- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

×

Forum Header

Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

- Armin

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 2

12 Nov 2019 14:26 - 12 Nov 2019 14:36 #150202

by Armin

Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again was created by Armin

When I was constructing my first CNC mill with LinuxCNC, the main annoyances for a noob like me were having to execute Stepconf again and again. Why? Because my initial values for the impellent weren't correct at first go. So for every little change I had to make I had to execute the whole Stepconf procedure again. This provokes of course new errors, even for the values that were right before . . .

After finishing the Stepconf Wizard, it generates various files in ~/linuxcnc/configs/My_Machine.

The Important file is the [machine name].ini.

While such values as velocity, acceleration, travel and switches configuration are easy to detect inside this file (and therefore can be edited by a simple text editor), the values for Motor/Microstepping/Pulley and Leadscrew pitch seem to be missing.

Here is the solution:

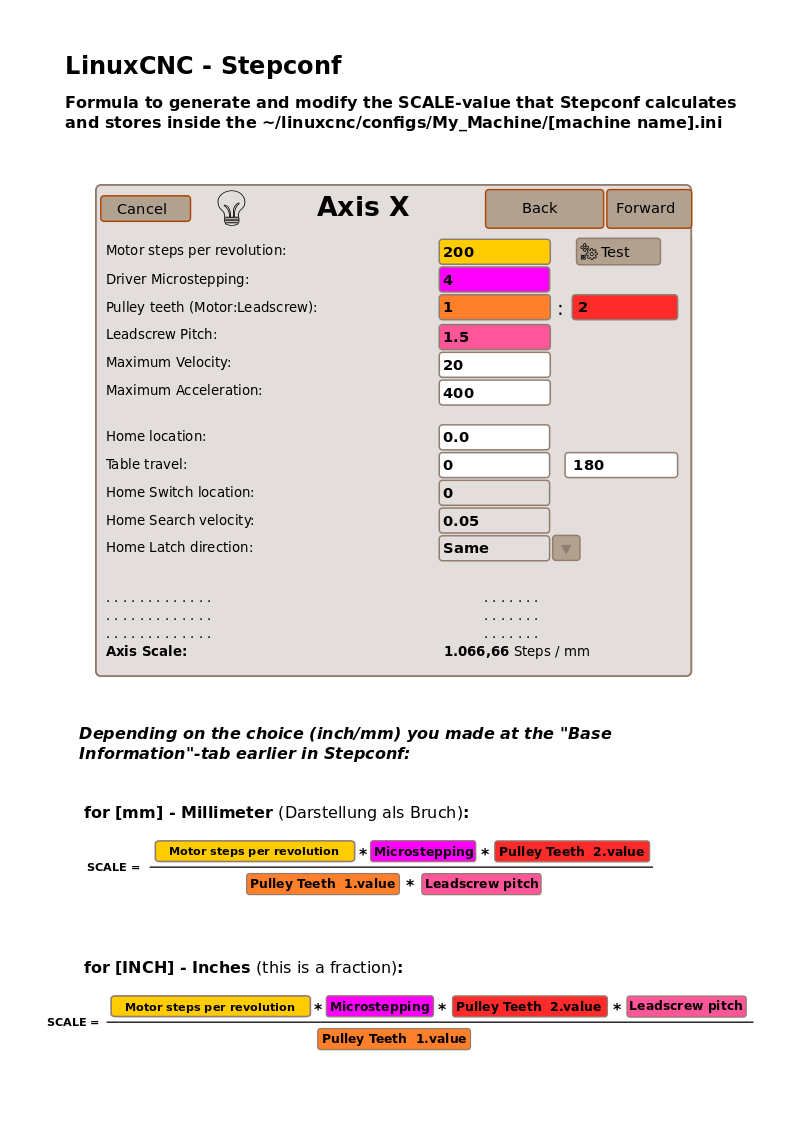

The Stepconf Wizard amalgamates the 5 values of the impellent to one SCALE-value that can be found in the ...ini.

