Homemade CNC Router for Oxy and Plasma

- nmnbento

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

05 Jun 2014 06:07 #47696

by nmnbento

Homemade CNC Router for Oxy and Plasma was created by nmnbento

Hi!

I'm from Portugal and I have some doubts and i like know if any one can help me.

I'm new in this area and i want make a router for me.

I make a diagram and i like know your feedback and if is possible do this router.

Hope I have some answers for my questions, and i will make a diy step by step whit photos as draws in the construction.

I'm from Portugal and I have some doubts and i like know if any one can help me.

I'm new in this area and i want make a router for me.

I make a diagram and i like know your feedback and if is possible do this router.

Hope I have some answers for my questions, and i will make a diy step by step whit photos as draws in the construction.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

05 Jun 2014 18:14 #47713

by BigJohnT

Replied by BigJohnT on topic Homemade CNC Router for Oxy and Plasma

Almost anything is possible with LinuxCNC...

A 12' gantry is going to be too heavy for a stepper to move at plasma cutting speeds.

When combining functions like plasma and router the forces that the drive system sees are very different as plasma has no load from cutting while a router does. Careful calculations are needed for the drive system.

JT

A 12' gantry is going to be too heavy for a stepper to move at plasma cutting speeds.

When combining functions like plasma and router the forces that the drive system sees are very different as plasma has no load from cutting while a router does. Careful calculations are needed for the drive system.

JT

The following user(s) said Thank You: nmnbento

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 23377

- Thank you received: 4966

05 Jun 2014 19:07 #47715

by andypugh

it might even be worth considering a lightweight fast gantry for plasma and a slower, stiffer one for routing.

(it might even be possible to run both at the same time)

My lathe/mill is set up a little like that. Depending on which configuration file I load different combinations of motors are active, and have different names.

Replied by andypugh on topic Homemade CNC Router for Oxy and Plasma

When combining functions like plasma and router the forces that the drive system sees are very different as plasma has no load from cutting while a router does

it might even be worth considering a lightweight fast gantry for plasma and a slower, stiffer one for routing.

(it might even be possible to run both at the same time)

My lathe/mill is set up a little like that. Depending on which configuration file I load different combinations of motors are active, and have different names.

The following user(s) said Thank You: nmnbento

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 7000

- Thank you received: 1176

05 Jun 2014 19:31 #47716

by BigJohnT

Yep with a machine that big you could park the unused gantry at the end...

JT

Replied by BigJohnT on topic Homemade CNC Router for Oxy and Plasma

When combining functions like plasma and router the forces that the drive system sees are very different as plasma has no load from cutting while a router does

it might even be worth considering a lightweight fast gantry for plasma and a slower, stiffer one for routing.

(it might even be possible to run both at the same time)

My lathe/mill is set up a little like that. Depending on which configuration file I load different combinations of motors are active, and have different names.

Yep with a machine that big you could park the unused gantry at the end...

JT

Please Log in or Create an account to join the conversation.

- nmnbento

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

05 Jun 2014 23:35 - 05 Jun 2014 23:41 #47723

by nmnbento

Hi!

I'm glad to heve some feedback from you.

I have a CNC with Oxy Fuel and Plasma but is a machine with more than 30 years.

There is here some photos.

