- Hardware & Machines

- CNC Machines

- Milling Machines

- RF45 Conversion - stepper drivers and power supply

RF45 Conversion - stepper drivers and power supply

- MachNegativeOne

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 1

28 Oct 2023 02:50 #283930

by MachNegativeOne

RF45 Conversion - stepper drivers and power supply was created by MachNegativeOne

I am doing an RF45 conversion. It already has Nema34 906 oz in steppers on a 1.5:1 pulleys. Just trying to figure out stepper drivers and the power supply.

My current thinging (pun intended) is to use DM850H 7.6A stepper drivers see link here

And then for a power supply. A buddy - who has built a few CNC machines - says a 12A power supply will work fine, ( like this one ) as I wont be running all axis at once while cutting.

Thoughts? Comments?

My current thinging (pun intended) is to use DM850H 7.6A stepper drivers see link here

And then for a power supply. A buddy - who has built a few CNC machines - says a 12A power supply will work fine, ( like this one ) as I wont be running all axis at once while cutting.

Thoughts? Comments?

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

28 Oct 2023 05:09 #283933

by spumco

Replied by spumco on topic RF45 Conversion - stepper drivers and power supply

It'll work, but I'd suggest considering a couple of changes or upgrades.

First - despite the fact that it already has open-loop steppers, closed-loop drives & motors are very inexpensive compared to just a couple years ago. While there are some high-end manufacturers available, even the fairly cheap ones provide some peace of mind against lost steps. I think this would be especially useful on a dovetail-way machine of perhaps dubious precision. There may be portions of an axis travel which bind up slightly, and with a closed loop system that can alarm out (and stop LCNC) you don't have to set your feeds/rapids as slow to make sure you never lose steps.

I've had pretty good experience with StepperOnline products, as well as Automation Technologies. Both of them carry rebranded Leadshine products as well as some no-name models. You might find that for a modest price jump you can get closed loop drives which will not only alarm if steps are lost, but will likely out-perform the open loop drive you linked at higher RPM.

Second - the drive you linked can handle 110Vdc input power, but you're contemplating a 48Vdc power supply. Running a stepper system at less than half the rated input voltage is crippling the upper RPM capability. All else being equal, higher input voltage permits higher RPM before a stepper motor stalls. A 96Vdc power supply will get much more speed out of those drives & motors.

Third - I'm not a fan of switching power supplies for drives. SMPS don't have much overload capacity, nor can they absorb much (if any) back-voltage spikes from decelerating a motor quickly. I prefer unregulated power supplies - specifically toroidal PSU's with great big capacitors to smooth out voltage ripple and provide a reserve of amps in case all the axes rapid at once.

Ametek sells some nice power supplies - they aren't super-cheap, but they're very robust. And they have a very nice range of output voltages available up to 1500W output. Lots of copper, heavy as sin, and lots of amps. There are other vendors, of course, and there's always ebay too.

Finally - have you considered AC servos? As with closed-loop steppers, servos are getting very inexpensive these days. And almost more importantly, some of the low-cost vendors are supplying tuning software that isn't completely useless jibberish. Maybe poke around online and see what's available in AC servo-land these days.

If you're just trying to get the thing running as cheap as possible, no shame in that. But I'd strongly suggest increasing the power supply voltage to something closer to the drive's rated value. Don't go right up to the edge as you need some headroom in case the line voltage fluctuates up a bit - don't want to over-volt the drives.

All this stuff depends on your location and taxes/duties. My suggestions may be rather more expensive in your location than mine.

First - despite the fact that it already has open-loop steppers, closed-loop drives & motors are very inexpensive compared to just a couple years ago. While there are some high-end manufacturers available, even the fairly cheap ones provide some peace of mind against lost steps. I think this would be especially useful on a dovetail-way machine of perhaps dubious precision. There may be portions of an axis travel which bind up slightly, and with a closed loop system that can alarm out (and stop LCNC) you don't have to set your feeds/rapids as slow to make sure you never lose steps.

I've had pretty good experience with StepperOnline products, as well as Automation Technologies. Both of them carry rebranded Leadshine products as well as some no-name models. You might find that for a modest price jump you can get closed loop drives which will not only alarm if steps are lost, but will likely out-perform the open loop drive you linked at higher RPM.

Second - the drive you linked can handle 110Vdc input power, but you're contemplating a 48Vdc power supply. Running a stepper system at less than half the rated input voltage is crippling the upper RPM capability. All else being equal, higher input voltage permits higher RPM before a stepper motor stalls. A 96Vdc power supply will get much more speed out of those drives & motors.

Third - I'm not a fan of switching power supplies for drives. SMPS don't have much overload capacity, nor can they absorb much (if any) back-voltage spikes from decelerating a motor quickly. I prefer unregulated power supplies - specifically toroidal PSU's with great big capacitors to smooth out voltage ripple and provide a reserve of amps in case all the axes rapid at once.

