Wiring of oil pump.

- deus

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 2

16 Jul 2022 06:42 #247432

by deus

Wiring of oil pump. was created by deus

Hi all,

Thought I get some advice/feedback as my electrical skills are very basic.I have an oil pump for my CNC slide ways which I plan to hook up to my MESA 7i76E. I want to switch the pump on when I am running an oiling routine prior to machining (or manually whenever I think it is good). I bought already a 24V DC / 240V AC solid state relay and plan to run a power cable together with a 24V signal cable to the pump. I think it all is pretty straight forward, however, I am confused about the attached Chinese wiring diagram which I found inside of the pump.I believe ‘T’ is the live connection and ‘R’ is the neutral connection. Assuming this is correct, they suggest to switch the neutral side (be it the relay or the feed switch). To my knowledge this seems NOT to be recommended with general household appliances. electronics.stackexchange.com/questions/...-is-switched-neutral

I am currently considering of rewiring the inside of the pump that the switches are on the live side of things and before the fuse. Does that make sense?

PS: If anybody has a good link how to set up an oiling routine please don't hold back.

Cheers

Thought I get some advice/feedback as my electrical skills are very basic.I have an oil pump for my CNC slide ways which I plan to hook up to my MESA 7i76E. I want to switch the pump on when I am running an oiling routine prior to machining (or manually whenever I think it is good). I bought already a 24V DC / 240V AC solid state relay and plan to run a power cable together with a 24V signal cable to the pump. I think it all is pretty straight forward, however, I am confused about the attached Chinese wiring diagram which I found inside of the pump.I believe ‘T’ is the live connection and ‘R’ is the neutral connection. Assuming this is correct, they suggest to switch the neutral side (be it the relay or the feed switch). To my knowledge this seems NOT to be recommended with general household appliances. electronics.stackexchange.com/questions/...-is-switched-neutral

I am currently considering of rewiring the inside of the pump that the switches are on the live side of things and before the fuse. Does that make sense?

PS: If anybody has a good link how to set up an oiling routine please don't hold back.

Cheers

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

16 Jul 2022 10:59 #247445

by tommylight

Replied by tommylight on topic Wiring of oil pump.

No rewiring.

R and T are 2 phases of an RST 3 phase system, so both are live.

R and T are 2 phases of an RST 3 phase system, so both are live.

Please Log in or Create an account to join the conversation.

- deus

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 2

16 Jul 2022 13:12 - 16 Jul 2022 13:23 #247461

by deus

Replied by deus on topic Wiring of oil pump.

Thanks tommylight.

Autsch... I knew there was something obvious missing.

Looks like this thing is no use for me as i only have 240v single phase.

Or is there a 'non-expensive' way to make this 2 phase 220V, 50Hz work on 240v single phase?

Autsch... I knew there was something obvious missing.

Looks like this thing is no use for me as i only have 240v single phase.

Or is there a 'non-expensive' way to make this 2 phase 220V, 50Hz work on 240v single phase?

Last edit: 16 Jul 2022 13:23 by deus.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21372

- Thank you received: 7289

16 Jul 2022 13:26 #247462

by tommylight

Replied by tommylight on topic Wiring of oil pump.

It should work with 240V, of course if the pump is rated for 220-240V.

In this case, cut the live wire.

In this case, cut the live wire.

Please Log in or Create an account to join the conversation.

- deus

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 2

16 Jul 2022 13:35 #247463

by deus

Replied by deus on topic Wiring of oil pump.

Ok - so my initial line of thought wasn't wrong to rewire it and effectively making 'R' neutral?

It seems the max i can input is 250V AC according to this drawing but description says 220V. This is the pump:

www.allworldmachinery.com/itemdetail/TM-302FW-T2P

It seems the max i can input is 250V AC according to this drawing but description says 220V. This is the pump:

www.allworldmachinery.com/itemdetail/TM-302FW-T2P

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1975

- Thank you received: 808

16 Jul 2022 14:41 #247467

by spumco

Replied by spumco on topic Wiring of oil pump.

A fair amount of this depends on where you live and what your "240vac single-phase" looks like.

Are you in the US and have 240-1P with two 120v 'hot' wires?

Or are your somewhere else and have a single 240v 'hot' conductor?

If you're in the US a very simple & cheap DPST (or DPDT) relay will work fine for this.

Are you in the US and have 240-1P with two 120v 'hot' wires?

