My first cnc router of wood (MDF)

- Thomas

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 4

28 May 2016 21:31 - 29 May 2016 10:00 #75197

by Thomas

My first cnc router of wood (MDF) was created by Thomas

Hello all,

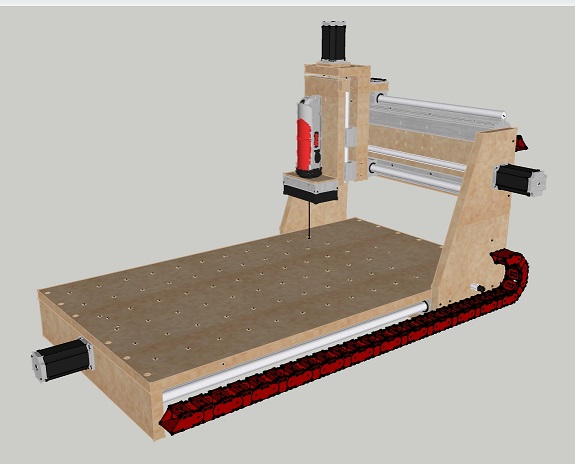

my first cnc router of wood (MDF) is almost finished. I used SketchUp to make the plans, this needs a lot of time, always when I thought its ready, I found something to make it better I watched a lot of YouTube movies and read different forums threads and so i build my own cnc router step by step.

I watched a lot of YouTube movies and read different forums threads and so i build my own cnc router step by step.

Technical specifications:

Dimensions: 1,169 mm long (46.02 inch), 760 mm wide (29.92 inch), 743 mm high (29,25 inch)

max. travel way: X-Axis 750 mm (29.53 inches); Y-Axis 450 mm (17.72 inches); Z-Axis 140 mm (5.51 inches)

used travel way: X-Axis 720 mm (28.35 inches); Y-Axis 420 mm (16.54 inches); Z-Axis 140 mm (5.51 inches)

supported rails 20mm (0.79 inches) on all axis

trapezoidal thread 16x4mm on all axis

reference switch: X- and Y-Axis (inductive proximity sensor switch); Z-Axis none

limit switch: Y-Axis 2; Z-Axis 1; (X-Axis same as reference switch)

Nema 23 stepper motors

Kress 1050 FME-1 milling motor

I'm using SketchUp v8.0 with SketchUCam and Estlcam8, and last but not least LinuxCNC

After 2 month engineer (including watching YouTube movies, reading forums, looking for software,...) and 2 month building I milled this week the first time . I was happy to see the machine working, but I also was frustrated about the noise. I live in a apartement and don't want to annoy my neighbors. So I started to build a box around my router and consequently I have to build a dust extraction too.

. I was happy to see the machine working, but I also was frustrated about the noise. I live in a apartement and don't want to annoy my neighbors. So I started to build a box around my router and consequently I have to build a dust extraction too.

The box is almost finished and only dampening materials / insulating is missing. Because the router is now in the box, I have to build the dust extraction, that's it for the next week.

Until next time....

greetings Thomas

my first cnc router of wood (MDF) is almost finished. I used SketchUp to make the plans, this needs a lot of time, always when I thought its ready, I found something to make it better

Technical specifications:

Dimensions: 1,169 mm long (46.02 inch), 760 mm wide (29.92 inch), 743 mm high (29,25 inch)

max. travel way: X-Axis 750 mm (29.53 inches); Y-Axis 450 mm (17.72 inches); Z-Axis 140 mm (5.51 inches)

used travel way: X-Axis 720 mm (28.35 inches); Y-Axis 420 mm (16.54 inches); Z-Axis 140 mm (5.51 inches)

supported rails 20mm (0.79 inches) on all axis

trapezoidal thread 16x4mm on all axis

reference switch: X- and Y-Axis (inductive proximity sensor switch); Z-Axis none

limit switch: Y-Axis 2; Z-Axis 1; (X-Axis same as reference switch)

Nema 23 stepper motors

Kress 1050 FME-1 milling motor

I'm using SketchUp v8.0 with SketchUCam and Estlcam8, and last but not least LinuxCNC

After 2 month engineer (including watching YouTube movies, reading forums, looking for software,...) and 2 month building I milled this week the first time

The box is almost finished and only dampening materials / insulating is missing. Because the router is now in the box, I have to build the dust extraction, that's it for the next week.

Until next time....

greetings Thomas

Last edit: 29 May 2016 10:00 by Thomas.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

28 May 2016 21:45 #75199

by BigJohnT

Replied by BigJohnT on topic My first cnc router of wood (MDF)

Looks good!

JT

JT

Please Log in or Create an account to join the conversation.

- lucky phil

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 0

28 May 2016 22:15 #75200

by lucky phil

Replied by lucky phil on topic My first cnc router of wood (MDF)

Great Work

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

28 May 2016 22:18 #75201

by tommylight

Replied by tommylight on topic My first cnc router of wood (MDF)

Neat !!!

As for the noise, you can change the spindle to a silent one, but as soon as it starts cutting the noise is back, so not much joy there.

Since you already have an enclosure in place, just get some sound dampening in, it might just get it to usable levels with the closed doors.

Regards,

Tom

As for the noise, you can change the spindle to a silent one, but as soon as it starts cutting the noise is back, so not much joy there.

