it is too fast to use F200 with G2?

18 Oct 2021 08:34 #223438

by curran209

Replied by curran209 on topic it is too fast to use F200 with G2?

May it caused by a time sequence problem, a few CNC senior Engineer analysizied that it caused by Y axis command period long 20ms than than x axis command period.

Please Log in or Create an account to join the conversation.

19 Oct 2021 00:06 #223512

by andypugh

Replied by andypugh on topic it is too fast to use F200 with G2?

So, your max acceleration in the INI is 600 mm/s2 and you need 2000 mm/s2. So your machine can not make that radius at that speed. (The machine units are mm)the result of the calculation v^2/R is 2m/s^2, the max acceleration in my INI is 600,

Please Log in or Create an account to join the conversation.

19 Oct 2021 03:24 #223515

by curran209

Replied by curran209 on topic it is too fast to use F200 with G2?

Attachments:

Please Log in or Create an account to join the conversation.

19 Oct 2021 04:00 #223517

by curran209

Replied by curran209 on topic it is too fast to use F200 with G2?

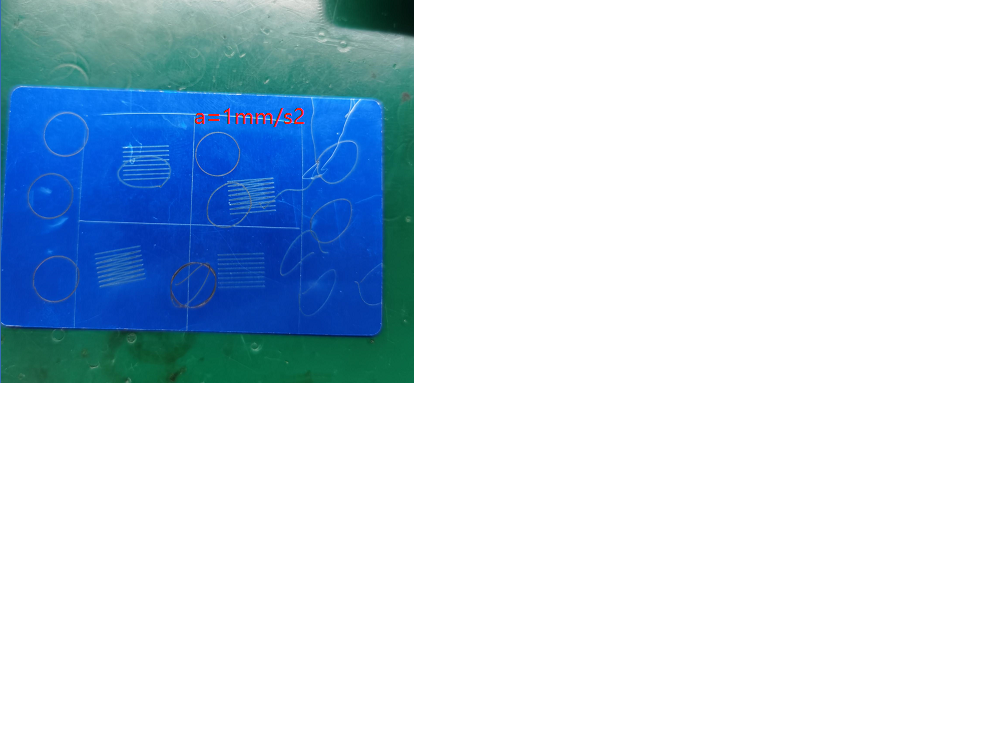

when i set max acceleration to more smaller, it's to gooder. a =1mm/s2, the effect was almost not too far, but the speed only can to be 120mm/min,it's too slow.

Attachments:

Please Log in or Create an account to join the conversation.

19 Oct 2021 05:11 #223521

by curran209

Replied by curran209 on topic it is too fast to use F200 with G2?

Attachments:

Please Log in or Create an account to join the conversation.

19 Oct 2021 08:47 #223535

by andypugh

Replied by andypugh on topic it is too fast to use F200 with G2?

Physics dictates the acceleration required to draw a circle of given size and speed.

Your mechanical design dictates the maximum possible acceleration.

If your machine can not actually accelerate at the required rate then it can't draw the circle.

You need to make your machine lighter and more powerful.

