ECMO VMC100 Retrofit with Carousel/Toolchanger

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

26 Jul 2025 12:06 - 26 Jul 2025 12:07 #332363

by hitchhiker

ECMO VMC100 Retrofit with Carousel/Toolchanger was created by hitchhiker

Hi guys!

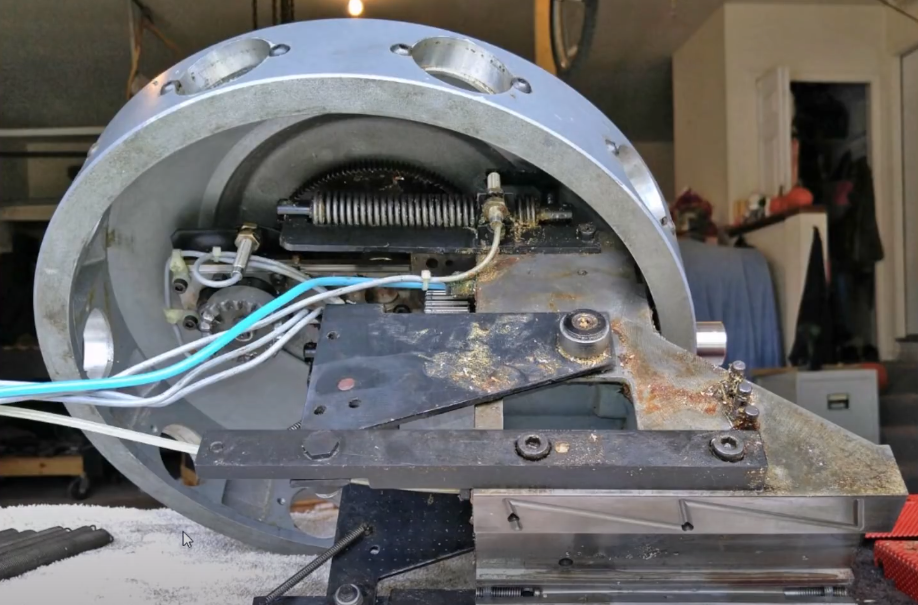

I get a VMC-100 as gift from a school.

I owm a F1P which i retrofit to LINUXCNC years ago. works perfect.

Same Machine as the VMC-100 but with manual Toolchange.

Now the VMC-100 has a carousel as Toolchanger.

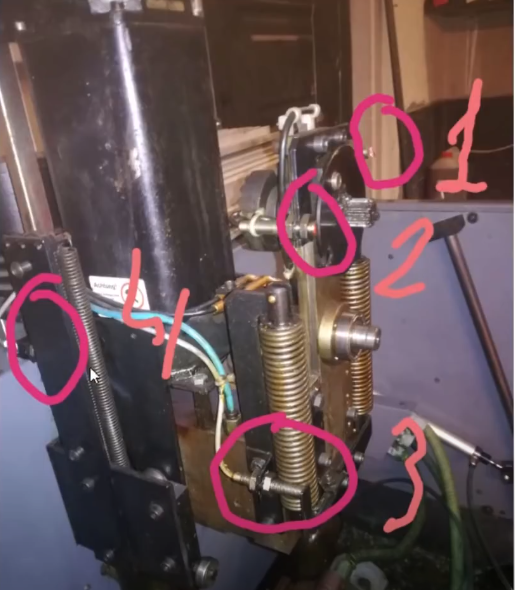

This carousel have 4 proximity switch to operate the Toolchanger.

Sensor1 is a sensor to reference tool 1.

Sensor2 counts a hole in a parallel gear. is it counts 2 times the next toolslot is reached.

Sensor3 tells that the tool is engaged.

Sensor4 tells that the tool is disengaged and the mainspindle can rotate the carousel.

Main issue for me is that the carousel works above the Z reference sensor.

At Z reference positon the Carousel begins to disengage the tool and when sensor 4 is reached the carousel can rotate.

Does someone ever retrofit this in Linuxcnc and can share his experience?

I searched a bit arround but found only some videos with MACH3 and some dead threads.

I will use the orignial maindrive which has a encoder on it at the beginning.

the maindrive works with step/dir signals.

On my f1p was the same maindrive which i use to tap threads.. spindle orient is used for this but iswitch to a 1kw servo.

this time i will use everything orignial because i have 3 orignial stepperdrivers for the 5 phase steppers. later i would change to nema23 2 phase.

Main focus is to bring everything back to live without changing to different steppermotors or maindrive.

The maindrive is working and the encoder counts.

Steppers working.

all proximity sensors are working.

thanks for any help

the pictures are taken from youtube

I get a VMC-100 as gift from a school.

I owm a F1P which i retrofit to LINUXCNC years ago. works perfect.

Same Machine as the VMC-100 but with manual Toolchange.

Now the VMC-100 has a carousel as Toolchanger.

This carousel have 4 proximity switch to operate the Toolchanger.

Sensor1 is a sensor to reference tool 1.

Sensor2 counts a hole in a parallel gear. is it counts 2 times the next toolslot is reached.

Sensor3 tells that the tool is engaged.

Sensor4 tells that the tool is disengaged and the mainspindle can rotate the carousel.

Main issue for me is that the carousel works above the Z reference sensor.

At Z reference positon the Carousel begins to disengage the tool and when sensor 4 is reached the carousel can rotate.

Does someone ever retrofit this in Linuxcnc and can share his experience?

