Spindle speed via SuperPID

- x26iclone

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 4

12 Apr 2024 00:03 - 12 Apr 2024 00:04 #298035

by x26iclone

Spindle speed via SuperPID was created by x26iclone

Hoping for some help.

I was using a Dell Optiplex 780 SFF with a 5i25 a G540 and a SuperPID. All worked well until the G540 died. I replaced it with some sainsmart bobs and stepperonline motors/drivers. All worked great until the Dell died. I went with a RPi4 and 7c81 with mx3660x2d firmware. I had to remove the relay in order to use the DB25-14 pin as pwm. The output on that pin ranges from 0.90v to 5v when I click the + for the spindle speed in axis. When I do a M3 S8000 the rpm is something like 15000 and the pin voltage is something like 1.7v. I have the pwm_frequncy set to 50 as I believe is needed. Whats the best way to calibrate the spindle?

Thanks for any help.

I can try to upload my configs if needed.

I was using a Dell Optiplex 780 SFF with a 5i25 a G540 and a SuperPID. All worked well until the G540 died. I replaced it with some sainsmart bobs and stepperonline motors/drivers. All worked great until the Dell died. I went with a RPi4 and 7c81 with mx3660x2d firmware. I had to remove the relay in order to use the DB25-14 pin as pwm. The output on that pin ranges from 0.90v to 5v when I click the + for the spindle speed in axis. When I do a M3 S8000 the rpm is something like 15000 and the pin voltage is something like 1.7v. I have the pwm_frequncy set to 50 as I believe is needed. Whats the best way to calibrate the spindle?

Thanks for any help.

I can try to upload my configs if needed.

Last edit: 12 Apr 2024 00:04 by x26iclone.

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17382

- Thank you received: 5068

12 Apr 2024 01:12 #298040

by PCW

Replied by PCW on topic Spindle speed via SuperPID

The 5ABOB firmware should match the Sainsmart BOB

(the common one has PWM on pin 1)

Are you using the analog 0 to 10V output?

The analog out seems OK with a quick test:

% FS PWM VOLTAGE

0 0.026

10 0.944

20 1.862

30 2.794

40 3.744

50 4.706

60 5.686

70 6.681

80 7.692

90 8.720

100 9.754

(the PWM output pin needs to be inverted as the BOB PWM input is active low)

test conditions: 12V on 12-24V power 50 Hz PWM

(the common one has PWM on pin 1)

Are you using the analog 0 to 10V output?

The analog out seems OK with a quick test:

% FS PWM VOLTAGE

0 0.026

10 0.944

20 1.862

30 2.794

40 3.744

50 4.706

60 5.686

70 6.681

80 7.692

90 8.720

100 9.754

(the PWM output pin needs to be inverted as the BOB PWM input is active low)

test conditions: 12V on 12-24V power 50 Hz PWM

Please Log in or Create an account to join the conversation.

- x26iclone

- Offline

- New Member

-

Less

More

- Posts: 18

- Thank you received: 4

14 Apr 2024 03:59 #298215

by x26iclone

Replied by x26iclone on topic Spindle speed via SuperPID

Thanks for the reply and sorry for the late response.

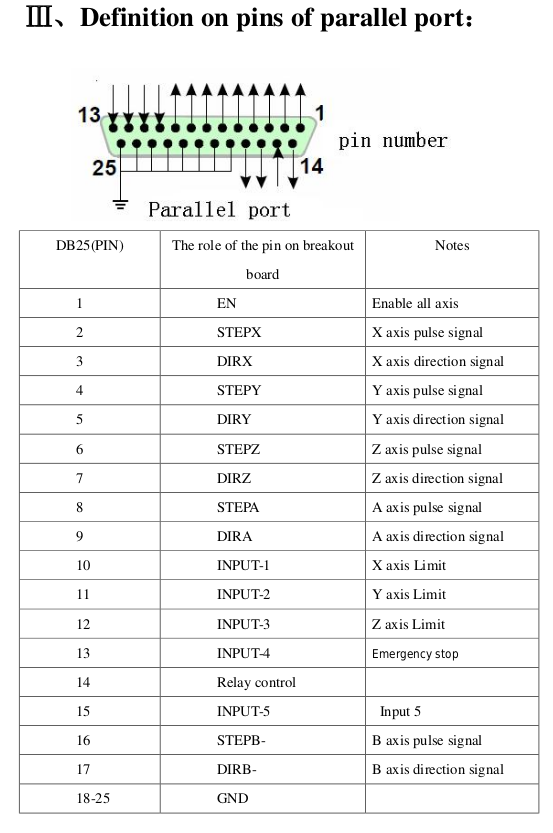

The reason I'm using the mx3660x2d firmware is according the docs for the bobs I have pin one is enable, see pic.

