Gantry table - One rail or Two?

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

16 Dec 2016 09:08 #84256

by rodw

Gantry table - One rail or Two? was created by rodw

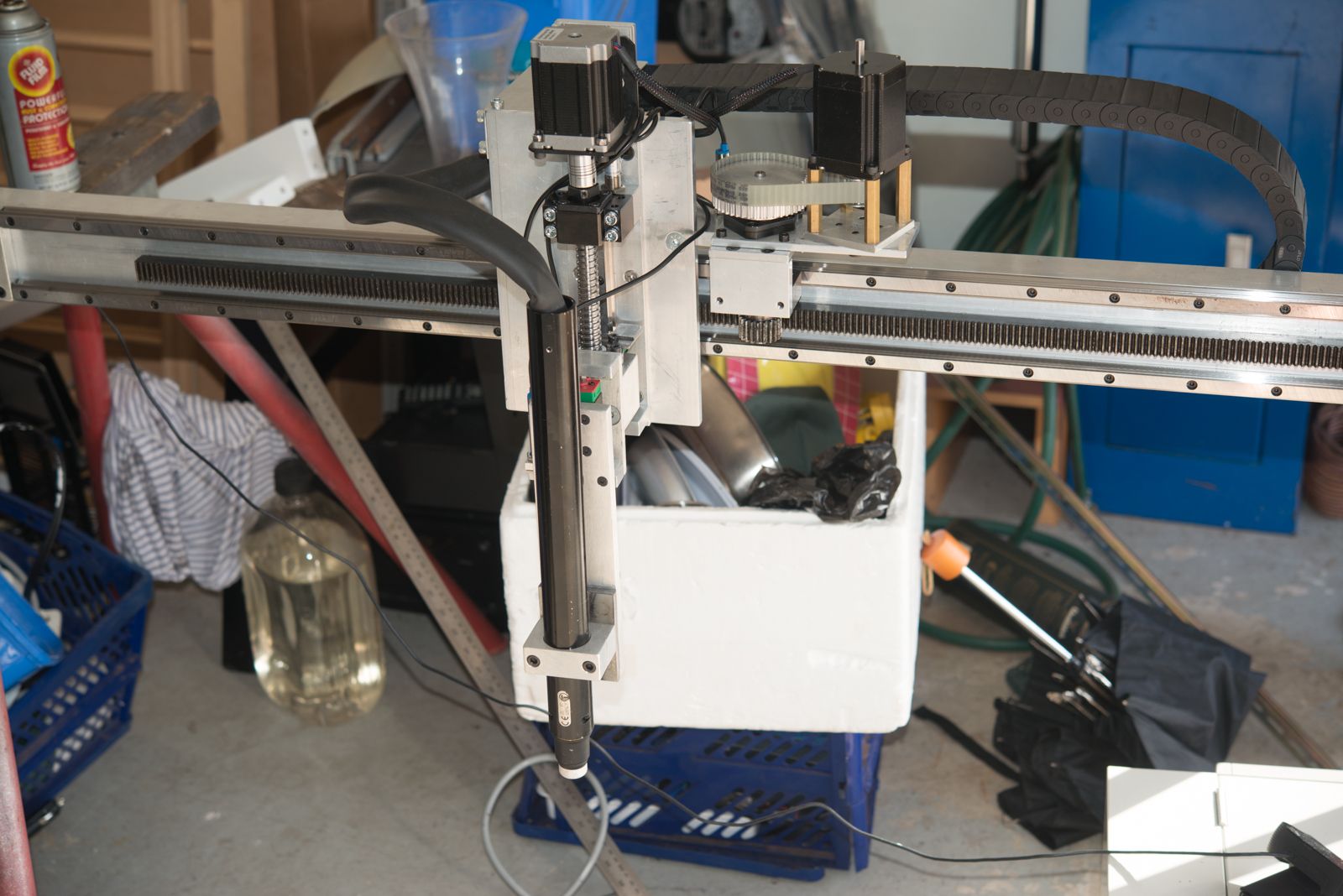

The six month anniversary since I commenced my scratch build plasma table is rapidly aproaching, You guys have been super helpful so far to get my Scratch built plasma to here

And you helped me build a new PC with Running Mint 17.3 and LinuxCNC to drive my Mesa 7i76e card

And I've built the electronics so I can get things to actually move all on my own (after countless hours studying this forum).

