Small spindle crashed (SOLVED)

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

02 Nov 2021 16:34 - 07 Nov 2021 11:05 #225008

by PhilipME

Small spindle crashed (SOLVED) was created by PhilipME

Last edit: 07 Nov 2021 11:05 by PhilipME.

Please Log in or Create an account to join the conversation.

- bevins

-

- Offline

- Platinum Member

-

Less

More

- Posts: 1942

- Thank you received: 338

02 Nov 2021 16:40 #225010

by bevins

post your gcode file. That might help for others to troubleshoot.

Replied by bevins on topic Small spindle crashed

Did yopu write the gcode with the linuxcnc post or just try and run it from the arduino post?

post your gcode file. That might help for others to troubleshoot.

The following user(s) said Thank You: PhilipME

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4612

02 Nov 2021 16:41 #225011

by andypugh

Replied by andypugh on topic Small spindle crashed

It sounds like, possibly, the Z axis stalled.

What happens if you MDI a G0 Z (high) with the spindle running?

(I was going to suggest G53 G0 Z0 but then realised that perhaps you are not configured with Z at top of travel.)

I assume that you have checked the G-code?

What happens if you MDI a G0 Z (high) with the spindle running?

(I was going to suggest G53 G0 Z0 but then realised that perhaps you are not configured with Z at top of travel.)

I assume that you have checked the G-code?

The following user(s) said Thank You: PhilipME

Please Log in or Create an account to join the conversation.

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

02 Nov 2021 16:48 - 02 Nov 2021 16:49 #225016

by PhilipME

Replied by PhilipME on topic Small spindle crashed

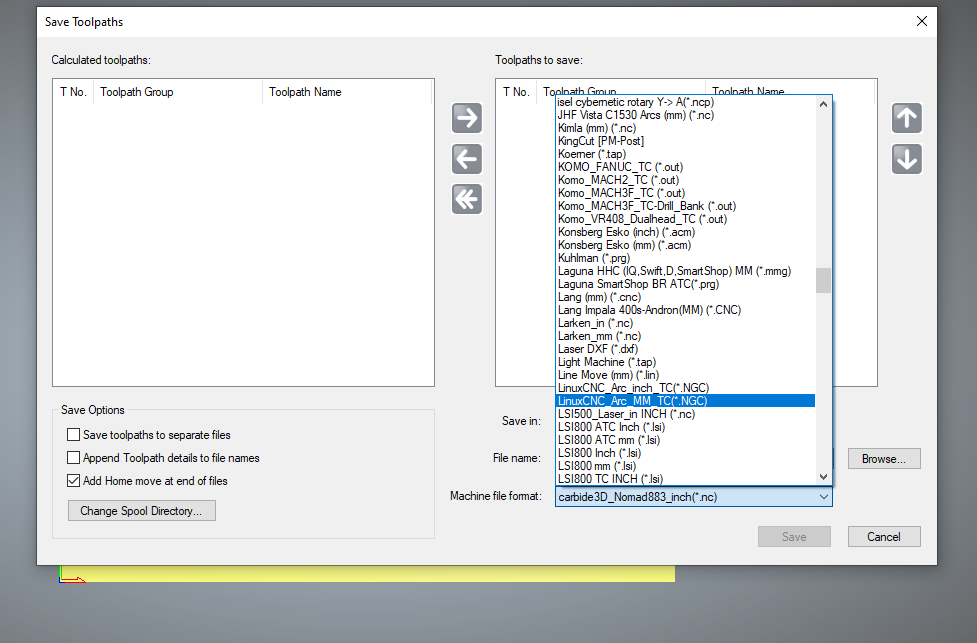

Attachments:

Last edit: 02 Nov 2021 16:49 by PhilipME.

Please Log in or Create an account to join the conversation.

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

03 Nov 2021 02:53 - 05 Nov 2021 08:43 #225067

by PhilipME

Replied by PhilipME on topic Small spindle crashed

I think what hapened is that the Z-carrage is too heavy for the Z-motor.

I think the Z-motor missed the steps going up.Eventhough the Z was driving at 180 mm/minute.