I'm using 0 - 5v out. I've been doing a lot of messing around with it and can't seem to get the M3 Sxxx to match what the SuperPID displays.

I've switched to qtdragon from axis due to a glade error when adding a spindle tab. The spindle speed in qtdragon matches the SuperPID display.

I believe this is my last ini and hal before giving up.

======================================================================

# Generated by PNCconf at Sat Apr 13 10:38:01 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = MuttCNC_No-Limits_RPi4

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = qtvcp qtdragon

PREFERENCE_FILE_PATH = WORKINGFOLDER/qtdragon.pref

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_0_OVERRIDE = 1.000000

MIN_SPINDLE_0_OVERRIDE = 0.500000

DEFAULT_SPINDLE_0_SPEED = 500

MIN_SPINDLE_0_SPEED = 100

MAX_SPINDLE_0_SPEED = 2500

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/cnc/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 158.333333

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

CYCLE_TIME = 100

[MDI_COMMAND_LIST]

MDI_COMMAND = G0 Z0;X0 Y0

MDI_COMMAND = G53 G0 Z0;G53 G0 X0 Y0

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G90 G94 G97 G64 P0.025

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7c81.0

[HAL]

HALUI = halui

HALFILE = MuttCNC_No-Limits_RPi4.hal

HALFILE = custom.hal

POSTGUI_HALFILE = qtvcp_postgui.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 20.83

MAX_LINEAR_VELOCITY = 208.33

POSITION_FILE = position.txt

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

MIN_LIMIT = -0.0

MAX_LIMIT = 785.0

[JOINT_0]

TYPE = LINEAR

HOME = 2.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 260.42

STEPGEN_MAXACCEL = 1437.5

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 160.9

MIN_LIMIT = -0.0

MAX_LIMIT = 785.0

HOME_OFFSET = 2.0

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

MIN_LIMIT = -0.0

MAX_LIMIT = 283.0

[JOINT_1]

TYPE = LINEAR

HOME = 2.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 260.42

STEPGEN_MAXACCEL = 1437.5

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 159.1

MIN_LIMIT = -0.0

MAX_LIMIT = 283.0

HOME_OFFSET = 2.0

HOME_SEQUENCE = 3

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 46.666666666666664

MAX_ACCELERATION = 250.0

MIN_LIMIT = -150.0

MAX_LIMIT = 0.0

[JOINT_2]

TYPE = LINEAR

HOME = -2.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 46.666666666666664

MAX_ACCELERATION = 250.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 58.33

STEPGEN_MAXACCEL = 312.5

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -804.2

MIN_LIMIT = -150.0

MAX_LIMIT = 0.0

HOME_OFFSET = -2.0

HOME_SEQUENCE = 1

#******************************************

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 25000.0

ENCODER_SCALE = 1

OUTPUT_SCALE = 50000

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 25000.0

======================================================================

======================================================================

# Generated by PNCconf at Sat Apr 13 10:38:01 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_rpspi config="firmware=hm2/7c81/MX3660X2.BIT num_encoders=2 num_pwmgens=2 num_stepgens=8 sserial_port_0=00xxxxxx"

setp [HMOT](CARD0).pwmgen.pwm_frequency 50

setp [HMOT](CARD0).pwmgen.pdm_frequency 6000000

setp [HMOT](CARD0).watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt scale names=scale.gear

loadrt near

loadrt mux16 names=ratio_select

addf [HMOT](CARD0).read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf ratio_select servo-thread

addf scale.gear servo-thread

addf near.0 servo-thread

addf [HMOT](CARD0).write servo-thread

setp [HMOT](CARD0).dpll.01.timer-us -50

setp [HMOT](CARD0).stepgen.timer-number 1

# external output signals

# --- MACHINE-IS-ENABLED ---

setp [HMOT](CARD0).gpio.000.is_output true

net machine-is-enabled => [HMOT](CARD0).gpio.000.out

setp [HMOT](CARD0).gpio.000.invert_output true

# --- MACHINE-IS-ENABLED ---

setp [HMOT](CARD0).gpio.019.is_output true

net machine-is-enabled => [HMOT](CARD0).gpio.019.out

setp [HMOT](CARD0).gpio.019.invert_output true

# --- COOLANT-FLOOD ---

setp [HMOT](CARD0).gpio.039.is_output true

net coolant-flood => [HMOT](CARD0).gpio.039.out

# --- COOLANT-MIST ---

setp [HMOT](CARD0).gpio.043.is_output true

net coolant-mist => [HMOT](CARD0).gpio.043.out

# --- SPINDLE-ENABLE ---

setp [HMOT](CARD0).gpio.045.is_output true

net spindle-enable => [HMOT](CARD0).gpio.045.out

setp [HMOT](CARD0).gpio.045.invert_output true

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= [HMOT](CARD0).gpio.003.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.04.dirsetup [JOINT_0]DIRSETUP

