G76 doesn´t work right

- Skyline

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

28 Oct 2017 14:36 #100929

by Skyline

G76 doesn´t work right was created by Skyline

Hey Guys,

I hope i´m at the right "adress" here for my topic.

Since weeks i can not solve my problem with G76 threading.

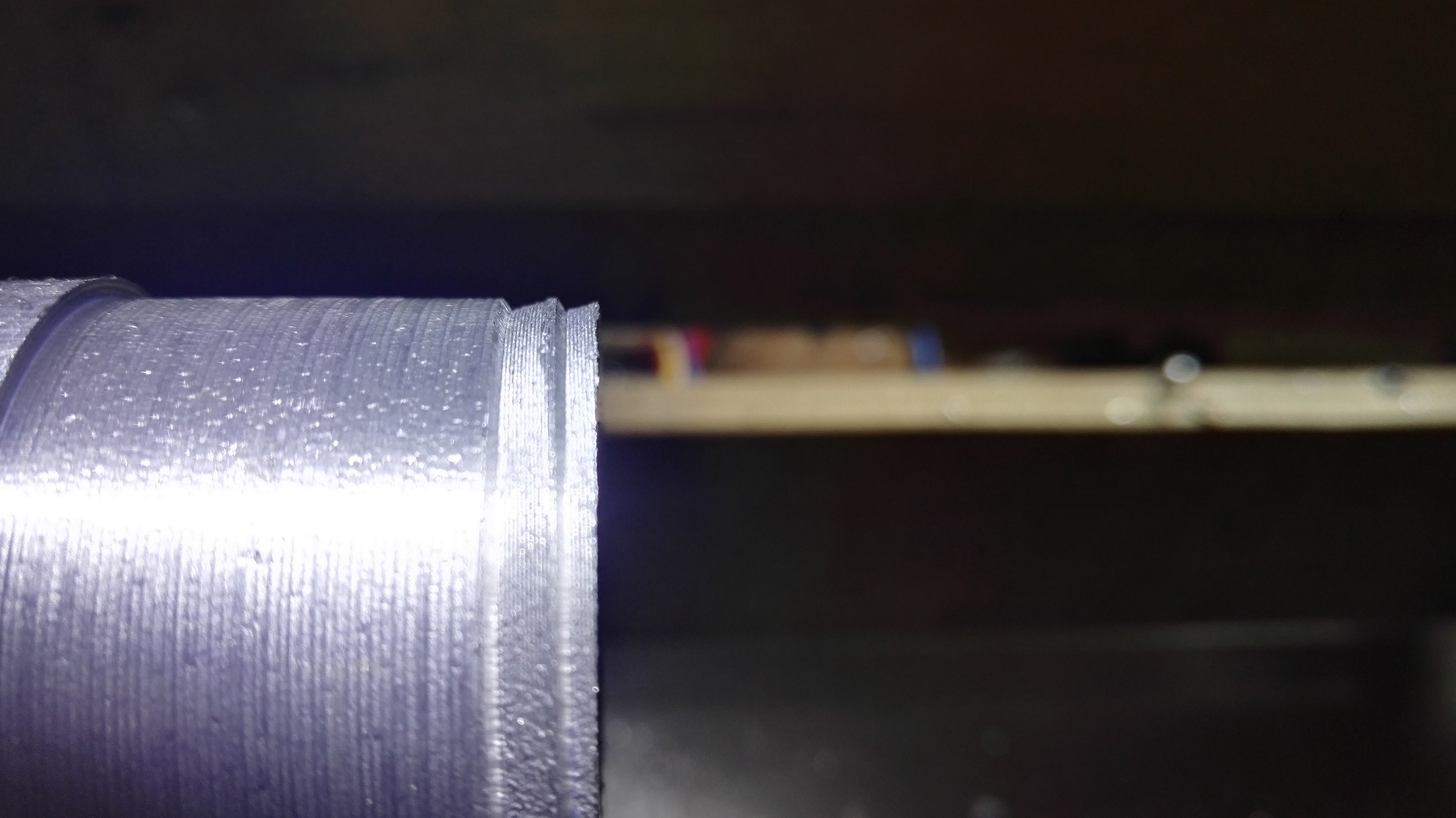

The problem is: Every cut, is a bit more behind or in front of the cut he did before. But all cuts are parallel. Here´s a pic:

So there has to be a problem to start every cut at the same point.

