Lathe threading random start

- DEVILHUNTER

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 10

When I perform a G76 cycle, the machine does all it should do, but the threads looks weird, like each pass started in a random position. At first, after configuring the encoder in stepconfig I found the Index was inverted and that made sense, but after inverting the signal it still looked weird.

Got a couple of parts that looked like buttress thread and thought that I may have the compound angle parameter wrong (Q), since I was doing OD thread with an ID tool going backwards. But still did not work either with Q30, Q0 or Q-30. Found somebody with a similar looking issue:

www.forum.linuxcnc.org/38-general-linuxc...ions/38627-g76-issue

Then added the "near" component to the spindle speed to activate the index-enable. Althought it shoulnd't be needed as the threading was starting, I got even more random thread starts.

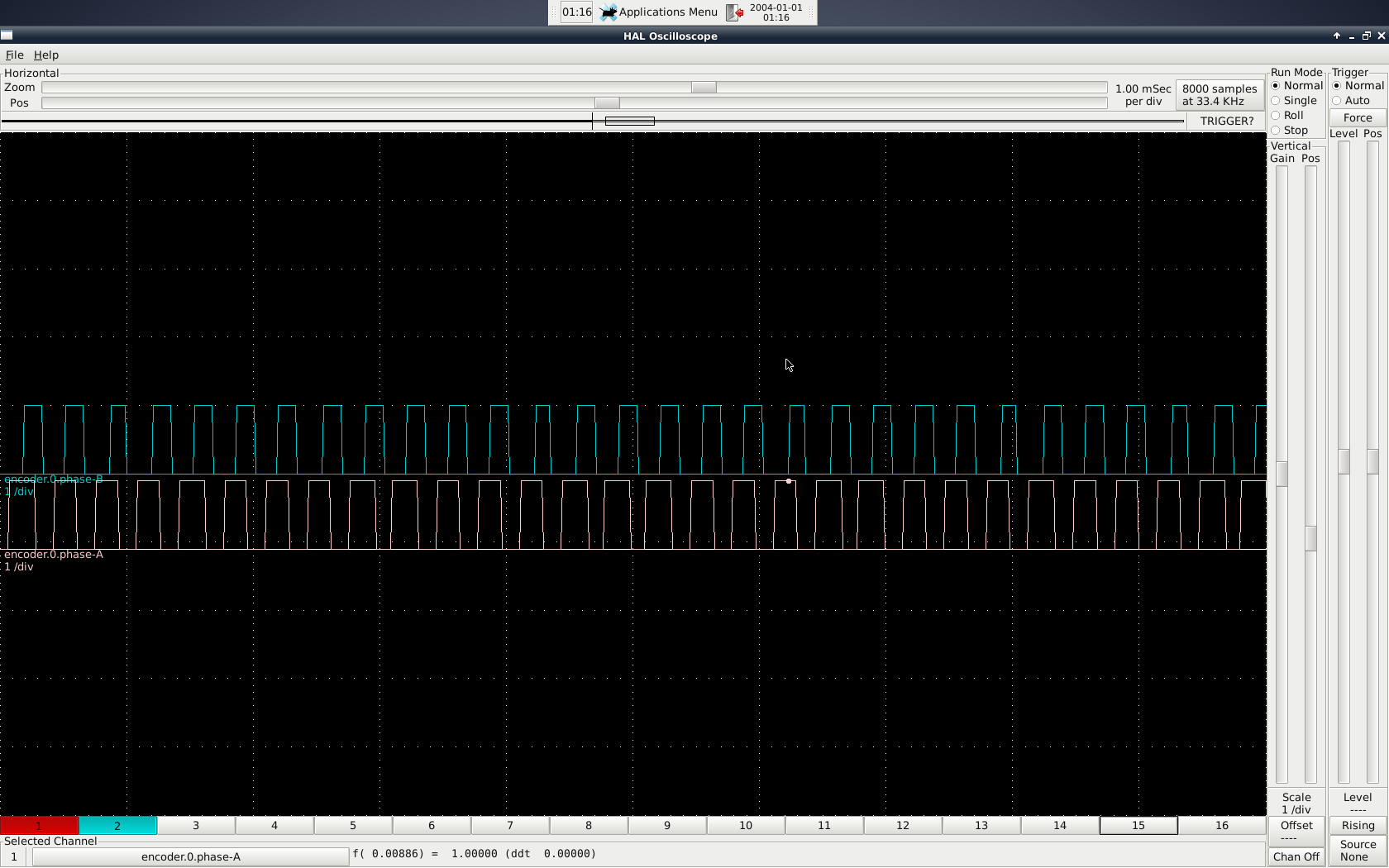

I'm using LinuxCNC 2.7.14 on parallel port, not ideal but it's fast enough (400rpm at 360ppr) as I have not been able to update this old PC to a newer version. Have adjusted the encoder pots to get the cleanest A/B/Z signals and they look really great on the halscope, plus the pitch is perfect.