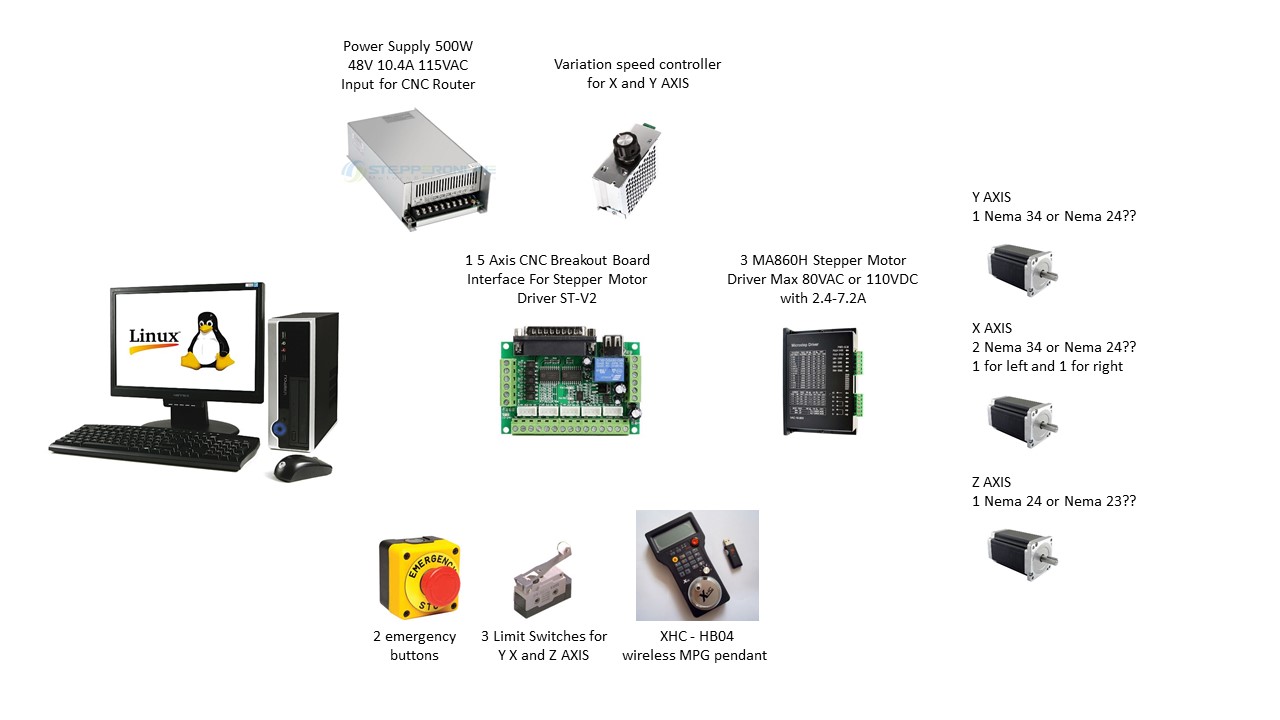

My idea is make one with this kit

www.omc-stepperonline.com/3axis-nema-34-...m708-ozin-p-187.html

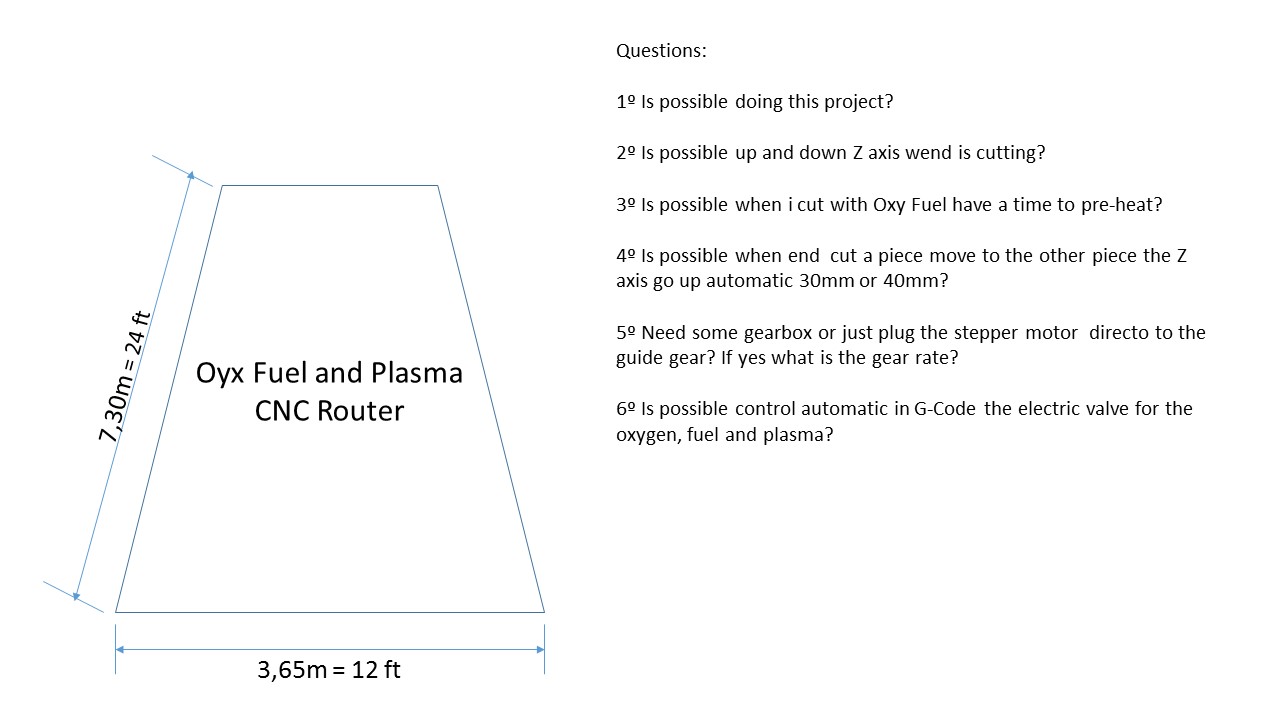

I need a table with this dimensions because I work with some suppliers who have sheet metal with 6.000m x 2.000m and bigger to make boilers like the Alstom. But I'm so bad in linux and CNC and i dont want wast more than $5.000 to $6.000 USD, becouse I bught 3 years ago, a waterjet machine and cust me more or less $250.000 USD is a TCI BP-A 3-2040-1 is a machine with 4.000m x 2.000m work area.

There is here some photos.

So I real need help from you the experters to buil a great machine at low cust if is possible.

Sorry for my english is so primitive and bad.

Replied by nmnbento on topic Homemade CNC Router for Oxy and Plasma

When combining functions like plasma and router the forces that the drive system sees are very different as plasma has no load from cutting while a router does

it might even be worth considering a lightweight fast gantry for plasma and a slower, stiffer one for routing.

(it might even be possible to run both at the same time)

My lathe/mill is set up a little like that. Depending on which configuration file I load different combinations of motors are active, and have different names.

Yep with a machine that big you could park the unused gantry at the end...

JT

Hi!

I'm glad to heve some feedback from you.

I have a CNC with Oxy Fuel and Plasma but is a machine with more than 30 years.

There is here some photos.

My idea is make one with this kit

www.omc-stepperonline.com/3axis-nema-34-...m708-ozin-p-187.html

I need a table with this dimensions because I work with some suppliers who have sheet metal with 6.000m x 2.000m and bigger to make boilers like the Alstom. But I'm so bad in linux and CNC and i dont want wast more than $5.000 to $6.000 USD, becouse I bught 3 years ago, a waterjet machine and cust me more or less $250.000 USD is a TCI BP-A 3-2040-1 is a machine with 4.000m x 2.000m work area.

