Way Oiler Lube Pump Example

- BigJohnT

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

04 May 2011 13:39 - 04 Dec 2017 11:43 #9584

by BigJohnT

Way Oiler Lube Pump Example was created by BigJohnT

This is the Way Oiler for my Hardinge. I use classicladder to give me a time on and time off for my pump. It is a pneumatic type of pump where you apply pressure for so many seconds to depress the piston then take the pressure off and the piston is moved by the spring to pump a squirt of oil. So anytime there is motion I start the oiling timer. This saves on excess oil being used like the old control did.

This is the code in my hal file.

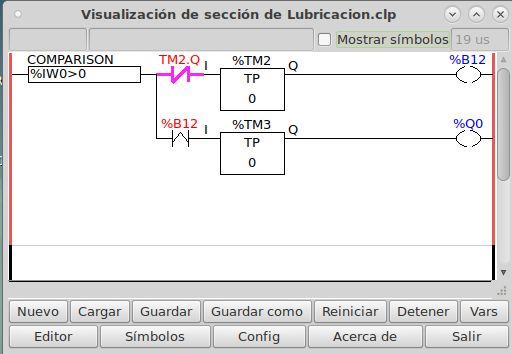

The ladder.

moving is classicladder.0.floatin-00

Oiler is classicladder.0.out-07

Names can be changed in the Symbol window

Because classicladder converts floats to s32 I had to multiply the motion.current-velocity by some big number as it is reported as 0-1 to get the compare to see the motion.

www.linuxcnc.org/docview/html/ladder_classic_ladder.html#r1_8

Timer 2 preset is 300 and timer 3 preset is 10.

The logic in pseudo-code is:

1 If moving > 0 the the comparison is true.

2 If timer 2 output is on the N/C contact is open and is false after the N/C contact.

2 If timer 2 output is off the N/C contact is closed and is true up to that point.

3 If timer 2 input is true start timer 2.

4 If timer 2 output is on turn on bit 12

lower branch

5 If a rising edge (just turned on) has been detected from bit 12 pulse timer 3 input for one scan.

6 If timer 3 input is on start timer 3

7 If timer 3 output is on turn on the oiler.

John

This is the code in my hal file.

# Way Oiler

setp mult2.2.in0 1000

net mult-vel mult2.2.in1 <= motion.current-vel

net in-motion classicladder.0.floatin-00 <= mult2.2.out

net oil-on hm2_5i20.0.gpio.045.out <= classicladder.0.out-07The ladder.

Attachment not found

moving is classicladder.0.floatin-00

Oiler is classicladder.0.out-07

Names can be changed in the Symbol window

Because classicladder converts floats to s32 I had to multiply the motion.current-velocity by some big number as it is reported as 0-1 to get the compare to see the motion.

www.linuxcnc.org/docview/html/ladder_classic_ladder.html#r1_8

Timer 2 preset is 300 and timer 3 preset is 10.

The logic in pseudo-code is:

1 If moving > 0 the the comparison is true.

2 If timer 2 output is on the N/C contact is open and is false after the N/C contact.

2 If timer 2 output is off the N/C contact is closed and is true up to that point.

3 If timer 2 input is true start timer 2.

4 If timer 2 output is on turn on bit 12

lower branch

5 If a rising edge (just turned on) has been detected from bit 12 pulse timer 3 input for one scan.

6 If timer 3 input is on start timer 3

7 If timer 3 output is on turn on the oiler.

John

Last edit: 04 Dec 2017 11:43 by BigJohnT.

The following user(s) said Thank You: virencq

Please Log in or Create an account to join the conversation.

- BigJohnT

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

04 May 2011 14:03 - 04 Dec 2017 11:40 #9585

by BigJohnT

Replied by BigJohnT on topic Re:Way Oiler Example

This shows the symbol window where you can change the names.

