Servo Spindle motor encoder Mesa 7i76e

- andypugh

-

- Offline

- Moderator

-

- Posts: 19752

- Thank you received: 4584

Im thinking of using this encoder and connect it through a small timing belt to the spindle and not using the encoder of the motor anymore.

Should work. It has an index (not all do)

Though as Blazini showed, motor encoder + separate index can work well.

Please Log in or Create an account to join the conversation.

- Erikcnc

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 153

- Thank you received: 0

Im thinking of using this encoder and connect it through a small timing belt to the spindle and not using the encoder of the motor anymore.

Should work. It has an index (not all do)

Though as Blazini showed, motor encoder + separate index can work well.

How do i realize this? I got a bunch o NPN NO sensors to test it.

I have to make sure that the spindle rotates the right rpm.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

- Posts: 566

- Thank you received: 108

Attachments:

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

For that you'll have to use a known good device to either calculate the spindle speed or measure it. Assuming you have no optical tach or anything to measure the spindle directly......If you spin your motor exactly 1 rotation (just the motor), the number of counts from the encoder count pin should match it x4, so a 1000ppr encoder should show 4000 counts, in that case your "scale" in the .ini is 4000, and your velocity feedpack pin will represent rotations per second exactly at the motor, but this is not what you want unless your belt ratio is exactly 1:1.

Im thinking of using this encoder and connect it through a small timing belt to the spindle and not using the encoder of the motor anymore.

Should work. It has an index (not all do)

Though as Blazini showed, motor encoder + separate index can work well.

How do i realize this? I got a bunch o NPN NO sensors to test it.

I have to make sure that the spindle rotates the right rpm.

Excuse any math mistakes, I'm writing this off the top of my head, I'll use the 1000ppr as an example....

Since you are not using a timing belt you should spin your spindle by hand and let it drive your motor then you can estimate the difference, how accurate you get is all in how thorough you are. Spin the spindle exactly 1 time and look at how many counts feed back from the motor, if you get 2500 counts, then divide 2500 into 4000 and you get 0.625. Now if LinuxCNC is driving your motor based on the encoder feedback then you want to leave your hm2.7i76e.......encoder.scale pin at 4000. Use the scale hal component with the gain pin set at 0.625 to feed back into motion.spindle−speed−in pin. You also need to use another scale component to scale the position pin the exact same amount into the motion.spindle−revs pin. Now your spindle speed/position requirements are satisfied for LinuxCNC.

To make the index work when your motor is not 1:1 with the spindle exactly, disconnect the index pin in hal and physically, you don't need it. Use the NPN prox switch with the signal wire tied into the 7i76e's encoder index input. then connect the motion.spindle−index−enable pin to the 7i76e......encoder.index-enable hal pin. This works because the spindle index prox is still resetting the position pin on the 7i76e at a rate that will roughly equal "1" to motion since it is scaled to do so. in order to use a Prox in the 7i76e's encoder index it has to either be NPN or 5v PNP, do not use a higher voltage prox with the encoder index unless it is NPN and shares common with the 7i76e's logic side..

Please Log in or Create an account to join the conversation.