Ametek sells some nice power supplies - they aren't super-cheap, but they're very robust. And they have a very nice range of output voltages available up to 1500W output. Lots of copper, heavy as sin, and lots of amps. There are other vendors, of course, and there's always ebay too.

Finally - have you considered AC servos? As with closed-loop steppers, servos are getting very inexpensive these days. And almost more importantly, some of the low-cost vendors are supplying tuning software that isn't completely useless jibberish. Maybe poke around online and see what's available in AC servo-land these days.

If you're just trying to get the thing running as cheap as possible, no shame in that. But I'd strongly suggest increasing the power supply voltage to something closer to the drive's rated value. Don't go right up to the edge as you need some headroom in case the line voltage fluctuates up a bit - don't want to over-volt the drives.

All this stuff depends on your location and taxes/duties. My suggestions may be rather more expensive in your location than mine.

Please Log in or Create an account to join the conversation.

- MachNegativeOne

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 1

28 Oct 2023 15:02 #283966

by MachNegativeOne

Replied by MachNegativeOne on topic RF45 Conversion - stepper drivers and power supply

Thanks for the info! I am trying to keep costs down, but I will investigate your recommendations.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

28 Oct 2023 20:15 #283987

by rodw

Replied by rodw on topic RF45 Conversion - stepper drivers and power supply

Spumco has good advice.

I would not buy a drive from a random amazon supplier who does not provide documentation.

Looking at the Stepperonline docs www.omc-stepperonline.com/digital-steppe...nema-34-motor-dm860t

I see they can take an AC voltage so they don't even need the Amtek AC-DC rectifier so just a bare AC toroid will suffice. I would use a 60 volt toroid about 12 amps as you say.