John

Attachment not found

John

Last edit: 04 Dec 2017 11:40 by BigJohnT.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

04 May 2011 14:26 - 04 Dec 2017 11:40 #9587

by BigJohnT

Replied by BigJohnT on topic Re:Way Oiler Example

This screen shot shows the machine in motion and TM2 timing down. The red part of the rung indicates that part is true.

John

Attachment not found

John

Last edit: 04 Dec 2017 11:40 by BigJohnT.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

Topic Author

Topic Author

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

04 May 2011 14:30 - 04 Dec 2017 11:41 #9588

by BigJohnT

Replied by BigJohnT on topic Re:Way Oiler Example

This screen shot shows the oiler output on as TM3 has not timed out yet. Notice that both timers get started at the same time and have the same count.

John

Attachment not found

John

Last edit: 04 Dec 2017 11:41 by BigJohnT.

The following user(s) said Thank You: jlviloria

Please Log in or Create an account to join the conversation.

- jlviloria

- Offline

- Elite Member

-

Less

More

- Posts: 161

- Thank you received: 9

19 Nov 2012 00:54 #26766

by jlviloria

Replied by jlviloria on topic Re:Way Oiler Example

John.

works perfect on my lathe cincinnati! thank you very much.

Jorge.

works perfect on my lathe cincinnati! thank you very much.

Jorge.

Please Log in or Create an account to join the conversation.

- COFHAL

- Offline

- Platinum Member

-

Less

More

- Posts: 414

- Thank you received: 52

17 Jun 2022 21:39 #245354

by COFHAL

Replied by COFHAL on topic Way Oiler Lube Pump Example

This is my HAL:

# LUBRICATION

loadrt mult2 count=1

addf mult2.0 servo-thread

setp mult2.0.in0 1000

net mult-vel mult2.0.in1 <= motion.current-vel

net in-motion classicladder.0.floatin-00 <= mult2.0.out

net oil-on hm2_7i96.0.ssr.00.out-00 <= classicladder.0.out-00

#net lube-ps-float-sw lube.pressuresw_floatsw classicladder.0.in-04 <= hm2_7i96.0.gpio.004.in

But I have not been able to connect the comparator, I have it at %IW0, but when I move any of the axes it does not change state, classicladder.0.floatin-00 always remains at 0, I do not know if my error is in comparing %IW0 as if off classicladder.0.floatin-00

# LUBRICATION

loadrt mult2 count=1

addf mult2.0 servo-thread

setp mult2.0.in0 1000

net mult-vel mult2.0.in1 <= motion.current-vel

net in-motion classicladder.0.floatin-00 <= mult2.0.out

net oil-on hm2_7i96.0.ssr.00.out-00 <= classicladder.0.out-00

#net lube-ps-float-sw lube.pressuresw_floatsw classicladder.0.in-04 <= hm2_7i96.0.gpio.004.in

But I have not been able to connect the comparator, I have it at %IW0, but when I move any of the axes it does not change state, classicladder.0.floatin-00 always remains at 0, I do not know if my error is in comparing %IW0 as if off classicladder.0.floatin-00

Attachments:

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4693

- Thank you received: 1438

08 Jul 2022 13:49 - 08 Jul 2022 13:59 #246861

by Todd Zuercher

Replied by Todd Zuercher on topic Way Oiler Lube Pump Example

In Classicladder the halpin "classicladder.0.floatin-00" is %IF0, not %IW0.

%IW0 would be the halpin "classicladder.0.s32in-00".

It is a little confusing since Classicladder doesn't really do floats internally, but it still has float pins externally. This saves having to convert halpins to S32, but you have to remember that all these floats are converted to S32 in CL and are seperate variables from the S32 word variables.

%IW0 would be the halpin "classicladder.0.s32in-00".

It is a little confusing since Classicladder doesn't really do floats internally, but it still has float pins externally. This saves having to convert halpins to S32, but you have to remember that all these floats are converted to S32 in CL and are seperate variables from the S32 word variables.

Last edit: 08 Jul 2022 13:59 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

Time to create page: 0.190 seconds