7i76e Analog Spindle Control vs RS-485

- jpvonoy

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

23 Dec 2020 03:43 - 23 Dec 2020 03:44 #192919

by jpvonoy

7i76e Analog Spindle Control vs RS-485 was created by jpvonoy

I have a 7i76e with a Huanyang HY series VFD, connected to a Raspberry Pi 4, running a CNC router. I'm currently using the Analog Spindle Control from the 7i76e, but I realized I don't have spindle-at-speed functionality (no encoder).

I'm thinking of switching to RS-485 control. Can someone confirm that spindle speed feedback is provided over RS-485 to enable use of the spindle-at-speed signal?

What are the pros and cons of analog control through the 7i76e vs RS-485 control? Is the real-time aspect of analog control not important for a CNC router?

I'm thinking of switching to RS-485 control. Can someone confirm that spindle speed feedback is provided over RS-485 to enable use of the spindle-at-speed signal?

What are the pros and cons of analog control through the 7i76e vs RS-485 control? Is the real-time aspect of analog control not important for a CNC router?

Last edit: 23 Dec 2020 03:44 by jpvonoy. Reason: I wanted to be notified of replies

Please Log in or Create an account to join the conversation.

- chris@cnc

- Offline

- Platinum Member

-

Less

More

- Posts: 529

- Thank you received: 140

23 Dec 2020 17:58 - 23 Dec 2020 18:01 #192990

by chris@cnc

Replied by chris@cnc on topic 7i76e Analog Spindle Control vs RS-485

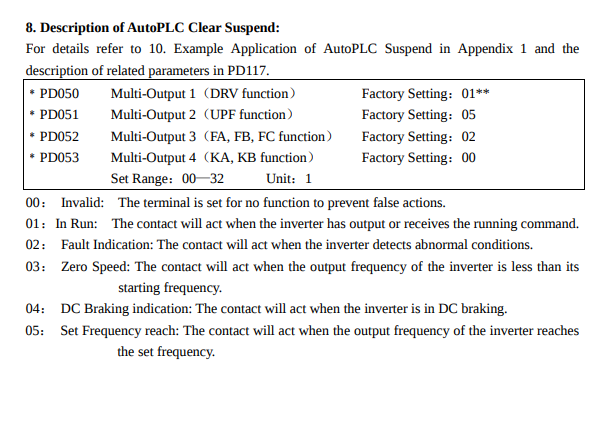

You have on your VDF a multi-output function. Adjust parameter by table and you have a spindle at speed signal or spindel lost speed signal. There are some more in manual...

Not necessary switch to sserial. But of course this is pretty cool and you can adjust some more and have life health information. But i can not adjust it.

Not necessary switch to sserial. But of course this is pretty cool and you can adjust some more and have life health information. But i can not adjust it.

Attachments:

Last edit: 23 Dec 2020 18:01 by chris@cnc.

Please Log in or Create an account to join the conversation.

- jpvonoy

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

24 Dec 2020 16:03 #193128

by jpvonoy

Replied by jpvonoy on topic 7i76e Analog Spindle Control vs RS-485

Thanks chris@cnc. That's good news. I'll try wiring up one or more of those outputs from the VFD.

If anyone else has any input, I'm still curious just for the sake of learning, if there are any pros/cons of using RS-485 vs the 7i76e analog control.

If anyone else has any input, I'm still curious just for the sake of learning, if there are any pros/cons of using RS-485 vs the 7i76e analog control.

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

Less

More

- Posts: 4650

- Thank you received: 2077

24 Dec 2020 16:12 #193131

by Aciera

Replied by Aciera on topic 7i76e Analog Spindle Control vs RS-485

You might actually be able to use the analog control you already have set up and use the RS485 just for reading the extra information you need from the vfd.

I found that, for some reason, using RS485 with my vfd was very slow for adjusting the spindle speed while machining.

I found that, for some reason, using RS485 with my vfd was very slow for adjusting the spindle speed while machining.

Please Log in or Create an account to join the conversation.

- jpvonoy

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 0

26 Dec 2020 19:28 #193247

by jpvonoy

That's good thought. I hadn't considered that option. Thanks for the input.

Replied by jpvonoy on topic 7i76e Analog Spindle Control vs RS-485

You might actually be able to use the analog control you already have set up and use the RS485 just for reading the extra information you need from the vfd.

I found that, for some reason, using RS485 with my vfd was very slow for adjusting the spindle speed while machining.

That's good thought. I hadn't considered that option. Thanks for the input.

Please Log in or Create an account to join the conversation.

Moderators: PCW, jmelson

Time to create page: 0.077 seconds