How this is done - look at my illustration.

The two following considerations transpired for me:

1) The entry in the field „Driver Microstepping“ MUST be a square of 2 (i.e. 4, 8, 16 …) and the „Motor steps per revolution“ multiplied by „Driver Microstepping“ must add up to what you tuned your Stepper Driver Unit to. (200 Mot.St.p.rev. * 8 Microst. = 1600 Microsteps at your Driver).

2) If your mill runs too short (e.g. you command 10mm and the carriage only moves 5mm), the value of your SCALE has to be INCREASED (by factor 2 in this example) (. . . and opposite). The SCALE value is linear. This means: Reducing the SCALE value by 4% means the carriage will move 4% less than before.

Hope this will help you save time and brain while fine-tuning your mill

After finishing the Stepconf Wizard, it generates various files in ~/linuxcnc/configs/My_Machine.

The Important file is the [machine name].ini.

While such values as velocity, acceleration, travel and switches configuration are easy to detect inside this file (and therefore can be edited by a simple text editor), the values for Motor/Microstepping/Pulley and Leadscrew pitch seem to be missing.

Here is the solution:

The Stepconf Wizard amalgamates the 5 values of the impellent to one SCALE-value that can be found in the ...ini.

How this is done - look at my illustration.

The two following considerations transpired for me:

1) The entry in the field „Driver Microstepping“ MUST be a square of 2 (i.e. 4, 8, 16 …) and the „Motor steps per revolution“ multiplied by „Driver Microstepping“ must add up to what you tuned your Stepper Driver Unit to. (200 Mot.St.p.rev. * 8 Microst. = 1600 Microsteps at your Driver).

2) If your mill runs too short (e.g. you command 10mm and the carriage only moves 5mm), the value of your SCALE has to be INCREASED (by factor 2 in this example) (. . . and opposite). The SCALE value is linear. This means: Reducing the SCALE value by 4% means the carriage will move 4% less than before.

Hope this will help you save time and brain while fine-tuning your mill

Attachments:

Last edit: 12 Nov 2019 14:36 by Armin. Reason: image not displayed

The following user(s) said Thank You: andypugh, tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

12 Nov 2019 14:39 #150205

by tommylight

Replied by tommylight on topic Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

Are you aware that Linuxcnc has a "calibration" menu, there you can change scale, velocity invert motion, etc, all from a running system and in real time, and of course save those values, so no need for restarting Linuxcnc, or for stepconf.

Please Log in or Create an account to join the conversation.

- Armin

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 2

12 Nov 2019 14:44 #150206

by Armin

Replied by Armin on topic Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

No, I didn't - would be helpful to know how to run this calibration menu.

I didn't find anything about this inside the Manpage manual.

I didn't find anything about this inside the Manpage manual.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21342

- Thank you received: 7283

12 Nov 2019 15:43 #150216

by tommylight

Replied by tommylight on topic Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

AXIS GUI, machine menu, near the bottom part there is calibration.

The following user(s) said Thank You: Leon82

Please Log in or Create an account to join the conversation.

- pl7i92

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1872

- Thank you received: 358

12 Nov 2019 16:22 #150223

by pl7i92

Replied by pl7i92 on topic Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

it is actually quite in the middle !

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

12 Nov 2019 17:06 #150231

by Todd Zuercher

Replied by Todd Zuercher on topic Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

It is different for different user interfaces, but for the Axis user interface you select the Machine pull down menu, then select the Calibration menu item. The tune-able items in Calibration are different with different machine configurations. For example most stepper configs will only have Scale and Max Acceleration. But a servo will have a bunch of PID tuning options as well. The Items available are pulled from your INI file, and it is possible to add custom ones. (I've done it but don't remember the exact steps.)

The following user(s) said Thank You: Clive S

Please Log in or Create an account to join the conversation.

- Configuring LinuxCNC

- Configuration Tools

- StepConf Wizard

- Put an end to Stepconf-Wizard Groundhog day - don't execute it again and again

Time to create page: 0.358 seconds