Retrofit Schaublin 32...(?)

- Alexandre

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 1

26 Nov 2021 21:45 #227690

by Alexandre

Retrofit Schaublin 32...(?) was created by Alexandre

tommylight post=226641 userid=17274

(...)

Alexandre, it would be best to start a new topic and upload more pictures of the machine and cabinet, diagrams you have, and yank on of the drives out and check if there is silk screening on the board regarding pinouts.

Hi.

I hope I'm not exaggerating when creating a new topic, I'm still new to the forum.

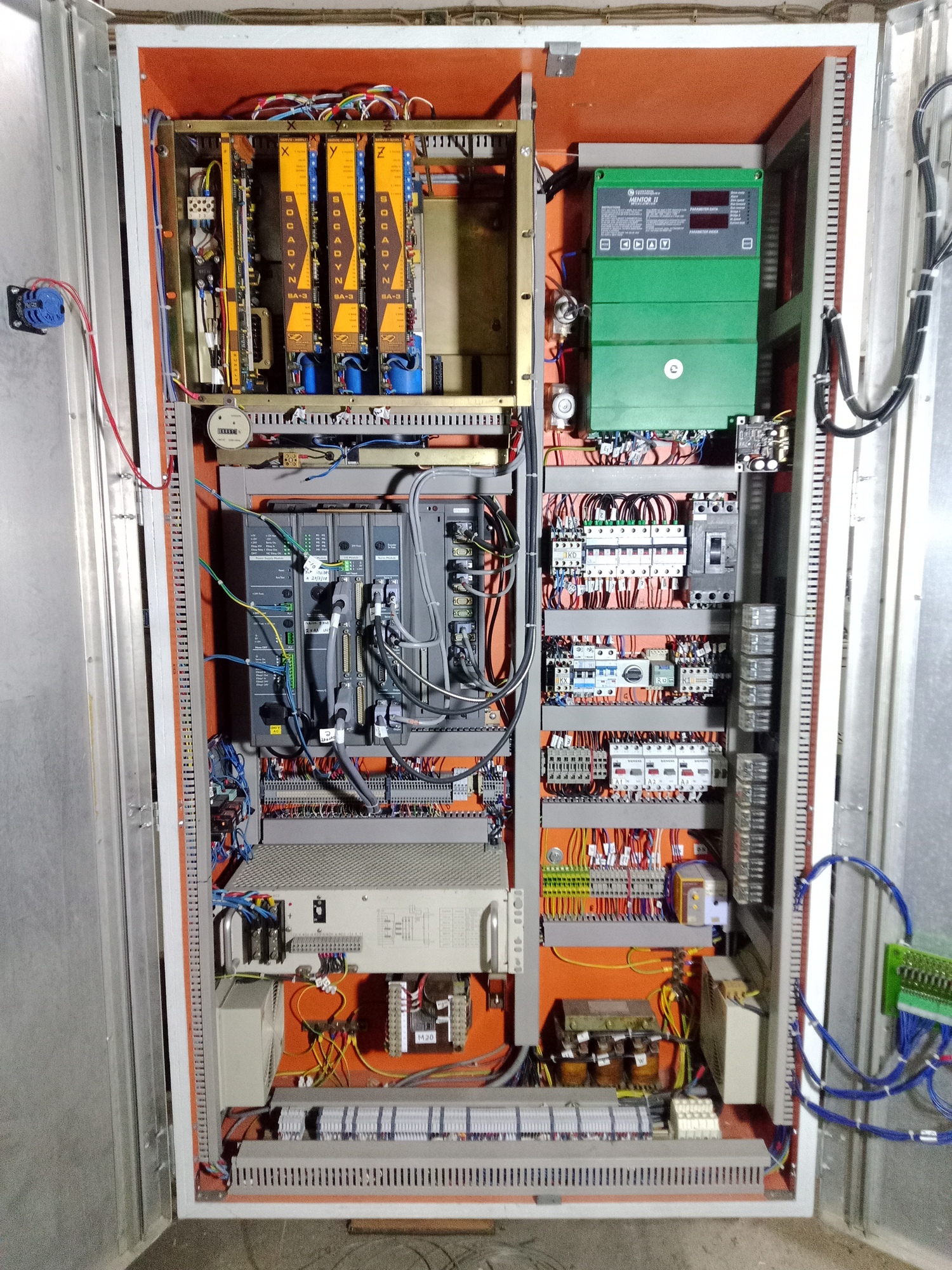

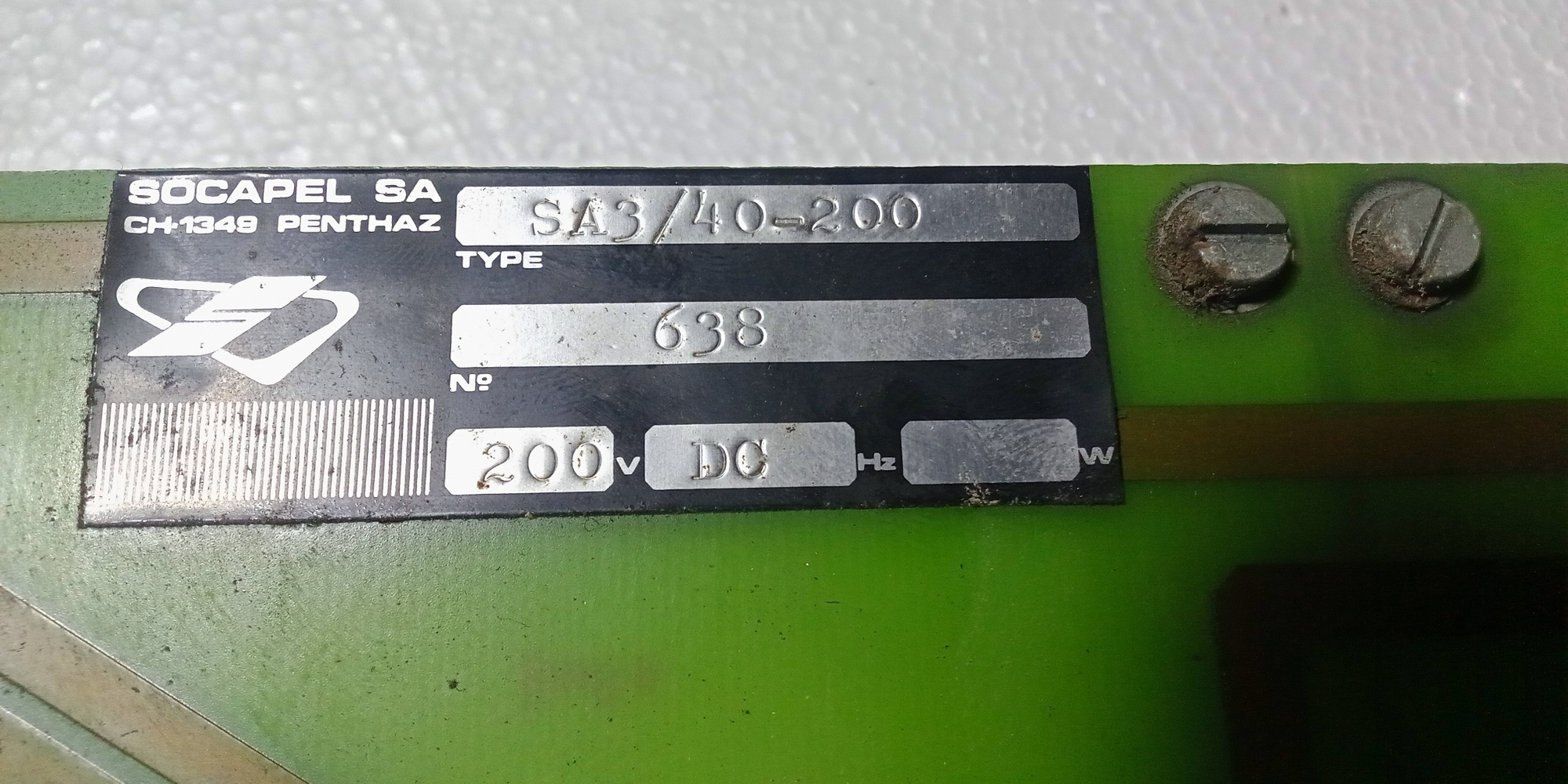

I have a Schaublin CNC milling machine with a faulty controller. She had a spindle problem, I called a technician to solve it, the technician walked 5 hours back to her and didn't solve anything.

The next day I turned on the machine and errors appeared on the controller saying that the memory was corrupt.

