Compact Router

26 May 2014 17:07 - 26 May 2014 17:09 #47336

by Skippy1

Compact Router was created by Skippy1

Guys,

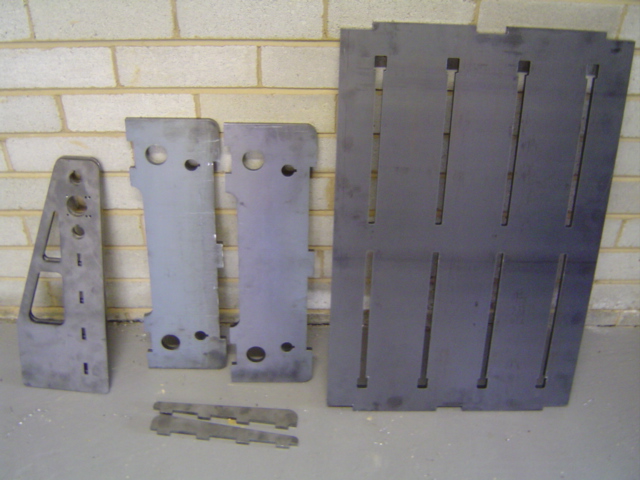

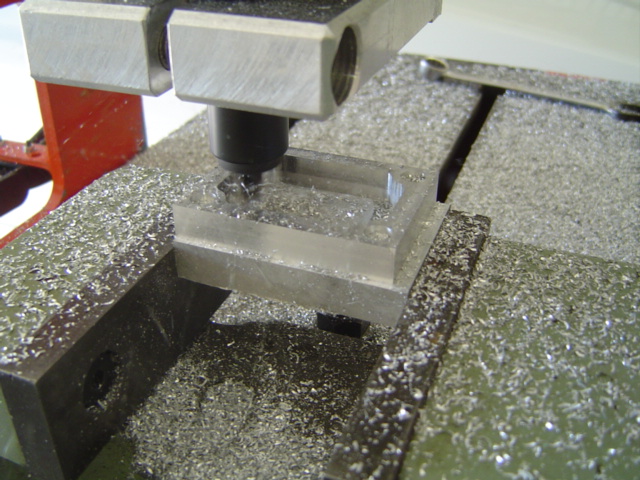

A few pictures of my home made router. What it lacks in size, it makes up for in rigidity and grunt. Frame made from 12 mm and 8 mm steel plate and 30 mm and 35 mm steel bars. Stepper motors, Parker ZL4 drives, Mesa 5i25 and 7i76 cards. I bit over-engineered for MDF and plastic, but has been a great project. A big thanks to LinuxCNC and the forum for making it happen so painlessly.

Cheers,

Steve

A few pictures of my home made router. What it lacks in size, it makes up for in rigidity and grunt. Frame made from 12 mm and 8 mm steel plate and 30 mm and 35 mm steel bars. Stepper motors, Parker ZL4 drives, Mesa 5i25 and 7i76 cards. I bit over-engineered for MDF and plastic, but has been a great project. A big thanks to LinuxCNC and the forum for making it happen so painlessly.

Cheers,

Steve

Last edit: 26 May 2014 17:09 by Skippy1.

The following user(s) said Thank You: ArcEye

Please Log in or Create an account to join the conversation.

26 May 2014 21:53 #47355

by ArcEye

Replied by ArcEye on topic Compact Router

Very nice build.

Absolutely nothing wrong with over-engineering, at least you know it will not flex

Absolutely nothing wrong with over-engineering, at least you know it will not flex

Please Log in or Create an account to join the conversation.

02 Jun 2014 20:25 #47627

by green751

Replied by green751 on topic Compact Router

Actually, I personally wouldn't call this over-engineered.

There are definite benefits to making any machine tool more massive (in the right way, obviously... depleted uranium bearings won't help), even if it only cuts "lightweight" materials like plastics and wood.

Elimination of flex is a big one, but so is vibration damping. Improved performance over the same machine built in lighter materials is likely because of both of those, or alternatively the ability to build a design that simply would not work in a less stiff material.