Or are your somewhere else and have a single 240v 'hot' conductor?

If you're in the US a very simple & cheap DPST (or DPDT) relay will work fine for this.

Please Log in or Create an account to join the conversation.

- deus

- Offline

- Junior Member

-

Less

More

- Posts: 24

- Thank you received: 2

16 Jul 2022 14:55 #247469

by deus

Replied by deus on topic Wiring of oil pump.

It is Australia with 240V /50Hz single phase with one hot conductor.

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1975

- Thank you received: 808

16 Jul 2022 15:04 #247470

by spumco

Replied by spumco on topic Wiring of oil pump.

Gotcha.

Do you want the ability to manually operate the pump using the on-board "FEED" button, or exclusively through LCNC?

Do you want the ability to manually operate the pump using the on-board "FEED" button, or exclusively through LCNC?

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1975

- Thank you received: 808

16 Jul 2022 16:06 #247473

by spumco

Replied by spumco on topic Wiring of oil pump.

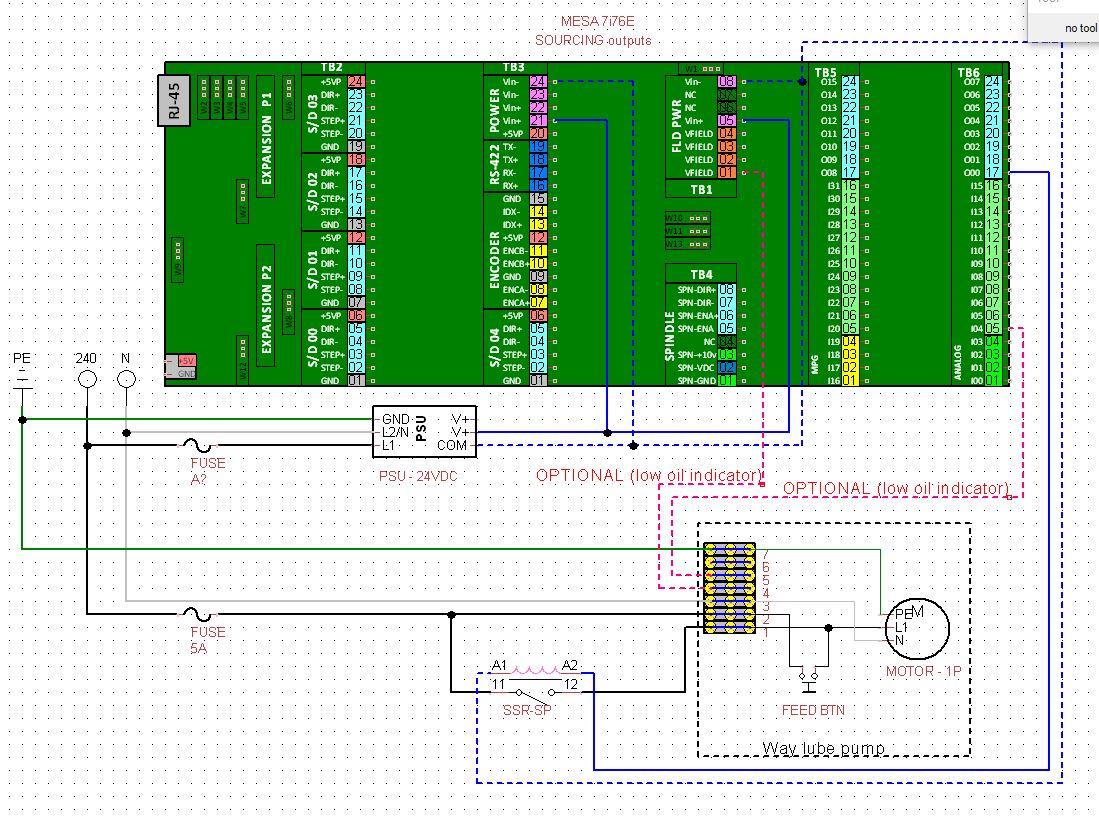

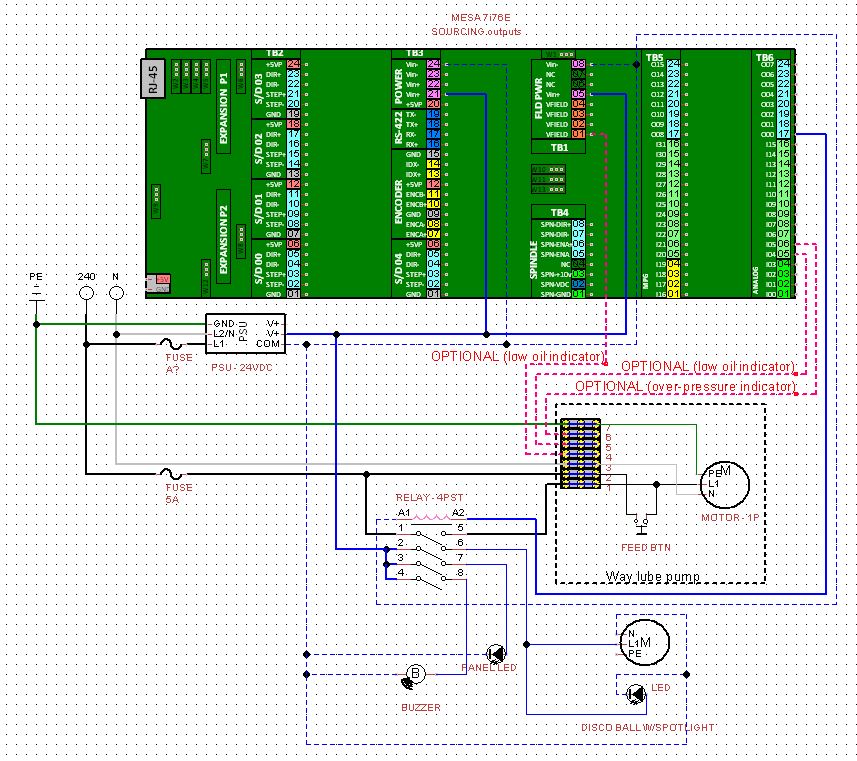

I'm shamelessly procrastinating on my own LCNC project, so here's a diagram of what I think you're after

NOTE - you did write that you're using a 7i76E, not "ED". Those are sourcing outputs and I've drawn it as such. If you're using an "ED" the 24vdc connections will be different.

PS - there are some examples of lube pump control using Classic Ladder in the CL sub-forum. Generally controls based on a timer that counts while some 'axis-is-moving' signal is on, plus a manual override to prime it.

NOTE - you did write that you're using a 7i76E, not "ED". Those are sourcing outputs and I've drawn it as such. If you're using an "ED" the 24vdc connections will be different.

- The pump is a 240VAC single-phase. It can be powered by

- single 240v conductor + neutral (your arrangement), or

- by 120v + 120v conductors and no neutral (US wiring)