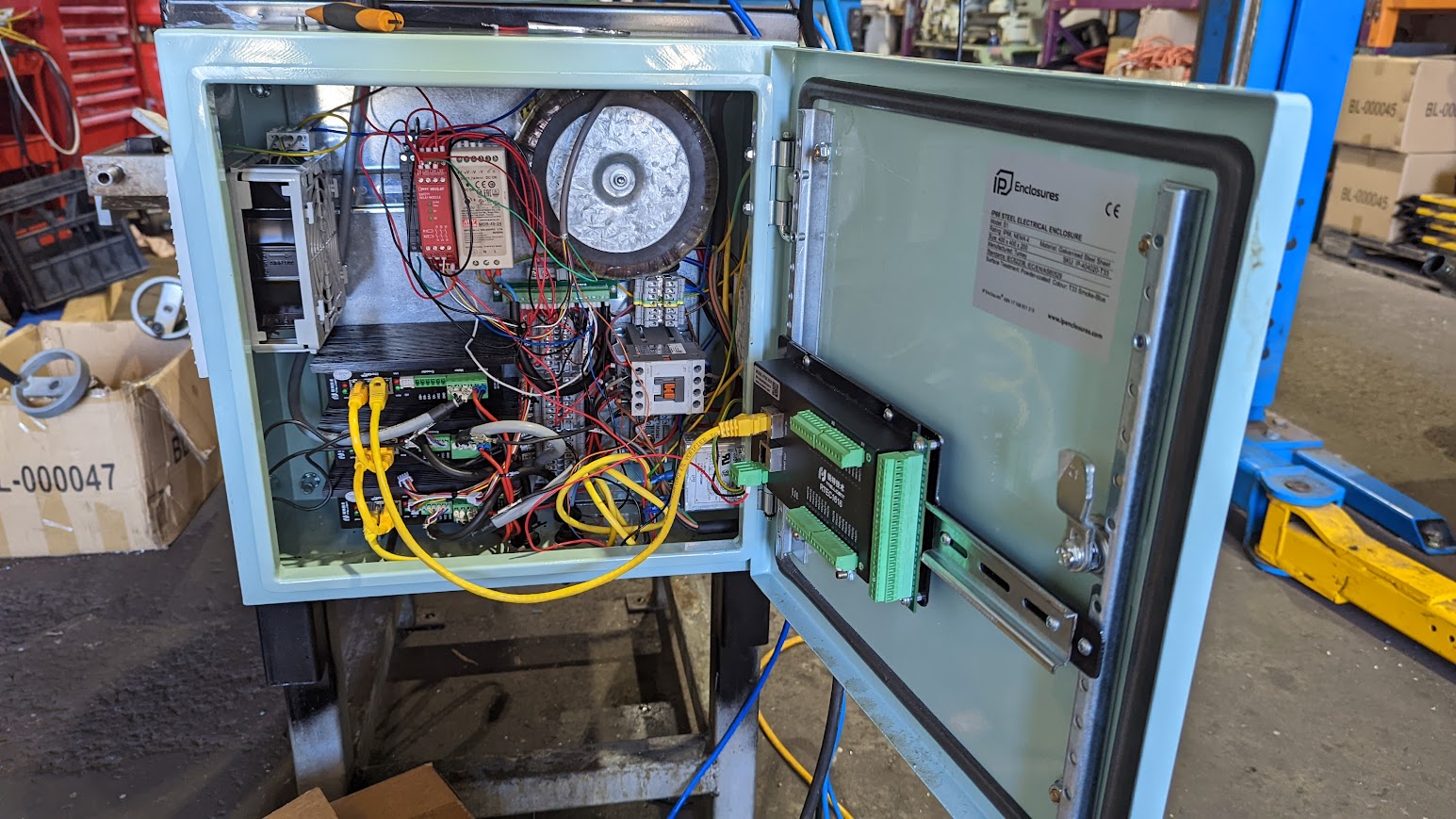

Wait, thats exactly what I did on a similar sized mill except I used closed loop ethercat stepper drives.

I would not buy a drive from a random amazon supplier who does not provide documentation.

Looking at the Stepperonline docs www.omc-stepperonline.com/digital-steppe...nema-34-motor-dm860t

I see they can take an AC voltage so they don't even need the Amtek AC-DC rectifier so just a bare AC toroid will suffice. I would use a 60 volt toroid about 12 amps as you say.

Wait, thats exactly what I did on a similar sized mill except I used closed loop ethercat stepper drives.

Attachments:

The following user(s) said Thank You: spumco

Please Log in or Create an account to join the conversation.

- MachNegativeOne

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 1

31 Oct 2023 14:38 #284192

by MachNegativeOne

Replied by MachNegativeOne on topic RF45 Conversion - stepper drivers and power supply

HI Gang,

So I already own my steppers, and I am trying to keep costs down. But I do have glass scales. I asked on another subforum if my scales would work with my Mesa board for closed loop operation and I got the thumbs up (if I get the Mesa encoder interface card).

I watched a video on closed loop stepper/drivers, and I am curious if using glass scales for closed loop would work the same way s the closed loop stepper/drivers.

I.e.

(1) If the motor starts missing steps, LinuxCNC will detect and keep sending pulses to the motor until it gets to the proper location

(2) if the motor misses steps beyond a a certain amount (e.g. 50 steps), linuxCNC will detect and stop

FWIW my scales are Ditron DC10 glass scales with .005mm resolution TTL EIA-422-A with a 60m/min max working speed, which is 1m/sec (@ 5um, that is 200,000 counts/sec. As it is a quadrature count of A/B, each channel is max 50Khz at 60m/min which is linear scale limit.)

And I would be interfacing to a Mesa 7I96S board with a Mesa 7185 encoder interface card.

So I already own my steppers, and I am trying to keep costs down. But I do have glass scales. I asked on another subforum if my scales would work with my Mesa board for closed loop operation and I got the thumbs up (if I get the Mesa encoder interface card).

I watched a video on closed loop stepper/drivers, and I am curious if using glass scales for closed loop would work the same way s the closed loop stepper/drivers.

I.e.

(1) If the motor starts missing steps, LinuxCNC will detect and keep sending pulses to the motor until it gets to the proper location

(2) if the motor misses steps beyond a a certain amount (e.g. 50 steps), linuxCNC will detect and stop

FWIW my scales are Ditron DC10 glass scales with .005mm resolution TTL EIA-422-A with a 60m/min max working speed, which is 1m/sec (@ 5um, that is 200,000 counts/sec. As it is a quadrature count of A/B, each channel is max 50Khz at 60m/min which is linear scale limit.)

And I would be interfacing to a Mesa 7I96S board with a Mesa 7185 encoder interface card.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

01 Nov 2023 05:12 #284235

by spumco

Replied by spumco on topic RF45 Conversion - stepper drivers and power supply

I believe your understanding is correct. With linear scales, LCNC will detect lost steps as a following error.

If the missed steps are few and the issue causing the missed steps is transient, LCNC will attempt to correct the position error. Beyond a certain point, LCNC will alarm with a following error. This value is adjustable.

LCNC cannot increase the motor power to overcome a significant overload - like when a stepper stalls. Only a drive can do that, and there aren't many stepper drives capable of briefly increasing the power sent to the motor in an overload condition (there is at least one Mfgr that does it). The drive you are considering cannot.

Most closed-loop drives do not have this feature either. However, they can manage the power sent to the motors better than an open loop drive, resulting in generally higher RPM before a stall, all else being equal (input volts, amp rating, etc.).

Open loop motors & drives coupled with linear scales will provide (possibly) less useful RPM than closed-loop drives, but they will accomplish the same safety feature (following error alarm) and likely better positioning accuracy assuming the sales are decent resolution and mounted properly.