- blazini36

- Offline

- Platinum Member

-

- Posts: 972

- Thank you received: 167

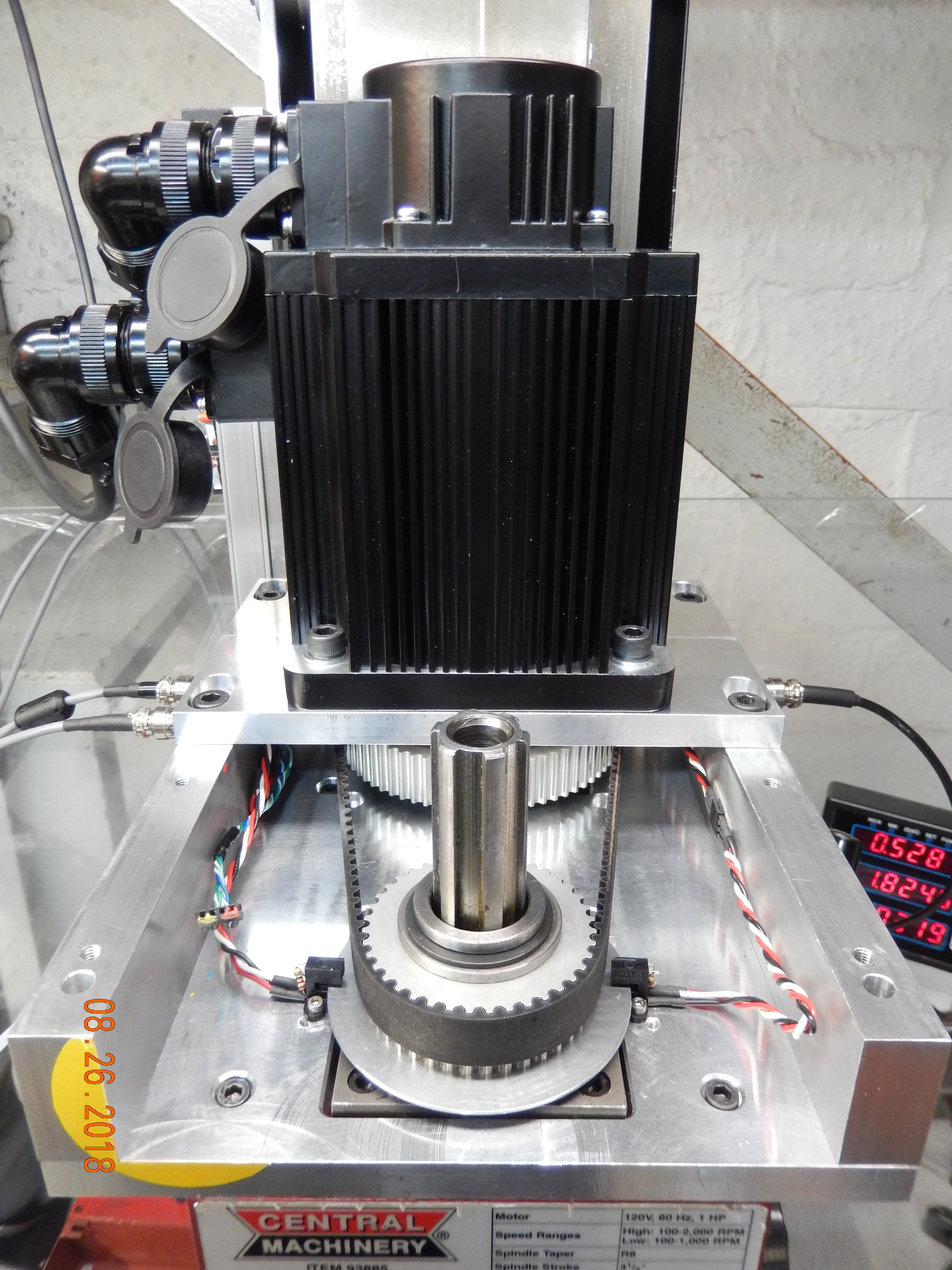

You could make that work. If it is geared 1:1 you can use the A/B/Z signals right from the encoder. On my mill I used the A/B signals that my spindle servo motor drive outputs and added a separate index signal to the spindle. This is because the spindle motor is geared 1:1.8. You will actually see two pickups for the index signal/ This is because the second one drives the a DRO that I also have on the mill.

Is that a 1kw motor? What kind of speed do you get out of that setup? I went with the 750w because it was the largest 5k rpm motor DMM had, figured I'd stick with the 2 step belt setup to get good torque upto 2500rpms and still be able to run upto 5k in high range. I really can't complain at all with this setup for this size mill, I haven't stalled the spindle yet.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

- Posts: 566

- Thank you received: 108

Is that a 1kw motor? What kind of speed do you get out of that setup? I went with the 750w because it was the largest 5k rpm motor DMM had, figured I'd stick with the 2 step belt setup to get good torque upto 2500rpms and still be able to run upto 5k in high range. I really can't complain at all with this setup for this size mill, I haven't stalled the spindle yet.

It is the 1.8kw. Max motor speed is 3000 and I have it geared 1:1.8 for a 5400 rpm spindle speed. I have run it as slow as 150 rpm for some slit sawing. I saw another fellow that had his geared 1:2 for 6K top speed. I am getting good torque. The biggest endmill I use is 1/2 inch. I am able to do rigid tapping at 500 rpm. I could go faster but I don't need the extra excitement and drama. I have a second 24k water cooled spindle mounted on the mill for engraving and micro machining or anytime I want to do a lot of cutting with a 1/8 or smaller bit.

Please Log in or Create an account to join the conversation.

- Erikcnc

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 153

- Thank you received: 0

Yumo COM-11102 Encoder 1024 P/R

Today i installed it and it works perfectly. one resolution is the same as the encoder counts. 1024

two issues.

#1 Spindle-at-speed. while it should be at the right rpm, spindle at speed signal keeps red. at a program it waits.

#2 the rpm is not perfectly stable. it changes somewhere between 990 and 1008 as far i can see while it should be 1000.

any suggestions?

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17483

- Thank you received: 5108

so has a settable tolerance (say +-10%)

Displayed speed will always have some variation, this variation is made worse

by the fact that is the calculated speed from the last millisecond. The flicker in the displayed speed is normally fixed by filtering it with the low pass filter

which averages the noise to give a more stable display

Please Log in or Create an account to join the conversation.

- Erikcnc

-

Topic Author

Topic Author

- Offline

- Premium Member

-

- Posts: 153

- Thank you received: 0

Typically spindle at speed is driven by a "near" component

so has a settable tolerance (say +-10%)

Displayed speed will always have some variation, this variation is made worse

by the fact that is the calculated speed from the last millisecond. The flicker in the displayed speed is normally fixed by filtering it with the low pass filter

which averages the noise to give a more stable display

i got in my hal file near.0.scale 1.50 now, still no green light.

also near.0.difference value is 3.333333

Maybe i am missing something.

lowpass.spindle.gain is set to 1.50

correct me if im doing wrong.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

- Posts: 17483

- Thank you received: 5108

Please Log in or Create an account to join the conversation.