- Break the 'hot' line with the SSR ("R") and treat "T" as the neutral.

- Note - not a fan of SSR's in certain applications as they tend to fail closed (on)

- Should be fine here however as long as you've got a real estop contactor or main disconnect on the machine.

- My preference would be to use a DPST or DPDT mechanical relay, and use the second set of contacts to trigger a pilot light. Would make a nice control panel trinket, and is a good indicator of when the pump is powered with zero LCNC programming required.

- Contact #1 - 240 pump power

- Contact #2 - 24vdc to a yellow "LUBE ON" lamp

- Hot line goes to terminals #1 & #2.

- #1 is switched with the SSR by LCNC using the 7i76E output

- #2 is always-hot, permitting local pump control using the "FEED" button on the pump assy.

- Neutral is internally fused

- Optional

- There's a float switch indicator circuit internal to the way lube assy. Feel free to connect that to an input on the 7i76E so you can trigger an on-screen message to refill the pump.

- These look like dry contacts, so should be fine with the 24VDC to/from 7i76E. But leave disconnected until you power the pump and verify there's no voltage at those terminals.

- Extra-optional, not drawn

- Connect terminal #6 to another 7i76E input and you can have a pump over-pressure alarm

PS - there are some examples of lube pump control using Classic Ladder in the CL sub-forum. Generally controls based on a timer that counts while some 'axis-is-moving' signal is on, plus a manual override to prime it.

Attachments:

Please Log in or Create an account to join the conversation.

- spumco

- Offline

- Platinum Member

-

Less

More

- Posts: 1975

- Thank you received: 808

16 Jul 2022 16:25 #247479

by spumco

Replied by spumco on topic Wiring of oil pump.

Attachments:

The following user(s) said Thank You: arvidb, tommylight, pommen, deus

Please Log in or Create an account to join the conversation.

Time to create page: 0.135 seconds