So now its time to start the next stage, building the plasma table and adding the gantry X axis.

You see, I used two Hiwin HGR15 linear guide rails on the Y axis

And now I think this was overkill just adding weight and cost to the project. I need to design the table and intend to use Hiwin HGR20 linear rails and carriages for each side of the plasma table to support the gantry. So the question is:

Do I use two rails each side or just one?

Now I know at this point some reader's eyes will glaze over...

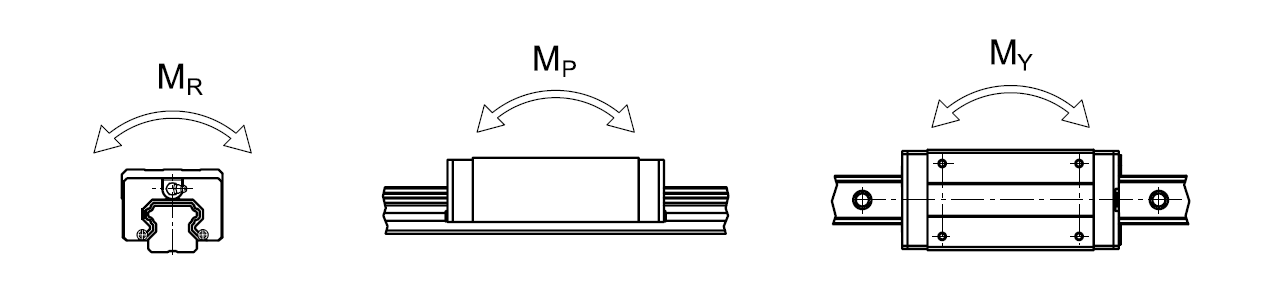

My engineering is incredibly rusty not having played with it since the early 1980's but I remember enough to know I need to ensure the table can handle the twisting moments applied to the linear carriages. Hiwin have this nice little diagram of them

For the HGR20 carriages, they say it can handle the following forces.

Mr = 0.27 kN/m, Mp = 0.20 kN.m and My = 0.20 kN/m

Converting back to Newtons, these become 270, 200 and 200 N.

There are no cutting forces on a plasma table that (hopefully) just hovers around just above the material surface so we must just need to worry about the twisting moments that the machine applies when moving.

Using round figures, I know that the Z axis assembly which moves along the Y axis weighs 10kg and LCNC is able of accelerating at 1.0 m/s/s. My guess of the total gantry weight is around 30 kg and I am assuming it will be able to accelerate at the same rate.

Lets assume the gantry is 0.5 m above the X axis rails and that the linear rails will be attached to the table side, not the table top (eg. oriented as per the My diagram above) and I will use 2 carriages per linear rail.

So the z axis gantry head has a force of 10 newtons applied to it (10kg x 1 m/s/s)

And therefore Mr = 10N x 0.5m = 5 Newtons which is well within the 270Nm allowed In a single rail setup, I think this force would be spread across 4 carriages (2 on each side) so each carriage is only subjected to about 1.25 Nm on the MR moment.

So does that sound right?

There appears to be nothing that will exert any Mp forces on the carriages. That implies a twisting moment on the gantry when the carriages are oriented on the side of the table.

So the My moment is going to be a bit bigger as its influenced by the whole weight of the gantry. Assuming the same acceleration applies, we've got 30kg x 1 m/s/s = 30 newtons so therefore Mp = 30 x 0.5 = 15 Newtons which spread over 4 carriages becomes 15/4 = 3.75 Nm per carriage.

So based on these calculations there appears to be no justification for installing 2 rails per side other than to line the suppliers pockets.

Bearing in mind I'm an absolute noob with everything I've done so far and have no experience with this stuff in the real world, the question I have before ordering anything is do I need to spend another $500-$1000 to add a second rail to achieve my goal of commercial quality performance?

Of course my maths may be way out as I've proven by being out by a factor of about 3 when designing the Y axis.

Thank for reading this far (if you made it) and I'd be interested to hear some feedback on this key design decision.