setp [HMOT](CARD0).stepgen.04.dirhold [JOINT_0]DIRHOLD

setp [HMOT](CARD0).stepgen.04.steplen [JOINT_0]STEPLEN

setp [HMOT](CARD0).stepgen.04.stepspace [JOINT_0]STEPSPACE

setp [HMOT](CARD0).stepgen.04.position-scale [JOINT_0]STEP_SCALE

setp [HMOT](CARD0).stepgen.04.step_type 0

setp [HMOT](CARD0).stepgen.04.control-type 1

setp [HMOT](CARD0).stepgen.04.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.04.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => [HMOT](CARD0).stepgen.04.velocity-cmd

net x-pos-fb <= [HMOT](CARD0).stepgen.04.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => [HMOT](CARD0).stepgen.04.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp [HMOT](CARD0).stepgen.01.dirhold [JOINT_1]DIRHOLD

setp [HMOT](CARD0).stepgen.01.steplen [JOINT_1]STEPLEN

setp [HMOT](CARD0).stepgen.01.stepspace [JOINT_1]STEPSPACE

setp [HMOT](CARD0).stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp [HMOT](CARD0).stepgen.01.step_type 0

setp [HMOT](CARD0).stepgen.01.control-type 1

setp [HMOT](CARD0).stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => [HMOT](CARD0).stepgen.01.velocity-cmd

net y-pos-fb <= [HMOT](CARD0).stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => [HMOT](CARD0).stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp [HMOT](CARD0).stepgen.02.dirhold [JOINT_2]DIRHOLD

setp [HMOT](CARD0).stepgen.02.steplen [JOINT_2]STEPLEN

setp [HMOT](CARD0).stepgen.02.stepspace [JOINT_2]STEPSPACE

setp [HMOT](CARD0).stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp [HMOT](CARD0).stepgen.02.step_type 0

setp [HMOT](CARD0).stepgen.02.control-type 1

setp [HMOT](CARD0).stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => [HMOT](CARD0).stepgen.02.velocity-cmd

net z-pos-fb <= [HMOT](CARD0).stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => [HMOT](CARD0).stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

net ratio_select.out pid.s.maxoutput

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-pid-out pid.s.output => scale.gear.in

net gear-ratio ratio_select.out-f => scale.gear.gain

setp ratio_select.in00 0.000200

setp ratio_select.in01 0.000040

net gear-select-a => ratio_select.sel0

net spindle-output <= scale.gear.out

# ---PWM Generator signals/setup---

setp [HMOT](CARD0).pwmgen.01.output-type 1

setp [HMOT](CARD0).pwmgen.01.scale [SPINDLE_0]OUTPUT_SCALE

setp hm2_7c81.0.gpio.020.invert_output true

net spindle-output => [HMOT](CARD0).pwmgen.01.value

net spindle-enable => [HMOT](CARD0).pwmgen.01.enable

# ---Encoder feedback signals/setup---

setp [HMOT](CARD0).encoder.01.counter-mode 1

setp [HMOT](CARD0).encoder.01.filter 1

setp [HMOT](CARD0).encoder.01.index-invert 0

setp [HMOT](CARD0).encoder.01.index-mask 0

setp [HMOT](CARD0).encoder.01.index-mask-invert 0

setp [HMOT](CARD0).encoder.01.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= [HMOT](CARD0).encoder.01.position

net spindle-vel-fb-rps <= [HMOT](CARD0).encoder.01.velocity

net spindle-vel-fb-rpm <= [HMOT](CARD0).encoder.01.velocity-rpm

net spindle-index-enable <=> [HMOT](CARD0).encoder.01.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 3.333333

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

======================================================================

Any change I made was through pncconf to keep me from making a change while screwing around that I would later forget about and be scratching my head if something was working...

Thanks.