I tried a lot the last weeks and i´m 99% sure, it´s a (user-)software problem.

I use china components with a simple DB25-1205 breakout board.

My spindle encoder is a photocell at the gear which is directly at the spindle. He has a 0V/5V clear "digital" signal.

I use a 60° thread cuter.

Here´s a example of my code:

%

(GEWINDE TEST)

M3

G0X19Z5

G76 P3 Z-5 I-1 J0.05 R1 K0.8 Q0

G0X16Z180

M5

%

My HAL:

You have any idea where´s my problem?

I hope you understand everything I write. If you need more information, please write what you need.

I´m glade about every help

Best regards

Matthias

I hope i´m at the right "adress" here for my topic.

Since weeks i can not solve my problem with G76 threading.

The problem is: Every cut, is a bit more behind or in front of the cut he did before. But all cuts are parallel. Here´s a pic:

So there has to be a problem to start every cut at the same point.

I tried a lot the last weeks and i´m 99% sure, it´s a (user-)software problem.

I use china components with a simple DB25-1205 breakout board.

My spindle encoder is a photocell at the gear which is directly at the spindle. He has a 0V/5V clear "digital" signal.

I use a 60° thread cuter.

Here´s a example of my code:

%

(GEWINDE TEST)

M3

G0X19Z5

G76 P3 Z-5 I-1 J0.05 R1 K0.8 Q0

G0X16Z180

M5

%

My HAL:

# Generated by stepconf 1.1 at Sat Sep 23 13:13:57 2017

# Änderungen an dieser Datei werden beim nächsten

# Aufruf von stepconf überschrieben.

loadrt trivkins

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hal_parport cfg="0 out"

loadrt stepgen step_type=0,0

loadrt encoder num_chan=1

loadrt abs count=1

loadrt scale count=1

loadrt lowpass count=1

loadrt pwmgen output_type=1

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf encoder.update-counters base-thread

addf pwmgen.make-pulses base-thread

addf parport.0.write base-thread

addf stepgen.capture-position servo-thread

addf encoder.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

addf pwmgen.update servo-thread

addf abs.0 servo-thread

addf scale.0 servo-thread

addf lowpass.0 servo-thread

net spindle-cmd-rpm => pwmgen.0.value

net spindle-on <= motion.spindle-on => pwmgen.0.enable

net spindle-pwm <= pwmgen.0.pwm

setp pwmgen.0.pwm-freq 1000.0

setp pwmgen.0.scale 624.0

setp pwmgen.0.offset 0.0128205128205

setp pwmgen.0.dither-pwm true

net spindle-cmd-rpm <= motion.spindle-speed-out

net spindle-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-cmd-rps <= motion.spindle-speed-out-rps

net spindle-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-at-speed => motion.spindle-at-speed