Don't think is backlash either, as it's always going in the same direction and would be compensated at thread start. Have also checked for noise in the Index signal, but looked perfect in halscope.

My last bullet will be to do try a "threading without index" component.

This is my HAL file:

loadrt trivkins

loadrt [EMCMOT]EMCMOT base_period_nsec=[EMCMOT]BASE_PERIOD servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[TRAJ]AXES

loadrt hal_parport cfg="0 out"

setp parport.0.reset-time 1000

loadrt stepgen step_type=0,0

loadrt encoder num_chan=1

loadrt abs names=abs.spindle

loadrt lowpass names=lowpass.spindle

loadrt scale names=scale.spindle

loadrt near

loadrt debounce cfg="6"

setp debounce.0.delay 100

addf parport.0.read base-thread

addf stepgen.make-pulses base-thread

addf encoder.update-counters base-thread

addf parport.0.write base-thread

addf parport.0.reset base-thread

addf scale.spindle servo-thread

addf abs.spindle servo-thread

addf lowpass.spindle servo-thread

addf near.0 servo-thread

addf stepgen.capture-position servo-thread

addf encoder.capture-position servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf stepgen.update-freq servo-thread

net spindle-cmd-rpm <= motion.spindle-speed-out

net spindle-cmd-rpm-abs <= motion.spindle-speed-out-abs

net spindle-cmd-rps <= motion.spindle-speed-out-rps

net spindle-cmd-rps-abs <= motion.spindle-speed-out-rps-abs

net spindle-at-speed => motion.spindle-at-speed

setp encoder.0.position-scale 1440.000000

net spindle-position encoder.0.position => motion.spindle-revs

net spindle-vel-fb-rps encoder.0.velocity => motion.spindle-speed-in

net spindle-index-enable encoder.0.index-enable <=> motion.spindle-index-enable

net spindle-phase-a encoder.0.phase-A

net spindle-phase-b encoder.0.phase-B

net spindle-index encoder.0.phase-Z

# ---Setup spindle at speed signals---

net spindle-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

#sets spindle-at-speed true

setp near.0.scale 1.250000

setp near.0.difference 0.000000

# Use ACTUAL spindle velocity from spindle encoder

# spindle-velocity bounces around so we filter it with lowpass

# spindle-velocity is signed so we use absolute component to remove sign

# ACTUAL velocity is in RPS not RPM so we scale it.

setp scale.spindle.gain 60

setp lowpass.spindle.gain 1.000000

net spindle-vel-fb-rps => scale.spindle.in

net spindle-fb-rpm scale.spindle.out => abs.spindle.in

net spindle-fb-rpm-abs abs.spindle.out => lowpass.spindle.in

net spindle-fb-rpm-abs-filtered lowpass.spindle.out

net xstep => parport.0.pin-02-out

setp parport.0.pin-02-out-reset 1

net xdir => parport.0.pin-03-out

net zstep => parport.0.pin-04-out

setp parport.0.pin-04-out-reset 1

net zdir => parport.0.pin-05-out

net spindle-phase-a <= parport.0.pin-10-in-not

net spindle-phase-b <= parport.0.pin-11-in

net spindle-index <= parport.0.pin-12-in-not

setp stepgen.0.position-scale [AXIS_0]SCALE

setp stepgen.0.steplen 1

setp stepgen.0.stepspace 0

setp stepgen.0.dirhold 35000

setp stepgen.0.dirsetup 35000

setp stepgen.0.maxaccel [AXIS_0]STEPGEN_MAXACCEL

net xpos-cmd axis.0.motor-pos-cmd => stepgen.0.position-cmd

net xpos-fb stepgen.0.position-fb => axis.0.motor-pos-fb

net xstep <= stepgen.0.step

net xdir <= stepgen.0.dir

net xenable axis.0.amp-enable-out => stepgen.0.enable

setp stepgen.1.position-scale [AXIS_2]SCALE

setp stepgen.1.steplen 1

setp stepgen.1.stepspace 0

setp stepgen.1.dirhold 35000

setp stepgen.1.dirsetup 35000

setp stepgen.1.maxaccel [AXIS_2]STEPGEN_MAXACCEL

net zpos-cmd axis.2.motor-pos-cmd => stepgen.1.position-cmd

net zpos-fb stepgen.1.position-fb => axis.2.motor-pos-fb

net zstep <= stepgen.1.step

net zdir <= stepgen.1.dir

net zenable axis.2.amp-enable-out => stepgen.1.enable

net estop-out <= iocontrol.0.user-enable-out

net estop-out => iocontrol.0.emc-enable-in

loadusr -W hal_manualtoolchange

net tool-change iocontrol.0.tool-change => hal_manualtoolchange.change

net tool-changed iocontrol.0.tool-changed <= hal_manualtoolchange.changed

net tool-number iocontrol.0.tool-prep-number => hal_manualtoolchange.number

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-preparedThanks to everyone!

Please Log in or Create an account to join the conversation.

- robh

- Offline

- Premium Member

-

- Posts: 102

- Thank you received: 22

