Programs start and end in different locations

- poofjunior

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

29 Mar 2016 03:57 #72290

by poofjunior

Programs start and end in different locations was created by poofjunior

Hi everyone,

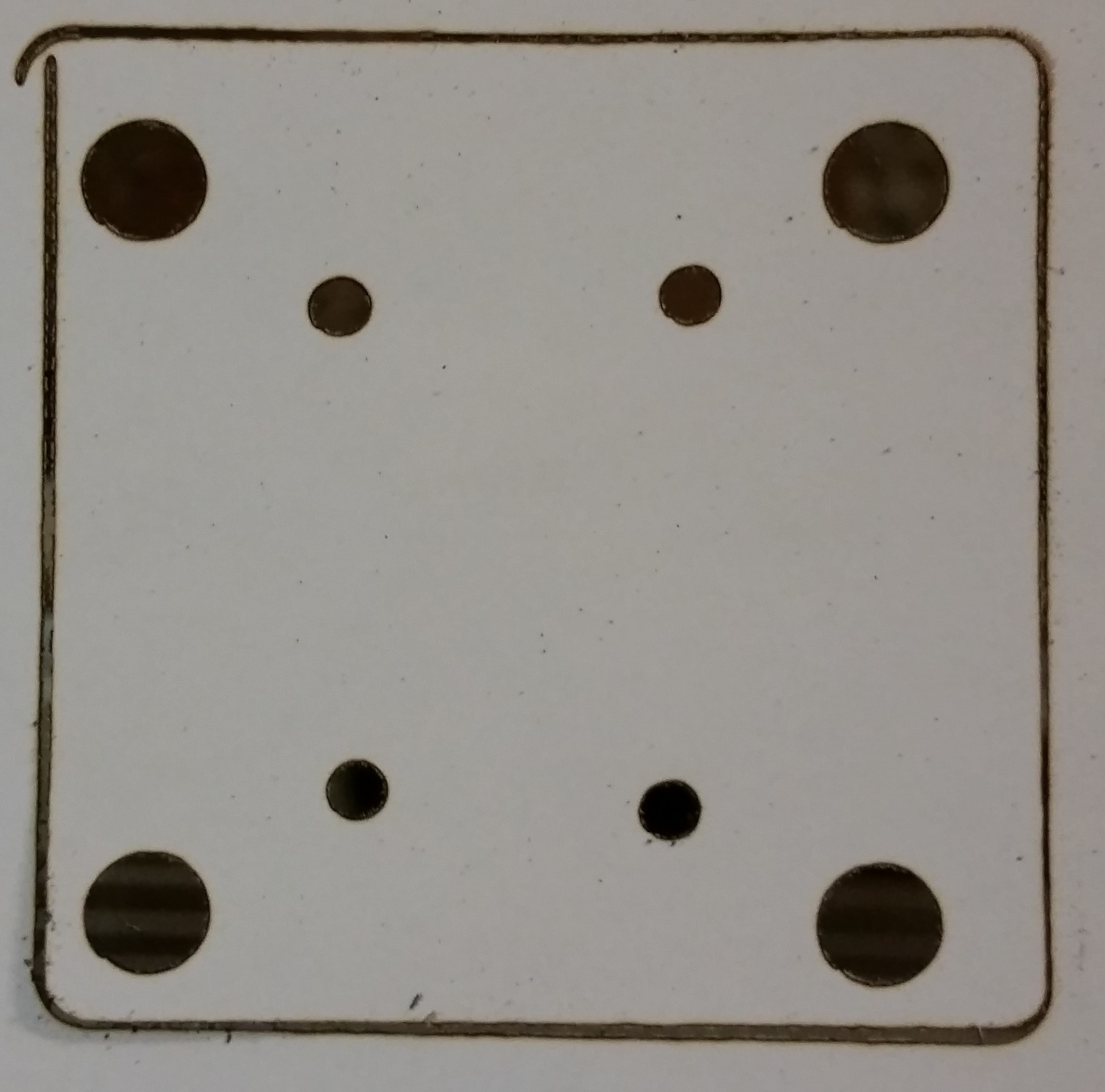

I'm putting together a laser cutter, and I'm almost there, but I've run into an interesting phenomenon that I can't identify: my GCode test program starts and finishes cuts in different locations! The finishing location is consistent every time, about 0.05 inches to the right (+x) and 0.05 inches up (+Y).

At first, I thought my issue was backlash, but my diagnosis doesn't seem to prove it. Here's what I've done.

If I re-run the program, the location for HOME has been lost, and new cuts start off set by about 0.05 inches to the right and about 0.05 inches up--just like the finishing location. Re-running the program over and over will continue to move the home location slightly up and slightly to the right by a consistent amount.

