Servo as spindle problems with speed and encoder feedback

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 161

- Thank you received: 15

So I connected the servo up and hooked it to a spare stepgen on the 7i96. To get the basic settings I ran a pnc conf for a 7i76 and copied pasted the spindle section across editing the bits to 7i96. Read the 1.8 manual about mesa, hal and ini but couldn't find the answer.

The spindle turns on and monitoring the hal pins shows things should be correct apart from:

- Speed is limited to 1100 RPM gained from the servo driver readout. This is achieved with one click of the 'axis button that increases speed'.

- My encoder feedback through the 7i96 is stupidly high. Its suggesting I'm doing 3 million rpm

- I don't think my PID is hooked up as spindle-output when monitored as a signal never moves

Any help is appreciated.

Jools

NB: The 1.8 documentation for the INI configuration doesn't document SPINDLE

HAL

# This file was created with the 7i96 Wizard on Nov 21 2019 15:52:11

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS]KINEMATICS

# motion controller

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

# standard components

loadrt pid num_chan=4

# hostmot2 driver

loadrt hostmot2

loadrt [HOSTMOT2](DRIVER) board_ip=[HOSTMOT2](IPADDRESS) config="num_encoders=[HOSTMOT2](ENCODERS)num_stepgens=[HOSTMOT2](STEPGENS)"sserial_port_0=[HOSTMOT2](SSERIAL_PORT)pwm_gens=1

setp hm2_[HOSTMOT2](BOARD).0.watchdog.timeout_ns 25000000

# THREADS

addf hm2_[HOSTMOT2](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

setp hm2_[HOSTMOT2](BOARD).0.dpll.01.timer-us -100

setp hm2_[HOSTMOT2](BOARD).0.stepgen.timer-number 1

addf pid.0.do-pid-calcs servo-thread

addf pid.1.do-pid-calcs servo-thread

addf pid.2.do-pid-calcs servo-thread

addf pid.3.do-pid-calcs servo-thread

addf hm2_[HOSTMOT2](BOARD).0.write servo-thread

# Spindle

setp pid.3.Pgain [SPINDLE]P

setp pid.3.Igain [SPINDLE]I

setp pid.3.Dgain [SPINDLE]D

setp pid.3.bias [SPINDLE]BIAS

setp pid.3.FF0 [SPINDLE]FF0

setp pid.3.FF1 [SPINDLE]FF1

setp pid.3.FF2 [SPINDLE]FF2

setp pid.3.deadband [SPINDLE]DEADBAND

setp pid.3.maxoutput [SPINDLE]MAX_RPM

setp pid.3.maxerror [SPINDLE]MAX_ERROR

setp pid.3.error-previous-target true

setp pid.3.maxerror .1

net spindle-index-enable <=> pid.3.index-enable

net spindle-enable => pid.3.enable

net spindle-vel-cmd-rpm => pid.3.command

net spindle-vel-fb-rpm => pid.3.feedback

net spindle-output <= pid.3.output

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.dirsetup [SPINDLE]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.dirhold [SPINDLE]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.steplen [SPINDLE]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.stepspace [SPINDLE]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.position-scale [SPINDLE]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.maxvel [SPINDLE]MAX_RPM

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.maxaccel [SPINDLE]STEPGEN_MAX_ACCEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.control-type 1

#

net spindle-enable => hm2_7i96.0.stepgen.03.enable

net speedsend spindle.0.speed-out => hm2_7i96.0.stepgen.03.velocity-cmd

net spindle-vel-fb-rpm <= hm2_7i96.0.encoder.00.velocity

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# Standard I/O Block - EStop, Etc

# create a signal for the estop loopback

net estop-loop iocontrol.0.user-enable-out => iocontrol.0.emc-enable-in

net all-fault hm2_7i96.0.gpio.005.in <= joint.0.amp-fault-in

net home-joint-1 joint.1.home-sw-in <= hm2_7i96.0.gpio.000.in

net home-joint-2 joint.2.home-sw-in <= hm2_7i96.0.gpio.001.in

net home-joint-0 joint.0.home-sw-in <= hm2_7i96.0.gpio.002.in

# create signals for tool loading loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change => iocontrol.0.tool-changed.INI

