No spindle stopped signal from VFD

- tom_no

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 7

14 Jan 2024 12:45 #290634

by tom_no

No spindle stopped signal from VFD was created by tom_no

Hi,

I'm having issues with the spindle stopped signal from the VFD on a Biesse Rover 322 retrofit.

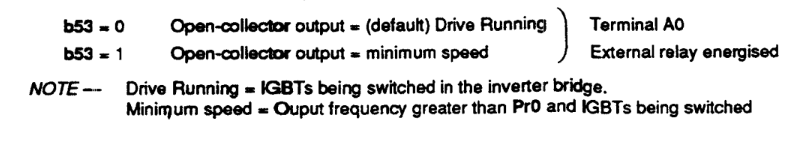

VFD is a Commander CD-series, with a spindle stopped signal configured on Terminal A0 (see attachment for details). I suspect the output to be bruned, as it gives 24V out, no matter the state of the VFD (ready, accelerating, at speeds, decelerating, stopped).

Original config of the machine uses this output for spindle stopped signal, and RS-485 for speed and other commands. As the serial link uses ANSI x3.28 (not modbus) I've not been able to get it running with LinuxCNC. Hence I've been left with analog control of the VFD.

Reading the 0-10 volt output from the VFD with analog in on MESA hardware gives me 2.3 to 6.1 volts with lots of noise. Tried several different cables and shielding strategies without luck.

Would appreciate any and all input on following:

I'm having issues with the spindle stopped signal from the VFD on a Biesse Rover 322 retrofit.

VFD is a Commander CD-series, with a spindle stopped signal configured on Terminal A0 (see attachment for details). I suspect the output to be bruned, as it gives 24V out, no matter the state of the VFD (ready, accelerating, at speeds, decelerating, stopped).

Original config of the machine uses this output for spindle stopped signal, and RS-485 for speed and other commands. As the serial link uses ANSI x3.28 (not modbus) I've not been able to get it running with LinuxCNC. Hence I've been left with analog control of the VFD.

Reading the 0-10 volt output from the VFD with analog in on MESA hardware gives me 2.3 to 6.1 volts with lots of noise. Tried several different cables and shielding strategies without luck.

Would appreciate any and all input on following:

- Has there been any work done on implementing ANSI x3.28 over RS-485?

- What's involved in writing a driver to get the serial interface working via USB dongle?

- Can the output terminal on the VFD be repaired?

- How to reliably read the 0-10 volt speed output from VFD

Attachments:

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19798

- Thank you received: 4608

14 Jan 2024 17:18 #290670

by andypugh

Replied by andypugh on topic No spindle stopped signal from VFD

It doesn't say what type of

Open Collector output

it is. How are you testing the output? It might need a pull-up or pull-down resistor if it is driving a digital input rather than a relay.

Is there a spindle encoder?

Writing a driver is probably possible, but not trivial. If I was trying to do it I would probably look at Python and the pyserial library as a starting point.

linuxcnc.org/docs/stable/html/hal/halmodule.html has some information about how to create HAL pins to communicate with the rest of LinuxCNC from Python.

Is there a spindle encoder?

Writing a driver is probably possible, but not trivial. If I was trying to do it I would probably look at Python and the pyserial library as a starting point.

linuxcnc.org/docs/stable/html/hal/halmodule.html has some information about how to create HAL pins to communicate with the rest of LinuxCNC from Python.

Please Log in or Create an account to join the conversation.

- tom_no

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 7

15 Jan 2024 21:27 #290802

by tom_no

Replied by tom_no on topic No spindle stopped signal from VFD

the open collector output drives a relay as per the original configuration of the machine. relay ties furter into the hardware, likely providing hard-wired safety logic of sorts. Also connection from relay to IO on MESA.

I've tested reading IO from relay and mulimeter at VFD terminals both with and without relay connected to VFD.

No spindle ecoder (woodworking machine).

Thanks for place to start wrt driver development. Would be interesting as ways of contributing to community in addition to solving my problem. Decided to pay my way out of the problem by ordering replacement VFD. Hope I won't regret it...

I've tested reading IO from relay and mulimeter at VFD terminals both with and without relay connected to VFD.

No spindle ecoder (woodworking machine).

Thanks for place to start wrt driver development. Would be interesting as ways of contributing to community in addition to solving my problem. Decided to pay my way out of the problem by ordering replacement VFD. Hope I won't regret it...

Please Log in or Create an account to join the conversation.

- imperial

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

28 Jan 2024 19:26 #291816

by imperial

Replied by imperial on topic No spindle stopped signal from VFD

hi.

i'm new here and in automation.

i have an biesse 322 and want to ungrade it.

please if you can help me give an answer, i want to have a large discussion in privat

thanks

i'm new here and in automation.

i have an biesse 322 and want to ungrade it.

please if you can help me give an answer, i want to have a large discussion in privat

thanks

Please Log in or Create an account to join the conversation.

- imperial

- Offline

- New Member

-

Less

More

- Posts: 6

- Thank you received: 0

28 Jan 2024 19:28 #291817

by imperial

Replied by imperial on topic No spindle stopped signal from VFD

of course, linux cnc will be the software but i am scared by the dimensions of the electric schemes

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7278

29 Jan 2024 08:07 #291876

by tommylight

Replied by tommylight on topic No spindle stopped signal from VFD

Spammer left...

Please Log in or Create an account to join the conversation.

- tom_no

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 31

- Thank you received: 7

18 Feb 2024 20:32 #293709

by tom_no

Replied by tom_no on topic No spindle stopped signal from VFD

To close this post: I eventually gave up on the original VFD and opted to buy a new Delta MS300 that has MODBUS communication. After some fooling around I got it up and running with proper spindle stopped, spindle at speed +++ signals. All well.

Top tip to anyone following the same path: MB2HAL does not support MODBUS ASCII (default on the drive). Need to change drive to MODBUS RTU. Would have saved me a couple of days of hairloss if I knew when starting out.

Top tip to anyone following the same path: MB2HAL does not support MODBUS ASCII (default on the drive). Need to change drive to MODBUS RTU. Would have saved me a couple of days of hairloss if I knew when starting out.

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21310

- Thank you received: 7278

18 Feb 2024 21:03 #293719

by tommylight

Replied by tommylight on topic No spindle stopped signal from VFD

LOL@ profile picture

The following user(s) said Thank You: tom_no

Please Log in or Create an account to join the conversation.

Time to create page: 0.111 seconds