I thought this issue might be lost steps, so I slowed down the cutting speed from 1500mm/sec to 300mm/sec. Oddly enough, the slower it gets, the worse the offset becomes (as if the sheer amount of time spent cutting makes the problem worse the longer it goes).

As a heads-up, this is a new issue. Cuts used to start and finish in the same place without issue.

I'd love your thoughts on this one. Thanks!

Here's an example of the offset at 300mm/sec:

I'm putting together a laser cutter, and I'm almost there, but I've run into an interesting phenomenon that I can't identify: my GCode test program starts and finishes cuts in different locations! The finishing location is consistent every time, about 0.05 inches to the right (+x) and 0.05 inches up (+Y).

At first, I thought my issue was backlash, but my diagnosis doesn't seem to prove it. Here's what I've done.

If I re-run the program, the location for HOME has been lost, and new cuts start off set by about 0.05 inches to the right and about 0.05 inches up--just like the finishing location. Re-running the program over and over will continue to move the home location slightly up and slightly to the right by a consistent amount.

I thought this issue might be lost steps, so I slowed down the cutting speed from 1500mm/sec to 300mm/sec. Oddly enough, the slower it gets, the worse the offset becomes (as if the sheer amount of time spent cutting makes the problem worse the longer it goes).

As a heads-up, this is a new issue. Cuts used to start and finish in the same place without issue.

I'd love your thoughts on this one. Thanks!

Here's an example of the offset at 300mm/sec:

Please Log in or Create an account to join the conversation.

- Rick G

-

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

29 Mar 2016 06:12 #72292

by Rick G

Replied by Rick G on topic Programs start and end in different locations

Sounds like missing steps.

Besides checking for mechanical problems such as binding try dramatically reducing you acceleration settings in your configuration file.

Rick G

Besides checking for mechanical problems such as binding try dramatically reducing you acceleration settings in your configuration file.

Rick G

Please Log in or Create an account to join the conversation.

- poofjunior

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

30 Mar 2016 03:43 #72360

by poofjunior

Replied by poofjunior on topic [Solved] Programs start/end in different locations

Yup! That was it! Missing steps....

Speedwise, things were OK. It turned out to be my motor controllers from GeckoDrive

Two minor tweaks fixed the problem:

After that, everything looks good again, and I can kick out paper cuts at a respectable 1500mm/min.

