Newbie question

- schaet

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

22 Mar 2018 14:33 #107722

by schaet

Newbie question was created by schaet

Hello,

I am a total newbie here feeling my through. I tried running my first program and got the following error:

"Cannot feed with zero spindle speed in feed per rev mode"

Can anyone shed some light on this? I'm sure it's a simple setting I have wrong

Attached is my g-code

Thank you

Steven

My setup:

Sherline 5400 CNC

LinuxCNC

BobCAD/CAM with the Sherline post processor

I am a total newbie here feeling my through. I tried running my first program and got the following error:

"Cannot feed with zero spindle speed in feed per rev mode"

Can anyone shed some light on this? I'm sure it's a simple setting I have wrong

Attached is my g-code

Thank you

Steven

My setup:

Sherline 5400 CNC

LinuxCNC

BobCAD/CAM with the Sherline post processor

Please Log in or Create an account to join the conversation.

- DanMN

-

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 10

22 Mar 2018 15:13 - 22 Mar 2018 15:26 #107725

by DanMN

Replied by DanMN on topic Newbie question

I'm presuming you start your spindle manually, i.e., not via gcode -- since you only have M0 specified -- which is spindle stop. In essence, the you are instructing the machine to plunge cutter that isn't spinning. Obviously, in systems that have spindle control automated this would be a big no-no.

Try adding an M3 statement here:

(MSG, " Spindle Speed 1191")

(M0)

M3 S1 F1

Touch off your Z well above your table or workpiece for a dry run. Let the spindle cut some air while you observe the behavior and become comfortable with the new instructions. I always test creative new ideas with my hand on the e-stop button

PS: I just modified and loaded your file, and you have other problems -- namely that line 11 command being a country mile long and obviously weird. I changed the Y value to 133 and it loaded, but with some expected problems with scale. It looks like you're cutting a postage stamp size object on a billiard table -- so, you've got some CAM setup issues to work out as well.

Try adding an M3 statement here:

(MSG, " Spindle Speed 1191")

(M0)

M3 S1 F1

Touch off your Z well above your table or workpiece for a dry run. Let the spindle cut some air while you observe the behavior and become comfortable with the new instructions. I always test creative new ideas with my hand on the e-stop button

PS: I just modified and loaded your file, and you have other problems -- namely that line 11 command being a country mile long and obviously weird. I changed the Y value to 133 and it loaded, but with some expected problems with scale. It looks like you're cutting a postage stamp size object on a billiard table -- so, you've got some CAM setup issues to work out as well.

Last edit: 22 Mar 2018 15:26 by DanMN. Reason: Added observation..

Please Log in or Create an account to join the conversation.

- schaet

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

22 Mar 2018 18:56 #107730

by schaet

Replied by schaet on topic Newbie question

DanMN,

Thanks for the info. I'll check it out when I get home tonight.

Any ideas what to look for with the CAM setup? Maybe I'll re-create the job and do a stare and compare with the two posts.

Also, what was it that you saw that showed you that the scale was off?

Thanks again!

Thanks for the info. I'll check it out when I get home tonight.

Any ideas what to look for with the CAM setup? Maybe I'll re-create the job and do a stare and compare with the two posts.

Also, what was it that you saw that showed you that the scale was off?

Thanks again!

Please Log in or Create an account to join the conversation.