Since you already have an enclosure in place, just get some sound dampening in, it might just get it to usable levels with the closed doors.

Regards,

Tom

Please Log in or Create an account to join the conversation.

- Thomas

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 4

29 May 2016 09:56 - 01 Jun 2016 20:07 #75216

by Thomas

Replied by Thomas on topic My first cnc router of wood (MDF)

Kress company documentation says sound pressure level 78 dB(A) and noise power level 89 dB(A). My phone app decibel meter says the same, 77 dB(A) without cutting and box open, 62 dB(A) without cutting and box closed.

@tommylight: you're right, the most noise is coming from milling, not the milling motor itself. I'll make some insulating / sound dampening materials in it the next days to reduce the noise.

motor on, box open:

motor on, box closed:

Tomorrow I'm at work again and when I've finished the work, I'll take a professional decibel meter with home to measure the noise.

Yesterday I ordered 2 energy chain at ebay, i need it because the machine can't move in the box without cable mess

My project the next week ist to finish the box, building the dust extraction and the cable chain.

pictures following...

@tommylight: you're right, the most noise is coming from milling, not the milling motor itself. I'll make some insulating / sound dampening materials in it the next days to reduce the noise.

motor on, box open:

motor on, box closed:

Tomorrow I'm at work again and when I've finished the work, I'll take a professional decibel meter with home to measure the noise.

Yesterday I ordered 2 energy chain at ebay, i need it because the machine can't move in the box without cable mess

My project the next week ist to finish the box, building the dust extraction and the cable chain.

pictures following...

Last edit: 01 Jun 2016 20:07 by Thomas.

Please Log in or Create an account to join the conversation.

- globaldynamix

- Offline

- New Member

-

Less

More

- Posts: 2

- Thank you received: 0

31 May 2016 11:07 #75276

by globaldynamix

Replied by globaldynamix on topic My first cnc router of wood (MDF)

This is my first CNC:

After many mistakes it is working :

:

After many mistakes it is working

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

31 May 2016 11:42 #75279

by andypugh

Replied by andypugh on topic My first cnc router of wood (MDF)

I am (part of the time) an NVH specialist for a car manufacturer.

When we want to put a part of the system in a box so that we can measure the noise level of another part, we build the box of plywood and line it with a special self-adhesive foam / lead / foam sandwich.

The foam / lead / foam material is the most effective thing for this job. You probably also should mount the whole router on a layer of foam to eliminate structure-borne noise through the table to the floor. Also make sure that your box is not touching the wall.

One of our vehicles had a very noticable noise in the driver cabin. It was eventually fixed by fitting a longer and softer engine earth strap. So don't assume that no noise can come down the wires.

When we want to put a part of the system in a box so that we can measure the noise level of another part, we build the box of plywood and line it with a special self-adhesive foam / lead / foam sandwich.

The foam / lead / foam material is the most effective thing for this job. You probably also should mount the whole router on a layer of foam to eliminate structure-borne noise through the table to the floor. Also make sure that your box is not touching the wall.

One of our vehicles had a very noticable noise in the driver cabin. It was eventually fixed by fitting a longer and softer engine earth strap. So don't assume that no noise can come down the wires.

Please Log in or Create an account to join the conversation.

- cncbasher

- Offline

- Moderator

-

Less

More

- Posts: 1021

- Thank you received: 202

31 May 2016 15:54 #75294

by cncbasher

Replied by cncbasher on topic My first cnc router of wood (MDF)

mount the router on some rubber feet , and the same with the case , and as andy says keep the box away from touching the walls . will help a great deal in isolation of noise .

Please Log in or Create an account to join the conversation.

- Thomas

- Offline

- New Member

-

Less

More

- Posts: 17

- Thank you received: 4

01 Jun 2016 19:43 #75307

by Thomas

Replied by Thomas on topic My first cnc router of wood (MDF)

sorry for my late answer, I was busy  Thank you all for your help

Thank you all for your help

@globaldynamix: nice video, looks very good and professional

@Andy: I made the box of particle board (hope is correct, in german "Spanplatte" or "Pressspanplatte"). Tomorrow will arrive my ordered damping foam.

@cncbasher: I have 3 mm rubber plates, I'll put them under the box and the router.

The box is almost ready, foam will arrive tomorrow and my dust extraction too...

@globaldynamix: nice video, looks very good and professional

@Andy: I made the box of particle board (hope is correct, in german "Spanplatte" or "Pressspanplatte"). Tomorrow will arrive my ordered damping foam.

@cncbasher: I have 3 mm rubber plates, I'll put them under the box and the router.

The box is almost ready, foam will arrive tomorrow and my dust extraction too...

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

01 Jun 2016 23:48 #75311

by andypugh

www.carbuildersolutions.com/uk/lead-foam-sandwich-1m-x-300mm

Is the sort of stuff you might need.

Replied by andypugh on topic My first cnc router of wood (MDF)

@Andy: I made the box of particle board (hope is correct, in german "Spanplatte" or "Pressspanplatte"). Tomorrow will arrive my ordered damping foam.

www.carbuildersolutions.com/uk/lead-foam-sandwich-1m-x-300mm

Is the sort of stuff you might need.

Please Log in or Create an account to join the conversation.

Time to create page: 0.822 seconds