The reason I'm using the mx3660x2d firmware is according the docs for the bobs I have pin one is enable, see pic.

I'm using 0 - 5v out. I've been doing a lot of messing around with it and can't seem to get the M3 Sxxx to match what the SuperPID displays.

I've switched to qtdragon from axis due to a glade error when adding a spindle tab. The spindle speed in qtdragon matches the SuperPID display.

I believe this is my last ini and hal before giving up.

======================================================================

# Generated by PNCconf at Sat Apr 13 10:38:01 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

[EMC]

MACHINE = MuttCNC_No-Limits_RPi4

DEBUG = 0

VERSION = 1.1

[DISPLAY]

DISPLAY = qtvcp qtdragon

PREFERENCE_FILE_PATH = WORKINGFOLDER/qtdragon.pref

POSITION_OFFSET = RELATIVE

POSITION_FEEDBACK = ACTUAL

MAX_FEED_OVERRIDE = 2.000000

MAX_SPINDLE_0_OVERRIDE = 1.000000

MIN_SPINDLE_0_OVERRIDE = 0.500000

DEFAULT_SPINDLE_0_SPEED = 500

MIN_SPINDLE_0_SPEED = 100

MAX_SPINDLE_0_SPEED = 2500

INTRO_GRAPHIC = linuxcnc.gif

INTRO_TIME = 5

PROGRAM_PREFIX = /home/cnc/linuxcnc/nc_files

INCREMENTS = 5mm 1mm .5mm .1mm .05mm .01mm .005mm

POSITION_FEEDBACK = ACTUAL

DEFAULT_LINEAR_VELOCITY = 6.000000

MAX_LINEAR_VELOCITY = 158.333333

MIN_LINEAR_VELOCITY = 0.500000

DEFAULT_ANGULAR_VELOCITY = 12.000000

MAX_ANGULAR_VELOCITY = 180.000000

MIN_ANGULAR_VELOCITY = 1.666667

EDITOR = gedit

GEOMETRY = xyz

CYCLE_TIME = 100

[MDI_COMMAND_LIST]

MDI_COMMAND = G0 Z0;X0 Y0

MDI_COMMAND = G53 G0 Z0;G53 G0 X0 Y0

[FILTER]

PROGRAM_EXTENSION = .png,.gif,.jpg Greyscale Depth Image

PROGRAM_EXTENSION = .py Python Script

png = image-to-gcode

gif = image-to-gcode

jpg = image-to-gcode

py = python

[TASK]

TASK = milltask

CYCLE_TIME = 0.010

[RS274NGC]

PARAMETER_FILE = linuxcnc.var

RS274NGC_STARTUP_CODE = G21 G40 G90 G94 G97 G64 P0.025

[EMCMOT]

EMCMOT = motmod

COMM_TIMEOUT = 1.0

SERVO_PERIOD = 1000000

[HMOT]

CARD0=hm2_7c81.0

[HAL]

HALUI = halui

HALFILE = MuttCNC_No-Limits_RPi4.hal

HALFILE = custom.hal

POSTGUI_HALFILE = qtvcp_postgui.hal

POSTGUI_HALFILE = custom_postgui.hal

SHUTDOWN = shutdown.hal

[HALUI]

[KINS]

JOINTS = 3

KINEMATICS = trivkins coordinates=XYZ

[TRAJ]

COORDINATES = XYZ

LINEAR_UNITS = mm

ANGULAR_UNITS = degree

DEFAULT_LINEAR_VELOCITY = 20.83

MAX_LINEAR_VELOCITY = 208.33

POSITION_FILE = position.txt

[EMCIO]

EMCIO = io

CYCLE_TIME = 0.100

TOOL_TABLE = tool.tbl

#******************************************

[AXIS_X]

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

MIN_LIMIT = -0.0

MAX_LIMIT = 785.0

[JOINT_0]

TYPE = LINEAR

HOME = 2.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 260.42

STEPGEN_MAXACCEL = 1437.5

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 160.9

MIN_LIMIT = -0.0

MAX_LIMIT = 785.0

HOME_OFFSET = 2.0

HOME_SEQUENCE = 2

#******************************************

#******************************************

[AXIS_Y]

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

MIN_LIMIT = -0.0

MAX_LIMIT = 283.0

[JOINT_1]

TYPE = LINEAR

HOME = 2.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 208.33333333333334

MAX_ACCELERATION = 1150.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 260.42

