Retrofitting a Brother TC321N PPC

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

22 May 2023 13:35 #271930

by mugurlu

Retrofitting a Brother TC321N PPC was created by mugurlu

Hello friends,

I have some questions about the conversion of Brother TC321N PPC CNC machine to LinuxCNC.

I will also try to answer your questions to the best of my ability.

Control section:

Mesa 6i25 and my own developed STMF2 series USB interface card

The modified parts are as follows:

Axis drivers and motors

Linear rails and carriages

Z-axis with a ball screw spindle

For the movement of the PPC 2xTable, I designed a special setup with a ball screw spindle.

I have also replaced the spindle motor, but after extensive testing, I managed to run the original spindle motor. In the next operation, I will be using the original spindle.

I am planning to share detailed information about this topic. (20BA150FFWB2 Sanyodenki BL Super)

Now I have some questions about the spindle and bearings that I am having issues with. I value the opinions of all my friends regarding this matter.

The machine has a BT30 spindle.For example, when I use a 6mm diameter endmill to drill a hole, I encounter a result of 6.19mm.

Therefore, I have removed the spindle and drawbar because of this issue.

I want to replace the angular bearings of the spindle because when I manually push the spindle, there is a play of approximately 30um to 50um in the spindle shaft.

Therefore, I have removed the spindle and drawbar because of this issue.

I have noticed that the springs on the drawbar are broken, and I have placed an order to replace them.

The specifications of the Draw Bar are as follows:

Size: 22.5x11.2x1.25 mm

Material: DIN 2093 (50CrV4)

Quantity: 130 pieces, consisting of 2 reverse and 2 straight springs.

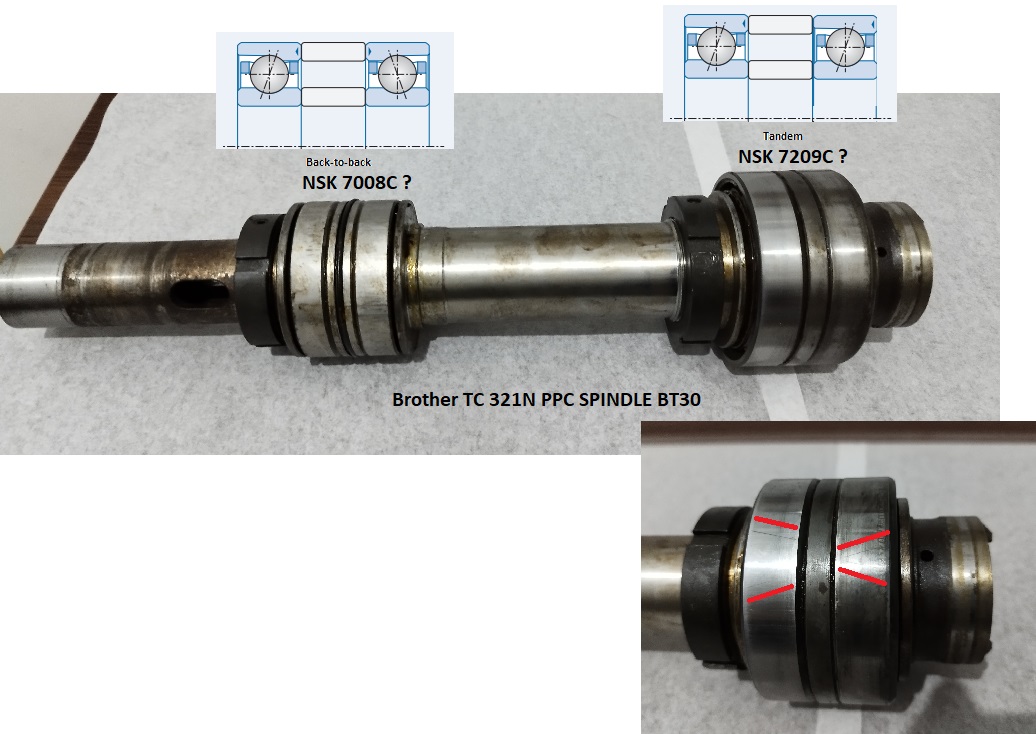

BT30 spindle

The codes on the bearings are very faint and difficult to understand.

