What hardware do I need, exactly

- charliem

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

26 Sep 2017 01:08 #99436

by charliem

What hardware do I need, exactly was created by charliem

Hi guys,

I am wanting to build a CNC router, but I'm having some difficulty understanding some of the hardware requirements. For example, I run linux on a newer laptop and there's no parallel port so, I'm looking at the Mesa 7i76 card. I know I need steppers, I'm looking at 3 or probably 4 NEMA 23's in 425 oz-in range, I know I need to supply power to everything. So besides some wiring to connect it all together, what else? Anything? If something else is needed, could I get a recommendation for something compatible with the Mesa card and steppers that size?

I am wanting to build a CNC router, but I'm having some difficulty understanding some of the hardware requirements. For example, I run linux on a newer laptop and there's no parallel port so, I'm looking at the Mesa 7i76 card. I know I need steppers, I'm looking at 3 or probably 4 NEMA 23's in 425 oz-in range, I know I need to supply power to everything. So besides some wiring to connect it all together, what else? Anything? If something else is needed, could I get a recommendation for something compatible with the Mesa card and steppers that size?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

26 Sep 2017 09:28 #99447

by rodw

Replied by rodw on topic What hardware do I need, exactly

They are pretty big steppers for a NEMA23. What is their current draw in amps?

You will need a power supply. I use a 10.5 amp 48 volt Meanwell power supply for 4 steppers (2 x Nema23's and 2 x Nema34's)

I use the Longs Motor DM542A stepper drivers. These are good for about 3.5 amps from memory and I was careful when selecting the NEMA 34's to not exceed this limit.

If your motors need more than 3.5 amps, you will need a different driver.

However, your biggest issue is making sure your PC has adequate latency figures to allow it to be used with LinuxCNC. Read the docs and make sure it is OK before you go down this path.

You will need a power supply. I use a 10.5 amp 48 volt Meanwell power supply for 4 steppers (2 x Nema23's and 2 x Nema34's)

I use the Longs Motor DM542A stepper drivers. These are good for about 3.5 amps from memory and I was careful when selecting the NEMA 34's to not exceed this limit.

If your motors need more than 3.5 amps, you will need a different driver.

However, your biggest issue is making sure your PC has adequate latency figures to allow it to be used with LinuxCNC. Read the docs and make sure it is OK before you go down this path.

Please Log in or Create an account to join the conversation.

- charliem

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

26 Sep 2017 13:15 #99460

by charliem

Replied by charliem on topic What hardware do I need, exactly

See? That's why all of this is so confusing. My computer is new-ish, if folks are running this stuff with 10, 15, 20-yo PCs running Windows XP over a parallel port, I shouldn't have any issues with a new-ish laptop running a current version of Linux over a 100BaseT ethernet bus with a 1000BaseT ethernet card.

I think the 425 oz-in steppers are probably the largest made in the NEMA 23 case, I'm still not sure what size cutting bed I'll end up with but I'm wanting to go 2' x 4' and I hoped these steppers would be large enough, but not too large.

What confuses me the most though, I wrote to the Mesa people to ask about the 7i76 card, they said "7I76E is a controller, not a drive so you still need step motor drives appropriatly sized to you motors" - okay, but when I start looking or those all I find is junque with DB25 connectors for parallel cables. I don't have parallel ports so I need to run ethernet-compatible, not parallel-compatible.

Figuring out what hardware I will need is making my head hurt.

I think the 425 oz-in steppers are probably the largest made in the NEMA 23 case, I'm still not sure what size cutting bed I'll end up with but I'm wanting to go 2' x 4' and I hoped these steppers would be large enough, but not too large.

What confuses me the most though, I wrote to the Mesa people to ask about the 7i76 card, they said "7I76E is a controller, not a drive so you still need step motor drives appropriatly sized to you motors" - okay, but when I start looking or those all I find is junque with DB25 connectors for parallel cables. I don't have parallel ports so I need to run ethernet-compatible, not parallel-compatible.

