- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- X Axis is drifting and wondered if my settings are to blame?

×

Forum Header

X Axis is drifting and wondered if my settings are to blame?

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

03 Dec 2018 09:52 #121744

by uptown47

X Axis is drifting and wondered if my settings are to blame? was created by uptown47

Hi all,

I've been building a CNC machine as a hobby and learning as I go.

I've got to the stage of actually cutting something and it all seems to work fine (ish) apart from my X axis seems to be drifting out of position.

I tried to carve out some lettering and it seemed to start fine but then, as the cut went on, it was returning to the first letters and chopping through them so obviously wasn't returning to the correct place. It was also drifting off the end of the wooden "blank" that I was cutting on.

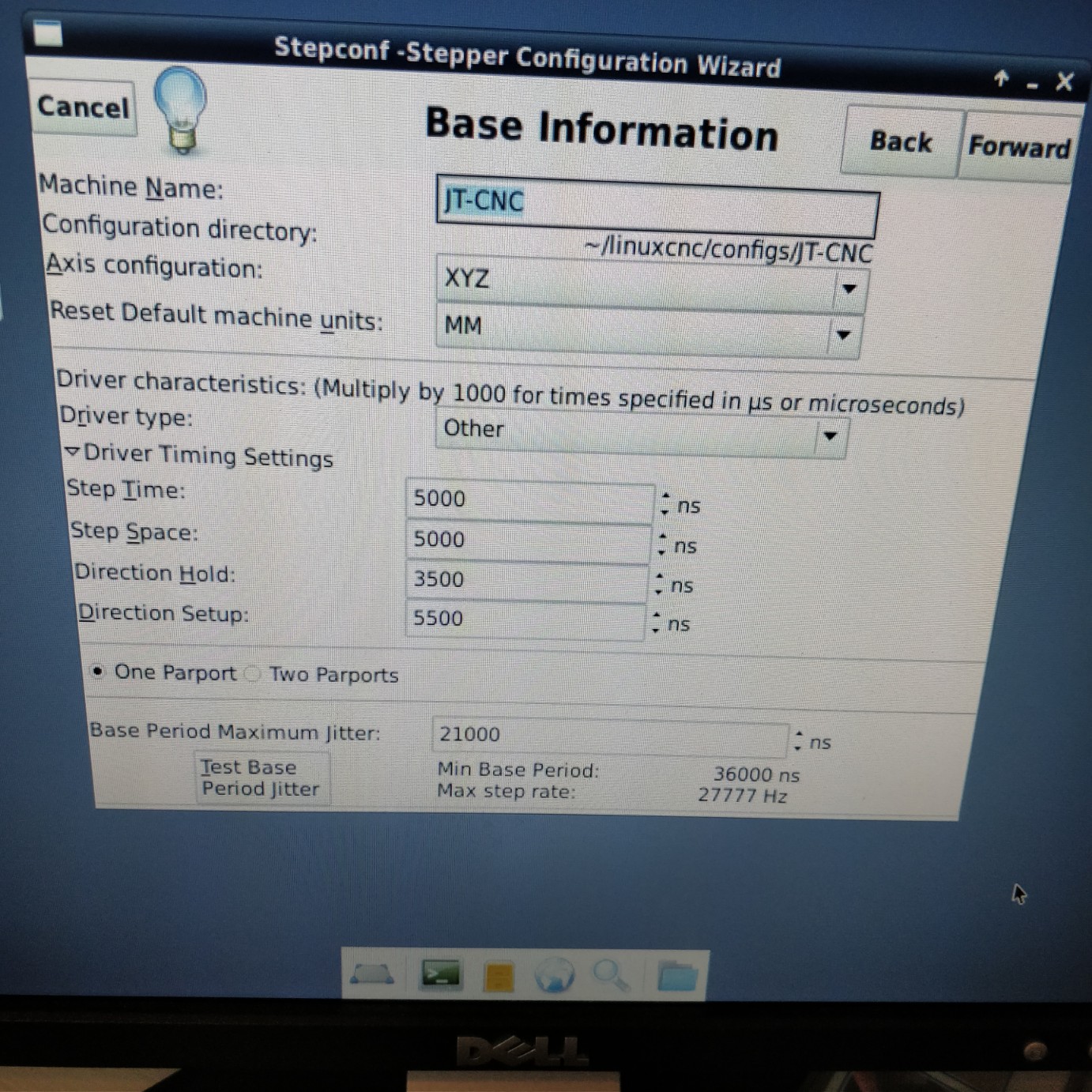

