Electrical Contactors/Relay Help?

- Looby

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 2

15 Feb 2026 00:03 - 15 Feb 2026 00:12 #342966

by Looby

Electrical Contactors/Relay Help? was created by Looby

Good Evening All,

I am building an electronics enclosure for my CNC router project and need some education on relays/contactors. I have a couple salvaged components from an industrial bandsaw that I am integrating such as safety relays, e-stops, buttons, terminal blocks, and maybe contactors… I preface all the below with I don’t know much about how electrical components work so PLEASE point out even something basic that I might have gotten wrong because I honestly do not know.

The very basic question of this is how do you size relays/contactors for inductive loads such as Makita RT0701C and 48vdc power supplies to run the steppers? I will be running two separate circuits but if I hit the e-stop I want to cut power to these components while leaving other things like PC, Mesa card, fans, and the e-stop system itself powered.

* Circuit 1 - Makita – 6.5 amp 120vac in

* Circuit 2 - 2x 48vdc PSUs 5amp 120vac in (6amp 3sec surge)

My research says you have to go 5-10x the load when sizing relays/contactors but does that mean I would need a 120amp contactor for my steppers that are a 10 amp regular load?! the 10x number was more related to solid state relays but this just seems nuts.

I found a McMaster-Carr table that shows a 1.5 hp motor drawing 20amps at full load (Makita claims 1.25) and I would need up to a 200 amp contactor?! www.mcmaster.com/7603KAC/

As stated electricity and I are not the best of friends so we avoid each other as much as possible. I could be (and hope I am) missing something very basic here.

Components I have:

* Idec SJ2S-07LW 8amp icecube type relays – 24vdc coil draws 0.025 amp when closed

* Mitsubishi S-T10 Contactors – 24vdc coil draws a MASSIVE 1.3amps when closed (not sure I want or even CAN use these also WHY would this draw so much?)

* TWTADE/JQX-62F-2Z 80 amp contactor - 24vdc coil draws 0.088 amp when closed

* LCTC Solid State Relay 80amp – Its in the mail but don’t know if its any good.