And you helped me build a new PC with Running Mint 17.3 and LinuxCNC to drive my Mesa 7i76e card

And I've built the electronics so I can get things to actually move all on my own (after countless hours studying this forum).

So now its time to start the next stage, building the plasma table and adding the gantry X axis.

You see, I used two Hiwin HGR15 linear guide rails on the Y axis

And now I think this was overkill just adding weight and cost to the project. I need to design the table and intend to use Hiwin HGR20 linear rails and carriages for each side of the plasma table to support the gantry. So the question is:

Do I use two rails each side or just one?

Now I know at this point some reader's eyes will glaze over...

My engineering is incredibly rusty not having played with it since the early 1980's but I remember enough to know I need to ensure the table can handle the twisting moments applied to the linear carriages. Hiwin have this nice little diagram of them

For the HGR20 carriages, they say it can handle the following forces.

Mr = 0.27 kN/m, Mp = 0.20 kN.m and My = 0.20 kN/m

Converting back to Newtons, these become 270, 200 and 200 N.

There are no cutting forces on a plasma table that (hopefully) just hovers around just above the material surface so we must just need to worry about the twisting moments that the machine applies when moving.

Using round figures, I know that the Z axis assembly which moves along the Y axis weighs 10kg and LCNC is able of accelerating at 1.0 m/s/s. My guess of the total gantry weight is around 30 kg and I am assuming it will be able to accelerate at the same rate.

Lets assume the gantry is 0.5 m above the X axis rails and that the linear rails will be attached to the table side, not the table top (eg. oriented as per the My diagram above) and I will use 2 carriages per linear rail.

So the z axis gantry head has a force of 10 newtons applied to it (10kg x 1 m/s/s)

And therefore Mr = 10N x 0.5m = 5 Newtons which is well within the 270Nm allowed In a single rail setup, I think this force would be spread across 4 carriages (2 on each side) so each carriage is only subjected to about 1.25 Nm on the MR moment.

So does that sound right?

There appears to be nothing that will exert any Mp forces on the carriages. That implies a twisting moment on the gantry when the carriages are oriented on the side of the table.

So the My moment is going to be a bit bigger as its influenced by the whole weight of the gantry. Assuming the same acceleration applies, we've got 30kg x 1 m/s/s = 30 newtons so therefore Mp = 30 x 0.5 = 15 Newtons which spread over 4 carriages becomes 15/4 = 3.75 Nm per carriage.

So based on these calculations there appears to be no justification for installing 2 rails per side other than to line the suppliers pockets.

Bearing in mind I'm an absolute noob with everything I've done so far and have no experience with this stuff in the real world, the question I have before ordering anything is do I need to spend another $500-$1000 to add a second rail to achieve my goal of commercial quality performance?

Of course my maths may be way out as I've proven by being out by a factor of about 3 when designing the Y axis.

Thank for reading this far (if you made it) and I'd be interested to hear some feedback on this key design decision.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

17 Dec 2016 07:51 #84307

by tommylight

Replied by tommylight on topic Gantry table - One rail or Two?

1 rail per side is more than enough for a plasma table, but you will need 2 cariages per rail. You could have goten away with only one rail on the X axis, but at least 20( i use only one 25mm hiwin rail on X for plasma).

Now aligning those 2 rails on both sides of the table is not easy, mounting them from above is easier for alignent but bad for dust.

If you intend to use a THC, miss alignents of up/down plane is not crucial as the THC will compensate for that.

If you intend to use a water table, put the rails as high as posible from the table so the splatering water can not get to them. Water table is a must if working inside a workshop. Down draft table would be better for plenty of reasons but that makes a lot of noise ( even plasma when cutting makes a lot of noise), it requires a closed box table and ducting and filtering. Plus covering the remainder of the table when cutting smal pieces.

Hope this helps.

Now aligning those 2 rails on both sides of the table is not easy, mounting them from above is easier for alignent but bad for dust.

If you intend to use a THC, miss alignents of up/down plane is not crucial as the THC will compensate for that.