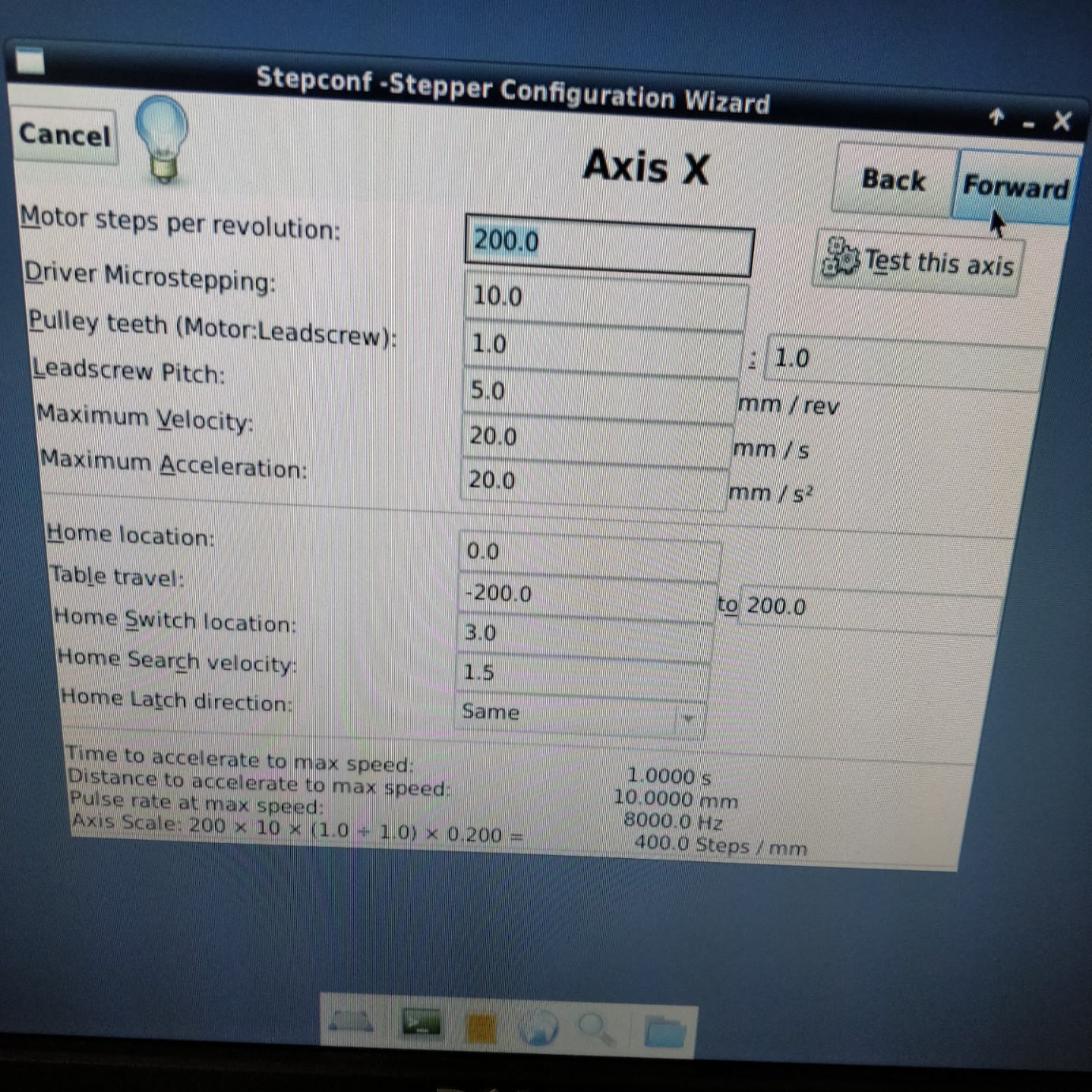

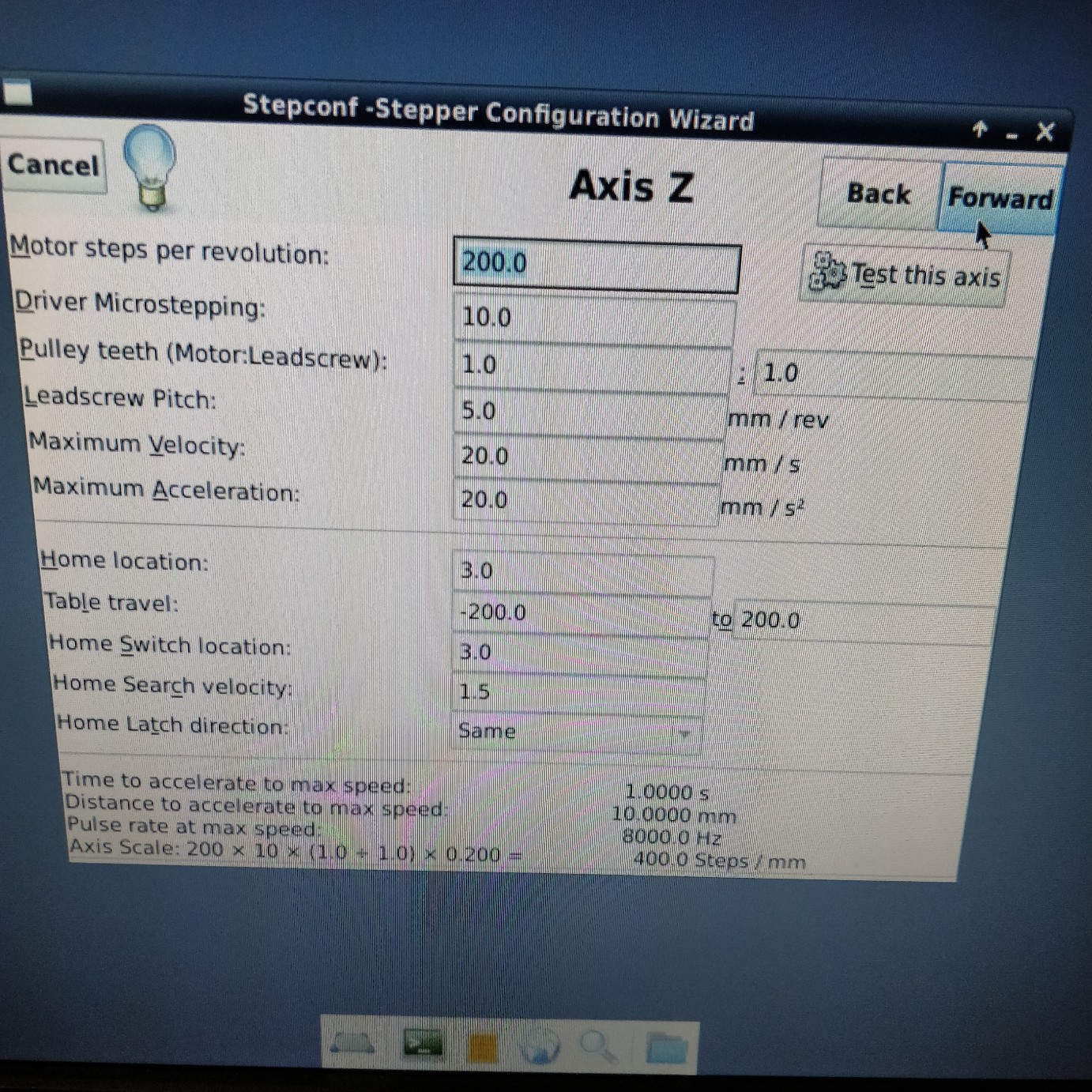

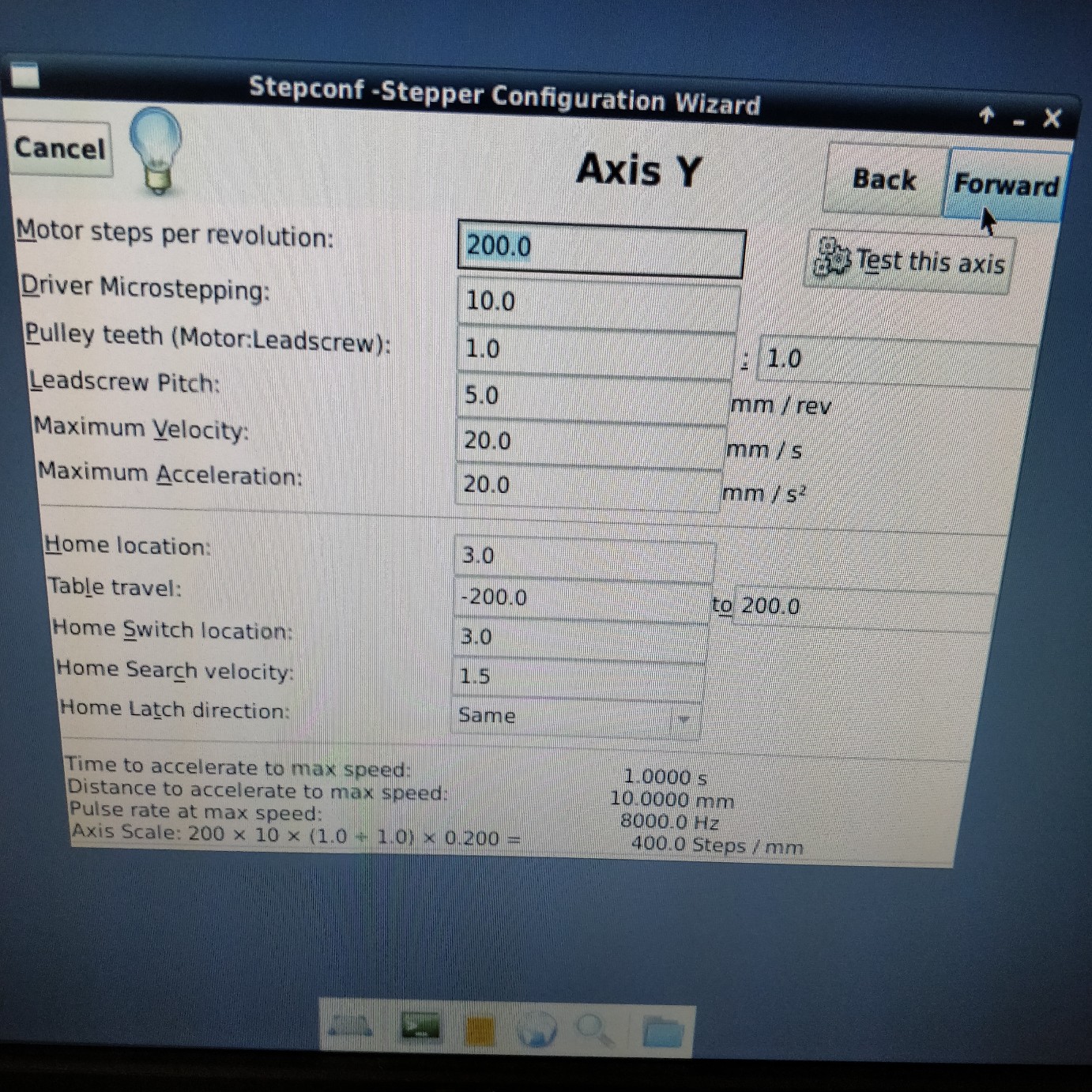

I tried reducing my Maximum Velocity and Maximum Acceleration down to 20.0 but I'm not sure if that's still too fast or normal??

I'm also not sure if Step Time / Step Space need adjusting?

