4axis xyuv constant velocity

- luckym

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

02 Jan 2013 01:20 #28268

by luckym

4axis xyuv constant velocity was created by luckym

Hello,

How linuxcnc compute constant velocity for 4 axis linear wire cutting machine? I have 4 axis foam cutter, X Y for the left side and A B axis for right side.

How linuxcnc treats for example this: 2 linear segments(segment I mean the tool trajectory). on the XY side they make 90 deg. corner and on the AB side they are almost coliner. Next the same but 90 deg corner on AB side and colinear on XY side. Will these situacions be treated equally?.

Or this example: On XY is the length of linear segment longer then corresponding segment on the AB side. If I set the feed for which side is this feed given.? Is there any option to tell linuxcnc, AB and XY are axes pairs? I think it would be good if the given feed is max of AB feed or XY feed. Is this solved in linuxcnc?

I'm using Mach3 now but I'm planning to use Linuxcnc. Just I've read little documentation, so sorry if this is explained there.

thanks

michal

How linuxcnc compute constant velocity for 4 axis linear wire cutting machine? I have 4 axis foam cutter, X Y for the left side and A B axis for right side.

How linuxcnc treats for example this: 2 linear segments(segment I mean the tool trajectory). on the XY side they make 90 deg. corner and on the AB side they are almost coliner. Next the same but 90 deg corner on AB side and colinear on XY side. Will these situacions be treated equally?.

Or this example: On XY is the length of linear segment longer then corresponding segment on the AB side. If I set the feed for which side is this feed given.? Is there any option to tell linuxcnc, AB and XY are axes pairs? I think it would be good if the given feed is max of AB feed or XY feed. Is this solved in linuxcnc?

I'm using Mach3 now but I'm planning to use Linuxcnc. Just I've read little documentation, so sorry if this is explained there.

thanks

michal

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 826

- Thank you received: 160

02 Jan 2013 01:34 #28270

by jmelson

makes the machine stop at every endpoint. G64 blends the moves so that when a move

begins to decelerate at the end, the next move begins to accelerate. This will cause

a curve to develop or square corners, and the size of the curve is inversely proportional

to the acceleration settings of the affected axes in the .ini file. G64 also has P and Q

parameters that allow redundant lines to be merged and to adjust the amount of

path variation due to the blending. This is described in greater detail in the user manual

on the documentation page in section 14.31.

Jon

Replied by jmelson on topic 4axis xyuv constant velocity

Well, there are 3 basic modes, settable by a G61/G64 codes. Exact path mode (G61)Hello,

How linuxcnc compute constant velocity for 4 axis linear wire cutting machine? I have 4 axis foam cutter, X Y for the left side and A B axis for right side.

How linuxcnc treats for example this: 2 linear segments(segment I mean the tool trajectory). on the XY side they make 90 deg. corner and on the AB side they are almost coliner. Next the same but 90 deg corner on AB side and colinear on XY side. Will these situacions be treated equally?.

Or this example: On XY is the length of linear segment longer then corresponding segment on the AB side. If I set the feed for which side is this feed given.? Is there any option to tell linuxcnc, AB and XY are axes pairs? I think it would be good if the given feed is max of AB feed or XY feed. Is this solved in linuxcnc?

I'm using Mach3 now but I'm planning to use Linuxcnc. Just I've read little documentation, so sorry if this is explained there.

thanks

michal

makes the machine stop at every endpoint. G64 blends the moves so that when a move

begins to decelerate at the end, the next move begins to accelerate. This will cause

a curve to develop or square corners, and the size of the curve is inversely proportional

to the acceleration settings of the affected axes in the .ini file. G64 also has P and Q

parameters that allow redundant lines to be merged and to adjust the amount of

path variation due to the blending. This is described in greater detail in the user manual

on the documentation page in section 14.31.

Jon

The following user(s) said Thank You: luckym

Please Log in or Create an account to join the conversation.

- luckym

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

02 Jan 2013 01:57 #28273

by luckym

Ok, thanks for answer, I understand this, I can imagine this for 2D xy or 3D xyz.

But I'm asking for feed rate. The feed for 2 or 3 axis is result vector of x, y (and z ) motion. But if I have 2 pairs of axis xy and uv there may be 2 feed rates for xy and uv. For which of axis pairs is the feed given?

Will these 2 examples move equally (just swaped xy and uv motion) or xy in both examples at feed 100?

g00 x0 y0 u0 v0

f100

g01 x100 y100 u200 v200

g00 x0 y0 u0 v0

f100

g01 x200 y200 u100 v100

michal

Replied by luckym on topic 4axis xyuv constant velocity

Well, there are 3 basic modes, settable by a G61/G64 codes. Exact path mode (G61)

makes the machine stop at every endpoint. G64 blends the moves so that when a move

begins to decelerate at the end, the next move begins to accelerate. This will cause

a curve to develop or square corners, and the size of the curve is inversely proportional

to the acceleration settings of the affected axes in the .ini file. G64 also has P and Q

parameters that allow redundant lines to be merged and to adjust the amount of

path variation due to the blending. This is described in greater detail in the user manual

on the documentation page in section 14.31.