Whether this machine takes advantage of abilities granted by this metal I can't say, that depends on a lot of math I'm not inclined to do without a CAD model of the machine and a very detailed description of how it's used.

I will mention that while it's pretty looking, putting the machine on a cart like that may not be the best idea. If you don't have a solid static foundation for the machine when it's running you lose some of the advantages of using the heavier material, because it's basically decoupled from the biggest vibration absorber of them all... the planet.

If you want a simple test, try cutting a part with smooth curves, a lot of direction reversals, and some fine details at the fastest speed you can manage on the cart. Then put the mill on a nice even concrete floor and do the same. You'll probably be able to see the difference.

Erik

There are definite benefits to making any machine tool more massive (in the right way, obviously... depleted uranium bearings won't help), even if it only cuts "lightweight" materials like plastics and wood.

Elimination of flex is a big one, but so is vibration damping. Improved performance over the same machine built in lighter materials is likely because of both of those, or alternatively the ability to build a design that simply would not work in a less stiff material.

Whether this machine takes advantage of abilities granted by this metal I can't say, that depends on a lot of math I'm not inclined to do without a CAD model of the machine and a very detailed description of how it's used.

I will mention that while it's pretty looking, putting the machine on a cart like that may not be the best idea. If you don't have a solid static foundation for the machine when it's running you lose some of the advantages of using the heavier material, because it's basically decoupled from the biggest vibration absorber of them all... the planet.

If you want a simple test, try cutting a part with smooth curves, a lot of direction reversals, and some fine details at the fastest speed you can manage on the cart. Then put the mill on a nice even concrete floor and do the same. You'll probably be able to see the difference.

Erik

Please Log in or Create an account to join the conversation.

03 Jun 2014 06:13 #47643

by andypugh

You are probably right. But I can also visualise a situation where letting the whole machine move freely on a frictionless plain (inhabited by light inextensible strings, frictionless pulleys and spherical cows) would give better performance in machine coordinates.

Replied by andypugh on topic Compact Router

If you want a simple test, try cutting a part with smooth curves, a lot of direction reversals, and some fine details at the fastest speed you can manage on the cart. Then put the mill on a nice even concrete floor and do the same. You'll probably be able to see the difference.

You are probably right. But I can also visualise a situation where letting the whole machine move freely on a frictionless plain (inhabited by light inextensible strings, frictionless pulleys and spherical cows) would give better performance in machine coordinates.

Please Log in or Create an account to join the conversation.

03 Jun 2014 16:44 - 03 Jun 2014 17:34 #47650

by Skippy1

Replied by Skippy1 on topic Compact Router

Pretty good observations guys.

There is a difference between 'building' and 'engineering'. Perhaps I threw bulk, force, and over sized rails and trucks etc at this instead of looking at the static and dynamic forces and 'engineering' in a structure to resist the forces.

While the base has a 12mm top and ends, two 35mm longitudinal bars between the ends, (where the big washers and 12 mm bolts are), and two 8 x 50 mm longitudinal stringers bolted on the bottom between the ends. What is missing is anything that would stop the base racking or twisting under load, (bit like one end of a shipping tanker would twist in respect to the other end in big seas).

If it were a well engineered machine, it would benefit from a diagonal lattice of criss-crossing members welded under the top tying the end and sides bars holding the rails together. (I'm sure you are familiar with this pattern of reinforcing in castings of the beds of lathes.) I did consider getting a few diagonals plasma cut the same time as the other parts were done, (pretty easy to develop the outline on the CAD package), tack welding them into the base, and then having the 'table' machined to remove the resultant distortion. But even then, the 'little router' project was getting way out of control.

No doubt the cabinet moves under the router, especially when I roll it over an uneven concrete floor. As the router is bolted to the cabinet in the four corners, I bet I could grab a dial indicator, check, and find some movement in it depending on where it is sitting on the floor. If I was dead serious, It would have to be taken off the cabinet and permanently mounted it somewhere flat and level. But I prefer to wheel it outside, because it's such a messy little sod once it gets going.