setp encoder.0.position-scale 62.000000

setp encoder.0.counter-mode 1

net spindle-position encoder.0.position => motion.spindle-revs

net spindle-velocity-feedback-rps encoder.0.velocity => motion.spindle-speed-in

net spindle-index-enable encoder.0.index-enable <=> motion.spindle-index-enable

net spindle-phase-a encoder.0.phase-A

net spindle-phase-b encoder.0.phase-B

net spindle-phase-a encoder.0.phase-Z

setp parport.0.pin-01-out-invert 1

net zstep => parport.0.pin-01-out

setp parport.0.pin-02-out-invert 1

net xenable => parport.0.pin-02-out

setp parport.0.pin-03-out-invert 1

net xdir => parport.0.pin-03-out

net zdir => parport.0.pin-07-out

setp parport.0.pin-08-out-invert 1

net xstep => parport.0.pin-08-out

setp parport.0.pin-14-out-invert 1

net xenable => parport.0.pin-14-out

net spindle-pwm => parport.0.pin-16-out

net max-x <= parport.0.pin-10-in-not

net min-z <= parport.0.pin-11-in-not

net spindle-phase-a <= parport.0.pin-12-in

net estop-ext <= parport.0.pin-15-in

setp stepgen.0.position-scale [AXIS_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 1

setp stepgen.0.dirhold 22650

setp stepgen.0.dirsetup 22650

setp stepgen.0.maxaccel [AXIS_0]STEPGEN_MAXACCEL

net xpos-cmd axis.0.motor-pos-cmd => stepgen.0.position-cmd

net xpos-fb stepgen.0.position-fb => axis.0.motor-pos-fb

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable axis.0.amp-enable-out => stepgen.0.enable

net max-x => axis.0.pos-lim-sw-in

setp stepgen.1.position-scale [AXIS_2]SCALE

setp stepgen.1.steplen 1

setp stepgen.1.stepspace 1

setp stepgen.1.dirhold 22650

setp stepgen.1.dirsetup 22650

setp stepgen.1.maxaccel [AXIS_2]STEPGEN_MAXACCEL

net zpos-cmd axis.2.motor-pos-cmd => stepgen.1.position-cmd

net zpos-fb stepgen.1.position-fb => axis.2.motor-pos-fb

net zstep <= stepgen.1.step

net zdir <= stepgen.1.dir

net zenable axis.2.amp-enable-out => stepgen.1.enable

net min-z => axis.2.neg-lim-sw-in

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-preparedYou have any idea where´s my problem?

I hope you understand everything I write. If you need more information, please write what you need.

I´m glade about every help

Best regards

Matthias

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17704

- Thank you received: 5176

28 Oct 2017 15:03 - 28 Oct 2017 15:21 #100931

by PCW

Replied by PCW on topic G76 doesn´t work right

You can only use encoder A for index if you have 1 pulse per turn

(you seem to have 62)

This means every threading pass you could start randomly at any of the 62 shaft

positions.

I do think its arguable that the encoder component should have the option of generating a simulated

index signal by dividing the count. This would not work quite as well as a real index signal

( The index position would be forgotten when LinuxCNC was shut down )

but would allow threading with a single detector having multiple counts per turn

(you seem to have 62)

This means every threading pass you could start randomly at any of the 62 shaft

positions.

I do think its arguable that the encoder component should have the option of generating a simulated

index signal by dividing the count. This would not work quite as well as a real index signal

( The index position would be forgotten when LinuxCNC was shut down )

but would allow threading with a single detector having multiple counts per turn

Last edit: 28 Oct 2017 15:21 by PCW.

Please Log in or Create an account to join the conversation.

- Skyline

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

28 Oct 2017 15:21 #100932

by Skyline

Replied by Skyline on topic G76 doesn´t work right

Oh, okay. How do i have to change it?

net spindle-phase-a encoder.0.phase-Z ?

net spindle-phase-a encoder.0.phase-Z ?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17704

- Thank you received: 5176

28 Oct 2017 15:25 #100933

by PCW

Replied by PCW on topic G76 doesn´t work right

You would need to add a 1 pulse per rev detector and wire it to phase-Z

You could retain the 62 PPR A signal if you have enough parallel port inputs available

if not you would wire the 1 PPR signal to A and Z as you have now

You could retain the 62 PPR A signal if you have enough parallel port inputs available

if not you would wire the 1 PPR signal to A and Z as you have now

Please Log in or Create an account to join the conversation.