The upper bearing assembly consists of NSK 7008C bearings arranged in a back-to-back configuration.

The lower bearing assembly consists of NSK 7209C bearings arranged in a tandem configuration.

Are they custom-made?

Does anyone have information about the original bearing codes?

Can you assist me with this matter?

Best regards.

I have some questions about the conversion of Brother TC321N PPC CNC machine to LinuxCNC.

I will also try to answer your questions to the best of my ability.

Control section:

Mesa 6i25 and my own developed STMF2 series USB interface card

The modified parts are as follows:

Axis drivers and motors

Linear rails and carriages

Z-axis with a ball screw spindle

For the movement of the PPC 2xTable, I designed a special setup with a ball screw spindle.

I have also replaced the spindle motor, but after extensive testing, I managed to run the original spindle motor. In the next operation, I will be using the original spindle.

I am planning to share detailed information about this topic. (20BA150FFWB2 Sanyodenki BL Super)

Now I have some questions about the spindle and bearings that I am having issues with. I value the opinions of all my friends regarding this matter.

The machine has a BT30 spindle.For example, when I use a 6mm diameter endmill to drill a hole, I encounter a result of 6.19mm.

Therefore, I have removed the spindle and drawbar because of this issue.

I want to replace the angular bearings of the spindle because when I manually push the spindle, there is a play of approximately 30um to 50um in the spindle shaft.

Therefore, I have removed the spindle and drawbar because of this issue.

I have noticed that the springs on the drawbar are broken, and I have placed an order to replace them.

The specifications of the Draw Bar are as follows:

Size: 22.5x11.2x1.25 mm

Material: DIN 2093 (50CrV4)

Quantity: 130 pieces, consisting of 2 reverse and 2 straight springs.

BT30 spindle

The codes on the bearings are very faint and difficult to understand.

The upper bearing assembly consists of NSK 7008C bearings arranged in a back-to-back configuration.

The lower bearing assembly consists of NSK 7209C bearings arranged in a tandem configuration.

Are they custom-made?

Does anyone have information about the original bearing codes?

Can you assist me with this matter?

Best regards.

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19773

- Thank you received: 4601

22 May 2023 13:49 #271931

by andypugh

Replied by andypugh on topic Retrofitting a Brother TC321N PPC

The hand engraving might indicate that the bearings were supplied as matched pairs. If so then the engraving might be indicating what they are matched for.

www.nsk.com/products/ballbearing/angularcontact/

(Click on "Reference 2")

You might expect to see codes "DB" "DF" or "DT" if that is the case.

www.nsk.com/products/ballbearing/angularcontact/

(Click on "Reference 2")

You might expect to see codes "DB" "DF" or "DT" if that is the case.

The following user(s) said Thank You: mugurlu

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

22 May 2023 15:24 #271942

by mugurlu

Replied by mugurlu on topic Retrofitting a Brother TC321N PPC

I plan to install the bearings as I deduced from the arrangement. The upper bearings will be aligned in a face-to-face (DB) configuration, and the

lower bearings will be aligned in a tandem (DT) configuration.The visual representation of the lower bearings is as follows.

I couldn't see the preload coding on the bearings in this visual.

