Vibrations in circular interpolation

- Samu_97

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

25 Nov 2019 12:45 #151215

by Samu_97

Vibrations in circular interpolation was created by Samu_97

Good morning, I speak to see if you can help me with a problem in my CNC milling machine.

The problem is a vibration that appears only when a circular interpolation between X-Y + is running. It only happens in this quadrant. I thought it was due to the lack of rigidity of the machine, which is homemade ... but in the rest of the movements the machine works very well.

I discovered that by introducing a G64 P0.05 to introduce more tolerance in the movements in my line of code, I managed to reduce the vibration, so it smells to me that this problem comes from a bad configuration of stepper motors.

If I generate CAM code in the form of multipoints, or in the form of arcs is indifferent, the same vibrates.

I don't know very well where to start looking for the solution. Increase the value of microsteping? (Is it at 3200 / rev) or maybe modify some value in the hal?

I don't provide information about my configuration because I don't know where to start.

I thank you in advance for the help. thank you

The problem is a vibration that appears only when a circular interpolation between X-Y + is running. It only happens in this quadrant. I thought it was due to the lack of rigidity of the machine, which is homemade ... but in the rest of the movements the machine works very well.

I discovered that by introducing a G64 P0.05 to introduce more tolerance in the movements in my line of code, I managed to reduce the vibration, so it smells to me that this problem comes from a bad configuration of stepper motors.

If I generate CAM code in the form of multipoints, or in the form of arcs is indifferent, the same vibrates.

I don't know very well where to start looking for the solution. Increase the value of microsteping? (Is it at 3200 / rev) or maybe modify some value in the hal?

I don't provide information about my configuration because I don't know where to start.

I thank you in advance for the help. thank you

The following user(s) said Thank You: Clive S, Leon82

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

25 Nov 2019 13:57 #151218

by Leon82

Replied by Leon82 on topic Vibrations in circular interpolation

Is it a spline looking surface finish or is it smooth or chattered?

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21072

- Thank you received: 7189

25 Nov 2019 14:35 #151224

by tommylight

Replied by tommylight on topic Vibrations in circular interpolation

That sounds like a bad bearing or reduction or belt tensioning, not software/stepper issue.

remove the motors, check if it takes the same force to move on both directions. Then do the same test with the motors/reduction/belts.

remove the motors, check if it takes the same force to move on both directions. Then do the same test with the motors/reduction/belts.

The following user(s) said Thank You: Samu_97

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Offline

- Platinum Member

-

Less

More

- Posts: 4690

- Thank you received: 1434

25 Nov 2019 15:38 #151232

by Todd Zuercher

Replied by Todd Zuercher on topic Vibrations in circular interpolation

I agree, it does sound more like a mechanical problem. Could you share a photo of the imperfection in the cut, and a better description of the machine's mechanics. Maybe we can better point you in the right direction of where to look for your problem.

The following user(s) said Thank You: Samu_97

Please Log in or Create an account to join the conversation.

- Samu_97

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

25 Nov 2019 23:58 - 26 Nov 2019 00:01 #151261

by Samu_97

Replied by Samu_97 on topic Vibrations in circular interpolation

Ok, I will test and remove the motors to verify that the shaft moves freely. I finished the machine a month ago and everything was soft, but I'll check it just in case.

The machine does not mount belts, it is direct drive, nema 34 closed loop (typical leadshine) directed by a mesa 7i76e.

25 mm screws and step 10.

I modified the Chinese spindle to eliminate axial clearance and work in trocoidal mode, that is already fixed. but this other axis vibration persists me.

I put a photo of the machine in case you see any apparent manufacturing error.

I recorded a video test machining 7075 aluminum forcing the problem a bit.

thank you very much.

https://ibb.co/VJfvn6F

https://ibb.co/R6Rzmjq

The machine does not mount belts, it is direct drive, nema 34 closed loop (typical leadshine) directed by a mesa 7i76e.

25 mm screws and step 10.