If you intend to use a water table, put the rails as high as posible from the table so the splatering water can not get to them. Water table is a must if working inside a workshop. Down draft table would be better for plenty of reasons but that makes a lot of noise ( even plasma when cutting makes a lot of noise), it requires a closed box table and ducting and filtering. Plus covering the remainder of the table when cutting smal pieces.

Hope this helps.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

17 Dec 2016 09:07 #84315

by rodw

Replied by rodw on topic Gantry table - One rail or Two?

Tommy, thanks for your advice once again.

I am planning on having the rails side mounted on laser cut plates so all of the mounting holes for the rails and gantry will be perfectly aligned. You reminded me about the vertical adjustment which I had thought of earlier and was thinking of having the rail mounting plates resting on bolts at each end that go through nuts or tapped holes welded to the table legs so they can be adjusted before all mounting bolts are tightened up.

I will have a Mesa THCAD as THC.

I will also laser cut the gantry end plates and probably have the edges folded back for extra stiffness.

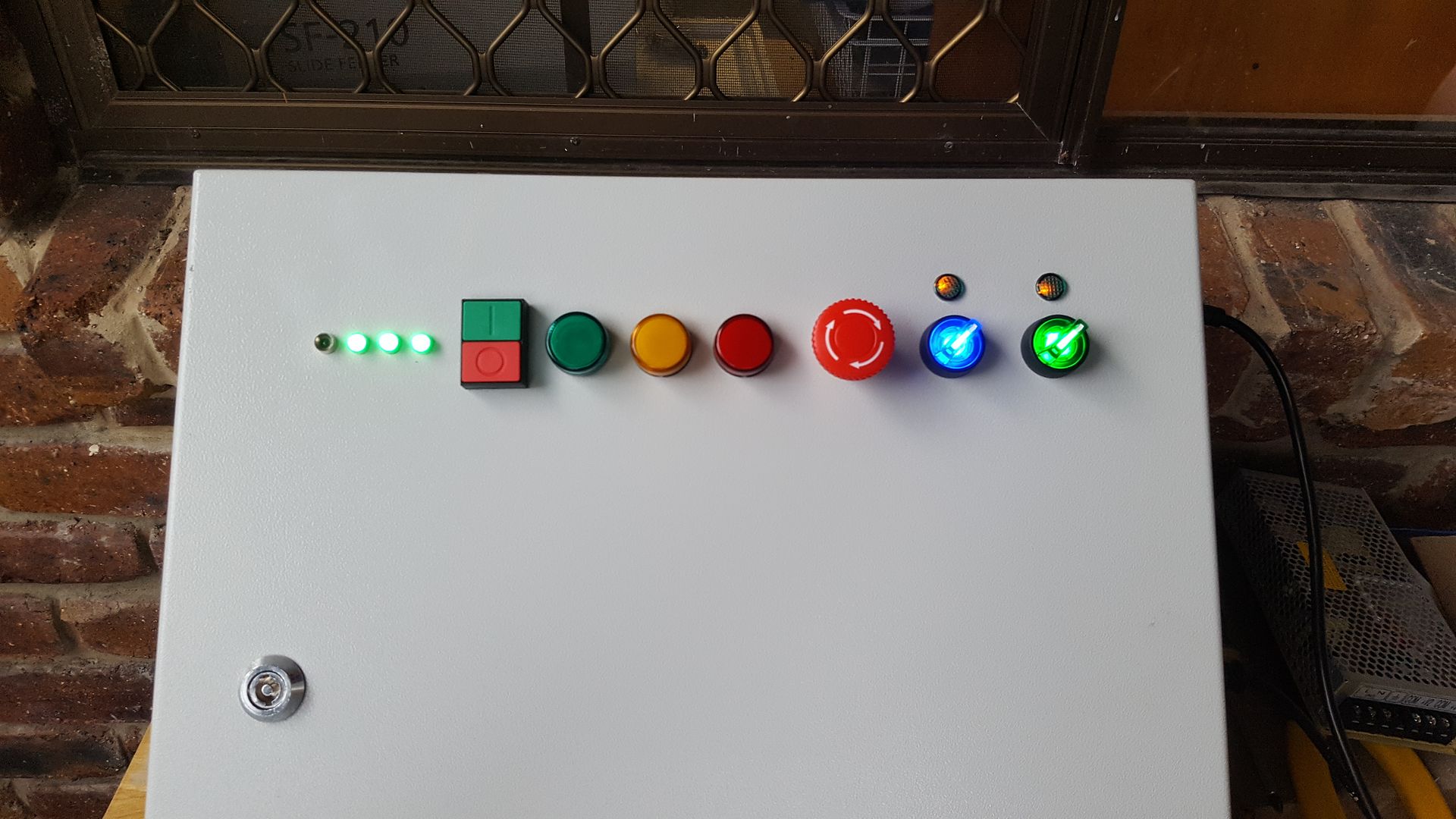

I was never keen on the idea of a water table so it will be a downdraft table. I am still not sure on what filtering is required. I have added a mains power point to my control box for the fan and have thought of allowing it to be turned on and off by the Mesa card as the machine runs to keep the noise down when not actually required.

I'll look for some 25mm rails.