Figuring out what hardware I will need is making my head hurt.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4696

- Thank you received: 1439

26 Sep 2017 14:48 #99467

by Todd Zuercher

Replied by Todd Zuercher on topic What hardware do I need, exactly

Parallel ports are just a convenient way to get a TTL signal from a computer. Most lower end stepper drives are set up for this. The Mesa cards like a 7i76 can produce a step signal compatible with those. Or it can also send a differential signal that is available on some higher end drives and most position mode servos.

If the drive you happen to get has a DB25 plug, you can just take a parallel port cable and wack one of the ends off and wire up the wires you need to the 7i76.

But the basic gist of what you need for a stepper system is:

a computer that can adequately run Linuxcnc. (sounds like you have that)

Step motors (You have them)

Step motor drivers (you need to find ones appropriately sized for your motors)

A way to connect the drivers to the computer.

The most basic way to connect the drivers to the computer is directly connecting them with a parallel port. (There is often an isolating breakout board used in between)

Then there is more sophisticated ways to connect them, such as using Mesa hardware.

It sounds like you've chosen the Mesa route with a 7i76e. It will take the place of any breakout board that would normally go between the parallel port and the stepper driver.

For your larger steppers I would discourage you from looking at smaller multi drive units that have built in breakout boards, the drivers in those usually are not powerful enough for large motors.

If the drive you happen to get has a DB25 plug, you can just take a parallel port cable and wack one of the ends off and wire up the wires you need to the 7i76.

But the basic gist of what you need for a stepper system is:

a computer that can adequately run Linuxcnc. (sounds like you have that)

Step motors (You have them)

Step motor drivers (you need to find ones appropriately sized for your motors)

A way to connect the drivers to the computer.

The most basic way to connect the drivers to the computer is directly connecting them with a parallel port. (There is often an isolating breakout board used in between)

Then there is more sophisticated ways to connect them, such as using Mesa hardware.

It sounds like you've chosen the Mesa route with a 7i76e. It will take the place of any breakout board that would normally go between the parallel port and the stepper driver.

For your larger steppers I would discourage you from looking at smaller multi drive units that have built in breakout boards, the drivers in those usually are not powerful enough for large motors.

Please Log in or Create an account to join the conversation.

- charliem

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

26 Sep 2017 22:55 #99495

by charliem

Replied by charliem on topic What hardware do I need, exactly

Thank you for the info.

I'm not set & committed on the 7i76, it's just the first ethernet bus solution I encountered. If there are better options, I'm all ears. Just looking for an optimal way to run a CNC router from my Linux laptop.

I'm not set & committed on the 7i76, it's just the first ethernet bus solution I encountered. If there are better options, I'm all ears. Just looking for an optimal way to run a CNC router from my Linux laptop.

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

26 Sep 2017 23:30 #99496

by rodw

Replied by rodw on topic What hardware do I need, exactly

The 7i76e is probably the best option for what you want to do.