# This file was created with the 7i96 Wizard on Nov 21 2019 15:52:11

# Changes to most things are ok and will be read by the wizard

[EMC]

VERSION = 1.1

MACHINE = jools

DEBUG = 0x00000000

[HOSTMOT2]

DRIVER = hm2_eth

IPADDRESS = "10.10.10.10"

BOARD = 7i96

STEPGENS = 4

ENCODERS = 1

SSERIAL_PORT = 1

[DISPLAY]

# required NativeCAM item :

NCAM_DIR = ncam

# required NativeCAM item :

PROGRAM_PREFIX = ncam/scripts/

# required NativeCAM item :

GLADEVCP = -U --catalog=mill /usr/share/linuxcnc/aux_gladevcp/NativeCAM/ncam.ui

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = COMMANDED

MAX_FEED_OVERRIDE = 2.0

CYCLE_TIME = 0.1

INTRO_GRAPHIC = emc2.gif

INTRO_TIME = 0

OPEN_FILE = ""

INCREMENTS = 30, 20, 10, 5, 1, .5, .05, .02, .01

DEFAULT_LINEAR_VELOCITY = 14

EDITOR = GEDIT

[KINS]

KINEMATICS = trivkins coordinates=XYZ

JOINTS = 3

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[RS274NGC]

# required NativeCAM item :

SUBROUTINE_PATH = ncam/my-stuff:ncam/lib/mill:ncam/lib/utilities

PARAMETER_FILE = jools.var

CENTER_ARC_RADIUS_TOLERANCE_MM = .001

[EMCMOT]

EMCMOT = motmod

SERVO_PERIOD = 1000000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = metric

ANGULAR_UNITS = degree

MAX_LINEAR_VELOCITY = 300

NO_FORCE_HOMING = 0

ARC_BLEND_ENABLE = 1

ARC_BLEND_OPTIMIZATION_DEPTH = 50

[HAL]

HALFILE = jools.hal

HALFILE = io.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui.hal

[HALUI]

[AXIS_X]

MIN_LIMIT = 0

MAX_LIMIT = 380

MAX_VELOCITY = 50

MAX_ACCELERATION = 600

[AXIS_Y]

MIN_LIMIT = -230

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 600

[AXIS_Z]

MIN_LIMIT = -200

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 125

[JOINT_0]

AXIS = X

MIN_LIMIT = 0

MAX_LIMIT = 380

MAX_VELOCITY = 50

MAX_ACCELERATION = 400

TYPE = LINEAR

SCALE = 1600

STEPGEN_MAX_VEL = 60

STEPGEN_MAX_ACC = 720

FERROR = 0.0051

MIN_FERROR = 0.0025

DIRSETUP = 6000

DIRHOLD = 6000

STEPLEN = 3000

STEPSPACE = 3000

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00013

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = .1

HOME_SEARCH_VEL = -10

HOME_LATCH_VEL = -1

HOME_SEQUENCE = 1

HOME_USE_INDEX = False

HOME_IGNORE_LIMITS = False

[JOINT_1]

AXIS = Y

MIN_LIMIT = -230

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 600

TYPE = LINEAR

SCALE = 1600

STEPGEN_MAX_VEL = 60

STEPGEN_MAX_ACC = 720

FERROR = 0.0051

MIN_FERROR = 0.0025

DIRSETUP = 6000

DIRHOLD = 6000

STEPLEN = 3000

STEPSPACE = 3000

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00013

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = .1

HOME_SEARCH_VEL = 10

HOME_LATCH_VEL = 1

HOME_SEQUENCE = 2

HOME_USE_INDEX = False

HOME_IGNORE_LIMITS = False

[JOINT_2]

