“Pressurization air” on HSD spindle?

- JetForMe

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 27

15 Jun 2019 05:39 #136952

by JetForMe

“Pressurization air” on HSD spindle? was created by JetForMe

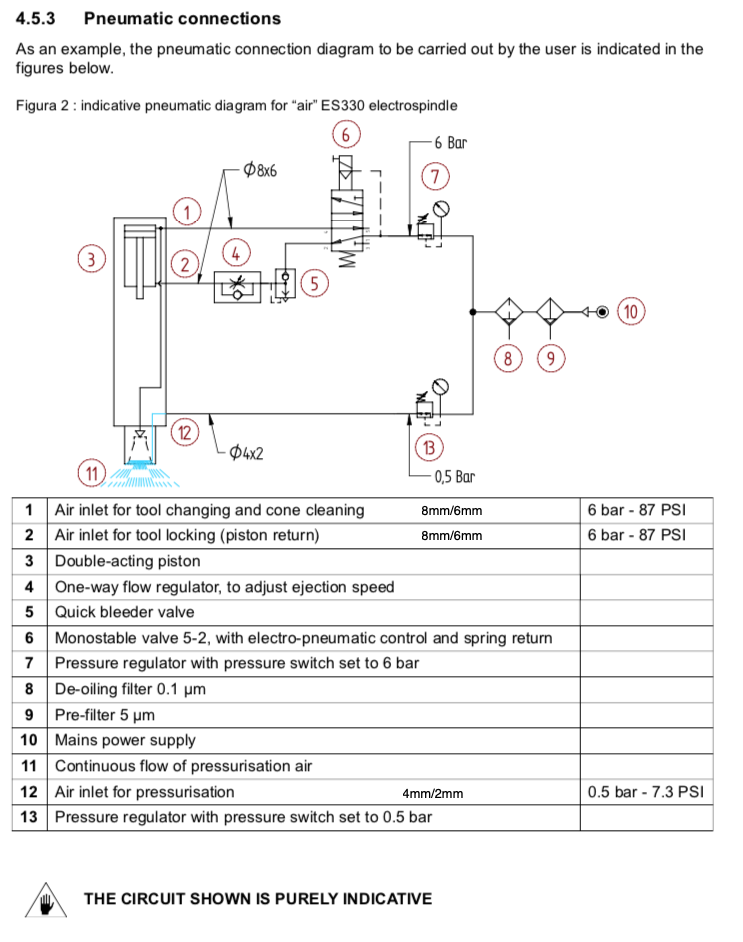

Hi. For my CNC router table, I've selected an HSD ES330 air-cooled spindle with pneumatic tool changer (power draw bar) capability. It's a sweet spindle (24 k rpm, 4.5 kW). It has two air inlets for opening and closing the draw bar, and they run at 90 psi.

It also has an inlet near the business end of the spindle referred to in the manual as "pressurization air," running at 7 psi. This air flows continuously, unlike the tool changer air which stops flowing when the tool is locked in place. You can feel this pressurization air coming out of the end of the spindle.

What is this air for? Does it make the bearing work better? I believe this spindle has a ceramic bearing at the bottom and a ball bearing at the top. The manual doesn't say this air is required to prevent damage, and I've run the motor a bit on the bench long before I got around to hooking this up. I don't believe I've caused any damage, but I'm a little worried about it.

In any case, I'm going to control that air supply with a solenoid so I can have LinuxCNC turn it off when the spindle isn't cutting.

But can anyone tell me its purpose? Thanks!

It also has an inlet near the business end of the spindle referred to in the manual as "pressurization air," running at 7 psi. This air flows continuously, unlike the tool changer air which stops flowing when the tool is locked in place. You can feel this pressurization air coming out of the end of the spindle.

What is this air for? Does it make the bearing work better? I believe this spindle has a ceramic bearing at the bottom and a ball bearing at the top. The manual doesn't say this air is required to prevent damage, and I've run the motor a bit on the bench long before I got around to hooking this up. I don't believe I've caused any damage, but I'm a little worried about it.

In any case, I'm going to control that air supply with a solenoid so I can have LinuxCNC turn it off when the spindle isn't cutting.

But can anyone tell me its purpose? Thanks!

Attachments:

Please Log in or Create an account to join the conversation.

- cmorley

- Offline

- Moderator

-

Less

More

- Posts: 7291

- Thank you received: 2128

15 Jun 2019 05:58 #136954

by cmorley

Replied by cmorley on topic “Pressurization air” on HSD spindle?

My guess is just to keep the internals clean by making it pressurized.

Heidenhain have kits to add pressurized air to some of their linear encoders to increase the dirt protection.

Chris

Heidenhain have kits to add pressurized air to some of their linear encoders to increase the dirt protection.

Chris

Please Log in or Create an account to join the conversation.

- JetForMe

-

Topic Author

Topic Author

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 27

15 Jun 2019 06:07 #136955

by JetForMe

Replied by JetForMe on topic “Pressurization air” on HSD spindle?

I think you might be right about this. I did some generalized (not ES330-specific) googling and came across an

article

that talks about some company's improvements to "pressurized air through labyrinth-type bearing seals."

Please Log in or Create an account to join the conversation.

- ihavenofish

- Offline

- Platinum Member

-

Less

More

- Posts: 986

- Thank you received: 281

15 Jun 2019 13:49 #136981

by ihavenofish

Replied by ihavenofish on topic “Pressurization air” on HSD spindle?

its a bearing purge. it keeps dust out of the bearings.

The following user(s) said Thank You: JetForMe

Please Log in or Create an account to join the conversation.

Time to create page: 0.082 seconds