I modified the Chinese spindle to eliminate axial clearance and work in trocoidal mode, that is already fixed. but this other axis vibration persists me.

I put a photo of the machine in case you see any apparent manufacturing error.

I recorded a video test machining 7075 aluminum forcing the problem a bit.

thank you very much.

https://ibb.co/VJfvn6F

https://ibb.co/R6Rzmjq

Last edit: 26 Nov 2019 00:01 by Samu_97. Reason: no photos

Please Log in or Create an account to join the conversation.

- Leon82

- Offline

- Platinum Member

-

Less

More

- Posts: 592

- Thank you received: 79

26 Nov 2019 00:06 #151262

by Leon82

Replied by Leon82 on topic Vibrations in circular interpolation

The back feed move sounds smooth.

It is possible the cutting forces create harmonics in a certain direction.

It is possible the cutting forces create harmonics in a certain direction.

The following user(s) said Thank You: Samu_97

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21072

- Thank you received: 7189

26 Nov 2019 00:55 #151266

by tommylight

Replied by tommylight on topic Vibrations in circular interpolation

That sure looks like backlash on X axis.

The following user(s) said Thank You: Samu_97

Please Log in or Create an account to join the conversation.

- Samu_97

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

26 Nov 2019 11:46 - 26 Nov 2019 11:49 #151289

by Samu_97

Replied by Samu_97 on topic Vibrations in circular interpolation

Good day.

After disassembling the motors, I was able to move the machine freely on the 2 axes, with little force I did with my hand to overcome the axis screw step. If I turn the axle screw by hand I can do it with 2 fingers.

I checked the backlash with a gauge, moving the machine, and also forcing the axes with the hand, 0 backlash and some flexion of the structure in the nose of the spindle of 0.05mm