STEPGEN_MAXACCEL = 1437.5

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 10000

DIRHOLD = 10000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = 159.1

MIN_LIMIT = -0.0

MAX_LIMIT = 283.0

HOME_OFFSET = 2.0

HOME_SEQUENCE = 3

#******************************************

#******************************************

[AXIS_Z]

MAX_VELOCITY = 46.666666666666664

MAX_ACCELERATION = 250.0

MIN_LIMIT = -150.0

MAX_LIMIT = 0.0

[JOINT_2]

TYPE = LINEAR

HOME = -2.0

FERROR = 10.0

MIN_FERROR = 1.0

MAX_VELOCITY = 46.666666666666664

MAX_ACCELERATION = 250.0

# The values below should be 25% larger than MAX_VELOCITY and MAX_ACCELERATION

# If using BACKLASH compensation STEPGEN_MAXACCEL should be 100% larger.

STEPGEN_MAXVEL = 58.33

STEPGEN_MAXACCEL = 312.5

P = 1000

I = 0

D = 0

FF0 = 0

FF1 = 1

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 0

# these are in nanoseconds

DIRSETUP = 20000

DIRHOLD = 20000

STEPLEN = 5000

STEPSPACE = 5000

STEP_SCALE = -804.2

MIN_LIMIT = -150.0

MAX_LIMIT = 0.0

HOME_OFFSET = -2.0

HOME_SEQUENCE = 1

#******************************************

[SPINDLE_0]

P = 0

I = 0

D = 0

FF0 = 1

FF1 = 0

FF2 = 0

BIAS = 0

DEADBAND = 0

MAX_OUTPUT = 25000.0

ENCODER_SCALE = 1

OUTPUT_SCALE = 50000

OUTPUT_MIN_LIMIT = 0

OUTPUT_MAX_LIMIT = 25000.0

======================================================================

======================================================================

# Generated by PNCconf at Sat Apr 13 10:38:01 2024

# Using LinuxCNC version: Master (2.9)

# If you make changes to this file, they will be

# overwritten when you run PNCconf again

loadrt [KINS]KINEMATICS

loadrt [EMCMOT]EMCMOT servo_period_nsec=[EMCMOT]SERVO_PERIOD num_joints=[KINS]JOINTS

loadrt hostmot2

loadrt hm2_rpspi config="firmware=hm2/7c81/MX3660X2.BIT num_encoders=2 num_pwmgens=2 num_stepgens=8 sserial_port_0=00xxxxxx"

