- GCode and Part Programs

- CAD CAM

- fusion360 to Linuxcnc CAM problem - multiple tools - manual changing

fusion360 to Linuxcnc CAM problem - multiple tools - manual changing

- gzcwnk

- Offline

- Premium Member

-

Less

More

- Posts: 83

- Thank you received: 2

08 Jan 2019 07:54 #123758

by gzcwnk

fusion360 to Linuxcnc CAM problem was created by gzcwnk

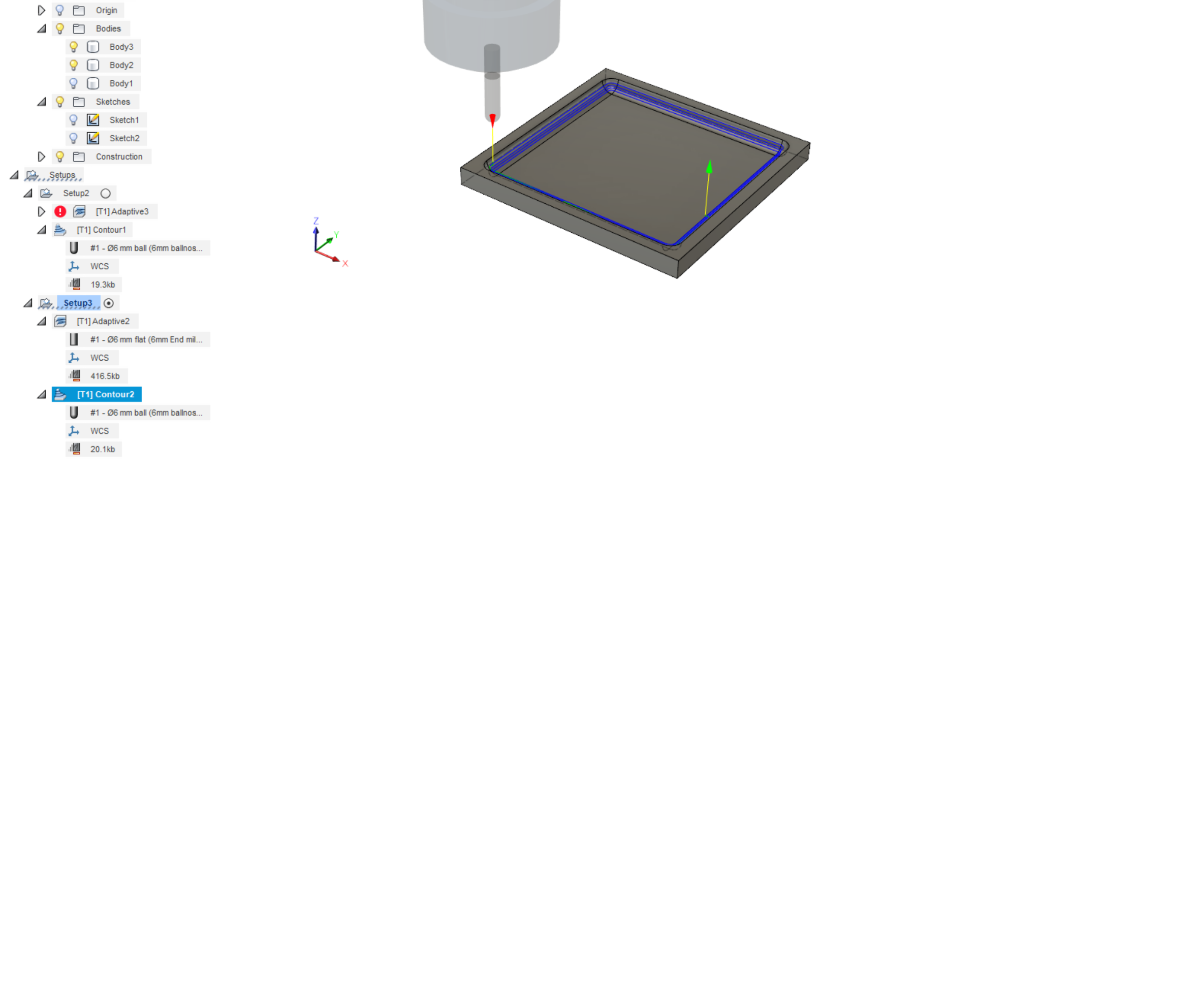

So I am trying to get Fusion 360 drawn piece to work on Linuxcnc and partially failing. The first run an adaptive clearing works fine. I then expect the spindle to wait for me to change the 3 flute roughing end mill to a ball nose for the second operation, this doesnt seem to occur. I have no idea what I am doing wrong.

The one of interest is setup3. setup3 is my second go setup 2 didnt work either just a bigger piece which took too long.

What info do you need to help me? the f3d file? ngc file?

The one of interest is setup3. setup3 is my second go setup 2 didnt work either just a bigger piece which took too long.