AXIS = Z

MIN_LIMIT = -200

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 125

TYPE = LINEAR

SCALE = 1000

STEPGEN_MAX_VEL = 60

STEPGEN_MAX_ACC = 150

FERROR = 0.0051

MIN_FERROR = 0.0025

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 10000

STEPSPACE = 10000

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00013

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = -.1

HOME_SEARCH_VEL = 10

HOME_LATCH_VEL = 1

HOME_SEQUENCE = 0

HOME_USE_INDEX = False

HOME_IGNORE_LIMITS = False

[SPINDLE]

SPINDLE_TYPE = closedLoop

SCALE = 10000

MAX_RPM = 2500

MIN_RPM = 0

STEPGEN_MAXVEL = 40

STEPGEN_MAX_ACCEL = 60

MAX_ERROR = .01

P = 50

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 2000.0

# these are in nanoseconds

DIRSETUP = 5000

DIRHOLD = 5000

STEPLEN = 2500

STEPSPACE = 2500

[INPUTS]

# DO NOT change the input text

INPUT_0 = Home

INPUT_JOINT_0 = 0

INPUT_1 = Home

INPUT_JOINT_1 = 1

INPUT_2 = Home

INPUT_JOINT_2 = 2

INPUT_3 = Select

INPUT_JOINT_3 = False

INPUT_4 = Select

INPUT_JOINT_4 = False

INPUT_5 = E-Stop In

INPUT_JOINT_5 = False

INPUT_6 = Home

INPUT_JOINT_6 = False

INPUT_7 = Select

INPUT_JOINT_7 = False

INPUT_8 = Select

INPUT_JOINT_8 = False

INPUT_9 = Select

INPUT_JOINT_9 = False

INPUT_10 = Select

INPUT_JOINT_10 = False

[OUTPUTS]

# DO NOT change the output text

OUTPUT_0 = Spindle CW

OUTPUT_1 = Spindle On

OUTPUT_2 = Spindle CCW

OUTPUT_3 = Select

OUTPUT_4 = Select

[OPTIONS]

MANUAL_TOOL_CHANGE = True

HALUI = False

PYVCP = False

GLADEVCP = False

LADDER = FalsePlease Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

- Posts: 17311

- Thank you received: 5037

2. if you are going to use a step/dir servo for a spindle, you don't really need PID at all,

you just set the stepgen velocity with commanded spindle RPM (with proper stepgen scaling)

3. You likely have a extremely high spindle RPM readout for 2 reasons, A: the encoder velocity pin is in RPS (= 60x RPM) newer LinuxCNC versions provide a velocity pin scaled in RPM, this should be used instead, lacking this the scale component would need to be used if you wanted to display encoder derived RPM

4. If you are using PWM and PID the tuning is chiefly done with FF0 = 1.00.

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 161

- Thank you received: 15

2. if you are going to use a step/dir servo for a spindle, you don't really need PID at all,

you just set the stepgen velocity with commanded spindle RPM (with proper stepgen scaling)

Yes you were correct. I was seeing 'scale' next to the stepgen output and abitrarily reading it as encoder scale.

I have the spindle working now in this mode and scaled correctly. I reduced the dir and pulse timings and I can get to the spindle speed I need and it seems to work fine; thanks for the pointer.

3. You likely have a extremely high spindle RPM readout for 2 reasons, A: the encoder velocity pin is in RPS (= 60x RPM) newer LinuxCNC versions provide a velocity pin scaled in RPM, this should be used instead, lacking this the scale component would need to be used if you wanted to display encoder derived RPM

I think I need to use the scale component here. I was reading the encoder pins on the HM2 in both RPS and RPM and neither was correct. Having sorted the speed and scaling though I can now say I am out by a factor of 10,000 which would seem to correspond to the quadrature count of my 2500 cpr encoder.

I tried to add the encoder but when I do again I get faults at start up. The 'loadrt' code is in my hal and references the number of encoders in my ini. This was set by the 7i96 config tool. If I addf encoder.update−counters as below from the manual then I need to add a thread for it to be sampled. Now my setup doesn't have a base thread which I would need, or something of a faster speed to the servo period, to attach this function to. I added a 'load rt' for base period just before the servo period in the hal and added 50000ns in the ini for it to reference. This threw me an error on start up.