- DanMN

-

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 10

22 Mar 2018 21:18 #107738

by DanMN

Replied by DanMN on topic Newbie question

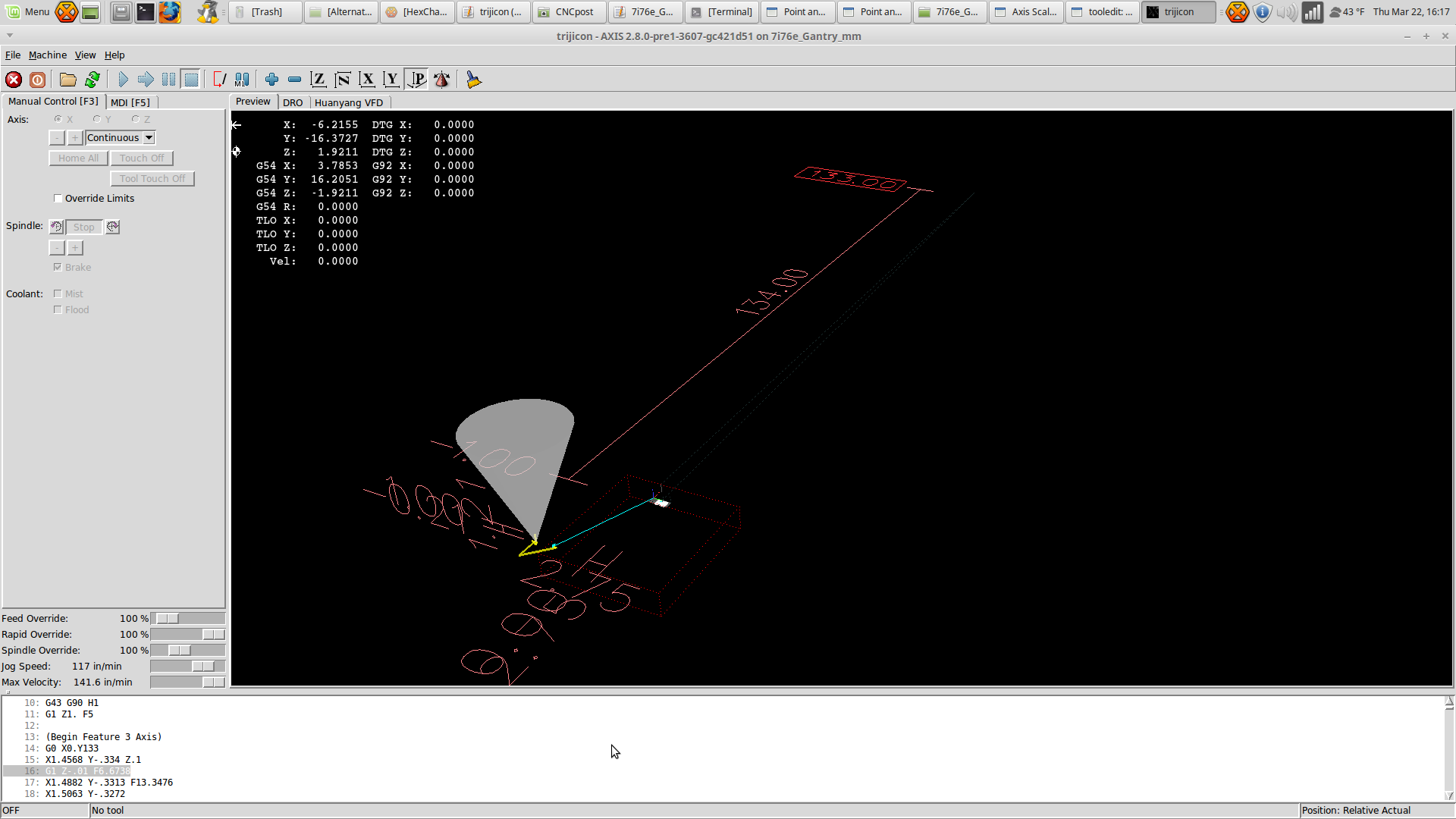

My comment on the scale was due to this picture -- notice your part is that tiny tool path in white, and for some reason your are getting gcode that tells you your toolpath includes a point 133 inches north in empty space. I don't have any explanation for that, but your original line 11 had a Y value that required a line wrap on my wide screen monitor -- I gave up looking after a few dozen digits. That's the value I shortened from 133 bazillion to just 133.

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

22 Mar 2018 21:29 #107739

by JohnnyCNC

Replied by JohnnyCNC on topic Newbie question

You might try G94 instead of G95 along with what DanMN said. M0 is program pause. I'm new at this also so trust but verify. Good Luck John

G94 - is Units per Minute Mode. In units per minute feed mode, an F word is interpreted to mean the controlled point should move at a certain number of inches per minute, millimeters per minute, or degrees per minute, depending upon what length units are being used and which axis or axes are moving.

G95 - is Units per Revolution Mode In units per revolution mode, an F word is interpreted to mean the controlled point should move a certain number of inches per revolution of the spindle, depending on what length units are being used and which axis or axes are moving. G95 is not suitable for threading, for threading use G33 or G76. G95 requires that motion.spindle-speed-in to be connected.

M0 - pause a running program temporarily. LinuxCNC remains in the Auto Mode so MDI and other manual actions are not enabled. Pressing the cycle start button will restart the program at the following line.

(TRIJICONV4-2.NC)

G17 G20 G95 G40 G49 G80 G90 G00 X0 Y0 Z0

(MSG, " Change to .25 ENDMILL ROUGH")

(MSG, " Spindle Speed 1191")

(M0)

G43 G90 H1

G1 Z1. F5

(M0)

(Begin Feature 3 Axis)

G94 - is Units per Minute Mode. In units per minute feed mode, an F word is interpreted to mean the controlled point should move at a certain number of inches per minute, millimeters per minute, or degrees per minute, depending upon what length units are being used and which axis or axes are moving.

G95 - is Units per Revolution Mode In units per revolution mode, an F word is interpreted to mean the controlled point should move a certain number of inches per revolution of the spindle, depending on what length units are being used and which axis or axes are moving. G95 is not suitable for threading, for threading use G33 or G76. G95 requires that motion.spindle-speed-in to be connected.