I am planning on having the rails side mounted on laser cut plates so all of the mounting holes for the rails and gantry will be perfectly aligned. You reminded me about the vertical adjustment which I had thought of earlier and was thinking of having the rail mounting plates resting on bolts at each end that go through nuts or tapped holes welded to the table legs so they can be adjusted before all mounting bolts are tightened up.

I will have a Mesa THCAD as THC.

I will also laser cut the gantry end plates and probably have the edges folded back for extra stiffness.

I was never keen on the idea of a water table so it will be a downdraft table. I am still not sure on what filtering is required. I have added a mains power point to my control box for the fan and have thought of allowing it to be turned on and off by the Mesa card as the machine runs to keep the noise down when not actually required.

I'll look for some 25mm rails.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21357

- Thank you received: 7286

17 Dec 2016 09:19 #84316

by tommylight

Replied by tommylight on topic Gantry table - One rail or Two?

That is a nice idea for the fan. 20mm rails are sufficient, but the price diference is smal overal, so if you can aford them, buy 25mm ones. You already have a sturdy X axis, so with litle mods you can use it as a wood or plastic router.

Please Log in or Create an account to join the conversation.

- rodw

-

Topic Author

Topic Author

- Away

- Platinum Member

-

Less

More

- Posts: 11731

- Thank you received: 3973

17 Dec 2016 12:06 #84321

by rodw

Replied by rodw on topic Gantry table - One rail or Two?

Well, I found a couple of pieces of HGR25 for less than what I'd been quoted for HGR20. I put my order in but I don't expect to see it until 2017.