From the manual:

FUNCTIONS

encoder.update−counters (no floating-point)

Does the actual counting, by sampling the encoder signals and decoding the quadrature waveforms. Must be called as frequently as possible, preferably twice as fast as the maximum desired count rate. Operates on all channels at once.

encoder.capture−position (uses floating point)

Captures the raw counts from update−counters and performs scaling and other necessary conversion, handles counter rollover, etc. Can (and should) be called less frequently than update−counters. Operates on all channels at once.

This is also referenced in the wiki

# --------------------------------------------------

# Closed Loop Spindle Control

# --------------------------------------------------

# Initialize the encoder (spindle)

loadrt encoder num_chan=1

addf encoder.update-counters base-thread

addf encoder.capture-position servo-thread

setp encoder.0.position-scale 1

setp encoder.0.counter-mode 1

# Initialize the PID

loadrt pid num_chan=1

addf pid.0.do-pid-calcs servo-thread

setp pid.0.Pgain 0

setp pid.0.Igain 1

setp pid.0.Dgain 1

setp pid.0.maxoutput 4000

# Initialize the pwmgen

loadrt pwmgen output_type=0

addf pwmgen.update servo-thread

addf pwmgen.make-pulses base-thread

setp pwmgen.0.pwm-freq 1000.0

setp pwmgen.0.scale 4000

setp pwmgen.0.dither-pwm true

# Initialize the scale

# (This is used to scale the encoder pulse to RPM)

# (In my case, i have 1 ppr so it is scaled by 60)

loadrt scale count=1

addf scale.0 servo-thread

setp scale.0.gain 60

# Initialize the sum2

loadrt sum2 count=1

addf sum2.0 servo-thread

# Attach the motion.spindle-on to enable the pwmgen and the pid

net spindle_enable motion.spindle-on => pwmgen.0.enable => pid.0.enable

# Attach the encoder to the parallel port pin

net parport_15_in parport.0.pin-15-in => encoder.0.phase-A => encoder.0.phase-Z

# Attach the encoder to the motion and the scale

net spindle_rev_count encoder.0.position => motion.spindle-revs

net spindle_index_enable encoder.0.index-enable <=> motion.spindle-index-enable

net encoder_raw_velocity encoder.0.velocity => scale.0.in

# Attach the pid to the scale, motion, and sum

net pid_feedback pid.0.feedback <= motion.spindle-speed-in <= scale.0.out

net pid_command pid.0.command <= motion.spindle-speed-out => sum2.0.in0

net pid_output pid.0.output => sum2.0.in1

# Attach the pwmgen to the sum and the parallel port

net pwmgen_value pwmgen.0.value <= sum2.0.out

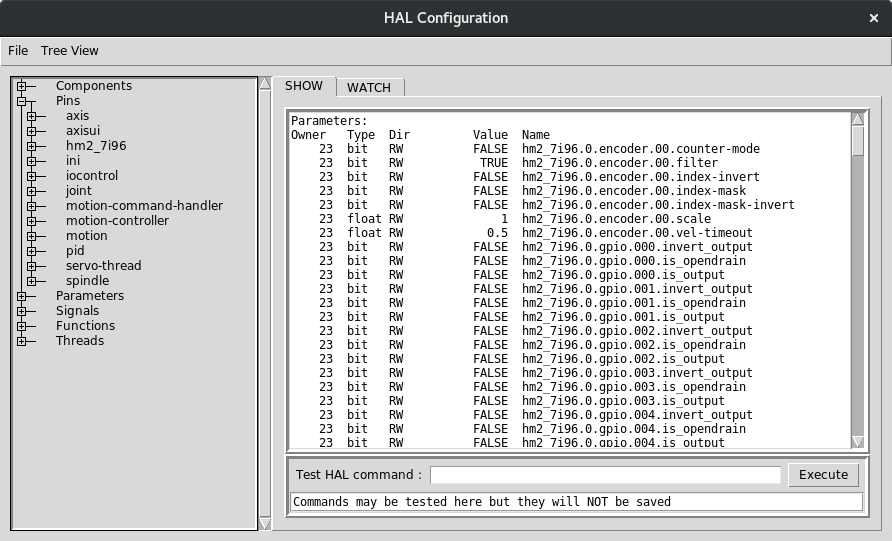

net pwmgen_out pwmgen.0.pwm => parport.0.pin-16-outLooking further I found in my parameters this. which says my encoder scale is 1. As it should be 10,000 then this seems the likely culprit to my ills. Looking through the hal though this parameter is not mentioned anywhere and isn't referenced in ini file either.

Managed to figure it out. After a few tries of setting it and it failing I managed to figure it out and set the parameter.

To help others my failings came from adding an = sign between the setp instance name... and the value.

