OLD Lathe conversion to a CNC

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17678

- Thank you received: 5170

15 Mar 2025 03:49 #323982

by PCW

Replied by PCW on topic OLD Lathe conversion to a CNC

What error do you get? Delayed sserial communications have no effect on Ethernet timing.

The following user(s) said Thank You: besriworld

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

15 Mar 2025 04:18 - 15 Mar 2025 04:47 #323986

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

Sometimes I get this warning:

hm2/m2_7198.0: Smart Serial port 0:Dolt not cleared from previous servo thread. Servo thread rate probably too fast. This message will not be

repeated, but the hm2_7198.0.sserial.O.fault-count pin will indicate if this is happening frequently

PS I'm wondering if I should try using an external LAN card in a PCI slot. What kind of PCIe x16 LAN card should I get?

hm2/m2_7198.0: Smart Serial port 0:Dolt not cleared from previous servo thread. Servo thread rate probably too fast. This message will not be

repeated, but the hm2_7198.0.sserial.O.fault-count pin will indicate if this is happening frequently

PS I'm wondering if I should try using an external LAN card in a PCI slot. What kind of PCIe x16 LAN card should I get?

Last edit: 15 Mar 2025 04:47 by besriworld.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17678

- Thank you received: 5170

15 Mar 2025 05:10 #323988

by PCW

Replied by PCW on topic OLD Lathe conversion to a CNC

Have you tried a 2 ms servo thread?

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

15 Mar 2025 07:10 #323993

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

I haven't tried it yet. But I think if this computer isn't good enough, I should try a new LAN card or even a new PC. I already have a hydraulic chuck and an additional servo motor waiting to be installed. The plan is to be able to mill on the lathe.  I want to have a fast servo thread

I want to have a fast servo thread

I can't explain why there are such delays in internet communication. In many places, I see mentions that a servo thread of up to 4 kHz is possible on network cards.So, should I try a new network card first?

I can't explain why there are such delays in internet communication. In many places, I see mentions that a servo thread of up to 4 kHz is possible on network cards.So, should I try a new network card first?

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

21 Apr 2025 18:40 - 21 Apr 2025 19:33 #326830

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

I'm not sure if this is the right place to ask about this issue, but I'm experiencing a strange and potentially dangerous problem.

I was running the same program all day without any issues. However, I had to stop the program halfway through due to a broken insert. First, I paused the program, then stopped the spindle, and finally stopped the G-code execution. The spindle was running with G96 (constant surface speed).

After fixing the issue, I reloaded the same G-code. But when the machine started moving with a G1 command, it moved at maximum speed right away. I couldn’t get it to execute G1 correctly until I restarted the LinuxCNC software.

Does anyone know what might be causing this? I was very lucky there was no damage.

I've also uploaded a video showing the problem.

Adding my configuration :

Is there anything wrong there?

I was running the same program all day without any issues. However, I had to stop the program halfway through due to a broken insert. First, I paused the program, then stopped the spindle, and finally stopped the G-code execution. The spindle was running with G96 (constant surface speed).

After fixing the issue, I reloaded the same G-code. But when the machine started moving with a G1 command, it moved at maximum speed right away. I couldn’t get it to execute G1 correctly until I restarted the LinuxCNC software.

Does anyone know what might be causing this? I was very lucky there was no damage.

I've also uploaded a video showing the problem.

Adding my configuration :

Is there anything wrong there?

Attachments:

Last edit: 21 Apr 2025 19:33 by besriworld.