I searched a bit arround but found only some videos with MACH3 and some dead threads.

I will use the orignial maindrive which has a encoder on it at the beginning.

the maindrive works with step/dir signals.

On my f1p was the same maindrive which i use to tap threads.. spindle orient is used for this but iswitch to a 1kw servo.

this time i will use everything orignial because i have 3 orignial stepperdrivers for the 5 phase steppers. later i would change to nema23 2 phase.

Main focus is to bring everything back to live without changing to different steppermotors or maindrive.

The maindrive is working and the encoder counts.

Steppers working.

all proximity sensors are working.

thanks for any help

the pictures are taken from youtube

Attachments:

Last edit: 26 Jul 2025 12:07 by hitchhiker.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

27 Jul 2025 15:57 #332417

by andypugh

Replied by andypugh on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

You can temporarily move the Z max limit using the inihal pins in a toolchange macro.

linuxcnc.org/docs/html/man/man1/milltask.1.html

The "carousel" HAL component can probably be used to control the tool carousel, in conjunction with a G-code subroutine to move the axes and check the sensors.

The sample config sim/axis/vismach/vmc_toolchange should be a good starting point.

linuxcnc.org/docs/html/man/man1/milltask.1.html

The "carousel" HAL component can probably be used to control the tool carousel, in conjunction with a G-code subroutine to move the axes and check the sensors.

The sample config sim/axis/vismach/vmc_toolchange should be a good starting point.

Please Log in or Create an account to join the conversation.

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

27 Jul 2025 16:25 #332424

by hitchhiker

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

issue is the toolchanger is turned by the spindle..  with spindle orient it works but its crap..

with spindle orient it works but its crap..

need spindle in velocity as spindle and in position mode for referencing the toolchanger and make toolchange...

need spindle in velocity as spindle and in position mode for referencing the toolchanger and make toolchange...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

27 Jul 2025 16:29 #332426

by andypugh

Replied by andypugh on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

Are you using the "orient" component? I _think_ that should allow you to set it to orient angles > 360 degrees.

Please Log in or Create an account to join the conversation.

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

27 Jul 2025 17:02 - 10 Sep 2025 20:07 #332431

by hitchhiker

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

Emco use encoder from spindle for ramp up and down speed between toolslots and calculate the way in theorie.. then the other sensors looking for the real position

Last edit: 10 Sep 2025 20:07 by hitchhiker.

Please Log in or Create an account to join the conversation.

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

27 Jul 2025 17:14 - 10 Sep 2025 20:05 #332435

by hitchhiker

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

Failures in spindle hal

Last edit: 10 Sep 2025 20:05 by hitchhiker. Reason: Dont want people bring to bad hals

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4607

27 Jul 2025 17:24 #332436

by andypugh

You couls consider using the carousel component and leave the spindle in velocity mode. Simoly use the spindle as a carousel motor and turn it on to change tools and off when the right tool is in position. (Use the slot sensor as the the strobe signal that "carousel" supports)

Replied by andypugh on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

This isn't the answer, nor even necessarily part of the answer, but M19 R720 P1 should work.m19 r360 p1

m5

m19 r360 p1

m5

You couls consider using the carousel component and leave the spindle in velocity mode. Simoly use the spindle as a carousel motor and turn it on to change tools and off when the right tool is in position. (Use the slot sensor as the the strobe signal that "carousel" supports)

Please Log in or Create an account to join the conversation.

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

27 Jul 2025 17:36 #332438

by hitchhiker

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

m19 r720 p1 doenst work. its limited value 0-360 this was the first i try.. i had another idea...

using 2 relays.. switching between 2 step/dir signals from the mesa.

when toolchange is called..

m5

g4 (some value)

switch the relay to get position mode from a stepgen

make the toolchange

toolhange done.. switch the relay back to the stepgen for velocity mode

this is the hardware solution... needs 3 extra pins... 1 for relays 2 for extra step/dir

but is this not possible without relays and inside the hal? thanks

using 2 relays.. switching between 2 step/dir signals from the mesa.

when toolchange is called..

m5

g4 (some value)

switch the relay to get position mode from a stepgen

make the toolchange

toolhange done.. switch the relay back to the stepgen for velocity mode

this is the hardware solution... needs 3 extra pins... 1 for relays 2 for extra step/dir

but is this not possible without relays and inside the hal? thanks

Please Log in or Create an account to join the conversation.

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

27 Jul 2025 19:03 - 27 Jul 2025 19:05 #332440

by hitchhiker

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

could you show me a exmple? i dont understand how i can connect the carousel.comp with the spindle... i go in basement and checked again. m19r720p1 doesnt work...

i understand that this compnent is very useful but i dont understand how i can link it up with the spindle to turn the carousel.

i understand that this compnent is very useful but i dont understand how i can link it up with the spindle to turn the carousel.

Last edit: 27 Jul 2025 19:05 by hitchhiker.

Please Log in or Create an account to join the conversation.

- hitchhiker

- Offline

- Elite Member

-

Less

More

- Posts: 210

- Thank you received: 17

27 Jul 2025 21:50 - 10 Sep 2025 20:08 #332447

by hitchhiker

Replied by hitchhiker on topic ECMO VMC100 Retrofit with Carousel/Toolchanger

With carousel it should be possible but its a hard way

Last edit: 10 Sep 2025 20:08 by hitchhiker.

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.139 seconds