What info do you need to help me? the f3d file? ngc file?

Attachments:

Please Log in or Create an account to join the conversation.

- snoozer77

-

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 12

08 Jan 2019 07:59 #123759

by snoozer77

Replied by snoozer77 on topic fusion360 to Linuxcnc CAM problem

Hi, You have both tools set to tool #1. Change your finishing tool to another number and you will be good to go. Cheers Matt

The following user(s) said Thank You: gzcwnk

Please Log in or Create an account to join the conversation.

- gzcwnk

- Offline

- Premium Member

-

Less

More

- Posts: 83

- Thank you received: 2

08 Jan 2019 08:18 #123760

by gzcwnk

Replied by gzcwnk on topic fusion360 to Linuxcnc CAM problem

Attachments:

Please Log in or Create an account to join the conversation.

- Skullworks

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 2

08 Jan 2019 08:23 #123761

by Skullworks

Replied by Skullworks on topic fusion360 to Linuxcnc CAM problem

Snoozer77 is correct, can't have all tools be #1 or T1

Also you will want to have your post processor insert a G64 P Q for each tool.

see v2.7 docs - G64

Also you will want to have your post processor insert a G64 P Q for each tool.

see v2.7 docs - G64

Please Log in or Create an account to join the conversation.

- gzcwnk

- Offline

- Premium Member

-

Less

More

- Posts: 83

- Thank you received: 2

08 Jan 2019 08:30 #123762

by gzcwnk

Replied by gzcwnk on topic fusion360 to Linuxcnc CAM problem

"G64 P Q"

no indication where or how to do that.

no indication where or how to do that.

Please Log in or Create an account to join the conversation.

- gzcwnk

- Offline

- Premium Member

-

Less

More

- Posts: 83

- Thank you received: 2

08 Jan 2019 08:32 #123763

by gzcwnk

Replied by gzcwnk on topic fusion360 to Linuxcnc CAM problem

"Snoozer77 is correct, can't have all tools be #1 or T1"

No problems, no idea why they all have the same number. I tried to increment them and nothing happened so did it manually.

No problems, no idea why they all have the same number. I tried to increment them and nothing happened so did it manually.

Please Log in or Create an account to join the conversation.

- snoozer77

-

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 12

08 Jan 2019 08:47 #123764

by snoozer77

Replied by snoozer77 on topic fusion360 to Linuxcnc CAM problem

Will give you a quick run down if your unsure on how to change it (or for anyone else who isn't sure). While using cam workspace, click on Manage, And select "Tool Library". In the Libraries Field (left hand side), click on the document name you are working on. Your tools will be displayed. Right click and select "edit tool" on the tool you want to change number (2nd tool in list). Go to post processor tab and change the tool number in the top box to "2", the numbers under will change automatically. Click Ok, you will want to check your feeds and speeds, as you can choose to override the previous data or not. After you check your feeds and speeds, you are ready to re-post the G-code and start machining.Hopefully i havnt forgotten anything. Hope this helps. Cheers Matt

The following user(s) said Thank You: gzcwnk

Please Log in or Create an account to join the conversation.

- snoozer77

-

- Offline

- Premium Member

-

Less

More

- Posts: 97

- Thank you received: 12

08 Jan 2019 08:50 #123765

by snoozer77

Replied by snoozer77 on topic fusion360 to Linuxcnc CAM problem

Got the pics in the wrong order. The circles have numbers to follow in the pics. You mat already know this, but i thought it might help anyone who doesnt.

The following user(s) said Thank You: gzcwnk

Please Log in or Create an account to join the conversation.

- gzcwnk

- Offline

- Premium Member

-

Less

More

- Posts: 83

- Thank you received: 2

09 Jan 2019 06:58 #123814

by gzcwnk

Replied by gzcwnk on topic fusion360 to Linuxcnc CAM problem

Ok so this fixed the problem, I can now change the tool OK, and the second part runs, thanks.

However I have no control over the axis(es) so I cant zero the second tool's Z and since its shorter it just ran in mid air.

I cant seem to find anything that allows me to zero Z to allow for the different lengths of the tools, how is that done?

Googling suggests I run different processes as different files?

However I have no control over the axis(es) so I cant zero the second tool's Z and since its shorter it just ran in mid air.

I cant seem to find anything that allows me to zero Z to allow for the different lengths of the tools, how is that done?

Googling suggests I run different processes as different files?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21012

- Thank you received: 7162

09 Jan 2019 07:54 #123817

by tommylight

Replied by tommylight on topic fusion360 to Linuxcnc CAM problem

Or you can use the tool table in Linunxcnc and set the Z offset there, for each tool separately.

Please Log in or Create an account to join the conversation.

- GCode and Part Programs

- CAD CAM

- fusion360 to Linuxcnc CAM problem - multiple tools - manual changing

Time to create page: 0.518 seconds