My encoder now reads the right speed my final hal and ini are below in case anyone else has this problem.

# This file was created with the 7i96 Wizard on Nov 21 2019 15:52:11

# If you make changes to this file DO NOT run the configuration tool again!

# This file will be replaced with a new file if you do!

# kinematics

loadrt [KINS]KINEMATICS

# motion controller

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

# standard components

loadrt pid num_chan=4

# hostmot2 driver

loadrt hostmot2

loadrt [HOSTMOT2](DRIVER) board_ip=[HOSTMOT2](IPADDRESS) config="num_encoders=1 num_stepgens=[HOSTMOT2](STEPGENS)"sserial_port_0=[HOSTMOT2](SSERIAL_PORT)pwm_gens=1

setp hm2_[HOSTMOT2](BOARD).0.watchdog.timeout_ns 25000000

#/////////////////////////////////

# THREADS

#///////////////////////////////

addf hm2_[HOSTMOT2](BOARD).0.read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

setp hm2_[HOSTMOT2](BOARD).0.dpll.01.timer-us -100

setp hm2_[HOSTMOT2](BOARD).0.stepgen.timer-number 1

addf pid.0.do-pid-calcs servo-thread

addf pid.1.do-pid-calcs servo-thread

addf pid.2.do-pid-calcs servo-thread

addf pid.3.do-pid-calcs servo-thread

addf hm2_[HOSTMOT2](BOARD).0.write servo-thread

setp hm2_7i96.0.encoder.00.scale 10000

#/////////////////////////////////////

# Joint 0

# axis enable chain

#/////////////////////////////////////

newsig emcmot.0.enable bit

sets emcmot.0.enable FALSE

net emcmot.0.enable <= joint.0.amp-enable-out

net emcmot.0.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.00.enable pid.0.enable

# position command and feedback

net emcmot.0.pos-cmd joint.0.motor-pos-cmd => pid.0.command

net motor.0.pos-fb <= hm2_[HOSTMOT2](BOARD).0.stepgen.00.position-fb joint.0.motor-pos-fb pid.0.feedback

net motor.0.command pid.0.output hm2_[HOSTMOT2](BOARD).0.stepgen.00.velocity-cmd

setp pid.0.error-previous-target true

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.dirsetup [JOINT_0]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.dirhold [JOINT_0]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.steplen [JOINT_0]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.stepspace [JOINT_0]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.position-scale [JOINT_0]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.maxvel [JOINT_0]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.maxaccel [JOINT_0]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.00.control-type 1

setp pid.0.Pgain [JOINT_0]P

setp pid.0.Igain [JOINT_0]I

setp pid.0.Dgain [JOINT_0]D

setp pid.0.bias [JOINT_0]BIAS

setp pid.0.FF0 [JOINT_0]FF0

setp pid.0.FF1 [JOINT_0]FF1

setp pid.0.FF2 [JOINT_0]FF2

setp pid.0.deadband [JOINT_0]DEADBAND

setp pid.0.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.0.maxerror [JOINT_0]MAX_ERROR

#///////////////////////////////////

# Joint 1

# axis enable chain

#////////////////////////////////////

newsig emcmot.1.enable bit

sets emcmot.1.enable FALSE

net emcmot.1.enable <= joint.1.amp-enable-out

net emcmot.1.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.01.enable pid.1.enable