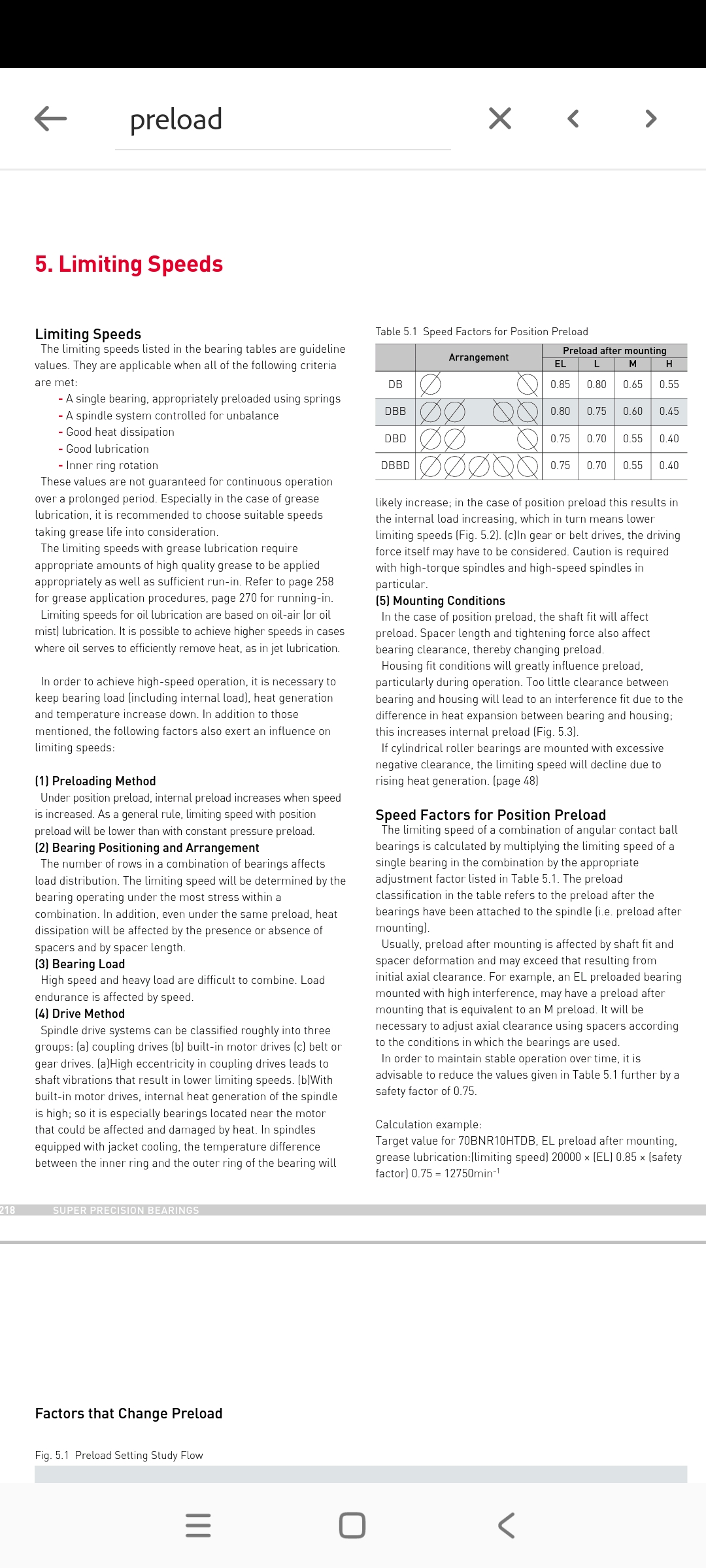

Can standard NSK bearings available on the market be used?The NSK bearings available from the NSK company are as follows: NSK 7008C DUL P3 and NSK 7209C DUL P3Here, I have a question regarding the preload issue. Should the bearing suffix be DUL or DUM?Which preload should be selected? L: Light M: Medium

Thank you,

Best regards.

lower bearings will be aligned in a tandem (DT) configuration.The visual representation of the lower bearings is as follows.

I couldn't see the preload coding on the bearings in this visual.

Can standard NSK bearings available on the market be used?The NSK bearings available from the NSK company are as follows: NSK 7008C DUL P3 and NSK 7209C DUL P3Here, I have a question regarding the preload issue. Should the bearing suffix be DUL or DUM?Which preload should be selected? L: Light M: Medium

Thank you,

Best regards.

