Newbie Setting the "X"

- Cayenne

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

22 Jun 2016 13:40 #76424

by Cayenne

Newbie Setting the "X" was created by Cayenne

I just finished setting up my lathe. All is working well mechanically/electronically. I have not set up any tools in the tool table because my tool changing is totally manual. The Z axis seems to be ok its the X that is confusing me. I'm not sure where to home it. And when I do a touch off and enter the radius of the work piece the tool icon jumps to zero in the linux display but the radius read out value reflects the radius I entered. I must be doing something wrong.. Any thoughts?

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19715

- Thank you received: 4570

22 Jun 2016 14:09 #76428

by andypugh

Replied by andypugh on topic Newbie Setting the "X"

What kind of tool holder do you have?

Please Log in or Create an account to join the conversation.

- Cayenne

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

22 Jun 2016 16:43 #76448

by Cayenne

Replied by Cayenne on topic Newbie Setting the "X"

tool holder? It is manual, I put the cutting tool in the holder a tighten it down with a wrench. no quick change or nothing. I lose reference each time I loosen the cutting tool.

Please Log in or Create an account to join the conversation.

- Cayenne

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

22 Jun 2016 16:48 #76449

by Cayenne

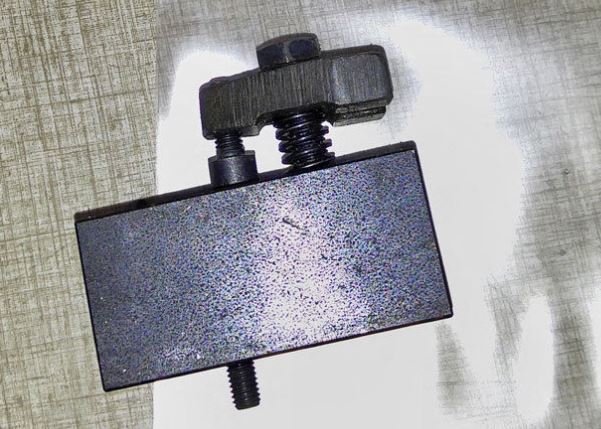

Replied by Cayenne on topic Newbie Setting the "X"

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19715

- Thank you received: 4570

22 Jun 2016 17:16 #76451

by andypugh

Replied by andypugh on topic Newbie Setting the "X"

OK, just checking to see what sort of idea would work best.

With a fully-manual tool holder you probably want to just use G54 (coordinate system) offsets all the time. For Z you can do this with a dowel pin, put the tool less than the pin dia from the end of the work then jog away until the pin slips through the gap.

X is probably best done with a touch then test cut method (very much like you would with a manual).

A quick-change toolholder might be a good investment, you are losing much of the advantage of CNC with that tool holder.

This is cute, but not what you would call cheap: www.ebay.co.uk/itm/152123879598

I don't know why the tool-point goes to zero if the DRO says not-zero. That's very strange, I have never seen it.

With a fully-manual tool holder you probably want to just use G54 (coordinate system) offsets all the time. For Z you can do this with a dowel pin, put the tool less than the pin dia from the end of the work then jog away until the pin slips through the gap.

X is probably best done with a touch then test cut method (very much like you would with a manual).

A quick-change toolholder might be a good investment, you are losing much of the advantage of CNC with that tool holder.

This is cute, but not what you would call cheap: www.ebay.co.uk/itm/152123879598

I don't know why the tool-point goes to zero if the DRO says not-zero. That's very strange, I have never seen it.

Please Log in or Create an account to join the conversation.

- Muzzer

- Away

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 37

22 Jun 2016 20:07 - 22 Jun 2016 20:12 #76460

by Muzzer

Replied by Muzzer on topic Newbie Setting the "X"

These are also Chinese

but a better price and nicely made. Also less of a weirdo than that German guy in my experience!

I have an "A" set - very nice.

I have an "A" set - very nice.

Last edit: 22 Jun 2016 20:12 by Muzzer. Reason: Actually "A" size, not "Aa".

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19715

- Thank you received: 4570

22 Jun 2016 20:20 #76461

by andypugh

Yes, I have the A set too, from Create Tool. Very nice company to work with, "Nina" responds promptly to emails. I bought some blank holders from them for special purposes (just the serrations and height adjustment, unhardened)

However I get the impression from that tool post clamp that this is a very tiny lathe being talked about,

Replied by andypugh on topic Newbie Setting the "X"

These are also Chinese but a better price and nicely made. Also less of a weirdo than that German guy in my experience!

I have an "A" set - very nice.

Yes, I have the A set too, from Create Tool. Very nice company to work with, "Nina" responds promptly to emails. I bought some blank holders from them for special purposes (just the serrations and height adjustment, unhardened)

However I get the impression from that tool post clamp that this is a very tiny lathe being talked about,

Please Log in or Create an account to join the conversation.

- Muzzer

- Away

- Elite Member

-

Less

More

- Posts: 252

- Thank you received: 37

22 Jun 2016 20:24 #76462

by Muzzer

Replied by Muzzer on topic Newbie Setting the "X"

Yes, as you say the German one is "cute", although it's 57mm vs 70mm overall for the "Aa" size, so not a massive difference.

Please Log in or Create an account to join the conversation.

- Cayenne

- Offline

- New Member

-

Less

More

- Posts: 12

- Thank you received: 0

22 Jun 2016 20:43 #76464

by Cayenne

Replied by Cayenne on topic Newbie Setting the "X"

Its an Emco Compact 5, 5x14 that i converted to CNC, and yes I will be investing in a quick change tool post soon...

Please Log in or Create an account to join the conversation.

Time to create page: 0.231 seconds