setp [HMOT](CARD0).pwmgen.pwm_frequency 50

setp [HMOT](CARD0).pwmgen.pdm_frequency 6000000

setp [HMOT](CARD0).watchdog.timeout_ns 5000000

loadrt pid names=pid.x,pid.y,pid.z,pid.s

loadrt scale names=scale.gear

loadrt near

loadrt mux16 names=ratio_select

addf [HMOT](CARD0).read servo-thread

addf motion-command-handler servo-thread

addf motion-controller servo-thread

addf pid.x.do-pid-calcs servo-thread

addf pid.y.do-pid-calcs servo-thread

addf pid.z.do-pid-calcs servo-thread

addf pid.s.do-pid-calcs servo-thread

addf ratio_select servo-thread

addf scale.gear servo-thread

addf near.0 servo-thread

addf [HMOT](CARD0).write servo-thread

setp [HMOT](CARD0).dpll.01.timer-us -50

setp [HMOT](CARD0).stepgen.timer-number 1

# external output signals

# --- MACHINE-IS-ENABLED ---

setp [HMOT](CARD0).gpio.000.is_output true

net machine-is-enabled => [HMOT](CARD0).gpio.000.out

setp [HMOT](CARD0).gpio.000.invert_output true

# --- MACHINE-IS-ENABLED ---

setp [HMOT](CARD0).gpio.019.is_output true

net machine-is-enabled => [HMOT](CARD0).gpio.019.out

setp [HMOT](CARD0).gpio.019.invert_output true

# --- COOLANT-FLOOD ---

setp [HMOT](CARD0).gpio.039.is_output true

net coolant-flood => [HMOT](CARD0).gpio.039.out

# --- COOLANT-MIST ---

setp [HMOT](CARD0).gpio.043.is_output true

net coolant-mist => [HMOT](CARD0).gpio.043.out

# --- SPINDLE-ENABLE ---

setp [HMOT](CARD0).gpio.045.is_output true

net spindle-enable => [HMOT](CARD0).gpio.045.out

setp [HMOT](CARD0).gpio.045.invert_output true

# external input signals

# --- ESTOP-EXT ---

net estop-ext <= [HMOT](CARD0).gpio.003.in

#*******************

# AXIS X JOINT 0

#*******************

setp pid.x.Pgain [JOINT_0]P

setp pid.x.Igain [JOINT_0]I

setp pid.x.Dgain [JOINT_0]D

setp pid.x.bias [JOINT_0]BIAS

setp pid.x.FF0 [JOINT_0]FF0

setp pid.x.FF1 [JOINT_0]FF1

setp pid.x.FF2 [JOINT_0]FF2

setp pid.x.deadband [JOINT_0]DEADBAND

setp pid.x.maxoutput [JOINT_0]MAX_OUTPUT

setp pid.x.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.x.maxerror 0.012700

net x-index-enable => pid.x.index-enable

net x-enable => pid.x.enable

net x-pos-cmd => pid.x.command

net x-pos-fb => pid.x.feedback

net x-output <= pid.x.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.04.dirsetup [JOINT_0]DIRSETUP

setp [HMOT](CARD0).stepgen.04.dirhold [JOINT_0]DIRHOLD

setp [HMOT](CARD0).stepgen.04.steplen [JOINT_0]STEPLEN

setp [HMOT](CARD0).stepgen.04.stepspace [JOINT_0]STEPSPACE

setp [HMOT](CARD0).stepgen.04.position-scale [JOINT_0]STEP_SCALE

setp [HMOT](CARD0).stepgen.04.step_type 0

setp [HMOT](CARD0).stepgen.04.control-type 1

setp [HMOT](CARD0).stepgen.04.maxaccel [JOINT_0]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.04.maxvel [JOINT_0]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net x-pos-cmd <= joint.0.motor-pos-cmd

net x-vel-cmd <= joint.0.vel-cmd

net x-output => [HMOT](CARD0).stepgen.04.velocity-cmd

net x-pos-fb <= [HMOT](CARD0).stepgen.04.position-fb

net x-pos-fb => joint.0.motor-pos-fb

net x-enable <= joint.0.amp-enable-out

net x-enable => [HMOT](CARD0).stepgen.04.enable

# ---setup home / limit switch signals---

net x-home-sw => joint.0.home-sw-in

net x-neg-limit => joint.0.neg-lim-sw-in

net x-pos-limit => joint.0.pos-lim-sw-in

#*******************

# AXIS Y JOINT 1

#*******************

setp pid.y.Pgain [JOINT_1]P

setp pid.y.Igain [JOINT_1]I

setp pid.y.Dgain [JOINT_1]D

setp pid.y.bias [JOINT_1]BIAS

setp pid.y.FF0 [JOINT_1]FF0

setp pid.y.FF1 [JOINT_1]FF1

setp pid.y.FF2 [JOINT_1]FF2

setp pid.y.deadband [JOINT_1]DEADBAND

setp pid.y.maxoutput [JOINT_1]MAX_OUTPUT

setp pid.y.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.y.maxerror 0.012700

net y-index-enable => pid.y.index-enable

net y-enable => pid.y.enable

net y-pos-cmd => pid.y.command

net y-pos-fb => pid.y.feedback

net y-output <= pid.y.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.01.dirsetup [JOINT_1]DIRSETUP

setp [HMOT](CARD0).stepgen.01.dirhold [JOINT_1]DIRHOLD

setp [HMOT](CARD0).stepgen.01.steplen [JOINT_1]STEPLEN

setp [HMOT](CARD0).stepgen.01.stepspace [JOINT_1]STEPSPACE

setp [HMOT](CARD0).stepgen.01.position-scale [JOINT_1]STEP_SCALE

setp [HMOT](CARD0).stepgen.01.step_type 0

setp [HMOT](CARD0).stepgen.01.control-type 1

setp [HMOT](CARD0).stepgen.01.maxaccel [JOINT_1]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.01.maxvel [JOINT_1]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net y-pos-cmd <= joint.1.motor-pos-cmd

