Remora - ethernet NVEM / EC300 / EC500 cnc board

- DarkPhoinix

- Offline

- Premium Member

-

Less

More

- Posts: 107

- Thank you received: 6

14 May 2025 16:15 - 14 May 2025 16:18 #328473

by DarkPhoinix

Replied by DarkPhoinix on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Attachments:

Last edit: 14 May 2025 16:18 by DarkPhoinix.

Please Log in or Create an account to join the conversation.

- Spyderbreath

-

- Offline

- Senior Member

-

Less

More

- Posts: 47

- Thank you received: 9

14 May 2025 20:56 #328488

by Spyderbreath

Replied by Spyderbreath on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

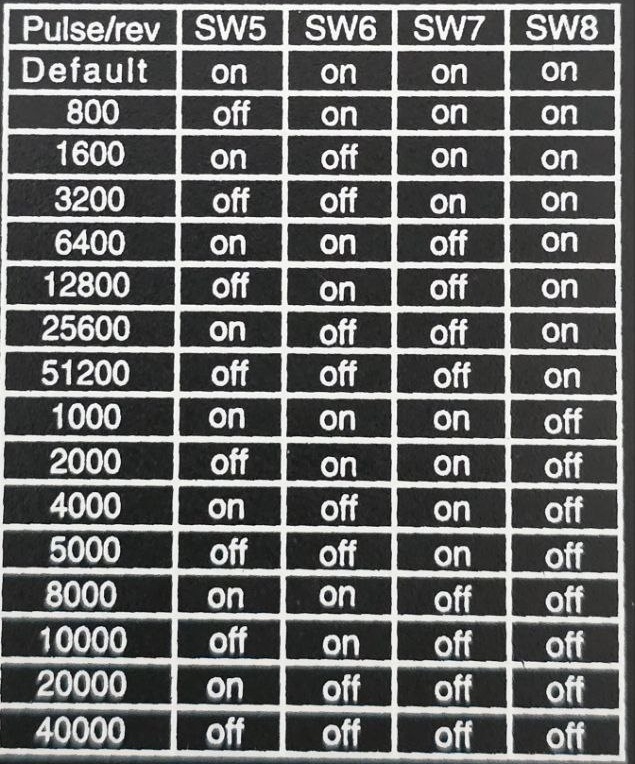

At the risk of the blind leading the blind, to me that is not quite the right question. That chart is for your micro-stepping. Like the 800 is 4 microsteps, if you're using a 1.8 deg. stepper. I have always looked at it this way - What are you doing with the motor? If your opening a door or driving a ram, picking 800 would be fine, but using that on a belt or lead screw may very well end up leaving artifacts in the work due to the rougher movement between points. The downside is the more micro-steps you have the more torque you lose. 3200 (16 micro-steps) seams to be a reasonable middle ground that most use as standard. The controller will put out as many steps as directed by LinuxCNC to make a revolution, just a matter of how fast it can do it.

Whatever you chose, that gets figured out when you tell LinuxCNC in your .ini file how many pulses it takes to move one unit. That is set with the SCALE on each axis. Like for me, I have 16 micro-steps (3200) and a 5mm pitch screw, which works out to SCALE = 640 or -640 depending which way you need the motor to move.

Whatever you chose, that gets figured out when you tell LinuxCNC in your .ini file how many pulses it takes to move one unit. That is set with the SCALE on each axis. Like for me, I have 16 micro-steps (3200) and a 5mm pitch screw, which works out to SCALE = 640 or -640 depending which way you need the motor to move.

The following user(s) said Thank You: DarkPhoinix

Please Log in or Create an account to join the conversation.

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

14 May 2025 22:09 #328493

by Murphy

Replied by Murphy on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Regarding my milling machine and setting up the EC500.

My denford mill is using 12v drivers

that need to sink the 12v to ground to move the axis.

i tried a bc537 transistor to try and switch the 12v to ground. I originally had this working with a cheap bob. But it seems the ec500 outputs are to low to drive the gate. I'm measuring 3.8v on the ec500's outputs.