This is entirely a problem with your mechanical design and there is nothing that LinuxCNC can do about it.

Your mechanical design dictates the maximum possible acceleration.

If your machine can not actually accelerate at the required rate then it can't draw the circle.

You need to make your machine lighter and more powerful.

This is entirely a problem with your mechanical design and there is nothing that LinuxCNC can do about it.

Please Log in or Create an account to join the conversation.

19 Oct 2021 15:23 #223567

by PCW

Replied by PCW on topic it is too fast to use F200 with G2?

It could also be a drive tuning issue.

Inability to reach 600mm/s^2 acceleration

with a linear motor is quite suspect.

curran209: Can you attach your hal and ini files?

Inability to reach 600mm/s^2 acceleration

with a linear motor is quite suspect.

curran209: Can you attach your hal and ini files?

Please Log in or Create an account to join the conversation.

20 Oct 2021 01:48 #223613

by curran209

Replied by curran209 on topic it is too fast to use F200 with G2?

Another CNC control software can use this machine draw circle with setting F6000 and r =5mm.

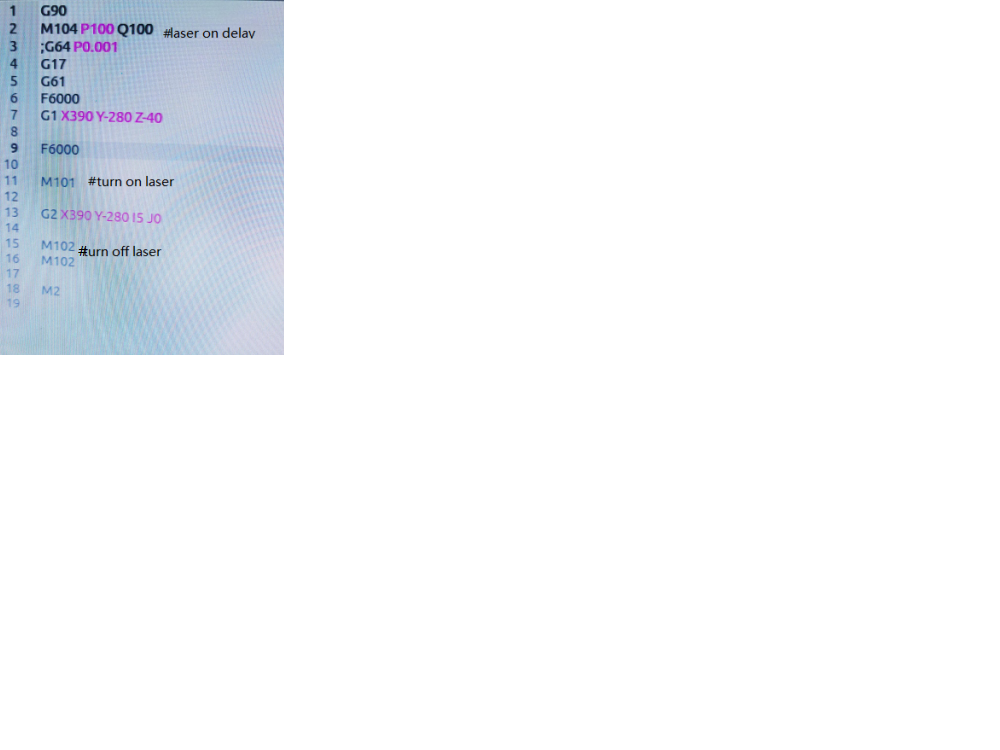

Does these hal and ini file image enough to analysis it?

Does these hal and ini file image enough to analysis it?

Please Log in or Create an account to join the conversation.

20 Oct 2021 03:27 #223625

by PCW

Replied by PCW on topic it is too fast to use F200 with G2?

Where does the joint feedback data come from?

That is, what drives joint.n.motor-pos-fb

or is this open loop

Is there some reason you cannot post the entire hal and ini files?

That is, what drives joint.n.motor-pos-fb

or is this open loop

Is there some reason you cannot post the entire hal and ini files?

Please Log in or Create an account to join the conversation.

20 Oct 2021 09:18 #223643

by curran209

Replied by curran209 on topic it is too fast to use F200 with G2?

please review it.

Please Log in or Create an account to join the conversation.

Time to create page: 0.245 seconds