And then there's the gantry, design-wise just plain wrong. Could you imagine the forces at work if you tried to anything serious with it? It could sure do with more depth and rigidity up the top behind the rails. But hey, no one in their right mind would use a gantry router for milling? Would they?

I'm now working on a conversion on a Harding HC lathe. (Now there's a solid little base to start with), but it will never be able to do big or heavy work. I suspect that when that's finished next year, that I'll start thinking about a proper CNC mill.

There is a difference between 'building' and 'engineering'. Perhaps I threw bulk, force, and over sized rails and trucks etc at this instead of looking at the static and dynamic forces and 'engineering' in a structure to resist the forces.

While the base has a 12mm top and ends, two 35mm longitudinal bars between the ends, (where the big washers and 12 mm bolts are), and two 8 x 50 mm longitudinal stringers bolted on the bottom between the ends. What is missing is anything that would stop the base racking or twisting under load, (bit like one end of a shipping tanker would twist in respect to the other end in big seas).

If it were a well engineered machine, it would benefit from a diagonal lattice of criss-crossing members welded under the top tying the end and sides bars holding the rails together. (I'm sure you are familiar with this pattern of reinforcing in castings of the beds of lathes.) I did consider getting a few diagonals plasma cut the same time as the other parts were done, (pretty easy to develop the outline on the CAD package), tack welding them into the base, and then having the 'table' machined to remove the resultant distortion. But even then, the 'little router' project was getting way out of control.

No doubt the cabinet moves under the router, especially when I roll it over an uneven concrete floor. As the router is bolted to the cabinet in the four corners, I bet I could grab a dial indicator, check, and find some movement in it depending on where it is sitting on the floor. If I was dead serious, It would have to be taken off the cabinet and permanently mounted it somewhere flat and level. But I prefer to wheel it outside, because it's such a messy little sod once it gets going.

And then there's the gantry, design-wise just plain wrong. Could you imagine the forces at work if you tried to anything serious with it? It could sure do with more depth and rigidity up the top behind the rails. But hey, no one in their right mind would use a gantry router for milling? Would they?

I'm now working on a conversion on a Harding HC lathe. (Now there's a solid little base to start with), but it will never be able to do big or heavy work. I suspect that when that's finished next year, that I'll start thinking about a proper CNC mill.

Last edit: 03 Jun 2014 17:34 by Skippy1.

Please Log in or Create an account to join the conversation.

03 Jun 2014 19:50 #47656

by green751

When you see the spherical cows, it's time to put down the pint, Andy

My point was just that if he went to the trouble to build a solid machine out of heavy materials he's working against himself by putting it on a relatively lightweight mobile cart.

I see that sort of thing a lot in the hobbyist CNC community... people build an expensive machine using extra heavy slides, precision ball screws, and cast precision plate metal. They go to extremes of work and technique to make sure all the corners are square, surfaces are flat and level, and materials are chosen to provide strength and vibration damping. They spend lots of time tweaking stepper drives and software to get the highest rapid speed and feed rate possible. Then they balance the whole thing on a crooked frame made from aluminum extrusion that thoroughly negates most of their extra time and money. Pet peeve, I suppose.

Replied by green751 on topic Compact Router

You are probably right. But I can also visualise a situation where letting the whole machine move freely on a frictionless plain (inhabited by light inextensible strings, frictionless pulleys and spherical cows) would give better performance in machine coordinates.

When you see the spherical cows, it's time to put down the pint, Andy

My point was just that if he went to the trouble to build a solid machine out of heavy materials he's working against himself by putting it on a relatively lightweight mobile cart.

I see that sort of thing a lot in the hobbyist CNC community... people build an expensive machine using extra heavy slides, precision ball screws, and cast precision plate metal. They go to extremes of work and technique to make sure all the corners are square, surfaces are flat and level, and materials are chosen to provide strength and vibration damping. They spend lots of time tweaking stepper drives and software to get the highest rapid speed and feed rate possible. Then they balance the whole thing on a crooked frame made from aluminum extrusion that thoroughly negates most of their extra time and money. Pet peeve, I suppose.

Please Log in or Create an account to join the conversation.

Moderators: cncbasher

Time to create page: 0.210 seconds