Jon

Ok, thanks for answer, I understand this, I can imagine this for 2D xy or 3D xyz.

But I'm asking for feed rate. The feed for 2 or 3 axis is result vector of x, y (and z ) motion. But if I have 2 pairs of axis xy and uv there may be 2 feed rates for xy and uv. For which of axis pairs is the feed given?

Will these 2 examples move equally (just swaped xy and uv motion) or xy in both examples at feed 100?

g00 x0 y0 u0 v0

f100

g01 x100 y100 u200 v200

g00 x0 y0 u0 v0

f100

g01 x200 y200 u100 v100

michal

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 155

02 Jan 2013 17:11 - 02 Jan 2013 17:12 #28296

by Rick G

Replied by Rick G on topic 4axis xyuv constant velocity

You might want to look here...

www.linuxcnc.org/docs/2.4/html/gcode_mai...ml#sub:G93,-G94:-Set

In theory linuxcnc should make the move at the demanded speed as long as all the axis involved can move at that speed, if the speed is not possible for one of the axis the entire move will be slowed down so that the all axis hit the endpoint at the same time.

When using G94 what you are really setting with those moves is the speed of the combined move the machine will make, not the individual axis speeds, so yes if the machine can handle it both moves will take the same time.

Rick G

www.linuxcnc.org/docs/2.4/html/gcode_mai...ml#sub:G93,-G94:-Set

In theory linuxcnc should make the move at the demanded speed as long as all the axis involved can move at that speed, if the speed is not possible for one of the axis the entire move will be slowed down so that the all axis hit the endpoint at the same time.

When using G94 what you are really setting with those moves is the speed of the combined move the machine will make, not the individual axis speeds, so yes if the machine can handle it both moves will take the same time.

Rick G

Last edit: 02 Jan 2013 17:12 by Rick G.

The following user(s) said Thank You: luckym

Please Log in or Create an account to join the conversation.

- luckym

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

02 Jan 2013 22:06 #28307

by luckym

Replied by luckym on topic 4axis xyuv constant velocity

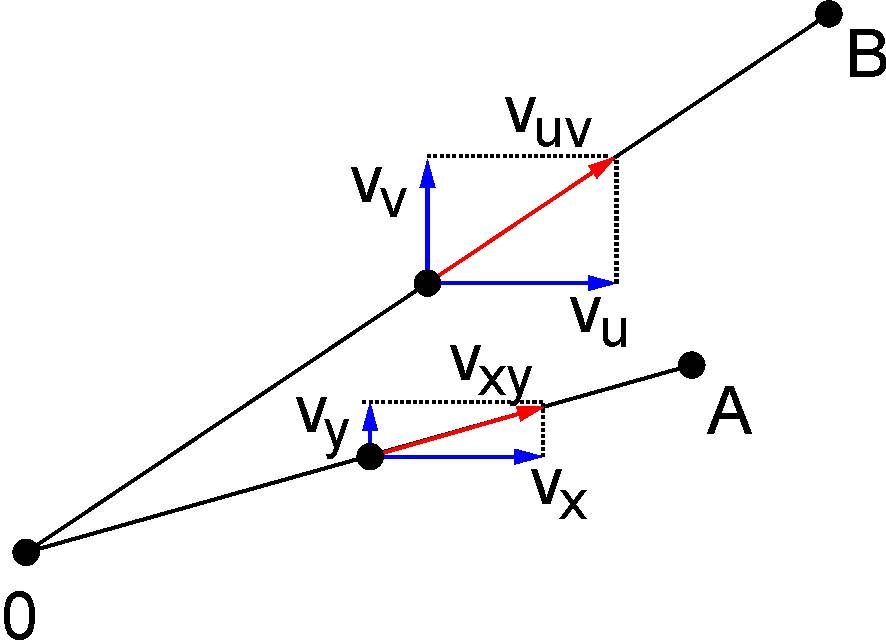

OK, please look at the picture. I have 4 linear axis xy and uv. Both axis pairs start from 0 and xy moves to A and uv moves to B At the same time they hit A and B. now What is the feed rate? is it computed in this manner : feed = sqrt(vx^2 + vy^2 + vu^2 +vz^2) ?

If yes this, then in this case the feed is not the relative tool speed in respect of work piece. If uv slow down, xy speed up. In a case both profiles uv and xy are the same the actual feed (wire speed) should by: setting_feed / sqrt(2). So if uv stops, xy move with setting _feed.

I'm thinking about this because: lets imagine: I've found the optimal cutting speed for the case both cutting contours xy and uv are equall. In a case no equall contours, if uv slow down xy can go above optimal speed and the foam doesn't manage to melt.