I also tried a IRLZ44n mosfet but that's also the same I can't switch the gate. Both circuits had pull up and down resistors. If I connect 5v straight to the gate (330omh resistor) I can switch the gate and pulse the drive. So I'm thinking the outputs of the EC500 are just not strong enough.

The IC in the ec500 is the am26ls31. If I connect the differential outputs to a am26ls32 will that restore a 5v stronger signal?

My denford mill is using 12v drivers

that need to sink the 12v to ground to move the axis.

i tried a bc537 transistor to try and switch the 12v to ground. I originally had this working with a cheap bob. But it seems the ec500 outputs are to low to drive the gate. I'm measuring 3.8v on the ec500's outputs.

I also tried a IRLZ44n mosfet but that's also the same I can't switch the gate. Both circuits had pull up and down resistors. If I connect 5v straight to the gate (330omh resistor) I can switch the gate and pulse the drive. So I'm thinking the outputs of the EC500 are just not strong enough.

The IC in the ec500 is the am26ls31. If I connect the differential outputs to a am26ls32 will that restore a 5v stronger signal?

Please Log in or Create an account to join the conversation.

- cakeslob

- Offline

- Platinum Member

-

Less

More

- Posts: 922

- Thank you received: 275

15 May 2025 04:35 #328499

by cakeslob

Replied by cakeslob on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

hey murph, i think scott said the outputs were just optocouplers or something like that, see if you can filter through his recent posts,

pheonix, like spyder said its based on application, but start with like 800-1600 and if you get following errors its too high

pheonix, like spyder said its based on application, but start with like 800-1600 and if you get following errors its too high

The following user(s) said Thank You: Murphy

Please Log in or Create an account to join the conversation.

- DarkPhoinix

- Offline

- Premium Member

-

Less

More

- Posts: 107

- Thank you received: 6

15 May 2025 14:01 - 15 May 2025 14:04 #328511

by DarkPhoinix

I have set 12800 and testing some gcode only with Y working.

I don't want to cause problems when all the stepper and spindle are physically working.

Replied by DarkPhoinix on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Thanks for reply,

Warning: Spoiler!At the risk of the blind leading the blind, to me that is not quite the right question. That chart is for your micro-stepping. Like the 800 is 4 microsteps, if you're using a 1.8 deg. stepper. I have always looked at it this way - What are you doing with the motor? If your opening a door or driving a ram, picking 800 would be fine, but using that on a belt or lead screw may very well end up leaving artifacts in the work due to the rougher movement between points. The downside is the more micro-steps you have the more torque you lose. 3200 (16 micro-steps) seams to be a reasonable middle ground that most use as standard. The controller will put out as many steps as directed by LinuxCNC to make a revolution, just a matter of how fast it can do it. Whatever you chose, that gets figured out when you tell LinuxCNC in your .ini file how many pulses it takes to move one unit. That is set with the SCALE on each axis. Like for me, I have 16 micro-steps (3200) and a 5mm pitch screw, which works out to SCALE = 640 or -640 depending which way you need the motor to move.

I have set 12800 and testing some gcode only with Y working.

I don't want to cause problems when all the stepper and spindle are physically working.

Last edit: 15 May 2025 14:04 by DarkPhoinix.

Please Log in or Create an account to join the conversation.