This is the G-code

My best regards

Philip

(1st-cut-4)

(Material Size) (X=250.000, Y=180.000, Z=11.000)

G90G80G21G49

G64 P0.001

M6 T1

(Tool Number:1) (3.000 mm dia. slot drill)

G43 H1 G0Z10.0000

M3 S15000

G0 X27.2060 Y69.3700 Z10.0000

G1 Z-1.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-2.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-3.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-4.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-5.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-6.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-7.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-8.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-9.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-10.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-11.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G0 Z10.0000

G0 X145.1290 Y100.2440

G1 Z-1.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-2.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-3.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-4.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-5.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-6.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-7.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-8.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-9.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-10.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-11.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G0 Z10.0000

G0 X0.0000 Y0.0000

G0Z10.0000

G0X0.0000Y0.0000

M5

M30

I think the Z-motor missed the steps going up.Eventhough the Z was driving at 180 mm/minute.

This is the G-code

My best regards

Philip

(1st-cut-4)

(Material Size) (X=250.000, Y=180.000, Z=11.000)

G90G80G21G49

G64 P0.001

M6 T1

(Tool Number:1) (3.000 mm dia. slot drill)

G43 H1 G0Z10.0000

M3 S15000

G0 X27.2060 Y69.3700 Z10.0000

G1 Z-1.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-2.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-3.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-4.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-5.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-6.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-7.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-8.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-9.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-10.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G1 Z-11.0000 F180

G2 X27.8357 Y74.3683 I20.0583 J0.0120 F300

G2 X38.5352 Y87.3978 I19.3945 J-5.0185

G2 X42.2077 Y88.7403 I8.6207 J-17.8871

G2 X52.2043 I4.9983 J-19.4983

G2 X65.2338 Y78.0408 I-5.0185 J-19.3945

G2 X66.5763 Y74.3683 I-17.8871 J-8.6207

G2 Y64.3717 I-19.4983 J-4.9983

G2 X55.8768 Y51.3422 I-19.3945 J5.0185

G2 X52.2043 Y49.9997 I-8.6207 J17.8871

G2 X42.2077 I-4.9983 J19.4983

G2 X29.1782 Y60.6992 I5.0185 J19.3945

G2 X27.8357 Y64.3717 I17.8871 J8.6207

G2 X27.2060 Y69.3700 I19.4286 J4.9863

G0 Z10.0000

G0 X145.1290 Y100.2440

G1 Z-1.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-2.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-3.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-4.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-5.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-6.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-7.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-8.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-9.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-10.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G1 Z-11.0000 F180

G1 Y150.2440 F300

X195.1290

Y100.2440

X145.1290

G0 Z10.0000

G0 X0.0000 Y0.0000

G0Z10.0000

G0X0.0000Y0.0000

M5

M30

Last edit: 05 Nov 2021 08:43 by PhilipME.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1974

- Thank you received: 808

03 Nov 2021 03:09 #225068

by spumco

Replied by spumco on topic Small spindle crashed

You can test this by creating a small program to move the Z-axis up and down at rapid speed.

You don't need to move far... just an inch or two, but far enough for the axis to reach top speed (depends on your axis acceleration).

Start with the head/tool at a known distance above the table, perhaps using a 1-2-3 block or a steel rule. Repeat the up-down move a number of times with the program ending at the start point. Make sure your reference height device is not in the way - nothing close ot the head in case you lose steps and the head is lower than you expect.

Once complete, check if the tool is in the same position. If it's not, then you've lost some steps. There are a number of fixes, but reducing top speed, acceleration, head weight, or friction all will help.

Or get bigger motors. That's my go-to solution

You don't need to move far... just an inch or two, but far enough for the axis to reach top speed (depends on your axis acceleration).

Start with the head/tool at a known distance above the table, perhaps using a 1-2-3 block or a steel rule. Repeat the up-down move a number of times with the program ending at the start point. Make sure your reference height device is not in the way - nothing close ot the head in case you lose steps and the head is lower than you expect.

Once complete, check if the tool is in the same position. If it's not, then you've lost some steps. There are a number of fixes, but reducing top speed, acceleration, head weight, or friction all will help.

Or get bigger motors. That's my go-to solution

The following user(s) said Thank You: PhilipME

Please Log in or Create an account to join the conversation.

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

03 Nov 2021 03:28 #225069

by PhilipME

I placed order for a closed loop stepper,

Actualy I have a 34 stepper motor (long body) but I have no driver. So I will swap the z-x because the x has the larger motor.