I had bought that machine for a low price with a malfunction on the Y-axis digital scale. After identifying the cause, I went to solve this malfunction and the machine started working on the three axes. I created a program in it so that it could go from a limit in X, Y and Z to the opposite limit and the machine was already doing that automatically, it was missing for the spindle to work.

As I hadn't saved any of her files yet, after these errors appeared I was unable to put her to work with that controller.

The technician dismissed himself saying that when he left none of that had happened, so it was nothing he did (that's what he said), but I don't see any other reason.

I wanted to retrofit it, I'm willing to rack my brain doing the retrofit, but there are things I don't know if I'm capable of doing it, and if I can't get help here on the forum, I know I won't be able to do it alone. My main problem I think is the PLC, I don't know anything about that type of programming.

The manuals I have for the machine are the spindle drive manual and the electrical schematic of cabinet.

About the axis drives I have nothing.

I would appreciate any help please. if you can...

I leave some pictures...

(...)

Alexandre, it would be best to start a new topic and upload more pictures of the machine and cabinet, diagrams you have, and yank on of the drives out and check if there is silk screening on the board regarding pinouts.

Hi.

I hope I'm not exaggerating when creating a new topic, I'm still new to the forum.

I have a Schaublin CNC milling machine with a faulty controller. She had a spindle problem, I called a technician to solve it, the technician walked 5 hours back to her and didn't solve anything.

The next day I turned on the machine and errors appeared on the controller saying that the memory was corrupt.

I had bought that machine for a low price with a malfunction on the Y-axis digital scale. After identifying the cause, I went to solve this malfunction and the machine started working on the three axes. I created a program in it so that it could go from a limit in X, Y and Z to the opposite limit and the machine was already doing that automatically, it was missing for the spindle to work.

As I hadn't saved any of her files yet, after these errors appeared I was unable to put her to work with that controller.

The technician dismissed himself saying that when he left none of that had happened, so it was nothing he did (that's what he said), but I don't see any other reason.

I wanted to retrofit it, I'm willing to rack my brain doing the retrofit, but there are things I don't know if I'm capable of doing it, and if I can't get help here on the forum, I know I won't be able to do it alone. My main problem I think is the PLC, I don't know anything about that type of programming.

The manuals I have for the machine are the spindle drive manual and the electrical schematic of cabinet.

About the axis drives I have nothing.

I would appreciate any help please. if you can...

I leave some pictures...

Attachments:

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

30 Nov 2021 14:03 #228012

by andypugh

Replied by andypugh on topic Retrofit Schaublin 32...(?)

Do you know what the PLC does? LinuxCNC has a software PLC built in, but it is possible that the functions of the existing PLC are already covered by LinuxCNC, or can be easily performed in the HAL layer.

Please Log in or Create an account to join the conversation.

- Alexandre

- Offline

- New Member

-

Less

More

- Posts: 9

- Thank you received: 1

03 Dec 2021 23:16 #228326

by Alexandre

Replied by Alexandre on topic Retrofit Schaublin 32...(?)

Yes, I have some knowledge of what the PLC does and why it is necessary, but it is a type of programming that I do not know and in this part I will have to rely on the help that the forum linux can give me here.

I know for example that when a program is running, the handwheel must be inactive by the PLC. I also know that when I select a specific spindle speed, it is the plc that, once configured, determines which gear to engage. If I want to change a tool, the plc only leaves it if the spindle is stopped, etc...

