Axes not moving correct distance

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

27 Dec 2020 03:44 #193264

by LinfieldGarage

Axes not moving correct distance was created by LinfieldGarage

Hey all,

What factors outside of Linuxcnc can cause the axes to move the wrong distance?

I say it this way because I just built a new Linuxcnc install with the new 2.8 image, clean configuration using pncconf, on a totally different PC. I don’t see how it could possibly be the computer or software at this point.

I have been chasing this problem for a long time and have not put my new machine into service yet because of it,

The X axis moves .150 inch more than the commanded distance

The Y axis moves .120 inch more

The interesting thing is that the pncconf built-in axis testing feature moves the axes even more than the final working config does. It was moving about 2.5 inches for a commanded 1 inch move.

I am using made up numbers that work for these values, changing them makes no difference in the moves.

Dirsetup 10000

Dirhold 10000

Steplen 5000

Stepspace 5000

Acceleration and maxvel changes also don’t affect the move distance.

This is a gantry style plasma table, XYYZ design

Mesa 7i96 board

Keiling 5056e drives

Rack and pinion drives with 3:1 reduction

Cheap Amazon multi-voltage power supplies

Good wiring in a nice solid enclosure

Shielded wiring

Any help is appreciated.

Thanks,

Jamie

What factors outside of Linuxcnc can cause the axes to move the wrong distance?

I say it this way because I just built a new Linuxcnc install with the new 2.8 image, clean configuration using pncconf, on a totally different PC. I don’t see how it could possibly be the computer or software at this point.

I have been chasing this problem for a long time and have not put my new machine into service yet because of it,

The X axis moves .150 inch more than the commanded distance

The Y axis moves .120 inch more

The interesting thing is that the pncconf built-in axis testing feature moves the axes even more than the final working config does. It was moving about 2.5 inches for a commanded 1 inch move.

I am using made up numbers that work for these values, changing them makes no difference in the moves.

Dirsetup 10000

Dirhold 10000

Steplen 5000

Stepspace 5000

Acceleration and maxvel changes also don’t affect the move distance.

This is a gantry style plasma table, XYYZ design

Mesa 7i96 board

Keiling 5056e drives

Rack and pinion drives with 3:1 reduction

Cheap Amazon multi-voltage power supplies

Good wiring in a nice solid enclosure

Shielded wiring

Any help is appreciated.

Thanks,

Jamie

Please Log in or Create an account to join the conversation.

27 Dec 2020 04:20 #193265

by PCW

Replied by PCW on topic Axes not moving correct distance

Is the motion consistent?

That is, after multiple motions, does a return accurately to a specific location?

That is, after multiple motions, does a return accurately to a specific location?

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

27 Dec 2020 04:27 #193266

by LinfieldGarage

Replied by LinfieldGarage on topic Axes not moving correct distance

It is consistent.. I use a 2” dial indicator for testing and the indicator returns to zero every time.

Thanks!

Jamie

Thanks!

Jamie

Please Log in or Create an account to join the conversation.

27 Dec 2020 04:31 #193267

by Aciera

Replied by Aciera on topic Axes not moving correct distance

So the extra distance is the same regardless of the commanded distance or is it larger for longer distances?

If the latter is the case you would need to adjust your STEP_SCALE in the INI file.

If the latter is the case you would need to adjust your STEP_SCALE in the INI file.

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

27 Dec 2020 04:43 #193268

by LinfieldGarage

Replied by LinfieldGarage on topic Axes not moving correct distance

That is a great question, I don’t remember so I will re-test in the morning.

Is it normal to have to “tune” the step_scale number? I used math to determine the correct step_scale, checked it with the gear reduction manufacturer, and both axes have identical motors, drives, and racks.

Thanks!

Jamie

Is it normal to have to “tune” the step_scale number? I used math to determine the correct step_scale, checked it with the gear reduction manufacturer, and both axes have identical motors, drives, and racks.

Thanks!

Jamie

Please Log in or Create an account to join the conversation.

27 Dec 2020 05:51 #193270

by rodw

Replied by rodw on topic Axes not moving correct distance

The missing value we need to help is details of your pinion. What module? How many teeth? how far does it move for one revolution?

On one of my axes, I had to resort to trial and error.

On one of my axes, I had to resort to trial and error.

Please Log in or Create an account to join the conversation.

27 Dec 2020 06:07 #193271

by Aciera

Replied by Aciera on topic Axes not moving correct distance

I usually divide the commanded distance by the the actually measured distance travelled and multiply that with the STEP_SCALE used.

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

27 Dec 2020 16:05 #193298

by LinfieldGarage

Replied by LinfieldGarage on topic Axes not moving correct distance

Thank you all for the help.