thread at one spindle speed, then speed it up and see what happens if it starts to cut in a different place then you know its a encoder issue, just you have to figure out if its mechanical or electrical, and id guess more mechanical

Please Log in or Create an account to join the conversation.

- DEVILHUNTER

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 10

Decided to do some more checking. Put an indicator on the chuck jaw and rotated the spindle by hand one turn, then other turn backwards, until encoder.rawcounts in halmeter went back to 0. The indicator shows that did not went back to original position maybe by a couple of degrees. Encoder is 360ppr in quadrature so the error is bigger than the resolution, seems that I'm loosing a few counts.

I have tried duplicatin the base-period just in case I had some unexpected high jitter, also deleted the parport reset time, but again same result.

Funny thing is that it seems to loose steps always in the same direction, no matter what direction I rotate the spindle first. Anyways this error is small and does not fit the random start I'm getting, at least on the start of the thread.

I will check again the A/B sinals in halscope. Also will connect the encoder to the MESA 7i76e of my mill to discard problems either on the encoder or the lathe BOB.

Please Log in or Create an account to join the conversation.

- DEVILHUNTER

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 10

Also checked the halscope log. I can se how there is at least two readings per quadrature phase change so should be enough for LinuxCNC to read all encoder pulses.

Attachments:

Please Log in or Create an account to join the conversation.

- scotth

- Away

- Elite Member

-

- Posts: 243

- Thank you received: 61

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19664

- Thank you received: 4547

Please Log in or Create an account to join the conversation.

- DEVILHUNTER

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 10

Both encoder and spindle pulleys are made from the same CAD file. Belt is HTD and the pulleys are press fitted, so the relation is 1:1 for sure. Also checked again in halscope the shape of the index signal and I see a clean signal, evenly spaced and without noise.

Connected the encoder to my 7i76e and checked the movement with the comparator against the chuck jaw. Turned the spindle a few turns in one direction, reading the encoder rawcounts each turn. Then turned it back to 0. Still see some error in the numbers but not too much, a few counts.

This weekend I will connect everything to the 7i76e and do a fresh config on my mill computer with LCNC 2.8.0

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

- Posts: 20808

- Thank you received: 7091

That points to encoder interference or fault, do you have another encoder to test with?Turned the spindle a few turns in one direction, reading the encoder rawcounts each turn. Then turned it back to 0. Still see some error in the numbers but not too much, a few counts.

-

Had a new encoder, cheap china one, on one side it would count perfectly, on the other side the pulses would get shorter with speed on one chanel. Changed to another of the same make and model and it worked.

Caused plenty of head scratching.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19664

- Thank you received: 4547

Do 10 (or 20, or more) full turns and see if the error accumulates or is constant (and therefore due only to how accurately you can do a single turn)Connected the encoder to my 7i76e and checked the movement with the comparator against the chuck jaw. Turned the spindle a few turns in one direction, reading the encoder rawcounts each turn. Then turned it back to 0. Still see some error in the numbers but not too much, a few counts.

The error isn't by any chance 1000 v 1024 is it? Both are common.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19664

- Thank you received: 4547

Actually, forget that. The threading start doesn't depend on the scale at all, it all resets to index at the start of each pass.

Do 10 (or 20, or more) full turns and see if the error accumulates or is constant (and therefore due only to how accurately you can do a single turn)

The error isn't by any chance 1000 v 1024 is it? Both are common.

Please Log in or Create an account to join the conversation.