Attachments:

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

24 May 2023 06:42 #272079

by mugurlu

Replied by mugurlu on topic Retrofitting a Brother TC321N PPC

Hello again, friends,

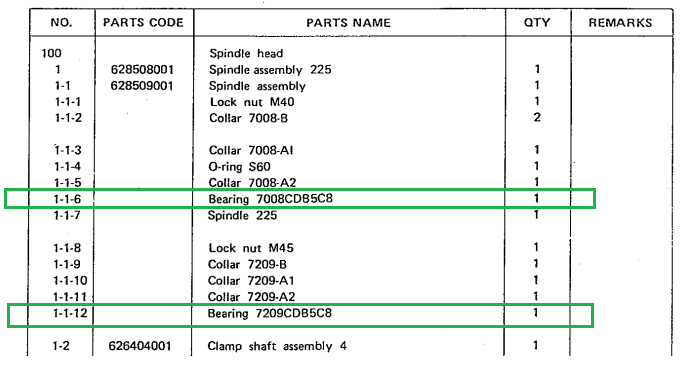

I don't have the parts list for Brother TC-321. Therefore, I don't have the exact bearing codes.

That's great that you found the parts list for Brother TC-225, and it provides the information that the top and bottom bearing codes are in a DB (back-to-back) configuration.

Top Bearing: 7008CDB5C8

Bottom Bearing: 7209CDB5C8

Lastly, I couldn't find the "5C8" code in the catalogs. Does anyone have information about it?

Also, when I disassembled the spindle, it appears that the lower bearings are connected in a DT (tandem) configuration. My question is, can bearings that are originally matched as DB be used as DT?

Is it possible that the spindle in my case has been modified later?

Thank you,

Best regards.

I don't have the parts list for Brother TC-321. Therefore, I don't have the exact bearing codes.

That's great that you found the parts list for Brother TC-225, and it provides the information that the top and bottom bearing codes are in a DB (back-to-back) configuration.

Top Bearing: 7008CDB5C8

Bottom Bearing: 7209CDB5C8

Lastly, I couldn't find the "5C8" code in the catalogs. Does anyone have information about it?

Also, when I disassembled the spindle, it appears that the lower bearings are connected in a DT (tandem) configuration. My question is, can bearings that are originally matched as DB be used as DT?

Is it possible that the spindle in my case has been modified later?

Thank you,

Best regards.

Attachments:

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

24 May 2023 19:23 #272097

by besriworld

Replied by besriworld on topic Retrofitting a Brother TC321N PPC

Hi, I have some experience with different spindles. The picture (wiring diagram) from the first comment is wrong. The front pair of bearings are fixed and the rear pair of bearings is movable in the spindle body. This is a standard configuration for high speed spindles. Both pairs of bearings are connected in a DB scheme.