@rodw I am using the rack and pinion drives below. They have a 20 tooth stepper pulley and a 60 tooth pulley driving the rack gear.

www.finelineautomation.com/product/rack-and-pinion-drive/

With 8x micro stepping step_scale should be:

(8 micro steps per step * 200 steps per rev * 3 gear reduction) / (1in pitch diameter * pi) = 1,527.88745 steps per inch

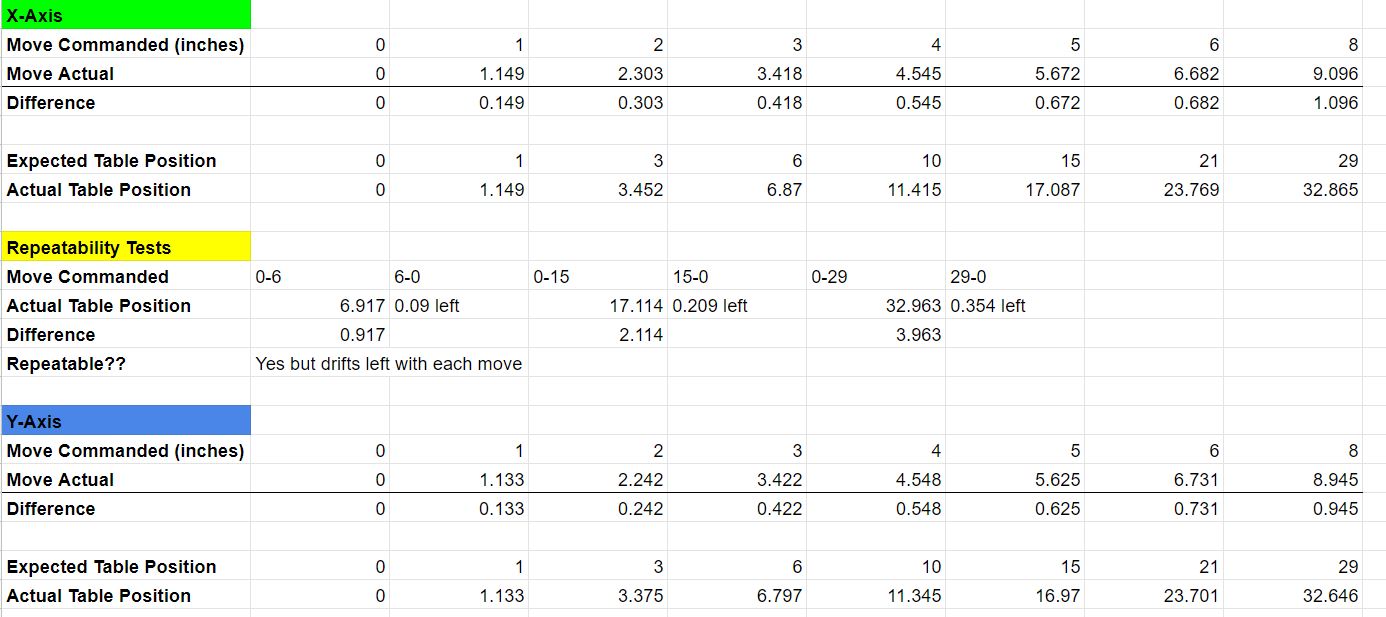

@Aciera and PCW, after lots of testing I believe this is a step_scale problem. The longer moves have more error and it goes past 0 on the way back. See table below.

Is it common to have to tune step_scale even when the math should be absolute?

Thanks again,

Jamie

@rodw I am using the rack and pinion drives below. They have a 20 tooth stepper pulley and a 60 tooth pulley driving the rack gear.

www.finelineautomation.com/product/rack-and-pinion-drive/

With 8x micro stepping step_scale should be:

(8 micro steps per step * 200 steps per rev * 3 gear reduction) / (1in pitch diameter * pi) = 1,527.88745 steps per inch

@Aciera and PCW, after lots of testing I believe this is a step_scale problem. The longer moves have more error and it goes past 0 on the way back. See table below.

Is it common to have to tune step_scale even when the math should be absolute?

Thanks again,

Jamie

Attachments:

Please Log in or Create an account to join the conversation.

27 Dec 2020 16:28 #193300

by Aciera

As I mentioned earlier you can calculate your step scale quite easily now for each axis:

STEP_SCALE = STEP_SCALE x "Expected Table Position" / "Actual Table Position"

Replied by Aciera on topic Axes not moving correct distance

Certainly not unheard of.Is it common to have to tune step_scale even when the math should be absolute?

As I mentioned earlier you can calculate your step scale quite easily now for each axis:

STEP_SCALE = STEP_SCALE x "Expected Table Position" / "Actual Table Position"

Please Log in or Create an account to join the conversation.

- LinfieldGarage

- Offline

- Junior Member

-

Less

More

- Posts: 37

- Thank you received: 11

27 Dec 2020 21:32 #193312

by LinfieldGarage

Replied by LinfieldGarage on topic Axes not moving correct distance

Great suggestion , I will give it a shot.

Please Log in or Create an account to join the conversation.

Time to create page: 0.108 seconds