Schaublin 125-CNC retrofit.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

www.willhaben.at/iad/kaufen-und-verkaufe...schaublin-483941779/

Shame it didn't come up for sale earlier, as it appears in a similarly good mechanical condition as mine. Harry bought it with a partially complete Mach 3 / Stepper conversion, but was in the process of a Siemens Sinumerik conversion when life got in the way. Really nice guy, so if any of you are looking for a project, get it before some one else snaps it up.

Mark

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

Oh, the poor thing!with a partially complete Mach 3 / Stepper conversion,

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

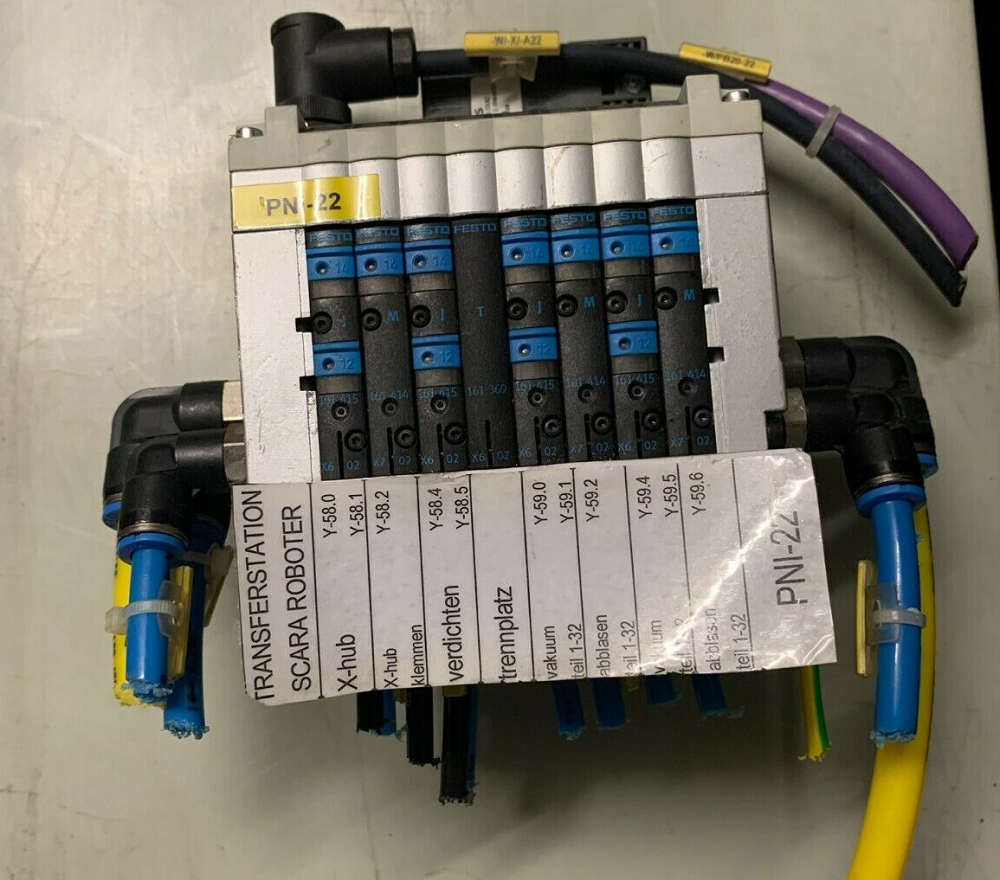

To advance that goal, I have bought this valve terminal...

I need six valves, and a separation between a single service with dry air and the rest lubricated. Also a mix of 2 way and four way valves (which Festo doesn't do, so it will be 5/3 and 3/2 valves). This module was on ebay germany and is the closest I could find with its divider module, mix of valve modules, endplates etc. This Festo CPV stuff is like advanced lego

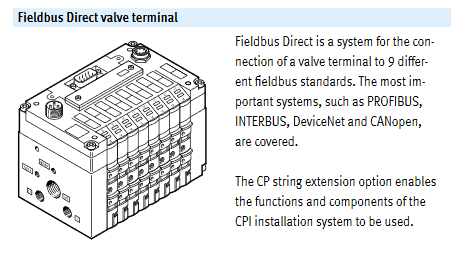

It comes with the Fieldbus electrical interface module which seems to support a few protocols.

I saw that there is a PyProfibus HAL comp in the github.

github.com/mbuesch/pyprofibus

The git hub has a dead link to pyprofibus hardware documentation

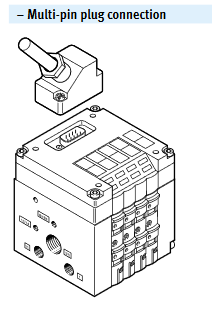

I have searched this forum for more information about this comp, and other than a link to the 130 page Ethercat thread, dont find any worked examples. Is there a simple way to control a Fieldbus device through mesa cards, and LinuxCNC with the pyprofibux comp? I dont see the lathe needing realtime control of it's pneumatics, as it all just stuff you use during set up. (Tool change, tailstock and collet clamping, coolant valve, backgear) Or should i just bite the bullet and buy a second terminal unit with a simple Multipol connector, and drive the individual valves with discrete wiring from Mesa outputs.

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19789

- Thank you received: 4605

I have searched this forum for more information about this comp, and other than a link to the 130 page Ethercat thread, dont find any worked examples.

Is there a simple way to control a Fieldbus device through mesa cards, and LinuxCNC with the pyprofibux comp?

Not that I can see. The driver seem to want to find a node in /dev/

github.com/mbuesch/pyprofibus/blob/maste...200s/pyprofibus.conf

And the Messa card UARTs etc are not accessed that way, generally.

It probably could be done, but it's probably not the easy way.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

Topic Author

Topic Author

- Offline

- Platinum Member

-

- Posts: 1542

- Thank you received: 572

www.ebay.at/itm/283951730912?ssPageName=...p2060353.m1438.l2649

The pinout is well documented in the festo manual:

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4649

- Thank you received: 2070

github.com/mbuesch/pyprofibus/blob/master/doc/hardware.rst

Using the Linux serial port is a supported way to connect pyprofibus to a Profibus network. On some boards it may only supports low baud rates of up to about 19200 baud. However that depends on the actual serial transceiver hardware. On certain embedded boards with flexible serial hardware, high baudrates such as 1.5 MBaud may also be possible.To run pyprofibus on serial port configure pyprofibus as follows:[PHY]

type=serial

dev=/dev/ttyS0

baud=19200

Please Log in or Create an account to join the conversation.