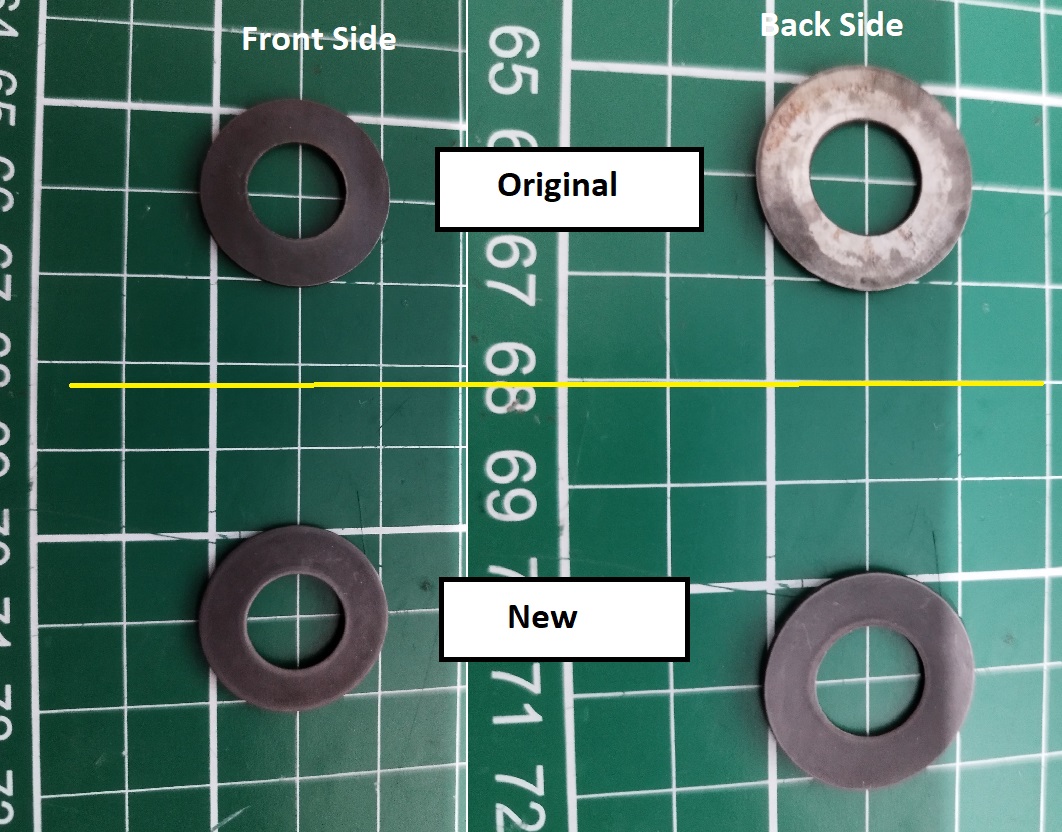

Most modern bearings are sold for universal joint. The higher the preload, the more it affects the maximum rpm. Check the two steel spacer bushings. They should be exactly the same thickness.

If you live in Europe check FAG bearings for LOW price

Most modern bearings are sold for universal joint. The higher the preload, the more it affects the maximum rpm. Check the two steel spacer bushings. They should be exactly the same thickness.

If you live in Europe check FAG bearings for LOW price

The following user(s) said Thank You: mugurlu

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

24 May 2023 19:40 #272100

by mugurlu

Replied by mugurlu on topic Retrofitting a Brother TC321N PPC

Hi,

besriworld, thanks for the information you provided.

When I removed it from the machine, the rear was assembled in a DB configuration, and the front was as shown in the picture (DT tandem). It is visible on the markings.

Can we definitely say it's incorrect?

By the way, I will check the steel spacer bushings.

Thank you,

Best regards.

besriworld, thanks for the information you provided.

When I removed it from the machine, the rear was assembled in a DB configuration, and the front was as shown in the picture (DT tandem). It is visible on the markings.

Can we definitely say it's incorrect?

By the way, I will check the steel spacer bushings.

Thank you,

Best regards.

Attachments:

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

24 May 2023 21:04 - 25 May 2023 05:05 #272116

by besriworld

Replied by besriworld on topic Retrofitting a Brother TC321N PPC

Yes, I think it's wrong. Thus, the axial load works in one direction.

I think the marking on the bearing shows the installer how to joint the bearing.

The lines must match in sequence! In the case when the bearing is for universal joint the lines must be the same size on both bearings.

ps: You can upload more photos of the project. Always like most pictures. I also work on a milling machine Mori seiki MV-junior . I will make a thread about the machine.

I think the marking on the bearing shows the installer how to joint the bearing.

The lines must match in sequence! In the case when the bearing is for universal joint the lines must be the same size on both bearings.

ps: You can upload more photos of the project. Always like most pictures. I also work on a milling machine Mori seiki MV-junior . I will make a thread about the machine.

Last edit: 25 May 2023 05:05 by besriworld.

The following user(s) said Thank You: mugurlu

Please Log in or Create an account to join the conversation.

- mugurlu

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 1

27 May 2023 09:00 #272252

by mugurlu

Replied by mugurlu on topic Retrofitting a Brother TC321N PPC

Attachments:

Please Log in or Create an account to join the conversation.

- besriworld

- Offline

- Elite Member

-

Less

More

- Posts: 309

- Thank you received: 83

27 May 2023 14:13 #272264

by besriworld

Replied by besriworld on topic Retrofitting a Brother TC321N PPC

Hi, no problem. Some manufacturers put bearings with a special preload. In your case you have standard bearings.

Preload affects RPM and life .

You can see the documentation. www.nsk-literature.com/en/super-precisio...offline/download.pdf

A few notes: Grease must be weighed. Too much grease can lead to overheating.

Preload affects RPM and life .

You can see the documentation. www.nsk-literature.com/en/super-precisio...offline/download.pdf

A few notes: Grease must be weighed. Too much grease can lead to overheating.

Attachments:

Please Log in or Create an account to join the conversation.

Time to create page: 0.511 seconds