate => halui.estop.activate

net reset vc-p4s.estop.reset => halui.estop.reset

net estop-is-activated halui.estop.is-activated => vc-p4s.estop.is-activated

# 14---MACHINE

net machine-on vc-p4s.machine.on => halui.machine.on

net machine-off vc-p4s.machine.off => halui.machine.off

#This stops the relay that controls the 48volts from briefly clicking on while LCNC is starting.

net machine-ison halui.machine.is-on => vc-p4s.machine.ison debounce.1.0.in

net mach-on debounce.1.0.out => hm2_5i25.0.7i76.0.0.output-02 #SSR 48Volt

net DYN4-Power hm2_5i25.0.7i76.0.0.output-04 hm2_5i25.0.7i76.0.0.input-16-not #DYN4 Power

##### P4-S PENDANT SETTINGS #####

# 15---STEP SIZE, SET 0 TO SKIP

setp stepsize-1 0.0001

# DEFAULT

setp stepsize-2 0.001

setp stepsize-3 0.01

setp stepsize-4 0.1

setp stepsize-5 1

setp stepsize-6 0

setp stepsize-7 0

setp stepsize-8 0

setp stepsize-9 0

vc-posthui.hal

Warning: Spoiler!

net axis_0_max_vel vc-p4s.ini.0.max.vel => ini.0.max_velocity

net axis_1_max_vel vc-p4s.ini.1.max.vel => ini.1.max_velocity

net axis_2_max_vel vc-p4s.ini.2.max.vel => ini.2.max_velocity

net axis_3_max_vel vc-p4s.ini.3.max.vel => ini.3.max_velocity

net axis_4_max_vel vc-p4s.ini.4.max.vel => ini.4.max_velocity

net axis_5_max_vel vc-p4s.ini.5.max.vel => ini.5.max_velocity

net spindle-speed hm2_5i25.0.encoder.00.count

net axis_1_max_vel vc-p4s.ini.1.max.vel => ini.1.max_velocity

net axis_2_max_vel vc-p4s.ini.2.max.vel => ini.2.max_velocity

net axis_3_max_vel vc-p4s.ini.3.max.vel => ini.3.max_velocity

net axis_4_max_vel vc-p4s.ini.4.max.vel => ini.4.max_velocity

net axis_5_max_vel vc-p4s.ini.5.max.vel => ini.5.max_velocity

net spindle-speed hm2_5i25.0.encoder.00.count

The following user(s) said Thank You: BeagleBrainz

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

30 Aug 2020 00:19 #179986

by JohnnyCNC

Replied by JohnnyCNC on topic Spindle Motor Advice

Check out the 3hp BT30 spindle that

Clough42

on youtube just put on his G0704. If I was upgrading now I would use the one he got. It is sweet!

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.247 seconds