Circular pocket milling routine

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 500

- Thank you received: 210

08 Jan 2019 02:18 #123743

by MaHa

Circular pocket milling routine was created by MaHa

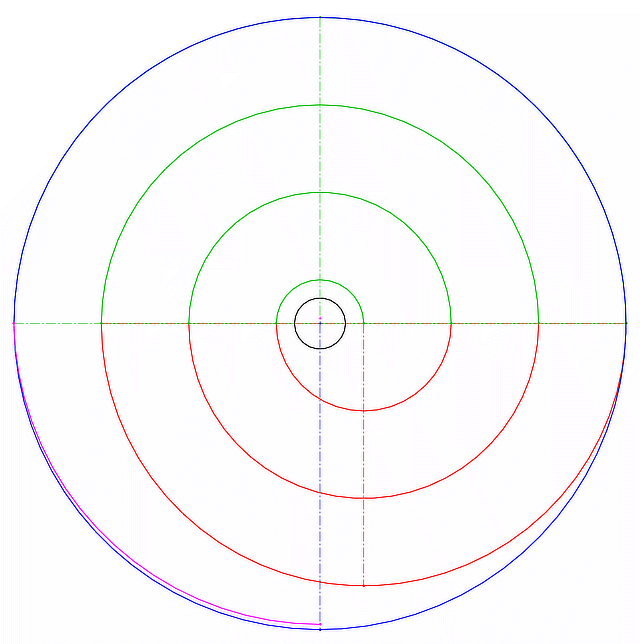

My pocket milling routine, polarcoordinates, is a bit outdated, in the meantime. One disadvantage is centerpoint forced at X0 Y0. Another is the rising arc length by increasing diameter. Difficult to control feed, smoothness of machining. Soon some parts in 7075 aluminium, with a lot of circular machining are pending. Recently on a long flight, creating the framework for the new routine which meets my expectations. In the meantime finished and tested, it's ready to use. I made this for my personal use, just drop it here, if someone is interrested. Should be selfexplaining. It is standalone, at the moment. I think about change it to subroutine, makes it easier to process levels.

The following user(s) said Thank You: tommylight, snoozer77

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 500

- Thank you received: 210

08 Jan 2019 11:01 #123769

by MaHa

Replied by MaHa on topic Circular pocket milling routine

I forgot to mention, the spiral is done by point to point movement, the amount of points calculated to a distance to go of 0.05 mm. It gives a smooth movement and loading time for large diameters is reasonable. If G61 is used, you can watch Hal pin: motion.distance-to-go, to see the distance to go on any diameter above 1 inch is always 0.05 mm. With G64 P0.05, the distance to go is depending on diameter. At D 30 it's about 2mm, D 100 4mm to go, D 150 about 5mm to go and D 200 goes 6mm. The G64 P0.05 setting is recommended for machining.

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 500

- Thank you received: 210

30 May 2019 22:05 #135430

by MaHa

Replied by MaHa on topic Circular pocket milling routine

The final version with z-levelling, now only metric, how to call:

#<CC_RL> = 2 ;G41/G3: 1 G42/G2: 2

#<CENTER_DIA> = 10 ;ZENTRUM D HELIX VORBEARBEITUNG

#<AZ> = 1 ;START / RÜCKZUG Z

#<DEPTH> = -4 ;TIEFE AB NULLPUNKT

#<Z_REV> = .5 ;HELIX MAX ZUST. Z PER REV

#<Z_STEP> = 1.5 ;SPIRALE MAX SCHNITTIEFE Z PRO DURCHLAUF

#<END_DIA> = 32.5 ;FERTIGDURCHMESSER

#<END_D_ALLOWANCE> = .5 ;SPIRAL AUFMASS IM D FÜR FERTIG G3/G2

#<DEPTH_R_PER_REV> = 3.6 ;RADIALE ZUSTELLUNG PER REV MAX TOOL D

#<F_HELIX> = 388 ;FEED HELIX DIVE

#<F_SPIRAL> = 1100 ;FEED SPIRAL

#<F_END_D> = 1300 ;FEED FINISHING DIA G2 G3

;TOOLTABLE USED FOR CUTTER COMPENSATION

o<archimedeanspiral> call [#<CC_RL>] [#<CENTER_DIA>] [#<AZ>] [#<DEPTH>] [#<Z_REV>] [#<Z_STEP>] [#<END_DIA>] [#<END_D_ALLOWANCE>] [#<DEPTH_R_PER_REV>] [#<F_HELIX>] [#<F_SPIRAL>] [#<F_END_D>]

#<CC_RL> = 2 ;G41/G3: 1 G42/G2: 2

#<CENTER_DIA> = 10 ;ZENTRUM D HELIX VORBEARBEITUNG

#<AZ> = 1 ;START / RÜCKZUG Z

#<DEPTH> = -4 ;TIEFE AB NULLPUNKT

#<Z_REV> = .5 ;HELIX MAX ZUST. Z PER REV

#<Z_STEP> = 1.5 ;SPIRALE MAX SCHNITTIEFE Z PRO DURCHLAUF

#<END_DIA> = 32.5 ;FERTIGDURCHMESSER

#<END_D_ALLOWANCE> = .5 ;SPIRAL AUFMASS IM D FÜR FERTIG G3/G2

#<DEPTH_R_PER_REV> = 3.6 ;RADIALE ZUSTELLUNG PER REV MAX TOOL D

#<F_HELIX> = 388 ;FEED HELIX DIVE

#<F_SPIRAL> = 1100 ;FEED SPIRAL

#<F_END_D> = 1300 ;FEED FINISHING DIA G2 G3

;TOOLTABLE USED FOR CUTTER COMPENSATION

o<archimedeanspiral> call [#<CC_RL>] [#<CENTER_DIA>] [#<AZ>] [#<DEPTH>] [#<Z_REV>] [#<Z_STEP>] [#<END_DIA>] [#<END_D_ALLOWANCE>] [#<DEPTH_R_PER_REV>] [#<F_HELIX>] [#<F_SPIRAL>] [#<F_END_D>]

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- MaHa

- Offline

- Platinum Member

-

Less

More

- Posts: 500

- Thank you received: 210

22 Oct 2024 21:45 - 22 Oct 2024 21:53 #312901

by MaHa

Replied by MaHa on topic Circular pocket milling routine

The former attempts for spiralpocket, first with polarcoordinates, next archimedean spiral, were running pretty rough and acceleration was not good. So it was difficult to reach a competitive feed.The new version with successive semicircles runs very nice, G2 or G3 is used. On end of spiral, the final D is reached with a semicircle and then finished with one round. Leadout with a quarter circle, 0.2 off. The depth can be finished with small allowance. Spacing can be set by value or % of tool diameter. Z-level is included also.

vimeo.com/1022290414?share=copy

vimeo.com/1022290414?share=copy

Attachments:

Last edit: 22 Oct 2024 21:53 by MaHa.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

Time to create page: 0.081 seconds