M0 - pause a running program temporarily. LinuxCNC remains in the Auto Mode so MDI and other manual actions are not enabled. Pressing the cycle start button will restart the program at the following line.

(TRIJICONV4-2.NC)

G17 G20 G95 G40 G49 G80 G90 G00 X0 Y0 Z0

(MSG, " Change to .25 ENDMILL ROUGH")

(MSG, " Spindle Speed 1191")

(M0)

G43 G90 H1

G1 Z1. F5

(M0)

(Begin Feature 3 Axis)

Please Log in or Create an account to join the conversation.

- JohnnyCNC

-

- Offline

- Platinum Member

-

Less

More

- Posts: 570

- Thank you received: 111

22 Mar 2018 23:07 #107741

by JohnnyCNC

Replied by JohnnyCNC on topic Newbie question

I changed the G95 to G94 and line 14 Y1333... to Y2 and Z2 to Z1 so it didn't exceed the bounds of my machine and the code will run.

%

( tool 1 ENDMILL ROUGH D.25 C0. L2.5)

(TRIJICONV4-2.NC)

G17 G20 G94 G40 G49 G80 G90 G00 X0 Y0 Z0

(MSG, " Change to .25 ENDMILL ROUGH")

(MSG, " Spindle Speed 1191")

(M0)

G43 G90 H1

G1 Z1. F5

(M0)

(Begin Feature 3 Axis)

G0 X0. Y2 Z.1

%

( tool 1 ENDMILL ROUGH D.25 C0. L2.5)

(TRIJICONV4-2.NC)

G17 G20 G94 G40 G49 G80 G90 G00 X0 Y0 Z0

(MSG, " Change to .25 ENDMILL ROUGH")

(MSG, " Spindle Speed 1191")

(M0)

G43 G90 H1

G1 Z1. F5

(M0)

(Begin Feature 3 Axis)

G0 X0. Y2 Z.1

Please Log in or Create an account to join the conversation.

- schaet

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

23 Mar 2018 00:42 #107742

by schaet

Replied by schaet on topic Newbie question

JohnnyCNC and DanMN

Thank you for the input!! You guys rock! I was able to load the file and I ran the program (without the mill attached) and it looks good. I'll try it tomorrow on some stock and see how it looks.

So much to learn here ..

I'll let you know how I make out.

Thank you for the input!! You guys rock! I was able to load the file and I ran the program (without the mill attached) and it looks good. I'll try it tomorrow on some stock and see how it looks.

So much to learn here ..

I'll let you know how I make out.

Please Log in or Create an account to join the conversation.

- schaet

- Offline

- New Member

-

Less

More

- Posts: 5

- Thank you received: 0

26 Mar 2018 13:31 #107898

by schaet

Replied by schaet on topic Newbie question

Well I made some good progress last night. I was able to run the program with decent results.

I made the above suggested changes, but in addition to that I took out the line: G43 G90 H1. It was starting my Z axis at .050 above my stock. After researching it appears to do with my offset setting. I'll have to figure that out with my software and correct that.

The only other issue I see is that the cutting dimensions are a little off. That may have to do with my mill, but I don't know yet.

Thanks again for the help!

I made the above suggested changes, but in addition to that I took out the line: G43 G90 H1. It was starting my Z axis at .050 above my stock. After researching it appears to do with my offset setting. I'll have to figure that out with my software and correct that.

The only other issue I see is that the cutting dimensions are a little off. That may have to do with my mill, but I don't know yet.

Thanks again for the help!

Please Log in or Create an account to join the conversation.

- DanMN

-

- Offline

- Senior Member

-

Less

More

- Posts: 74

- Thank you received: 10

26 Mar 2018 14:33 #107903

by DanMN

Replied by DanMN on topic Newbie question

Good to hear you are making progress. You can play with the SCALE variable for each axis first and see if that corrects dimension inaccuracies. Then you can look at backlash compensation, machine rigidity, etc.

Have fun. Don't crash it

Have fun. Don't crash it

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

27 Mar 2018 16:26 #107961

by andypugh

Most CAM packages assume that absolute 0 for the Z axis is right at the top. That means that the home position tends to be 0, max limit 0 and min limit some-negative-number.

Actually HOME is probably -0.05 and HOME_OFFSET +0.05 or similar arrangement.

Replied by andypugh on topic Newbie question

in addition to that I took out the line: G43 G90 H1. It was starting my Z axis at .050 above my stock.

Most CAM packages assume that absolute 0 for the Z axis is right at the top. That means that the home position tends to be 0, max limit 0 and min limit some-negative-number.

Actually HOME is probably -0.05 and HOME_OFFSET +0.05 or similar arrangement.

Please Log in or Create an account to join the conversation.

Time to create page: 0.488 seconds