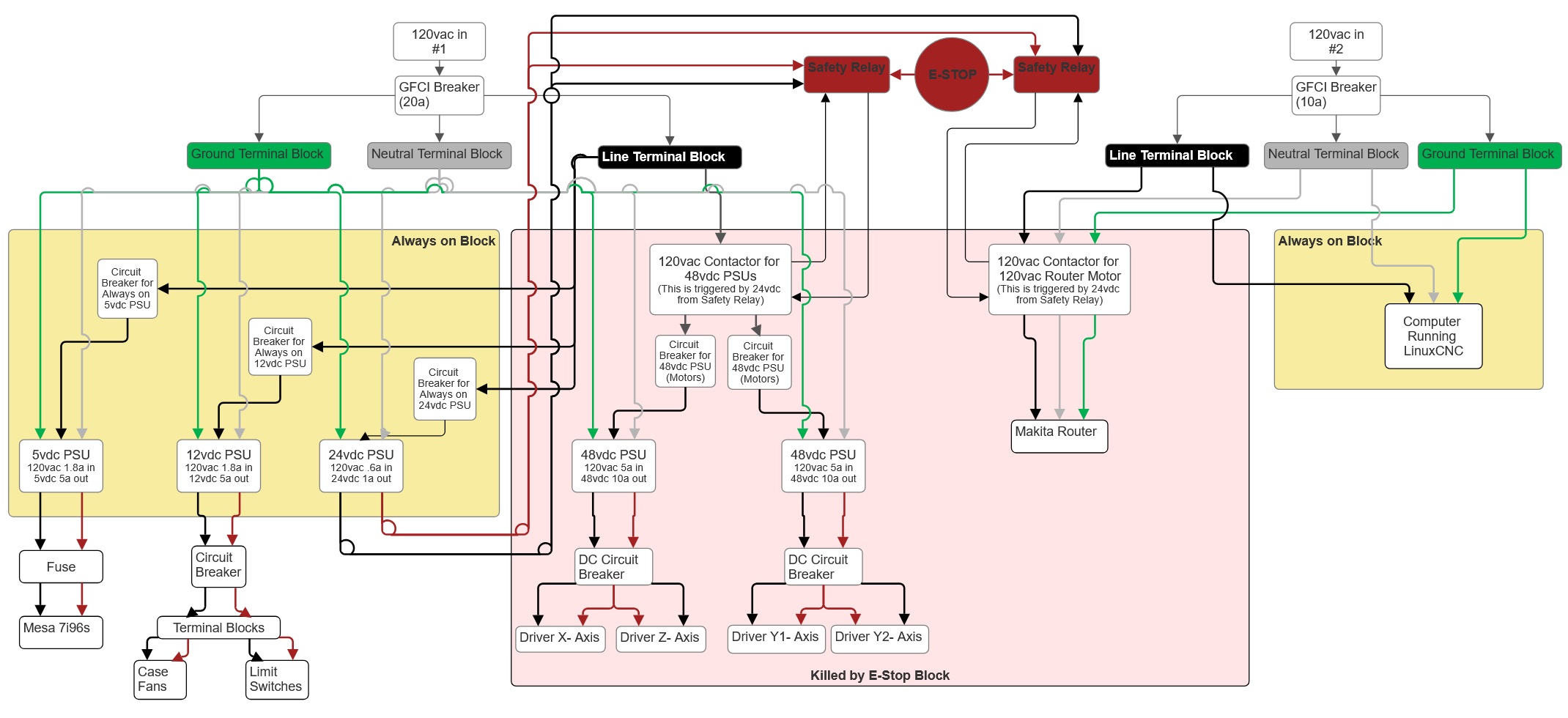

The below is the basic plan I have for wiring power. If anything in this looks wonky let me know as well please

I am building an electronics enclosure for my CNC router project and need some education on relays/contactors. I have a couple salvaged components from an industrial bandsaw that I am integrating such as safety relays, e-stops, buttons, terminal blocks, and maybe contactors… I preface all the below with I don’t know much about how electrical components work so PLEASE point out even something basic that I might have gotten wrong because I honestly do not know.

The very basic question of this is how do you size relays/contactors for inductive loads such as Makita RT0701C and 48vdc power supplies to run the steppers? I will be running two separate circuits but if I hit the e-stop I want to cut power to these components while leaving other things like PC, Mesa card, fans, and the e-stop system itself powered.

* Circuit 1 - Makita – 6.5 amp 120vac in

* Circuit 2 - 2x 48vdc PSUs 5amp 120vac in (6amp 3sec surge)

My research says you have to go 5-10x the load when sizing relays/contactors but does that mean I would need a 120amp contactor for my steppers that are a 10 amp regular load?! the 10x number was more related to solid state relays but this just seems nuts.

I found a McMaster-Carr table that shows a 1.5 hp motor drawing 20amps at full load (Makita claims 1.25) and I would need up to a 200 amp contactor?! www.mcmaster.com/7603KAC/

As stated electricity and I are not the best of friends so we avoid each other as much as possible. I could be (and hope I am) missing something very basic here.

Components I have:

* Idec SJ2S-07LW 8amp icecube type relays – 24vdc coil draws 0.025 amp when closed

* Mitsubishi S-T10 Contactors – 24vdc coil draws a MASSIVE 1.3amps when closed (not sure I want or even CAN use these also WHY would this draw so much?)

* TWTADE/JQX-62F-2Z 80 amp contactor - 24vdc coil draws 0.088 amp when closed

* LCTC Solid State Relay 80amp – Its in the mail but don’t know if its any good.

The below is the basic plan I have for wiring power. If anything in this looks wonky let me know as well please

Attachments:

Last edit: 15 Feb 2026 00:12 by Looby. Reason: Pasted from word and formating all wonky

Please Log in or Create an account to join the conversation.

- NWE

-

- Offline

- Premium Member

-

Less

More

- Posts: 156

- Thank you received: 42

15 Feb 2026 01:36 #342971

by NWE

Replied by NWE on topic Electrical Contactors/Relay Help?

Most contactors list a thermal current rating and an inductive current rating, if your load is less than those current ratings you're fine.

I usually use 30A contactors for 20A loads... just oversizing a bit for good measure.

Not sure about two power sources, are both going to the same box? I try to avoid that. It can cause accidents if someone disconnects one power source and starts working on it. If two power sources to one box is unavoidable, label the cover with a warning label stating the box is powered by more than one power source.

If the two 110V power inputs shown are going to separate boxes, I think it should be fine.

I usually use 30A contactors for 20A loads... just oversizing a bit for good measure.

Not sure about two power sources, are both going to the same box? I try to avoid that. It can cause accidents if someone disconnects one power source and starts working on it. If two power sources to one box is unavoidable, label the cover with a warning label stating the box is powered by more than one power source.

If the two 110V power inputs shown are going to separate boxes, I think it should be fine.

Please Log in or Create an account to join the conversation.

- Looby

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 2

15 Feb 2026 01:54 #342973

by Looby

Replied by Looby on topic Electrical Contactors/Relay Help?

The two 120v ins is more just because I think I will overload a single 120v outlet so trying to split the loads to different circuits. It SHOULDNT but really dont want to wire this whole thing and THEN find out. This is unfortunately a "mobile" setup that I have to load up and take to and from work as I cannot run a router like this in my apartment so I am also making some allowances for portability in this setup so both plugs will be detachable from the unit to ensure power safe if needing to work inside the box. All of this is going in a rolling road case... Yes I know sketchy sketchy sketchy but.... nah no buts I know its sketchy.