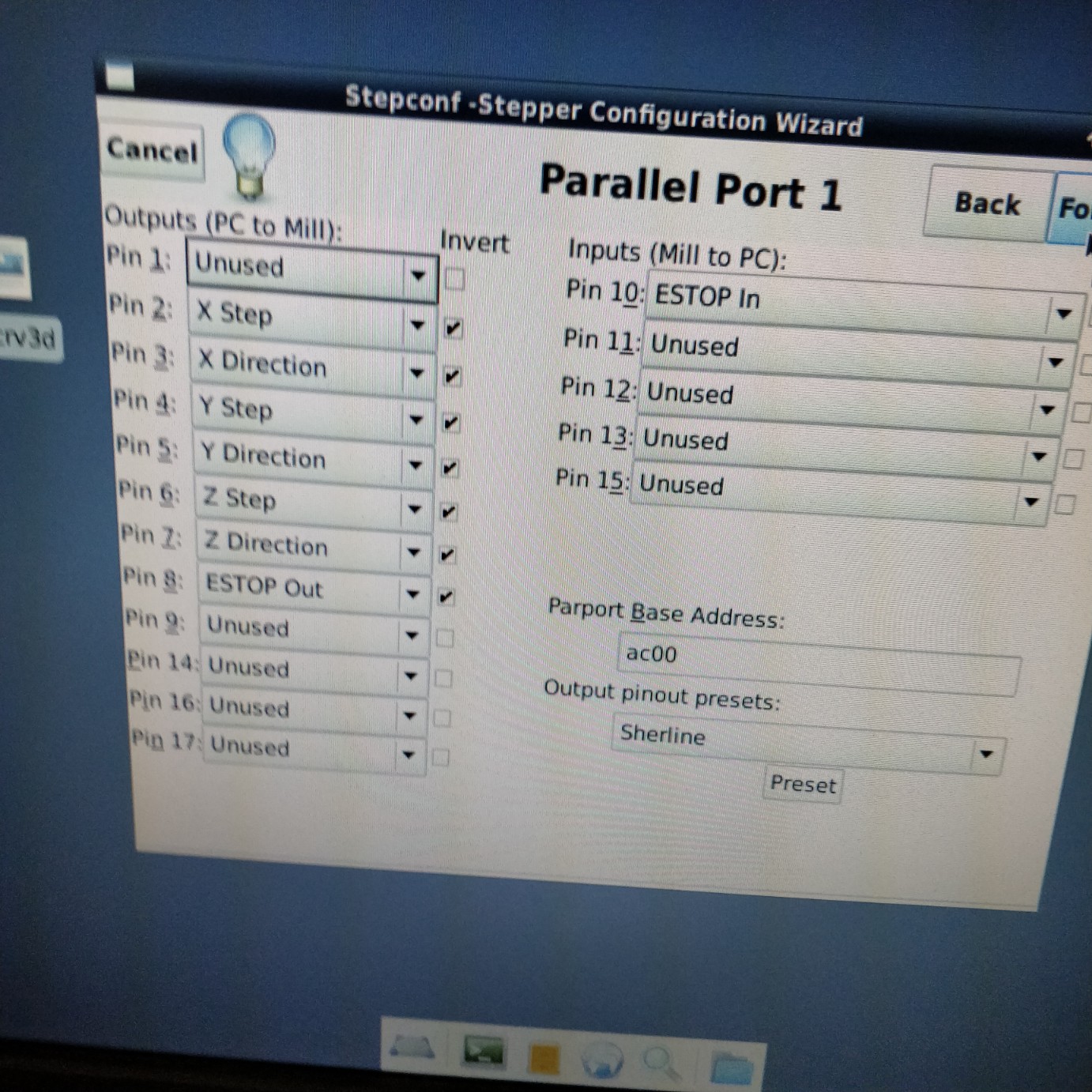

The drivers I'm using are DQ860MA

www.wantmotor.com/product/dq860ma.html

The motors are Stepper Motor 8.7Nm Nema34

www.cnc4you.co.uk/Stepper-Motor-8.7Nm-86HS115-4208-Nema34

If someone has a similar setup and could let me know their settings it would be appreciated?

Or if you have an idea on what sort of values should be going into Max Velocity and Acceleration and also Step Time etc it would be great. Or even info on how you work out these settings?

Thanks for any help you can give me.

John

I've been building a CNC machine as a hobby and learning as I go.

I've got to the stage of actually cutting something and it all seems to work fine (ish) apart from my X axis seems to be drifting out of position.