- Skyline

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

28 Oct 2017 15:43 #100935

by Skyline

Replied by Skyline on topic G76 doesn´t work right

Okay, so I need a 1PPR at Z, so it would work. If 62 PPR would stay at A, what would it do?

Is there any option to use my 62 PPR without 1 PPR and it still stays 62 PPR? Because 1 PPR is pretty inaccurate?

I´ve got the feeling, i don´t understand something basicaly how it works.

Is there any option to use my 62 PPR without 1 PPR and it still stays 62 PPR? Because 1 PPR is pretty inaccurate?

I´ve got the feeling, i don´t understand something basicaly how it works.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17704

- Thank you received: 5176

28 Oct 2017 15:50 - 28 Oct 2017 15:56 #100936

by PCW

Replied by PCW on topic G76 doesn´t work right

There are at least three main options here:

1. One wire 1PPR threading: simple but poor tracking if the spindle speed varies

2. Two wire ( A and Z ) multiple PPR threading: better tracking if spindle speed varies

3. Three wire ( A,B,Z ) multiple PPR threading, good tracking and reversable ( for tapping etc )

Note for the 1 PPR option, you must use the encoders "position-interpolated" rather than "position"

pin so that the Z axis moves smoothly rather than stepping every spindle count

1. One wire 1PPR threading: simple but poor tracking if the spindle speed varies

2. Two wire ( A and Z ) multiple PPR threading: better tracking if spindle speed varies

3. Three wire ( A,B,Z ) multiple PPR threading, good tracking and reversable ( for tapping etc )

Note for the 1 PPR option, you must use the encoders "position-interpolated" rather than "position"

pin so that the Z axis moves smoothly rather than stepping every spindle count

Last edit: 28 Oct 2017 15:56 by PCW.

The following user(s) said Thank You: andypugh

Please Log in or Create an account to join the conversation.

- Skyline

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

28 Oct 2017 15:56 #100937

by Skyline

Replied by Skyline on topic G76 doesn´t work right

Okay, so, if i understand right:

I add a 1 PPR (for indication?) to phase Z, the 62 PPR stays A and so i get the second option you listet? The tracking will be better then with only 1 PPR.?

I add a 1 PPR (for indication?) to phase Z, the 62 PPR stays A and so i get the second option you listet? The tracking will be better then with only 1 PPR.?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17704

- Thank you received: 5176

28 Oct 2017 16:04 - 28 Oct 2017 16:07 #100938

by PCW

Replied by PCW on topic G76 doesn´t work right

Yes, the tracking will be better because the spindle position is updated 62 times per revolution

rather than just once.

With 1 PPR you basically have to guess the spindle position by using the velocity calculated from the

previous revolution and the time from the last index ( That's what position-interpolated is )

Using position-interpolated may still be helpful even at 62 PPR, especially at low speeds

( so you avoid noticeable steps in the z motion )

rather than just once.

With 1 PPR you basically have to guess the spindle position by using the velocity calculated from the

previous revolution and the time from the last index ( That's what position-interpolated is )

Using position-interpolated may still be helpful even at 62 PPR, especially at low speeds

( so you avoid noticeable steps in the z motion )

Last edit: 28 Oct 2017 16:07 by PCW.

Please Log in or Create an account to join the conversation.

- Skyline

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

28 Oct 2017 16:07 #100939

by Skyline

Replied by Skyline on topic G76 doesn´t work right

Okay, now i got it. I will try to improvise a 1 PPR encoder and test it.

Very much thanks at this point!!!!

Very much thanks at this point!!!!

Please Log in or Create an account to join the conversation.

- Skyline

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

29 Oct 2017 17:43 #100976

by Skyline

Replied by Skyline on topic G76 doesn´t work right

That´s it! My improvise mounted sensor works and a thread was never that sexy before

Thank you!

Thank you!

Please Log in or Create an account to join the conversation.

Time to create page: 0.179 seconds