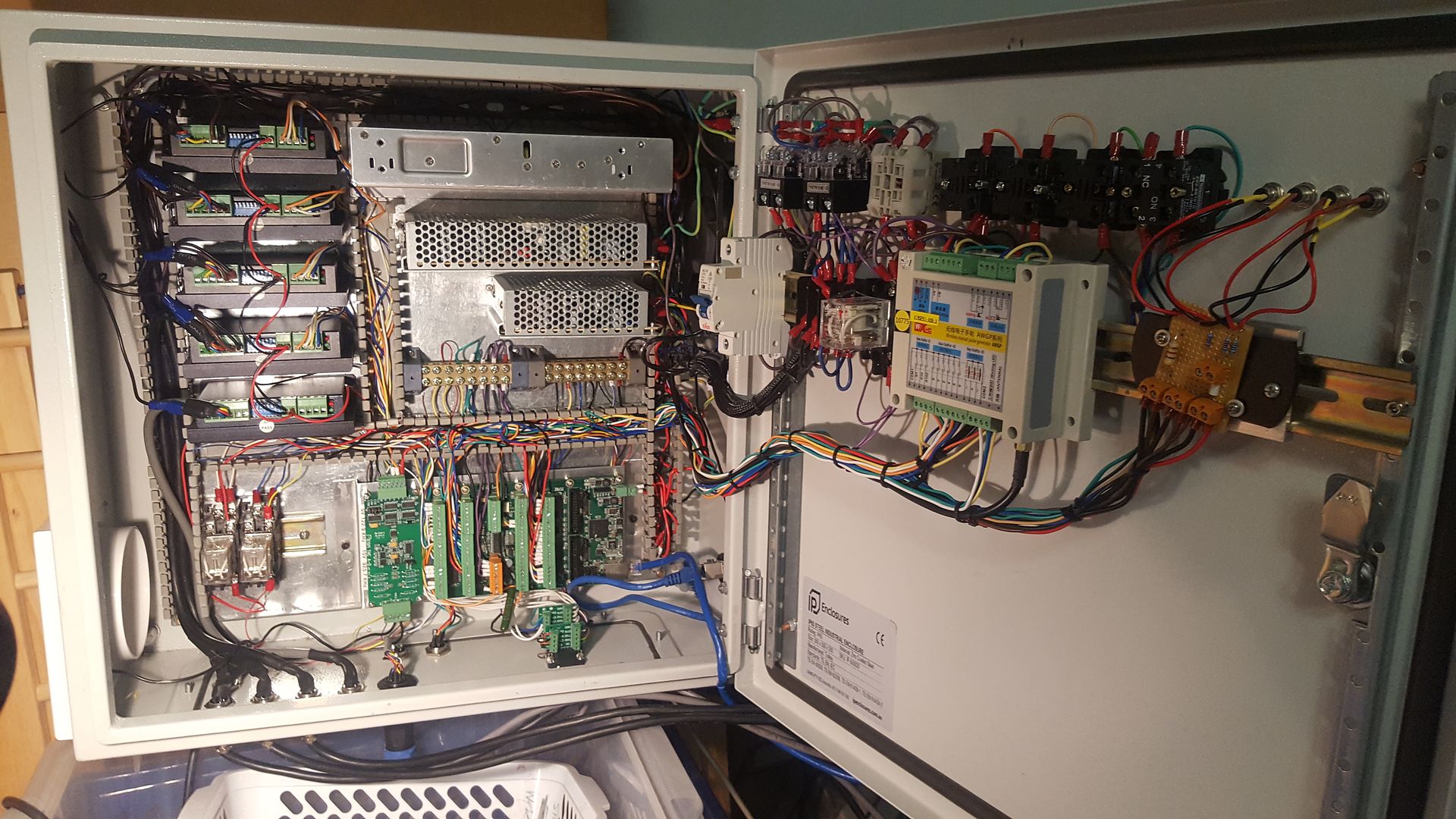

Here's mine in my control box

There's probbaly a lot more here than you will need

but the 7i76e is bottom right with Mesa THCAD beside it on left.

48 volt power supply top right

24 volt below it

5 volt next (but you probably won't need it.)

The top left shows the 5 stepper drivers that are connected to each stepper motor and 48 volt power.

The 7i76e's step generators are also connected to each driver.

The cables to the stepper motors connect to the bottom of the control box.

Here's mine in my control box

There's probbaly a lot more here than you will need

but the 7i76e is bottom right with Mesa THCAD beside it on left.

48 volt power supply top right

24 volt below it

5 volt next (but you probably won't need it.)

The top left shows the 5 stepper drivers that are connected to each stepper motor and 48 volt power.

The 7i76e's step generators are also connected to each driver.

The cables to the stepper motors connect to the bottom of the control box.