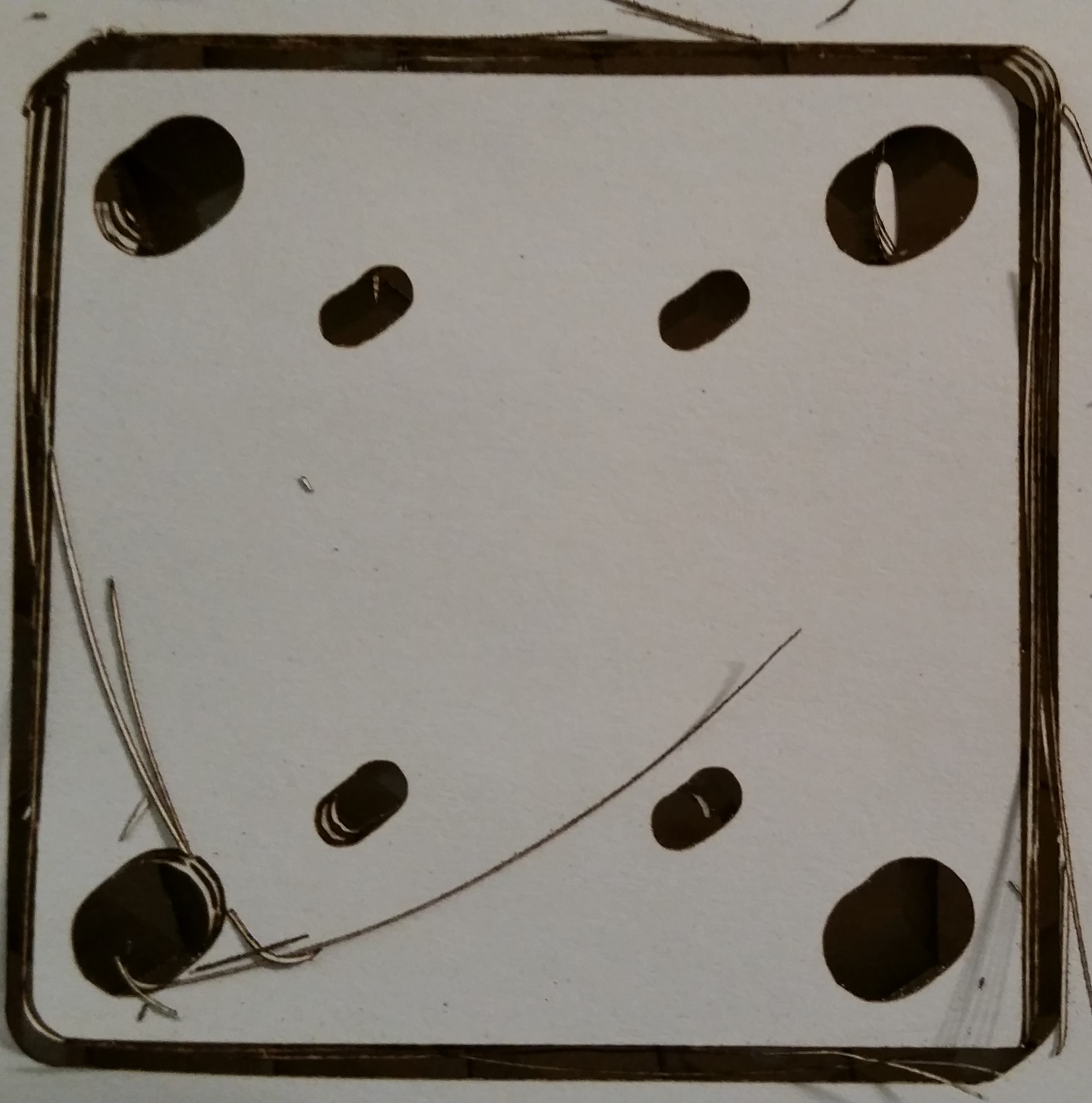

I'm adding another image back when I was skipping steps--just in case anyone else in the future needs to diagnose a problems like this. Here's a repeated run over five iterations:

Speedwise, things were OK. It turned out to be my motor controllers from GeckoDrive

Two minor tweaks fixed the problem:

- bumped up the maximum current sent to the y-axis motor

- tuned the trimpot such that the gantry would move with the minimum possible vibration at low speeds

After that, everything looks good again, and I can kick out paper cuts at a respectable 1500mm/min.

I'm adding another image back when I was skipping steps--just in case anyone else in the future needs to diagnose a problems like this. Here's a repeated run over five iterations:

Please Log in or Create an account to join the conversation.

- poofjunior

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

30 Mar 2016 03:43 - 30 Mar 2016 03:45 #72361

by poofjunior

Replied by poofjunior on topic [Solved] Programs start/end in different locations

Yup! That was it! Missing steps....

Speedwise, things were OK. It turned out to be my motor controllers from GeckoDrive

Two minor tweaks fixed the problem:

After that, everything looks good again, and I can kick out paper cuts at a respectable 1500mm/min.

I'm adding another image back when I was skipping steps--just in case anyone else in the future needs to diagnose a problem like this. Here's a repeated run over five iterations:

Speedwise, things were OK. It turned out to be my motor controllers from GeckoDrive

Two minor tweaks fixed the problem:

- bumped up the maximum current sent to the y-axis motor

- tuned the trimpot such that the gantry would move with the minimum possible vibration at low speeds

After that, everything looks good again, and I can kick out paper cuts at a respectable 1500mm/min.

I'm adding another image back when I was skipping steps--just in case anyone else in the future needs to diagnose a problem like this. Here's a repeated run over five iterations:

Last edit: 30 Mar 2016 03:45 by poofjunior.

Please Log in or Create an account to join the conversation.

- poofjunior

- Offline

- New Member

-

Less

More

- Posts: 7

- Thank you received: 0

10 Apr 2016 18:43 #73062

by poofjunior

Replied by poofjunior on topic Programs start and end in different locations

To revisit an old topic..

Yes, tuning the motor controllers did help, but the actual cause of the problem now appears to be electrical interference of the laser tube power supply acting on the motor controllers.

Switching from a motor controller with an exposed PCB to a motor controller enclosed in a metal housing has finally fixed the issue. I suspect, though, that putting the original motor controllers in a metal box may would've also done the same thing.

Cheers!

Yes, tuning the motor controllers did help, but the actual cause of the problem now appears to be electrical interference of the laser tube power supply acting on the motor controllers.

Switching from a motor controller with an exposed PCB to a motor controller enclosed in a metal housing has finally fixed the issue. I suspect, though, that putting the original motor controllers in a metal box may would've also done the same thing.

Cheers!

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4704

- Thank you received: 1443

10 Apr 2016 19:36 #73072

by Todd Zuercher

Replied by Todd Zuercher on topic Programs start and end in different locations

Glad to hear you solved your problem.

Please Log in or Create an account to join the conversation.

Time to create page: 0.134 seconds