# position command and feedback

net emcmot.1.pos-cmd joint.1.motor-pos-cmd => pid.1.command

net motor.1.pos-fb <= hm2_[HOSTMOT2](BOARD).0.stepgen.01.position-fb joint.1.motor-pos-fb pid.1.feedback

net motor.1.command pid.1.output hm2_[HOSTMOT2](BOARD).0.stepgen.01.velocity-cmd

setp pid.1.error-previous-target true

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.dirhold [JOINT_1]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.steplen [JOINT_1]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.stepspace [JOINT_1]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.position-scale [JOINT_1]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.maxvel [JOINT_1]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.maxaccel [JOINT_1]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.01.control-type 1

setp pid.1.Pgain [JOINT_1]P

setp pid.1.Igain [JOINT_1]I

setp pid.1.Dgain [JOINT_1]D

setp pid.1.bias [JOINT_1]BIAS

setp pid.1.FF0 [JOINT_1]FF0

setp pid.1.FF1 [JOINT_1]FF1

setp pid.1.FF2 [JOINT_1]FF2

setp pid.1.deadband [JOINT_1]DEADBAND

setp pid.1.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.1.maxerror [JOINT_1]MAX_ERROR

#//////////////////////////

# Joint 2

# axis enable chain

#////////////////////////////

newsig emcmot.2.enable bit

sets emcmot.2.enable FALSE

net emcmot.2.enable <= joint.2.amp-enable-out

net emcmot.2.enable => hm2_[HOSTMOT2](BOARD).0.stepgen.02.enable pid.2.enable

# position command and feedback

net emcmot.2.pos-cmd joint.2.motor-pos-cmd => pid.2.command

net motor.2.pos-fb <= hm2_[HOSTMOT2](BOARD).0.stepgen.02.position-fb joint.2.motor-pos-fb pid.2.feedback

net motor.2.command pid.2.output hm2_[HOSTMOT2](BOARD).0.stepgen.02.velocity-cmd

setp pid.2.error-previous-target true

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.dirhold [JOINT_2]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.steplen [JOINT_2]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.stepspace [JOINT_2]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.position-scale [JOINT_2]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.maxvel [JOINT_2]STEPGEN_MAX_VEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.maxaccel [JOINT_2]STEPGEN_MAX_ACC

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.02.control-type 1

setp pid.2.Pgain [JOINT_2]P

setp pid.2.Igain [JOINT_2]I

setp pid.2.Dgain [JOINT_2]D

setp pid.2.bias [JOINT_2]BIAS

setp pid.2.FF0 [JOINT_2]FF0

setp pid.2.FF1 [JOINT_2]FF1

setp pid.2.FF2 [JOINT_2]FF2

setp pid.2.deadband [JOINT_2]DEADBAND

setp pid.2.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.2.maxerror [JOINT_2]MAX_ERROR

#//////////////////////

# Spindle

#/////////////////////

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.dirsetup [SPINDLE]DIRSETUP

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.dirhold [SPINDLE]DIRHOLD

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.steplen [SPINDLE]STEPLEN

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.stepspace [SPINDLE]STEPSPACE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.position-scale [SPINDLE]SCALE

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.maxvel [SPINDLE]MAX_RPM

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.maxaccel [SPINDLE]STEPGEN_MAX_ACCEL

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.step_type 0

setp hm2_[HOSTMOT2](BOARD).0.stepgen.03.control-type 1

net spindle-enable => hm2_7i96.0.stepgen.03.enable

net speedsend spindle.0.speed-out => hm2_7i96.0.stepgen.03.velocity-cmd

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs hm2_7i96.0.encoder.00.velocity-rpm

