Wotan Rapid 1 LinuxCNC Retrofit

- deerefanatic

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 1

I'm in the process of acquiring a Wotan Rapid 1 CNC Horizontal Boring Mill. The mill is in solid shape, and was retrofit back in 1996 to a Dynapath Delta 50M. About 4 years ago, the roof over the machine's electrical cabinet sprung a leak and the motherboard of the control got wet and fried. Now the shop is closing and I'm getting the machine for the cost of moving it.

I have thought about sticking with the Dynapath, as I can buy the parts to get it running again for about $5000, but I think I'd rather go with LinuxCNC instead for a newer system.. The Dynapath is old, has very limited memory, and based on really antiquated hardware. Larger programs would require drip feeding, etc.

I'm thinking of Using a Dell PC that I have with Intel Core2 Quad, and MESA cards.. I have a couple questions...

1: Can you have a mix of both PCI express and ethernet cards in the same machine? I'd like to use PCI cards with daughter boards to control the machine itself, but this machine also has a remote operator interface on a swinging pendant. My thought was have one of the ethernet cards in there for the operators panel buttons and the MPG to interface to, vs having to have a huge bundle of wires running back to the control pc. The dynapath system had a board mounted in the pendant that communcated via CAN bus back to the dynapath control, but I'm guessing that would be a nightmare to reverse engineer.

2: Is there a particular motherboard/pc setup that is recommended for these conversions, like an ideal option? I know that it seems anything with good latency is fair game, but I also seem to gather that with the MESA cards, it's not really so much of an issue.

3: I have to do some digging, but I suspect that this machine uses Resolvers on the servos vs encoders. Is that a deal breaker, or will the mesa cards handle resolvers ok? I know my drives are Allen Bradley 1388's using 0-10v analog signaling. I also see that the machine has Heidenhain Linear scales with EXE 602E interface boxes, but it looks like they were used on the machine's original NC control and not used on the Dynapath retrofit (per the wiring diagram I have) I'd like the machine to be able to hold .0005 tolerances if possible, (assuming it's mechanically sound)

Here is a link to my google photos library of this machine and it's progress. photos.app.goo.gl/qvSGNdDSUBV871R8A

I'll start some separate threads with more specific questions and link them back here as a reference for anyone trying to pursue this in the future.

EDIT: The below links are other topic-specific threads started in regards to this project.. I'm linking them here for the sake of folks in the future undertaking a project like this.

I had trouble with the Y Axis acting crazy. Turned out to be a wiring fault: Vertical Axis PID Tuning questions - LinuxCNC

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

Yes, you can use any combination of Mesa cards that can be physically connected.1: Can you have a mix of both PCI express and ethernet cards in the same machine?

My thought was have one of the ethernet cards in there for the operators panel buttons and the MPG to interface to,

A 7i73 (or two) would be cheaper, and uses exactly the same cabling.

3: I have to do some digging, but I suspect that this machine uses Resolvers on the servos vs encoders. Is that a deal breaker, or will the mesa cards handle resolvers ok? I know my drives are Allen Bradley 1388's using 0-10v analog signaling.

Look at the Mesa 7i49. Probably in conjunction with a 5i24 as the FPGA card. (that is the combo running my lathe) I like resolvers.

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

- Posts: 1570

- Thank you received: 576

2: Is there a particular motherboard/pc setup that is recommended for these conversions, like an ideal option? I know that it seems anything with good latency is fair game, but I also seem to gather that with the MESA cards, it's not really so much of an issue.

What a beast of a machine.

You are right, LinuxCNC is not that choosy about the PC. If you are using Mesa Cards, then you can get most to work. SInce you already have it, tr outh the live image, and you can see if it's got anyunacceptable latency behaviours.

You really only need one Mesa FPGA card connected to the PC, as Andy said. you can get basically unlimited I/O, Encoders, Step/DIR, Analog servo etc by adding SS daughter cards.

Mark

Please Log in or Create an account to join the conversation.

- deerefanatic

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 1

On further investigation, it appears that there aren't actually any resolvers on this machine. The servo motors have Tach generators that are fed back into the servo Amps, but the dynapath was reading the glass scales for positional feedback. On one hand, that seems like a good deal as you can elminate backlash from the system, but on the other hand, maybe not such a great idea? Should I be planning to mount encoders to the servos?

Please Log in or Create an account to join the conversation.

- RotarySMP

-

- Offline

- Platinum Member

-

- Posts: 1570

- Thank you received: 576

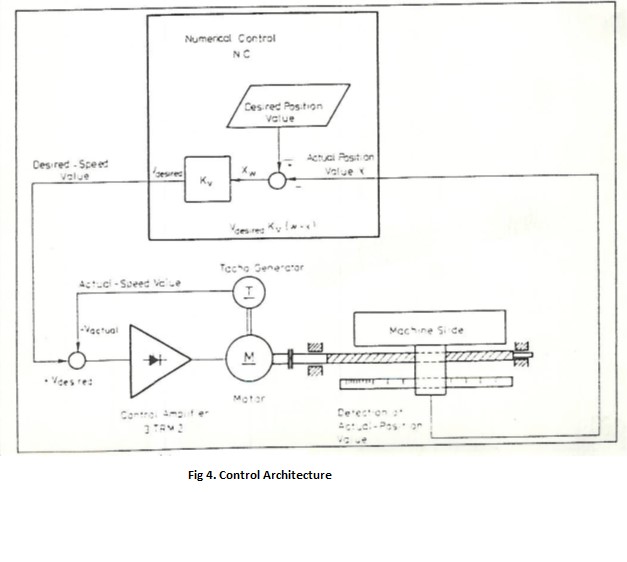

Here is the block diagram from my Indramat manual...

Mark

Attachments:

Please Log in or Create an account to join the conversation.

- deerefanatic

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

- Posts: 19804

- Thank you received: 4613

On further investigation, it appears that there aren't actually any resolvers on this machine. The servo motors have Tach generators that are fed back into the servo Amps, but the dynapath was reading the glass scales for positional feedback. On one hand, that seems like a good deal as you can elminate backlash from the system, but on the other hand, maybe not such a great idea? Should I be planning to mount encoders to the servos?

If you are keeping the drives then just leave the tachos closing the velocity loop and let LinuxCNC use the scales to close the position loop.

This is about as simple as a LinuxCNC servo retrofit gets, and should give excellent results.

Please Log in or Create an account to join the conversation.