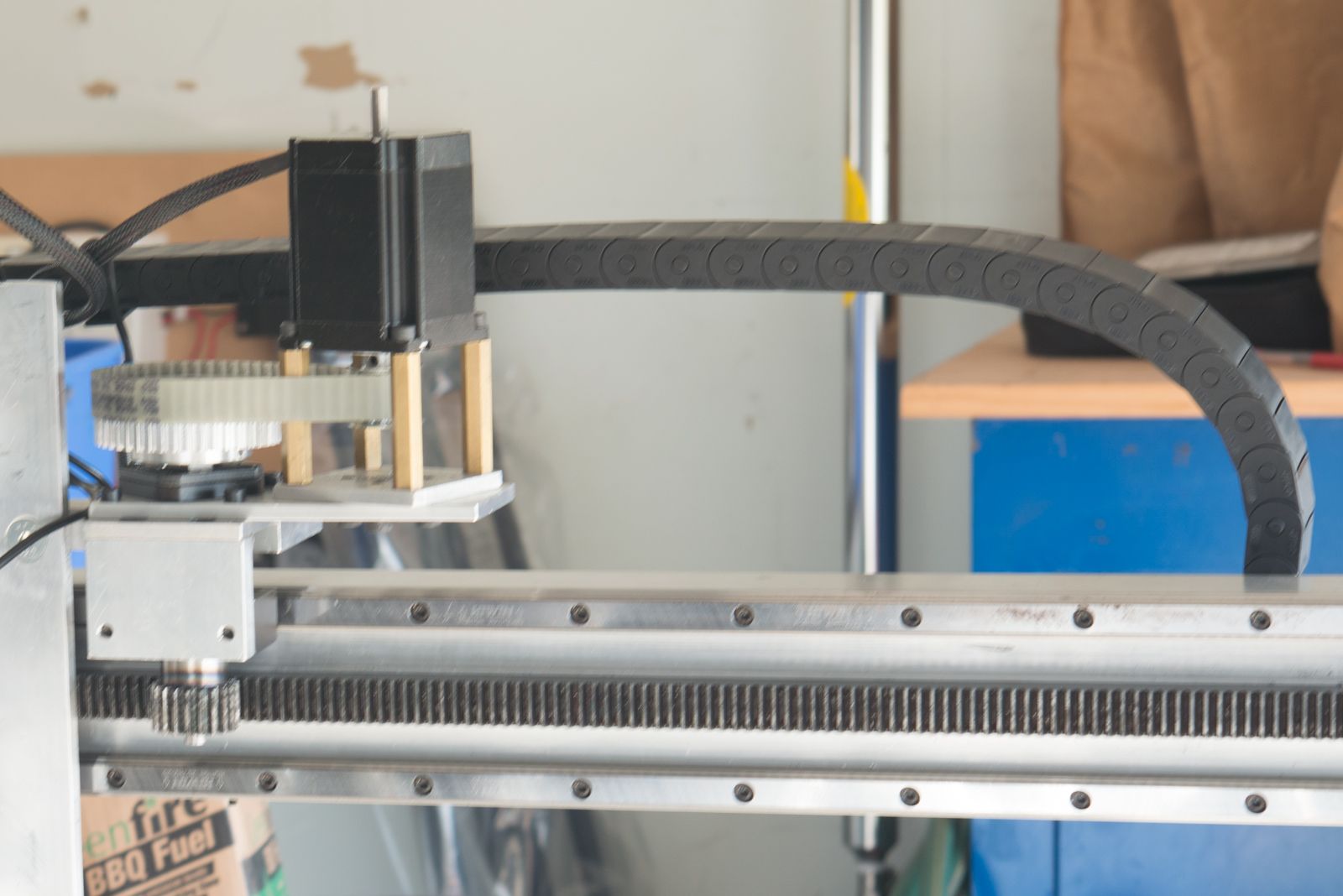

I have already ordered some helical gear rack and a couple of nice 5:1 timing belt pinion drive modules for NEMA 34 motors. I'll need to watch the power demands as I was anticipating using the NEMA23 drives I already have. But then again it won't be hard to adapt NEMA34 mounts to suit NEMA23 motors.

I played with my gantry limit switches today and Ive got a little bit of work to do to mount them but it looks like I'll have 1230mm of gantry travel which will easilly accommodate a standard 1200mm wide sheet. The Z axis is a bit less than I really wanted but I'll have 87mm of travel. That will be enough but next time, I will use a 200mm ball screw.

I have already ordered some helical gear rack and a couple of nice 5:1 timing belt pinion drive modules for NEMA 34 motors. I'll need to watch the power demands as I was anticipating using the NEMA23 drives I already have. But then again it won't be hard to adapt NEMA34 mounts to suit NEMA23 motors.

I played with my gantry limit switches today and Ive got a little bit of work to do to mount them but it looks like I'll have 1230mm of gantry travel which will easilly accommodate a standard 1200mm wide sheet. The Z axis is a bit less than I really wanted but I'll have 87mm of travel. That will be enough but next time, I will use a 200mm ball screw.

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19804

- Thank you received: 4613

18 Dec 2016 23:22 #84378

by andypugh

Indeed. In fact there is a danger in having paired rails that unless they are exactly aligned to within the internal clearance of the guides then there is the potential for an internal disagreement about where the parts should be, and you can end up with internally-generated forces between the rails larger than the externally applied forces.

Replied by andypugh on topic Gantry table - One rail or Two?

So based on these calculations there appears to be no justification for installing 2 rails per side other than to line the suppliers pockets.

Indeed. In fact there is a danger in having paired rails that unless they are exactly aligned to within the internal clearance of the guides then there is the potential for an internal disagreement about where the parts should be, and you can end up with internally-generated forces between the rails larger than the externally applied forces.

The following user(s) said Thank You: rodw

Please Log in or Create an account to join the conversation.

Time to create page: 0.100 seconds