Just be aware that LCNC will require some tuning once the scale feedback is introduced. It's non-trivial as a PID loop is required for each axis, but there are plenty of resources for help. And you can always turn off the feedback compensation while you're getting everything sorted out at first.

Coincidentally, I am using the 7i96S & 7i85s combo on my current build for exactly the reason you mentioned - adding linear scales (plus another SSerial port).

If the missed steps are few and the issue causing the missed steps is transient, LCNC will attempt to correct the position error. Beyond a certain point, LCNC will alarm with a following error. This value is adjustable.

LCNC cannot increase the motor power to overcome a significant overload - like when a stepper stalls. Only a drive can do that, and there aren't many stepper drives capable of briefly increasing the power sent to the motor in an overload condition (there is at least one Mfgr that does it). The drive you are considering cannot.

Most closed-loop drives do not have this feature either. However, they can manage the power sent to the motors better than an open loop drive, resulting in generally higher RPM before a stall, all else being equal (input volts, amp rating, etc.).

Open loop motors & drives coupled with linear scales will provide (possibly) less useful RPM than closed-loop drives, but they will accomplish the same safety feature (following error alarm) and likely better positioning accuracy assuming the sales are decent resolution and mounted properly.

Just be aware that LCNC will require some tuning once the scale feedback is introduced. It's non-trivial as a PID loop is required for each axis, but there are plenty of resources for help. And you can always turn off the feedback compensation while you're getting everything sorted out at first.

Coincidentally, I am using the 7i96S & 7i85s combo on my current build for exactly the reason you mentioned - adding linear scales (plus another SSerial port).

Please Log in or Create an account to join the conversation.

- MachNegativeOne

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 1

01 Nov 2023 13:32 #284254

by MachNegativeOne

Replied by MachNegativeOne on topic RF45 Conversion - stepper drivers and power supply

That is great - thanks for the detailed response!

BTW are you (or did you) have to flash new firmware onto the 7i96S or 7i85s to support glass encoders and closed loop feedback?

thanks again.

BTW are you (or did you) have to flash new firmware onto the 7i96S or 7i85s to support glass encoders and closed loop feedback?

thanks again.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

01 Nov 2023 19:10 #284279

by spumco

Replied by spumco on topic RF45 Conversion - stepper drivers and power supply

Mesa tidbit: only FPGA cards get flashed, not daughterboards.

Yes, I had to flash the 7i96S to tell it a 7i85S was attached; I used JT's Mesact program to create my base config and that has a flashing function built-in.

The file can be downloaded from Mesa's site; navigate to the product page, then the "Specifications" tab. Click on Download Support Software and you'll get a zip file. Buried inside that is a folder with a bunch of files - each of which is for a different configuration.

Sserial boards do not require a flash as (I think) they are self-identifying. Plug them in and all your new pins just show up.

Yes, I had to flash the 7i96S to tell it a 7i85S was attached; I used JT's Mesact program to create my base config and that has a flashing function built-in.

The file can be downloaded from Mesa's site; navigate to the product page, then the "Specifications" tab. Click on Download Support Software and you'll get a zip file. Buried inside that is a folder with a bunch of files - each of which is for a different configuration.

Sserial boards do not require a flash as (I think) they are self-identifying. Plug them in and all your new pins just show up.

Please Log in or Create an account to join the conversation.

- MachNegativeOne

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 1

01 Nov 2023 19:31 #284280

by MachNegativeOne

Replied by MachNegativeOne on topic RF45 Conversion - stepper drivers and power supply

Great - thanks for the help.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11722

- Thank you received: 3968

02 Nov 2023 10:10 #284311

by rodw

But this boost feature alone is likely sufficient to avoid lost steps. In my experience, steppers only loose steps when they get hot and they only get hot if they are asked to do too much. This is usually due to misconfiguration. To much current, accelleration too high, velocity too high.

Replied by rodw on topic RF45 Conversion - stepper drivers and power supply

Its possible that the Lam Technologies drivers that have a boost function could achieve the increase in power. I've used them with a custom component that detects if the drive is at constant velocity. When this occurs, the drives reduce their power to a level you define (maybe 30-50%). This allows the motor to cool. In theory, the following error should trigger a change in velocity which would trigger a boost event.LCNC cannot increase the motor power to overcome a significant overload - like when a stepper stalls. Only a drive can do that, and there aren't many stepper drives capable of briefly increasing the power sent to the motor in an overload condition (there is at least one Mfgr that does it). The drive you are considering cannot.

But this boost feature alone is likely sufficient to avoid lost steps. In my experience, steppers only loose steps when they get hot and they only get hot if they are asked to do too much. This is usually due to misconfiguration. To much current, accelleration too high, velocity too high.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

- Hardware & Machines

- CNC Machines

- Milling Machines

- RF45 Conversion - stepper drivers and power supply

Time to create page: 0.135 seconds