- Thayloreing

- Offline

- Premium Member

-

Less

More

- Posts: 94

- Thank you received: 3

18 May 2025 02:09 #328662

by Thayloreing

Replied by Thayloreing on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

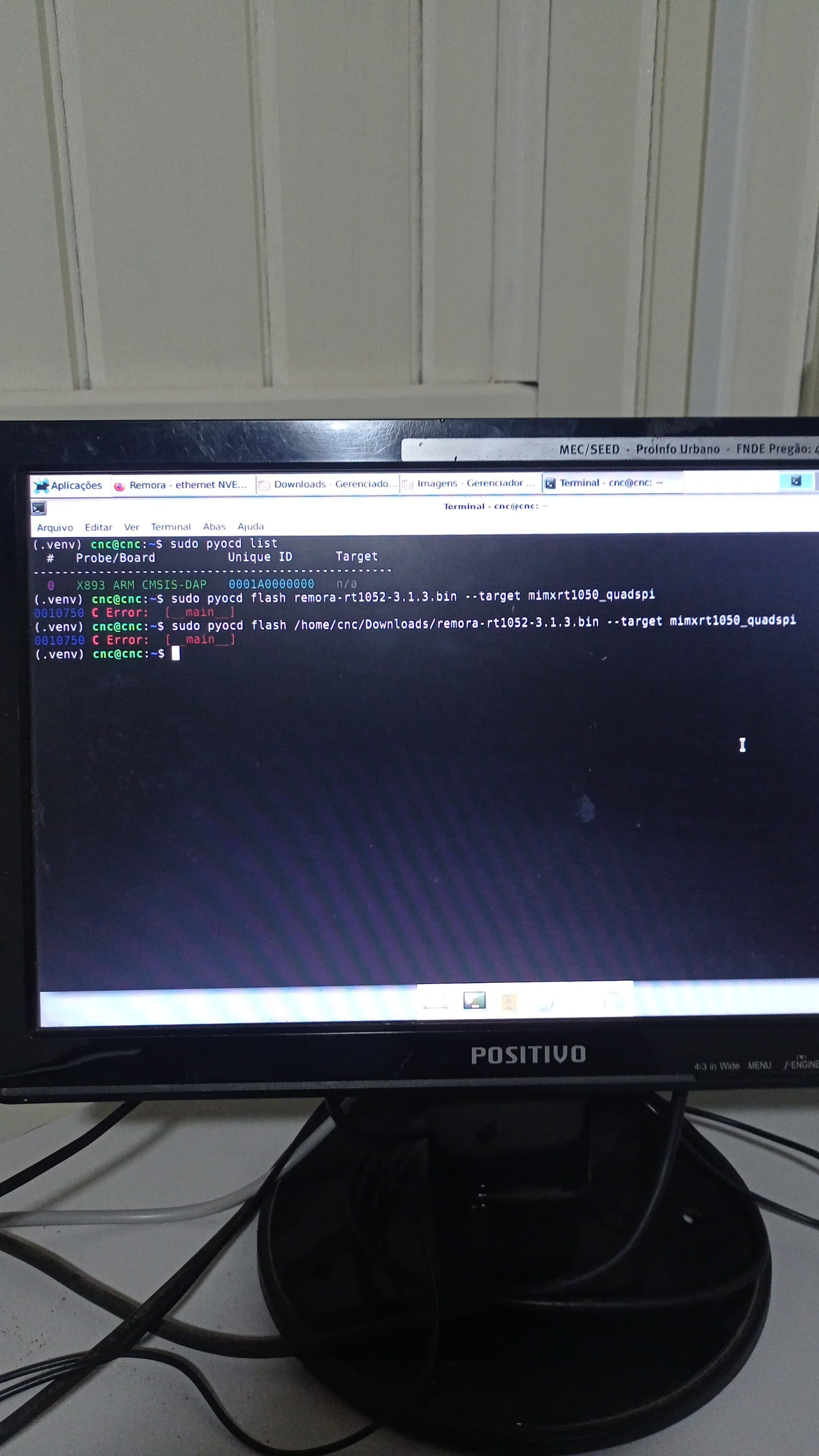

Please, I've been trying for months without success. Everything seems to be fine, but I can't compile it onto the board. I'm using v5 of the cloud. I have no idea what it could be. I see that everyone follows the steps and it works. However, I even had a lot of trouble installing pyocd, but with a lot of effort I finally managed to do it. Please, can someone tell me what I'm doing wrong?

Attachments:

Please Log in or Create an account to join the conversation.