net y-vel-cmd <= joint.1.vel-cmd

net y-output => [HMOT](CARD0).stepgen.01.velocity-cmd

net y-pos-fb <= [HMOT](CARD0).stepgen.01.position-fb

net y-pos-fb => joint.1.motor-pos-fb

net y-enable <= joint.1.amp-enable-out

net y-enable => [HMOT](CARD0).stepgen.01.enable

# ---setup home / limit switch signals---

net y-home-sw => joint.1.home-sw-in

net y-neg-limit => joint.1.neg-lim-sw-in

net y-pos-limit => joint.1.pos-lim-sw-in

#*******************

# AXIS Z JOINT 2

#*******************

setp pid.z.Pgain [JOINT_2]P

setp pid.z.Igain [JOINT_2]I

setp pid.z.Dgain [JOINT_2]D

setp pid.z.bias [JOINT_2]BIAS

setp pid.z.FF0 [JOINT_2]FF0

setp pid.z.FF1 [JOINT_2]FF1

setp pid.z.FF2 [JOINT_2]FF2

setp pid.z.deadband [JOINT_2]DEADBAND

setp pid.z.maxoutput [JOINT_2]MAX_OUTPUT

setp pid.z.error-previous-target true

# This setting is to limit bogus stepgen

# velocity corrections caused by position

# feedback sample time jitter.

setp pid.z.maxerror 0.012700

net z-index-enable => pid.z.index-enable

net z-enable => pid.z.enable

net z-pos-cmd => pid.z.command

net z-pos-fb => pid.z.feedback

net z-output <= pid.z.output

# Step Gen signals/setup

setp [HMOT](CARD0).stepgen.02.dirsetup [JOINT_2]DIRSETUP

setp [HMOT](CARD0).stepgen.02.dirhold [JOINT_2]DIRHOLD

setp [HMOT](CARD0).stepgen.02.steplen [JOINT_2]STEPLEN

setp [HMOT](CARD0).stepgen.02.stepspace [JOINT_2]STEPSPACE

setp [HMOT](CARD0).stepgen.02.position-scale [JOINT_2]STEP_SCALE

setp [HMOT](CARD0).stepgen.02.step_type 0

setp [HMOT](CARD0).stepgen.02.control-type 1

setp [HMOT](CARD0).stepgen.02.maxaccel [JOINT_2]STEPGEN_MAXACCEL

setp [HMOT](CARD0).stepgen.02.maxvel [JOINT_2]STEPGEN_MAXVEL

# ---closedloop stepper signals---

net z-pos-cmd <= joint.2.motor-pos-cmd

net z-vel-cmd <= joint.2.vel-cmd

net z-output => [HMOT](CARD0).stepgen.02.velocity-cmd

net z-pos-fb <= [HMOT](CARD0).stepgen.02.position-fb

net z-pos-fb => joint.2.motor-pos-fb

net z-enable <= joint.2.amp-enable-out

net z-enable => [HMOT](CARD0).stepgen.02.enable

# ---setup home / limit switch signals---

net z-home-sw => joint.2.home-sw-in

net z-neg-limit => joint.2.neg-lim-sw-in

net z-pos-limit => joint.2.pos-lim-sw-in

#*******************

# SPINDLE

#*******************

setp pid.s.Pgain [SPINDLE_0]P

setp pid.s.Igain [SPINDLE_0]I

setp pid.s.Dgain [SPINDLE_0]D

setp pid.s.bias [SPINDLE_0]BIAS

setp pid.s.FF0 [SPINDLE_0]FF0

setp pid.s.FF1 [SPINDLE_0]FF1

setp pid.s.FF2 [SPINDLE_0]FF2

setp pid.s.deadband [SPINDLE_0]DEADBAND

net ratio_select.out pid.s.maxoutput

setp pid.s.error-previous-target true

net spindle-index-enable => pid.s.index-enable

net spindle-enable => pid.s.enable

net spindle-vel-cmd-rpm-abs => pid.s.command

net spindle-vel-fb-rpm-abs => pid.s.feedback

net spindle-pid-out pid.s.output => scale.gear.in

net gear-ratio ratio_select.out-f => scale.gear.gain

setp ratio_select.in00 0.000200

setp ratio_select.in01 0.000040

net gear-select-a => ratio_select.sel0

net spindle-output <= scale.gear.out

# ---PWM Generator signals/setup---

setp [HMOT](CARD0).pwmgen.01.output-type 1

setp [HMOT](CARD0).pwmgen.01.scale [SPINDLE_0]OUTPUT_SCALE

setp hm2_7c81.0.gpio.020.invert_output true

net spindle-output => [HMOT](CARD0).pwmgen.01.value

net spindle-enable => [HMOT](CARD0).pwmgen.01.enable

# ---Encoder feedback signals/setup---

setp [HMOT](CARD0).encoder.01.counter-mode 1

setp [HMOT](CARD0).encoder.01.filter 1

setp [HMOT](CARD0).encoder.01.index-invert 0

setp [HMOT](CARD0).encoder.01.index-mask 0

setp [HMOT](CARD0).encoder.01.index-mask-invert 0

setp [HMOT](CARD0).encoder.01.scale [SPINDLE_0]ENCODER_SCALE

net spindle-revs <= [HMOT](CARD0).encoder.01.position

net spindle-vel-fb-rps <= [HMOT](CARD0).encoder.01.velocity