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

#///////////////////////

# Standard I/O Block - EStop, Etc

# create a signal for the estop loopback. Connect to input 5

#///////////////////////////////

net estop-loop iocontrol.0.user-enable-out => iocontrol.0.emc-enable-in

net all-fault hm2_7i96.0.gpio.005.in <= joint.0.amp-fault-in

#////////////////////////////

#Homing

#/////////////////////////

net home-joint-1 joint.1.home-sw-in <= hm2_7i96.0.gpio.000.in

net home-joint-2 joint.2.home-sw-in <= hm2_7i96.0.gpio.001.in

net home-joint-0 joint.0.home-sw-in <= hm2_7i96.0.gpio.002.in

#/////////////////////////////////////

#probe on input 3

#////////////////////////////////

net probe-trigger hm2_7i96.0.gpio.003.in => motion.probe-input

# create signals for tool loading loopback

net tool-prep-loop iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

net tool-change-loop iocontrol.0.tool-change => iocontrol.0.tool-changed# This file was created with the 7i96 Wizard on Nov 21 2019 15:52:11

# Changes to most things are ok and will be read by the wizard

[EMC]

VERSION = 1.1

MACHINE = jools

DEBUG = 0x00000000

[HOSTMOT2]

DRIVER = hm2_eth

IPADDRESS = "10.10.10.10"

BOARD = 7i96

STEPGENS = 4

ENCODERS = 1

SSERIAL_PORT = 1

[DISPLAY]

# required NativeCAM item :

NCAM_DIR = ncam

# required NativeCAM item :

PROGRAM_PREFIX = ncam/scripts/

# required NativeCAM item :

GLADEVCP = -U --catalog=mill /usr/share/linuxcnc/aux_gladevcp/NativeCAM/ncam.ui

DISPLAY = axis

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = COMMANDED

MAX_FEED_OVERRIDE = 2.0

CYCLE_TIME = 0.1

INTRO_GRAPHIC = emc2.gif

INTRO_TIME = 0

OPEN_FILE = ""

INCREMENTS = 30, 20, 10, 5, 1, .5, .05, .02, .01

DEFAULT_LINEAR_VELOCITY = 14

EDITOR = GEDIT

[KINS]

KINEMATICS = trivkins coordinates=XYZ

JOINTS = 3

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

[RS274NGC]

# required NativeCAM item :

SUBROUTINE_PATH = ncam/my-stuff:ncam/lib/mill:ncam/lib/utilities

PARAMETER_FILE = jools.var

CENTER_ARC_RADIUS_TOLERANCE_MM = .001

[EMCMOT]

EMCMOT = motmod

SERVO_PERIOD = 1000000

BASE_PERIOD = 50000

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = metric

ANGULAR_UNITS = degree

MAX_LINEAR_VELOCITY = 300

NO_FORCE_HOMING = 0

ARC_BLEND_ENABLE = 1

ARC_BLEND_OPTIMIZATION_DEPTH = 50

[HAL]

HALFILE = jools.hal

HALFILE = io.hal

HALFILE = custom.hal

POSTGUI_HALFILE = postgui.hal

[HALUI]

[AXIS_X]

MIN_LIMIT = 0

MAX_LIMIT = 380

MAX_VELOCITY = 50

MAX_ACCELERATION = 600

[AXIS_Y]

MIN_LIMIT = -230

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 600

[AXIS_Z]

MIN_LIMIT = -200

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 125

[JOINT_0]

AXIS = X

MIN_LIMIT = 0

MAX_LIMIT = 380

MAX_VELOCITY = 50

MAX_ACCELERATION = 400

TYPE = LINEAR

SCALE = 1600

STEPGEN_MAX_VEL = 60

STEPGEN_MAX_ACC = 720

FERROR = 0.0051

MIN_FERROR = 0.0025

DIRSETUP = 6000

DIRHOLD = 6000

STEPLEN = 3000

STEPSPACE = 3000

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00013

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = .1

HOME_SEARCH_VEL = -10

HOME_LATCH_VEL = -1

HOME_SEQUENCE = 1

HOME_USE_INDEX = False

HOME_IGNORE_LIMITS = False

[JOINT_1]