- Murphy

- Offline

- Premium Member

-

Less

More

- Posts: 158

- Thank you received: 5

18 May 2025 17:10 #328703

by Murphy

Replied by Murphy on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

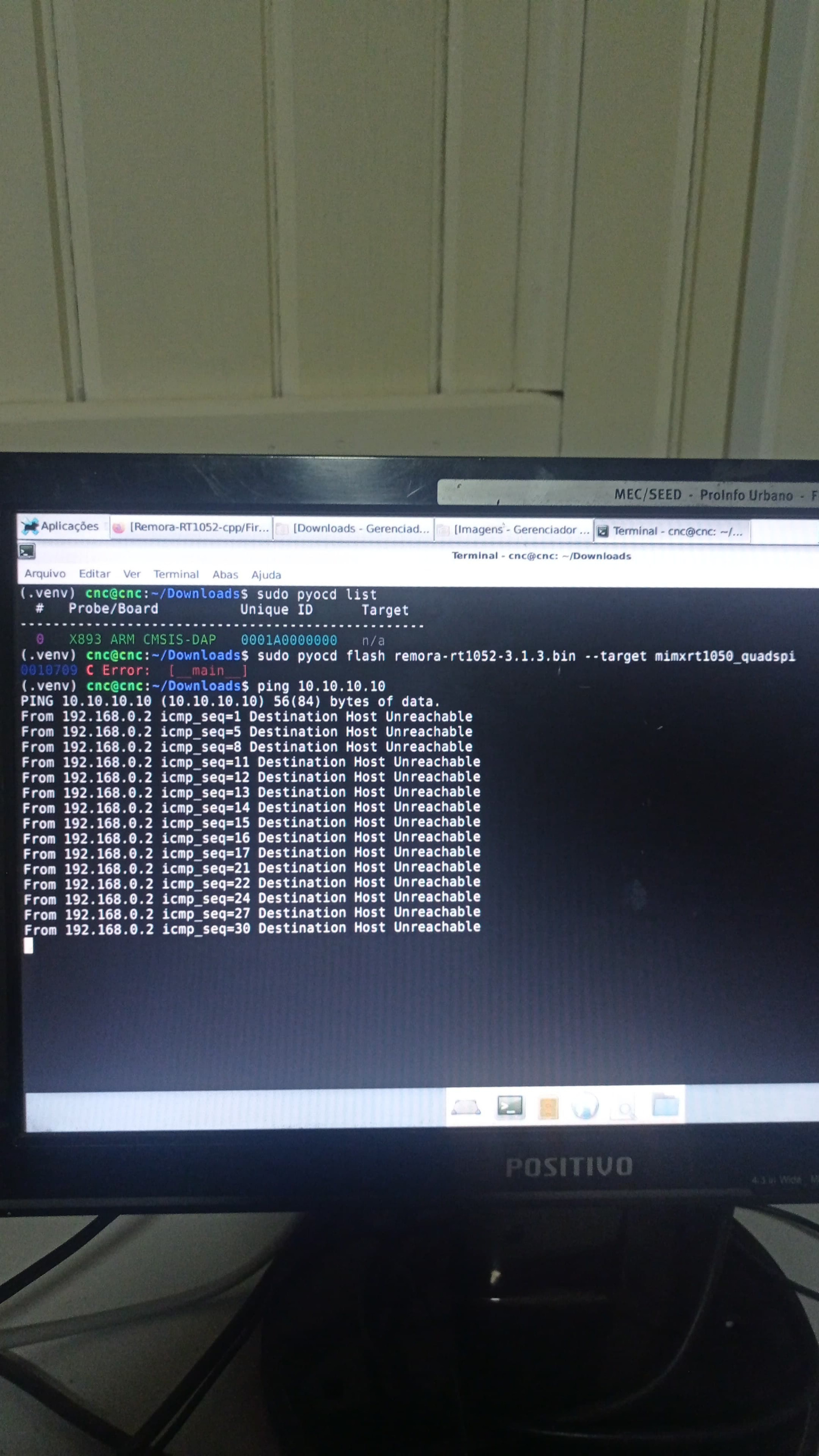

Try been in the directory where the file is located. Before you run pyocd. Are you able to ping the board. 10.10.10.10 ??