There is here some photos.

So I real need help from you the experters to buil a great machine at low cust if is possible.

Sorry for my english is so primitive and bad.

Last edit: 05 Jun 2014 23:41 by nmnbento. Reason: pics dont upload

Please Log in or Create an account to join the conversation.

- Livemill

- Offline

- New Member

-

Less

More

- Posts: 3

- Thank you received: 1

06 Jun 2014 00:11 #47728

by Livemill

Replied by Livemill on topic Homemade CNC Router for Oxy and Plasma

hi i own about 4 of this and we are every evening in our IRC channel

firs this mashines can also be run on nema23 at 30:1 worm gear

i use the Leadshine 880A and the mesa 7i76 for controlling them at 78V

the mashines are able to move 6m/min 8hr long workshift with no single steplos

mashine is on Rack and pinion Maedler.de

frame is standard I-type steel pricise metal rolles in a U-steel YZ at 7,5m X

you can also use the SBR25 if it is more commen but not nessesury

its a gantry XY 2 steppers etch axis as YZ has more then 500kg

LOOKING forwaard to see you on the IRC freenode #Linuxcnc

about 120 people are there to give you live help

firs this mashines can also be run on nema23 at 30:1 worm gear

i use the Leadshine 880A and the mesa 7i76 for controlling them at 78V

the mashines are able to move 6m/min 8hr long workshift with no single steplos

mashine is on Rack and pinion Maedler.de

frame is standard I-type steel pricise metal rolles in a U-steel YZ at 7,5m X

you can also use the SBR25 if it is more commen but not nessesury

its a gantry XY 2 steppers etch axis as YZ has more then 500kg

LOOKING forwaard to see you on the IRC freenode #Linuxcnc

about 120 people are there to give you live help

Please Log in or Create an account to join the conversation.