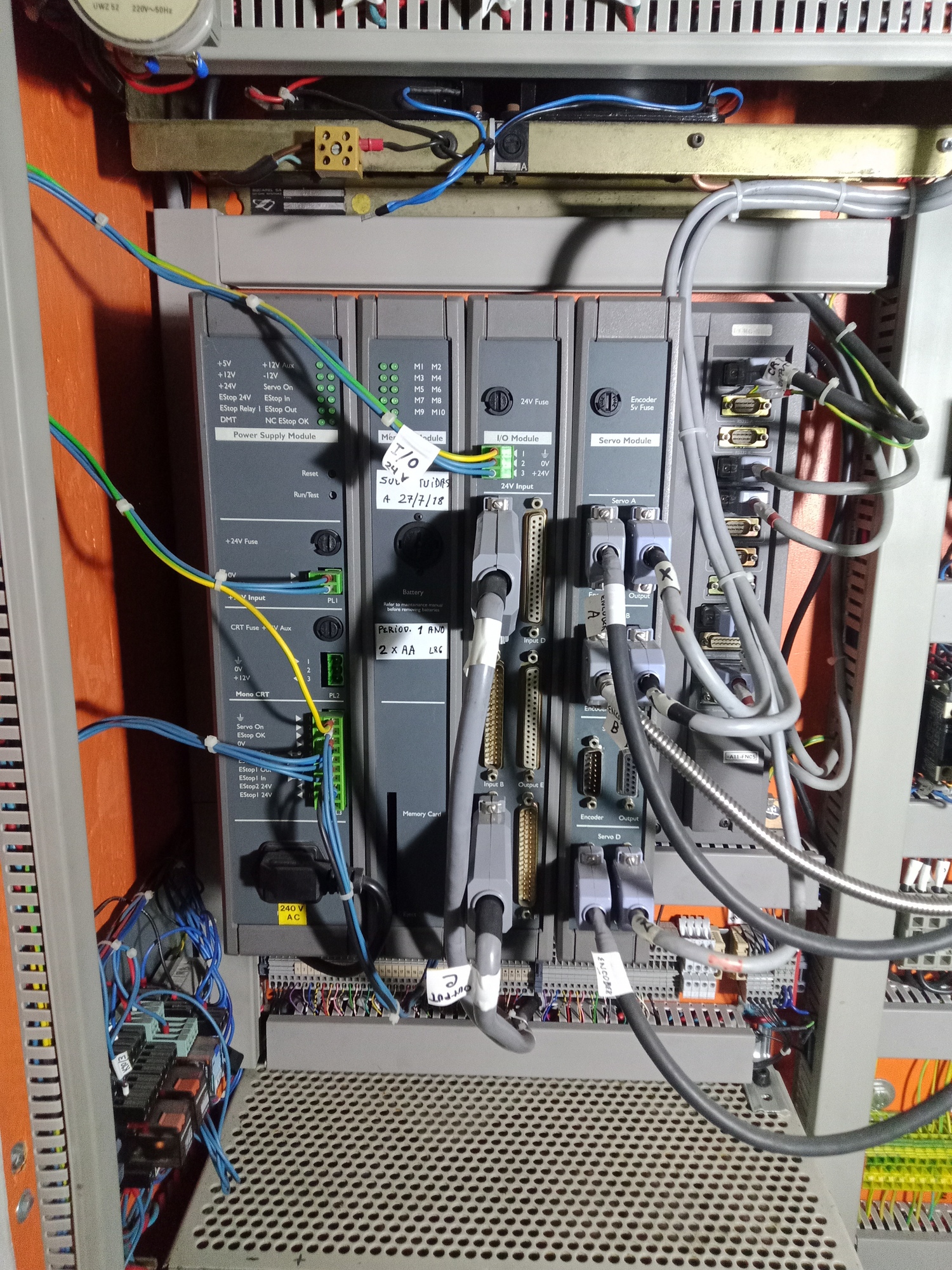

About the axis drives, I have the Control Techniques FNC4 manual. The FNC5 is very similar, and through the controller manual that's still there I think I can figure out how the axis drives are connected, so I can figure out what's currently done there.

I know for example that when a program is running, the handwheel must be inactive by the PLC. I also know that when I select a specific spindle speed, it is the plc that, once configured, determines which gear to engage. If I want to change a tool, the plc only leaves it if the spindle is stopped, etc...

About the axis drives, I have the Control Techniques FNC4 manual. The FNC5 is very similar, and through the controller manual that's still there I think I can figure out how the axis drives are connected, so I can figure out what's currently done there.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

04 Dec 2021 10:57 #228339

by andypugh

That is built-in behaviour with LinuxCNC.

Replied by andypugh on topic Retrofit Schaublin 32...(?)

I know for example that when a program is running, the handwheel must be inactive by the PLC.

That is built-in behaviour with LinuxCNC.

That can be handled with a LinuxCNC HAL component. I know there is one for the Maho gearbox. (and I hae a much simpler one for my 2-gear lathe)I also know that when I select a specific spindle speed, it is the plc that, once configured, determines which gear to engage.

This would be typically paet of the tool changer logic. There are a number of ways to do this, including with a hardware PLC. But also with HAL components or software PLC.If I want to change a tool, the plc only leaves it if the spindle is stopped, etc...

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.284 seconds