AXIS = Y

MIN_LIMIT = -230

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 600

TYPE = LINEAR

SCALE = 1600

STEPGEN_MAX_VEL = 60

STEPGEN_MAX_ACC = 720

FERROR = 0.0051

MIN_FERROR = 0.0025

DIRSETUP = 6000

DIRHOLD = 6000

STEPLEN = 3000

STEPSPACE = 3000

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00013

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = .1

HOME_SEARCH_VEL = 10

HOME_LATCH_VEL = 1

HOME_SEQUENCE = 2

HOME_USE_INDEX = False

HOME_IGNORE_LIMITS = False

[JOINT_2]

AXIS = Z

MIN_LIMIT = -200

MAX_LIMIT = 0.5

MAX_VELOCITY = 50

MAX_ACCELERATION = 125

TYPE = LINEAR

SCALE = 1000

STEPGEN_MAX_VEL = 60

STEPGEN_MAX_ACC = 150

FERROR = 0.0051

MIN_FERROR = 0.0025

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 10000

STEPSPACE = 10000

DEADBAND = 0

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0.00013

BIAS = 0

MAX_OUTPUT = 0

MAX_ERROR = 0.0127

HOME = 0

HOME_OFFSET = -.1

HOME_SEARCH_VEL = 10

HOME_LATCH_VEL = 1

HOME_SEQUENCE = 0

HOME_USE_INDEX = False

HOME_IGNORE_LIMITS = False

[SPINDLE]

SPINDLE_TYPE = closedLoop

SCALE = 165

MAX_RPM = 2500

MIN_RPM = 0

STEPGEN_MAXVEL = 120

STEPGEN_MAX_ACCEL = 600

MAX_ERROR = .01

P = 50

I = 0.0

D = 0.0

FF0 = 0.0

FF1 = 0.0

FF2 = 0.0

BIAS = 0.0

DEADBAND = 0.0

MAX_OUTPUT = 2000.0

# these are in nanoseconds

DIRSETUP = 1000

DIRHOLD = 1000

STEPLEN = 1000

STEPSPACE = 1000

[INPUTS]

# DO NOT change the input text

INPUT_0 = Home

INPUT_JOINT_0 = 0

INPUT_1 = Home

INPUT_JOINT_1 = 1

INPUT_2 = Home

INPUT_JOINT_2 = 2

INPUT_3 = Select

INPUT_JOINT_3 = False

INPUT_4 = Select

INPUT_JOINT_4 = False

INPUT_5 = E-Stop In

INPUT_JOINT_5 = False

INPUT_6 = Home

INPUT_JOINT_6 = False

INPUT_7 = Select

INPUT_JOINT_7 = False

INPUT_8 = Select

INPUT_JOINT_8 = False

INPUT_9 = Select

INPUT_JOINT_9 = False

INPUT_10 = Select

INPUT_JOINT_10 = False

[OUTPUTS]

# DO NOT change the output text

OUTPUT_0 = Spindle CW

OUTPUT_1 = Spindle On

OUTPUT_2 = Spindle CCW

OUTPUT_3 = Select

OUTPUT_4 = Select

[OPTIONS]

MANUAL_TOOL_CHANGE = True

HALUI = False

PYVCP = False

GLADEVCP = False

LADDER = FalseThanks again peter for pointing me in the right direction.

Jools

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19640

- Thank you received: 4537

I tried to add the encoder but when I do again I get faults at start up. The 'loadrt' code is in my hal and references the number of encoders in my ini. This was set by the 7i96 config tool. If I addf encoder.update−counters as below from the manual then I need to add a thread for it to be sampled.

Are you trying to use a software encoder counter or the 7i96 hardware encoder counter?

Please Log in or Create an account to join the conversation.

- jools

-

Topic Author

Topic Author

- Offline

- Elite Member

-

- Posts: 161

- Thank you received: 15

I’ve sorted it now thanks.

It was on the 7i96 but the doc’s didn’t say how to do that in the spindle section. I got there in the end though using other pncconf generated Hal’s and hunting around.

Cheers

Jools

Please Log in or Create an account to join the conversation.