net spindle-vel-fb-rpm <= [HMOT](CARD0).encoder.01.velocity-rpm

net spindle-index-enable <=> [HMOT](CARD0).encoder.01.index-enable

# ---setup spindle control signals---

net spindle-vel-cmd-rps <= spindle.0.speed-out-rps

net spindle-vel-cmd-rps-abs <= spindle.0.speed-out-rps-abs

net spindle-vel-cmd-rpm <= spindle.0.speed-out

net spindle-vel-cmd-rpm-abs <= spindle.0.speed-out-abs

net spindle-enable <= spindle.0.on

net spindle-cw <= spindle.0.forward

net spindle-ccw <= spindle.0.reverse

net spindle-brake <= spindle.0.brake

net spindle-revs => spindle.0.revs

net spindle-at-speed => spindle.0.at-speed

net spindle-vel-fb-rps => spindle.0.speed-in

net spindle-index-enable <=> spindle.0.index-enable

# ---Setup spindle at speed signals---

net spindle-vel-cmd-rps => near.0.in1

net spindle-vel-fb-rps => near.0.in2

net spindle-at-speed <= near.0.out

setp near.0.scale 1.000000

setp near.0.difference 3.333333

#******************************

# connect miscellaneous signals

#******************************

# ---HALUI signals---

net axis-select-x halui.axis.x.select

net jog-x-pos halui.axis.x.plus

net jog-x-neg halui.axis.x.minus

net jog-x-analog halui.axis.x.analog

net x-is-homed halui.joint.0.is-homed

net axis-select-y halui.axis.y.select

net jog-y-pos halui.axis.y.plus

net jog-y-neg halui.axis.y.minus

net jog-y-analog halui.axis.y.analog

net y-is-homed halui.joint.1.is-homed

net axis-select-z halui.axis.z.select

net jog-z-pos halui.axis.z.plus

net jog-z-neg halui.axis.z.minus

net jog-z-analog halui.axis.z.analog

net z-is-homed halui.joint.2.is-homed

net jog-selected-pos halui.axis.selected.plus

net jog-selected-neg halui.axis.selected.minus

net spindle-manual-cw halui.spindle.0.forward

net spindle-manual-ccw halui.spindle.0.reverse

net spindle-manual-stop halui.spindle.0.stop

net machine-is-on halui.machine.is-on

net jog-speed halui.axis.jog-speed

net MDI-mode halui.mode.is-mdi

# ---coolant signals---

net coolant-mist <= iocontrol.0.coolant-mist

net coolant-flood <= iocontrol.0.coolant-flood

# ---probe signal---

net probe-in => motion.probe-input

# ---motion control signals---

net in-position <= motion.in-position

net machine-is-enabled <= motion.motion-enabled

# ---digital in / out signals---

# ---estop signals---

net estop-out <= iocontrol.0.user-enable-out

net estop-ext => iocontrol.0.emc-enable-in

# ---manual tool change signals---

net tool-change-request <= iocontrol.0.tool-change

net tool-change-confirmed => iocontrol.0.tool-changed

net tool-number <= iocontrol.0.tool-prep-number

# ---ignore tool prepare requests---

net tool-prepare-loopback iocontrol.0.tool-prepare => iocontrol.0.tool-prepared

======================================================================

Any change I made was through pncconf to keep me from making a change while screwing around that I would later forget about and be scratching my head if something was working...

Thanks.

Attachments:

Please Log in or Create an account to join the conversation.

- PCW

-

- Away

- Moderator

-

Less

More

- Posts: 17382

- Thank you received: 5068

14 Apr 2024 18:13 #298243

by PCW

Replied by PCW on topic Spindle speed via SuperPID

OK that not the standard 5ABOB with the analog output

(I was assuming you were using the analog output)

If you set the spindle speed to 0, I would expect the PWM

pin to read very close to 0 V on a DVM.

Does the SuperPID provide duty cycle vs RPM information?

(I was assuming you were using the analog output)

If you set the spindle speed to 0, I would expect the PWM

pin to read very close to 0 V on a DVM.

Does the SuperPID provide duty cycle vs RPM information?

Please Log in or Create an account to join the conversation.

Time to create page: 0.160 seconds