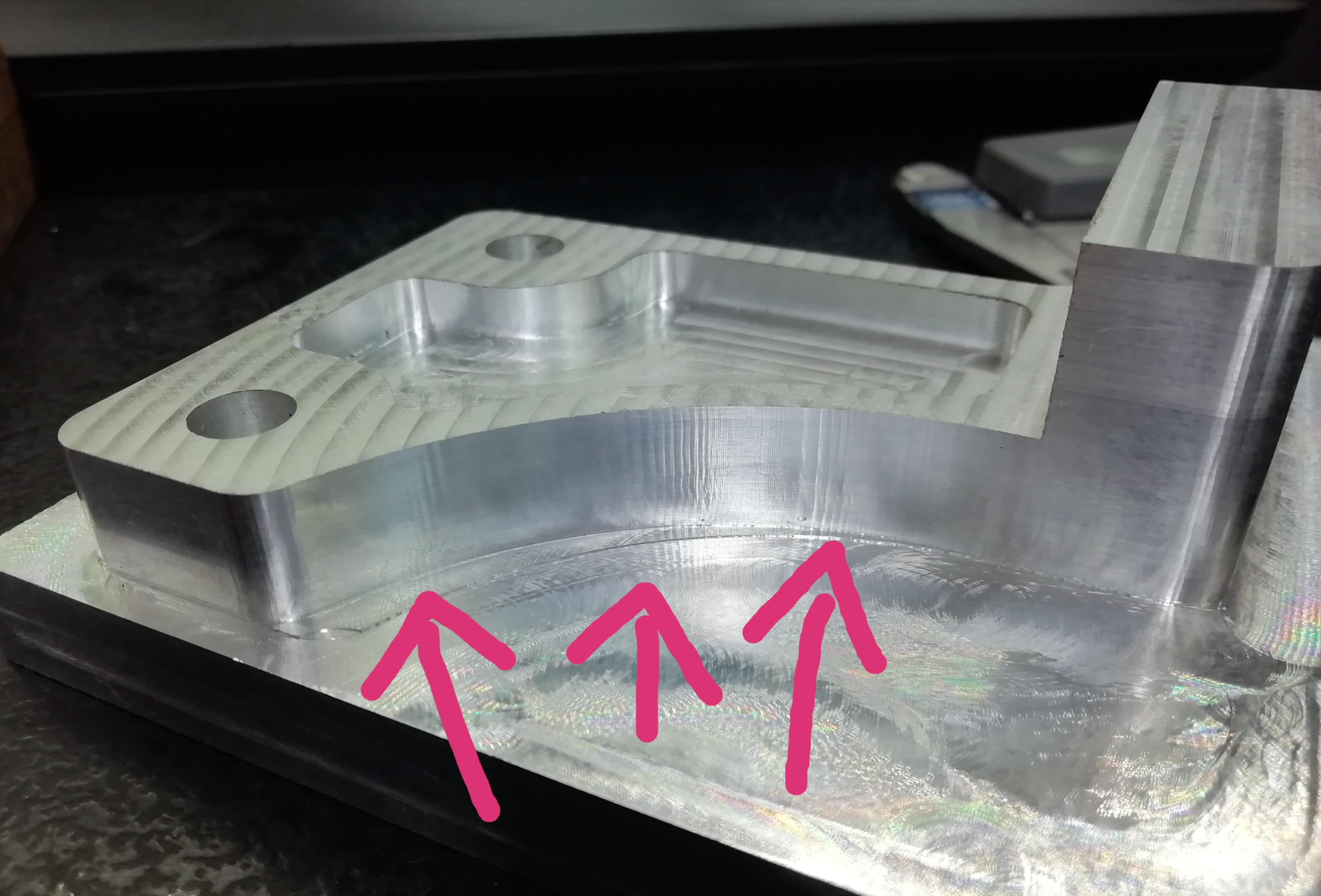

I machined a 5cent finishing pass in one piece and the vibration was much lower, but it produced some errors in the arches, in another direction, I put a photo here. something is wrong.

thank you very much

After disassembling the motors, I was able to move the machine freely on the 2 axes, with little force I did with my hand to overcome the axis screw step. If I turn the axle screw by hand I can do it with 2 fingers.

I checked the backlash with a gauge, moving the machine, and also forcing the axes with the hand, 0 backlash and some flexion of the structure in the nose of the spindle of 0.05mm

I machined a 5cent finishing pass in one piece and the vibration was much lower, but it produced some errors in the arches, in another direction, I put a photo here. something is wrong.

thank you very much

Last edit: 26 Nov 2019 11:49 by Samu_97.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Online

- Moderator

-

Less

More

- Posts: 21072

- Thank you received: 7189

26 Nov 2019 14:59 #151299

by tommylight

Replied by tommylight on topic Vibrations in circular interpolation

What drives and microstepping ?

you should try with no microstepping.

you should try with no microstepping.

The following user(s) said Thank You: Samu_97

Please Log in or Create an account to join the conversation.

- Samu_97

-

Topic Author

Topic Author

- Offline

- New Member

-

Less

More

- Posts: 11

- Thank you received: 4

27 Nov 2019 12:27 #151341

by Samu_97

Replied by Samu_97 on topic Vibrations in circular interpolation

I am using the HSS86 hybrid servo driver, Set to 3200 pulse\rev.

Now i tried to remove the microstepping and the result has been worse, the machine becomes more rough in its movements and that has increased the vibration.

I have also done the opposite process, and I raised the microstepping to 6400 steps/rev, the result has been the same as with 3200, maybe a little less vibration, but almost inappreciable.

I will disassemble the bearings of the axis screw head, I seem to hear some strange noise, although I don't have much hope in this.

Any more ideas?

thanks

Now i tried to remove the microstepping and the result has been worse, the machine becomes more rough in its movements and that has increased the vibration.

I have also done the opposite process, and I raised the microstepping to 6400 steps/rev, the result has been the same as with 3200, maybe a little less vibration, but almost inappreciable.

I will disassemble the bearings of the axis screw head, I seem to hear some strange noise, although I don't have much hope in this.

Any more ideas?

thanks

Please Log in or Create an account to join the conversation.

Time to create page: 0.105 seconds