If yes this, then in this case the feed is not the relative tool speed in respect of work piece. If uv slow down, xy speed up. In a case both profiles uv and xy are the same the actual feed (wire speed) should by: setting_feed / sqrt(2). So if uv stops, xy move with setting _feed.

I'm thinking about this because: lets imagine: I've found the optimal cutting speed for the case both cutting contours xy and uv are equall. In a case no equall contours, if uv slow down xy can go above optimal speed and the foam doesn't manage to melt.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

02 Jan 2013 22:26 #28309

by BigJohnT

Replied by BigJohnT on topic 4axis xyuv constant velocity

I don't think it is physically possible to have different lengths end up at the end point at the same time and travel the same speed.

John

John

Please Log in or Create an account to join the conversation.

- luckym

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

02 Jan 2013 23:26 #28314

by luckym

I don't claim that..... just asking about the relation between feed rate and the real tool speed (hot wire speed) by 4 axis machine.

Replied by luckym on topic 4axis xyuv constant velocity

I don't think it is physically possible to have different lengths end up at the end point at the same time and travel the same speed.

John

I don't claim that..... just asking about the relation between feed rate and the real tool speed (hot wire speed) by 4 axis machine.

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 6999

- Thank you received: 1176

02 Jan 2013 23:31 #28315

by BigJohnT

Replied by BigJohnT on topic 4axis xyuv constant velocity

The wire speed will vary along it's length. If your feed rate is 10 the longest move if possible will move at a feed rate of 10 and the short move will move at a speed so both moves end at the same time.

John

John

Please Log in or Create an account to join the conversation.

- jmelson

- Offline

- Moderator

-

Less

More

- Posts: 826

- Thank you received: 160

03 Jan 2013 00:46 #28320

by jmelson

will complete at the same time. The only way that could be different is if that would cause

the U or V axis to exceed its individual maximum velocity, then the whole move would be slowed

down. This is a fairly fundamental part of the current trajectory planner design, although

there has been some discussion about relieving these limitations in a future version.

Jon

Replied by jmelson on topic 4axis xyuv constant velocity

As I understand it, the F word sets the feed rate for the XY move specified, and the UV

I don't think it is physically possible to have different lengths end up at the end point at the same time and travel the same speed.

John

I don't claim that..... just asking about the relation between feed rate and the real tool speed (hot wire speed) by 4 axis machine.

will complete at the same time. The only way that could be different is if that would cause

the U or V axis to exceed its individual maximum velocity, then the whole move would be slowed

down. This is a fairly fundamental part of the current trajectory planner design, although

there has been some discussion about relieving these limitations in a future version.

Jon

Please Log in or Create an account to join the conversation.

- luckym

- Offline

- New Member

-

Less

More

- Posts: 8

- Thank you received: 0

03 Jan 2013 00:50 #28321

by luckym

OK, the speed along wire I don't consider ,just speed off carriages (heads)...

Does this mean that the longer move will move at feed rate and the shorter one at lower speed regardless of which side move longer xy or uv?

So is there any setting that say these axis are in pair: xy and uv? because I can wire the axis such: xu an yv. and linux cnc don't know which axis are in pair.

I tried this code in mach with the results of xy side speed:

g00 x0 y0 a0 b0

f1000

1 g01 x50 y50 u20 v20

2 g01 x100 y100 //xy speed increased

3 g01 x150 y150 u70 v70 //xy speed decreased

4 g01 x200 y200 u250 v250 //xy speed decreased

If you notice the travel of xy side is the same in each movement (delta is 50), uv travel changes (delta is 1:20 2:0 3:50 4:180)

According You linuxcnc should perform movement 1 2 3 at constant speed of xy side at defined feed (uv side has shorter movement)

in movement 4 xy decrease speed and uv move at defined feed.

Replied by luckym on topic 4axis xyuv constant velocity

The wire speed will vary along it's length. If your feed rate is 10 the longest move if possible will move at a feed rate of 10 and the short move will move at a speed so both moves end at the same time.

John

OK, the speed along wire I don't consider ,just speed off carriages (heads)...

Does this mean that the longer move will move at feed rate and the shorter one at lower speed regardless of which side move longer xy or uv?

So is there any setting that say these axis are in pair: xy and uv? because I can wire the axis such: xu an yv. and linux cnc don't know which axis are in pair.

I tried this code in mach with the results of xy side speed:

g00 x0 y0 a0 b0

f1000

1 g01 x50 y50 u20 v20

2 g01 x100 y100 //xy speed increased

3 g01 x150 y150 u70 v70 //xy speed decreased

4 g01 x200 y200 u250 v250 //xy speed decreased

If you notice the travel of xy side is the same in each movement (delta is 50), uv travel changes (delta is 1:20 2:0 3:50 4:180)

According You linuxcnc should perform movement 1 2 3 at constant speed of xy side at defined feed (uv side has shorter movement)

in movement 4 xy decrease speed and uv move at defined feed.

Please Log in or Create an account to join the conversation.

Time to create page: 0.106 seconds