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

22 Apr 2025 10:32 #326878

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

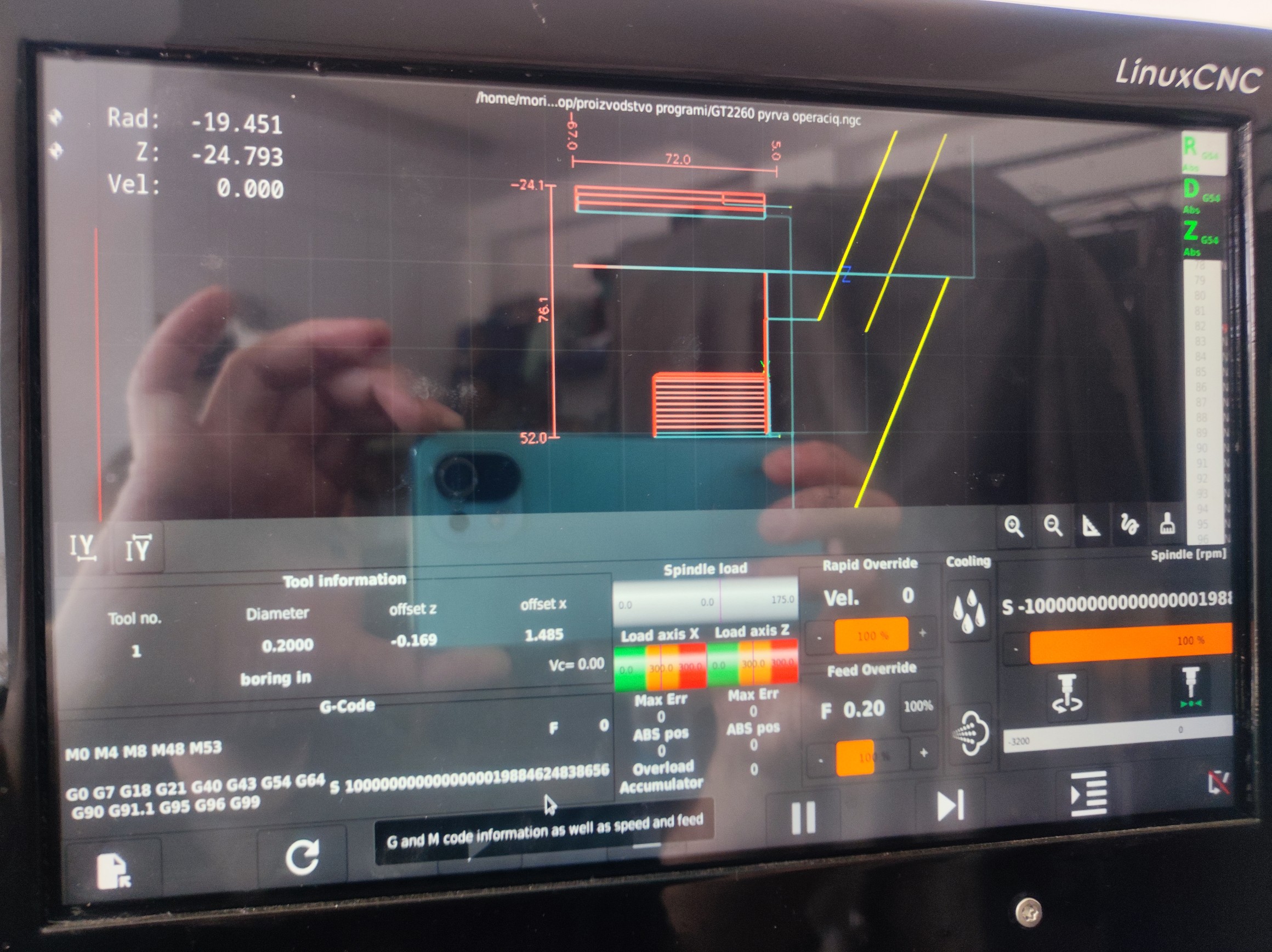

Today I reproduced the problem again. When running code with(constant surface speed), if I stop the spindle and then start it again, the spindle runs at 40–60% lower RPM than expected.If I resume the program at that point, the cutting feed does not adjust to the reduced spindle speed, which can be dangerous. After that, I stop the program, and Gmoccapy looks like it does in the attached screenshot.

Then, if I reload the program and start it from the beginning, the machine suddenly runs at a crazy high speed, and the graphical interface also shows the actual (high) speed.

G96Then, if I reload the program and start it from the beginning, the machine suddenly runs at a crazy high speed, and the graphical interface also shows the actual (high) speed.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19797

- Thank you received: 4606

22 Apr 2025 14:03 #326889

by andypugh

Replied by andypugh on topic OLD Lathe conversion to a CNC

This looks very odd. It looks like a gmoccapy glitch, but can you try the same sequence in:

1) The gmoccapy lathe sim config

2) The axis lathe sim config

And see if you see the same behaviour?

1) The gmoccapy lathe sim config

2) The axis lathe sim config

And see if you see the same behaviour?

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

22 Apr 2025 16:29 #326900

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

I guess there is a problem with the hall configuration. Today I broke 2 carbide inserts. After 10 made parts the axis started to move with a larger feed. But not too much, maybe 20-30% more. I tried in simulation but I don't know how to load my configuration into the simulation. There is no problem with the sample configurations.

Please Log in or Create an account to join the conversation.

- PCW

-

- Offline

- Moderator

-

Less

More

- Posts: 17678

- Thank you received: 5170

22 Apr 2025 21:52 #326923

by PCW

Replied by PCW on topic OLD Lathe conversion to a CNC

Not sure if it's related, but here is a similar issue, also using gmoccapy:

forum.linuxcnc.org/20-g-code/44739-g96-issue

forum.linuxcnc.org/20-g-code/44739-g96-issue

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 312

- Thank you received: 83

23 Apr 2025 06:22 #326934

by besriworld

Replied by besriworld on topic OLD Lathe conversion to a CNC

It seems that the two problems are related. I just have to try another gui

Please Log in or Create an account to join the conversation.

Moderators: piasdom

Time to create page: 0.229 seconds