Please Log in or Create an account to join the conversation.

- Thayloreing

- Offline

- Premium Member

-

Less

More

- Posts: 94

- Thank you received: 3

18 May 2025 18:14 - 18 May 2025 19:11 #328706

by Thayloreing

Replied by Thayloreing on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Attachments:

Last edit: 18 May 2025 19:11 by Thayloreing.

Please Log in or Create an account to join the conversation.

- JPeters

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

18 May 2025 19:29 #328711

by JPeters

Replied by JPeters on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Hello dear EC500 users,

same as Thayloreing , I had a quite frustrating time trying to flash my EC500 over the last months. And there still is no success. So I am considering quitting the whole thing but I want to give it a last try by registering to this forum.

The problem is to get the firmware into the flash... and I did not find any solution that is working for me. I even can not reproduce the video from scotta with the reprogrammed STLink/V2 stick.

I tried:

The DAP Link Probe is being detected under Linux and is attached to /dev/ttyACMx, but flashing with pyOCD leads only to the prompt: no ACK.

Using both probes under MCUExpressoIDE under Linux is useless, because they are not detected at all. JLink shows up, can be selected but stops programming by stating: can't stop CPU.

The EC500 seems to be a quite nice piece of hardware and I would like to use it in my projects.

Is there a working solution to flash this board available anywhere? I was not able to find any reliable solution what so ever.

Further on: Is the programming interface on the EC500 even usable? And what pins has to be used? There are:

I hope for any help on that topic. Programming a MCU should not be that complicated...

Cheers Julius

same as Thayloreing , I had a quite frustrating time trying to flash my EC500 over the last months. And there still is no success. So I am considering quitting the whole thing but I want to give it a last try by registering to this forum.

The problem is to get the firmware into the flash... and I did not find any solution that is working for me. I even can not reproduce the video from scotta with the reprogrammed STLink/V2 stick.

I tried:

- Modified STLink/V2

- DAP Link probe from Aliexpress

- JLink Edu mini

- pyOCD

- MCUExpressoIDE

- On Windows and Linux

The DAP Link Probe is being detected under Linux and is attached to /dev/ttyACMx, but flashing with pyOCD leads only to the prompt: no ACK.

Using both probes under MCUExpressoIDE under Linux is useless, because they are not detected at all. JLink shows up, can be selected but stops programming by stating: can't stop CPU.

The EC500 seems to be a quite nice piece of hardware and I would like to use it in my projects.

Is there a working solution to flash this board available anywhere? I was not able to find any reliable solution what so ever.

Further on: Is the programming interface on the EC500 even usable? And what pins has to be used? There are:

- VCC

- GND

- SCK

- SWO

- Boot_MO

- Pro_B

I hope for any help on that topic. Programming a MCU should not be that complicated...

Cheers Julius

Please Log in or Create an account to join the conversation.

- scotta

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

Less

More

- Posts: 954

- Thank you received: 486

18 May 2025 20:45 #328715

by scotta

Replied by scotta on topic Remora - ethernet NVEM / EC300 / EC500 cnc board

Hi Julius,

Very strange that one of those combinations don't work, especially MCUExpressoIDE.

For flashing

1. board is externally powered from 24v, so no VCC connection

2. GND, SCK and SWDIO is all the connections needed to the CMSIS-DAP probe

When I've experienced connection issues, powering on the board as the probe is trying to connect to the MCU has helped.

Very strange that one of those combinations don't work, especially MCUExpressoIDE.

For flashing

1. board is externally powered from 24v, so no VCC connection

2. GND, SCK and SWDIO is all the connections needed to the CMSIS-DAP probe

When I've experienced connection issues, powering on the board as the probe is trying to connect to the MCU has helped.

The following user(s) said Thank You: DarkPhoinix

Please Log in or Create an account to join the conversation.

Time to create page: 0.380 seconds