I under estimated the Z requirments.

This stuff is adictive and enjoiable. I am enjoying every nano second.

Philip

Replied by PhilipME on topic Small spindle crashed

YesYou can test this by creating a small program to move the Z-axis up and down at rapid speed.

You don't need to move far... just an inch or two, but far enough for the axis to reach top speed (depends on your axis acceleration).

Start with the head/tool at a known distance above the table, perhaps using a 1-2-3 block or a steel rule. Repeat the up-down move a number of times with the program ending at the start point. Make sure your reference height device is not in the way - nothing close ot the head in case you lose steps and the head is lower than you expect.

Once complete, check if the tool is in the same position. If it's not, then you've lost some steps. There are a number of fixes, but reducing top speed, acceleration, head weight, or friction all will help.

Or get bigger motors. That's my go-to solution

I placed order for a closed loop stepper,

Actualy I have a 34 stepper motor (long body) but I have no driver. So I will swap the z-x because the x has the larger motor.

I under estimated the Z requirments.

This stuff is adictive and enjoiable. I am enjoying every nano second.

Philip

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4612

04 Nov 2021 20:49 #225265

by andypugh

Replied by andypugh on topic Small spindle crashed

You might find that a lower Z joint acceleration will circumvent the issue.

The following user(s) said Thank You: PhilipME

Please Log in or Create an account to join the conversation.

- PhilipME

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 176

- Thank you received: 14

05 Nov 2021 04:02 - 05 Nov 2021 09:08 #225350

by PhilipME

Replied by PhilipME on topic Small spindle crashed

I think it is clear now

thanks everyone

It looks like the G-code is OK

It is obvious to me now that the Z-stepper missing steps, slower acceleration and speed should help. Also a larger motor maybe necessary.

Why the Z-step motor is missing steps?

because when the cut of the circle reached the depth of the cut (11mm) it is time to move the bit up to safe altitude.

It does that with G0 which is maximum speed. Which when I was jogging after first start of the machine I knew that G0 will not work.

While exited because this the very first time I run the machine after 8 months of work, I did not adjust the maximum speed in the ini file.

Maybe I thought also the bit will move up according to the cutting speed which I know the stepper motor is capable to handle, while in fact it will go up with G0 speed as I found the hardway.

So the first thing to do is to reduce the speed and acceleration until I change the motor, and run the program recommended by spumco in order to find the limit of the new motor.

I will install a spare small spindle, and be more carful this time.

Also I have to spend more time studying the G-code

during this thread, I made some wrong and confusing conclusion. And since no one quoted those posts, I edited, and deleted the wrong nonsense I wrote earlier. This is to make the lesson more clear for beginners like me who may have the same issue.

My best regards

Philip

thanks everyone

It looks like the G-code is OK

It is obvious to me now that the Z-stepper missing steps, slower acceleration and speed should help. Also a larger motor maybe necessary.

Why the Z-step motor is missing steps?

because when the cut of the circle reached the depth of the cut (11mm) it is time to move the bit up to safe altitude.

It does that with G0 which is maximum speed. Which when I was jogging after first start of the machine I knew that G0 will not work.

While exited because this the very first time I run the machine after 8 months of work, I did not adjust the maximum speed in the ini file.

Maybe I thought also the bit will move up according to the cutting speed which I know the stepper motor is capable to handle, while in fact it will go up with G0 speed as I found the hardway.

So the first thing to do is to reduce the speed and acceleration until I change the motor, and run the program recommended by spumco in order to find the limit of the new motor.

I will install a spare small spindle, and be more carful this time.

Also I have to spend more time studying the G-code

during this thread, I made some wrong and confusing conclusion. And since no one quoted those posts, I edited, and deleted the wrong nonsense I wrote earlier. This is to make the lesson more clear for beginners like me who may have the same issue.

My best regards

Philip

Last edit: 05 Nov 2021 09:08 by PhilipME.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4612

05 Nov 2021 15:29 #225405

by andypugh

Replied by andypugh on topic Small spindle crashed

Do you need to set a safe height and a rapid height in the CAM?

Please Log in or Create an account to join the conversation.

Time to create page: 0.618 seconds