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 702

- Thank you received: 139

06 Jun 2014 14:24 #47746

by emcPT

Replied by emcPT on topic Homemade CNC Router for Oxy and Plasma

Hello.

I am also in Portugal and I made a few machine with LinuxCNC so I can help you (also a plasma)

My last retrofit was a water jet machine, 4000bars.

Where are you located?

I can advise you with power supply's, motors, interfaces and so on.

In your initial post you placed Nema 23 or 24 motors.... I do not think so. You know that the environment of a plasma or oxicut is very bad (much metallic dust), and you need a machine to work (from what I saw in the pictures) not to play with, so you must think in a stronger solution.

I am also in Portugal and I made a few machine with LinuxCNC so I can help you (also a plasma)

My last retrofit was a water jet machine, 4000bars.

Where are you located?

I can advise you with power supply's, motors, interfaces and so on.

In your initial post you placed Nema 23 or 24 motors.... I do not think so. You know that the environment of a plasma or oxicut is very bad (much metallic dust), and you need a machine to work (from what I saw in the pictures) not to play with, so you must think in a stronger solution.

The following user(s) said Thank You: nmnbento

Please Log in or Create an account to join the conversation.

- nmnbento

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

06 Jun 2014 19:50 #47752

by nmnbento

Replied by nmnbento on topic Homemade CNC Router for Oxy and Plasma

Hi!

How are you Filipe? Nice to see you here.

I'm Nuno, work for Bruno in Setúbal

You have make a really, really good job in the waterjet machine.

We are trying make a Oxy Fuel and a Plasma machine in our workshop, i have already drawing machine in Autocad, but like i said, we dont know nothing about linuxcnc and configuration for the machine and many more...

Your software works really good, maybe we can make a deal, you make a basic software to Oxy Fuel and one for Plasma to convert DWG to G-Code

Thanks again for your feedback, keep doing greater works.

Abraços e bons trabalhos.

How are you Filipe? Nice to see you here.

I'm Nuno, work for Bruno in Setúbal

You have make a really, really good job in the waterjet machine.

We are trying make a Oxy Fuel and a Plasma machine in our workshop, i have already drawing machine in Autocad, but like i said, we dont know nothing about linuxcnc and configuration for the machine and many more...

Your software works really good, maybe we can make a deal, you make a basic software to Oxy Fuel and one for Plasma to convert DWG to G-Code

Thanks again for your feedback, keep doing greater works.

Abraços e bons trabalhos.

Please Log in or Create an account to join the conversation.

- emcPT

-

- Offline

- Platinum Member

-

Less

More

- Posts: 702

- Thank you received: 139

06 Jun 2014 20:54 #47756

by emcPT

Replied by emcPT on topic Homemade CNC Router for Oxy and Plasma

Thank you,

but still there is some issues in the waterJet:

- the deceleration issue that we though was made, but it is not yet correctly implemented.

- the control in Z (almost made)

Making a large machine (being your first machine) can be challenging with a lot of traps, but with the help of this forum, many things can be done.

Your initial approach (hardware selection) is quite wrong for a professional machine. Go for servos motors + drives and full encoder feedback.

Filipe

but still there is some issues in the waterJet:

- the deceleration issue that we though was made, but it is not yet correctly implemented.

- the control in Z (almost made)

Making a large machine (being your first machine) can be challenging with a lot of traps, but with the help of this forum, many things can be done.

Your initial approach (hardware selection) is quite wrong for a professional machine. Go for servos motors + drives and full encoder feedback.

Filipe

Please Log in or Create an account to join the conversation.

- nmnbento

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

06 Jun 2014 23:03 #47759

by nmnbento

Replied by nmnbento on topic Homemade CNC Router for Oxy and Plasma

Thanks again!

So what you advise me to the machine components/hardware?

What servo motors, breakout board, drivers, encoders???

Attention! This is a test machine and we don't want to spend a lot of money.

We don't want spending more than €1.250,00 in software and hardware (motors, driver, etc...)

So what you advise me to the machine components/hardware?

What servo motors, breakout board, drivers, encoders???

Attention! This is a test machine and we don't want to spend a lot of money.

We don't want spending more than €1.250,00 in software and hardware (motors, driver, etc...)

Please Log in or Create an account to join the conversation.

Time to create page: 0.282 seconds