I tried to carve out some lettering and it seemed to start fine but then, as the cut went on, it was returning to the first letters and chopping through them so obviously wasn't returning to the correct place. It was also drifting off the end of the wooden "blank" that I was cutting on.

I tried reducing my Maximum Velocity and Maximum Acceleration down to 20.0 but I'm not sure if that's still too fast or normal??

I'm also not sure if Step Time / Step Space need adjusting?

The drivers I'm using are DQ860MA

www.wantmotor.com/product/dq860ma.html

The motors are Stepper Motor 8.7Nm Nema34

www.cnc4you.co.uk/Stepper-Motor-8.7Nm-86HS115-4208-Nema34

If someone has a similar setup and could let me know their settings it would be appreciated?

Or if you have an idea on what sort of values should be going into Max Velocity and Acceleration and also Step Time etc it would be great. Or even info on how you work out these settings?

Thanks for any help you can give me.

John

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19802

- Thank you received: 4609

03 Dec 2018 13:46 #121745

by andypugh

Replied by andypugh on topic X Axis is drifting and wondered if my settings are to blame?

Normally I would suspect excessive acceleration, but If anything I would say that your acceleration seems rather low.

Your step length should be long enough too.

Having said all these things, try reducing velocity and acceleration by a factor of 2 and double the step length, then do a quick test to see if things are better.

Also set the direction setup / hold to 10,000 (and leave them there). The motors only ever reverse at very low speed so there is no harm in making sure.

What supply voltage are you using for the stepper drives?

This problem is often mechanical. Mark the couplings and pulleys with marker pen to make sure nothing is slipping on the shaft.

Can you monitor the stepper supply voltage during running? Is there any possiblity that the PSU is too small?

Your step length should be long enough too.

Having said all these things, try reducing velocity and acceleration by a factor of 2 and double the step length, then do a quick test to see if things are better.

Also set the direction setup / hold to 10,000 (and leave them there). The motors only ever reverse at very low speed so there is no harm in making sure.

What supply voltage are you using for the stepper drives?

This problem is often mechanical. Mark the couplings and pulleys with marker pen to make sure nothing is slipping on the shaft.

Can you monitor the stepper supply voltage during running? Is there any possiblity that the PSU is too small?

The following user(s) said Thank You: uptown47

Please Log in or Create an account to join the conversation.

- uptown47

- Offline

- Senior Member

-

Less

More

- Posts: 48

- Thank you received: 1

03 Dec 2018 18:40 #121759

by uptown47

Replied by uptown47 on topic X Axis is drifting and wondered if my settings are to blame?

Thanks for the great advice Andy.

I ran another test just now and it's worked fine.

I think I *may* have got to the bottom of it. I put the Step Time / Direction Hold et al to 5,000.

I then ran the machine without switching on my vacuum cleaner.

Eventually I'm fitting a dust shoe and a dust extractor but, for now, I've just been periodically turning on the vacuum and hoovering the dust away. What I noticed was that the light above the table would briefly flicker occasionally when I turned the vacuum on.

I'm now operating on the assumption that my switching the vacuum on is causing noise and maybe making the system lose a few steps here and there? These are accumulating into a large error.

I need to do more testing to be sure but I'm hoping that's all it is. I carved something tonight (just some letters) but the dimensions of them and the sharpness of them looks really good I think.

Keeping my fingers firmly crossed!!

Cheers

John

I ran another test just now and it's worked fine.

I think I *may* have got to the bottom of it. I put the Step Time / Direction Hold et al to 5,000.

I then ran the machine without switching on my vacuum cleaner.

Eventually I'm fitting a dust shoe and a dust extractor but, for now, I've just been periodically turning on the vacuum and hoovering the dust away. What I noticed was that the light above the table would briefly flicker occasionally when I turned the vacuum on.

I'm now operating on the assumption that my switching the vacuum on is causing noise and maybe making the system lose a few steps here and there? These are accumulating into a large error.

I need to do more testing to be sure but I'm hoping that's all it is. I carved something tonight (just some letters) but the dimensions of them and the sharpness of them looks really good I think.

Keeping my fingers firmly crossed!!

Cheers

John

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- X Axis is drifting and wondered if my settings are to blame?

Time to create page: 0.300 seconds