I know that some contactors are mechanical so going higher amps increases service life and solid state contactors are heat limited but why would companies state that such a high overage is needed?

I know that some contactors are mechanical so going higher amps increases service life and solid state contactors are heat limited but why would companies state that such a high overage is needed?

The following user(s) said Thank You: NWE

Please Log in or Create an account to join the conversation.

- NWE

-

- Offline

- Premium Member

-

Less

More

- Posts: 156

- Thank you received: 42

15 Feb 2026 04:07 #342979

by NWE

Replied by NWE on topic Electrical Contactors/Relay Help?

Frankly, I'm a bit puzzled where that 5-10x safety factor recommendation comes from. A quick google search shows me 1.25x and 1.5x safety factor recommendations. I tend to go for a 1.5x safety factor, in more extreme duty conditions I've done 2x or 3x. A big contactor killer is frequent start/stops. I can imagine 10x might be used in some special applications.I know that some contactors are mechanical so going higher amps increases service life and solid state contactors are heat limited but why would companies state that such a high overage is needed?

Please Log in or Create an account to join the conversation.

- Looby

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 2

15 Feb 2026 13:00 #342999

by Looby

Replied by Looby on topic Electrical Contactors/Relay Help?

I feel like Im taking crazy pills... I swear Ive read that 2 dozen times in the past few days. I THINK whats happened is I have been making an assumption on some things that I shouldnt have. I have seen that inrush current on inductive loads can be 5-10x the constant running amps and assumed that I needed to have a contactor that was rated for THAT amount. WOW I feel like a huge mental burden has been lifted as I have been stressing over this for a week. Ive bought all the stuff for this CNC project and then hit this and was worried my plan wasnt possible and I had wasted a bunch of time and money.

About a quarter the way down this states

"As a result, the motor attempts to draw the locked-rotor current (LRA), which is typically 6 to 8 times greater than the full-load current. If this high inrush current is not quickly reduced, the motor windings will overheat and may eventually burn out."

www.electricaltechnology.org/2025/06/siz...ctor-controller.html

Under the AC3

"The most common category, AC3, governs contactors for squirrel-cage induction motors, which constitute 70% of industrial motor applications812. These motors exhibit high inrush currents (5–7× rated current) during startup but stabilize during running."

viox.com/electrical-standards-for-contac...lization-categories/

The below are just amazon listings and are specific to solid state relays

At the bottom of the page under the wiring diagram this relay states

"How to choose correctly:

STEP 1: Choose a correct type Current of Equipment/Ratio = Current of SSR PS: The Ratio depend on the kind of your loading equipment. Resistive load :70%, Inductive load:20%,Capacitive load:10%."

www.amazon.com/CGELE-SSR-80DD-3-32VDC-5-...astic/dp/B09HRX922Z/

This one states the

"Step 2: Choose the Correct Current

For resistive loads:SSR current = 2 x operating current of the load (heating equipment, etc.)

For inductive loads:SSR current = 6 x operating current of the load (motor, etc.)

For capacitive loads:SSR current = 10 X the operating current of the load (capacitance, etc.)"

www.amazon.com/LCLCTC-Solid-Output-24-48...iator/dp/B0BVFP7YB2/

About a quarter the way down this states

"As a result, the motor attempts to draw the locked-rotor current (LRA), which is typically 6 to 8 times greater than the full-load current. If this high inrush current is not quickly reduced, the motor windings will overheat and may eventually burn out."

www.electricaltechnology.org/2025/06/siz...ctor-controller.html

Under the AC3

"The most common category, AC3, governs contactors for squirrel-cage induction motors, which constitute 70% of industrial motor applications812. These motors exhibit high inrush currents (5–7× rated current) during startup but stabilize during running."

viox.com/electrical-standards-for-contac...lization-categories/

The below are just amazon listings and are specific to solid state relays

At the bottom of the page under the wiring diagram this relay states

"How to choose correctly:

STEP 1: Choose a correct type Current of Equipment/Ratio = Current of SSR PS: The Ratio depend on the kind of your loading equipment. Resistive load :70%, Inductive load:20%,Capacitive load:10%."

www.amazon.com/CGELE-SSR-80DD-3-32VDC-5-...astic/dp/B09HRX922Z/

This one states the

"Step 2: Choose the Correct Current

For resistive loads:SSR current = 2 x operating current of the load (heating equipment, etc.)

For inductive loads:SSR current = 6 x operating current of the load (motor, etc.)

For capacitive loads:SSR current = 10 X the operating current of the load (capacitance, etc.)"

www.amazon.com/LCLCTC-Solid-Output-24-48...iator/dp/B0BVFP7YB2/

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.179 seconds