Please Log in or Create an account to join the conversation.

- charliem

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

27 Sep 2017 20:40 #99529

by charliem

Replied by charliem on topic What hardware do I need, exactly

Wow, that looks like quite a rig. Would you mind detailing the rest of your setup?

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

27 Sep 2017 21:42 #99532

by rodw

Replied by rodw on topic What hardware do I need, exactly

There is not much more to it

I've tried to use every feature of the 7i76e so I can learn as much as I can about LinuxCNC and Mesa.

The relays at bottom left. 1 switches the plasma torch on and off, the other switches 5 volts to the stepper driver disable signals on estop. There are 2 bus bars between the 7i76e and the power supplies. These are +24v (on left) and -24v

There are 2 DB9 connectors underneath. One for home/limit Gantry sensors and the other is for the sensors on the table.

The stuff on the door is mostly mains power, mains breaker, estop, pause/resume switches and indicator lights. The 4 LED's on the right are (Plasma Arc OK and indicators to show power supply status (48v, 24v and 5v). This was suggested by a friend and it has been handy for trouble shooting. I've also added a couple of neon indicators for mains power status.

The large control box is for my external 433 mHz wireless pendant which is wired up to the 7i76e inputs.

Plasma is much more complex so it might be abit overkill.

I've tried to use every feature of the 7i76e so I can learn as much as I can about LinuxCNC and Mesa.

The relays at bottom left. 1 switches the plasma torch on and off, the other switches 5 volts to the stepper driver disable signals on estop. There are 2 bus bars between the 7i76e and the power supplies. These are +24v (on left) and -24v

There are 2 DB9 connectors underneath. One for home/limit Gantry sensors and the other is for the sensors on the table.

The stuff on the door is mostly mains power, mains breaker, estop, pause/resume switches and indicator lights. The 4 LED's on the right are (Plasma Arc OK and indicators to show power supply status (48v, 24v and 5v). This was suggested by a friend and it has been handy for trouble shooting. I've also added a couple of neon indicators for mains power status.

The large control box is for my external 433 mHz wireless pendant which is wired up to the 7i76e inputs.

Plasma is much more complex so it might be abit overkill.

Please Log in or Create an account to join the conversation.

- charliem

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

27 Sep 2017 22:26 #99534

by charliem

Replied by charliem on topic What hardware do I need, exactly

Nice. What is the size of your cutting bed and what size motors are you using? You mentioned NEMA 23's and 34's earlier but what are they rated at? How many inch ounces? Or is it ounce-inches? Did you opt for threaded rods for the X and Y movement or rack and pinion? I have so many other questions, I hope you don't mind...

Please Log in or Create an account to join the conversation.

- rodw

-

- Offline

- Platinum Member

-

Less

More

- Posts: 11691

- Thank you received: 3942

27 Sep 2017 23:13 #99535

by rodw

Replied by rodw on topic What hardware do I need, exactly

The X & Z axis are driven by 269 Oz Nema 23's that draw about 2.8 amps

The Joint axis Y uses NEMA 34's 1000 Oz/in limited to 3.5 amps

The Z is 5mm/rev ballscrew

X is rack and pinion with 3:1 drive I built

Y is helical rack and pinion with 5:1 drive I bought (hence the use of NEMA 34's as that was what the reduction drives were built for).

Remember that plasmas are fast and light with no cutting forces vs routers that are slower and heavier so my hardware might not suit your machine.

The Joint axis Y uses NEMA 34's 1000 Oz/in limited to 3.5 amps

The Z is 5mm/rev ballscrew

X is rack and pinion with 3:1 drive I built

Y is helical rack and pinion with 5:1 drive I bought (hence the use of NEMA 34's as that was what the reduction drives were built for).

Remember that plasmas are fast and light with no cutting forces vs routers that are slower and heavier so my hardware might not suit your machine.

Please Log in or Create an account to join the conversation.

Time to create page: 0.186 seconds