Calling next subroutine messes up offsets

- Routerworks

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 12

Then I load my program which contains 3 subroutines. My tool position at start is program 0,0,N) N being the top of work what ever the program subroutine calls for.

Hit run and it works beautifully.

Next Engrave operation calls for a tool change and change of Z offset.

This is where it all gets lost. I change the tool and position it, set g54 Z offset and it takes off for the last G57 position.

Don't honestly know what I am missing.

Also would like to be able to call one of the subroutines out of order and be able to run it.

Thanks for any help in advance

I am determined to get a handle of these subroutines. I know I'm missing something here.

Attachments:

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4661

- Thank you received: 2078

Attachments:

Please Log in or Create an account to join the conversation.

- Routerworks

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 12

I would still appreciate knowing how to call anyone of these routines without going through the entire program. Also how to set the Z after the tool change.

Thank you

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4661

- Thank you received: 2078

I would still appreciate knowing how to call anyone of these routines without going through the entire program.

You can call any subroutine in a loaded program from MDI (eg 'o100 call')

Do you mean the tool-length offset or the work-offset?Also how to set the Z after the tool change.

The currently active work offset can be changed like this:

'G10 L20 P0 z123'

Please Log in or Create an account to join the conversation.

- Routerworks

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 12

I see now how to call another subrutine. If I'm in a running subroutine and stop it, do I have to end it (END SUB) before I call the new subrutine?

I meant "work offset".

If I am undestanding this L20 P0 would change the axis for all subroutines relative to the machine coordinates and not change the WCS offsets for each location i.e. G54...5,6,7. Is this the same as using the Axis Screen offset for P0?

Essintially the program ran the first opertion to all 4 locaions then lifted up and stopped. I want to be able to move it back to the first location and change the tool and set the Z work offset for the nest operation.

Many thanks

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4661

- Thank you received: 2078

P0 just selects whatever WCS is currently active. If you want to change a specific offset system you would use P1 ... P9.

Yes axis gui's P0 issues G10 L20 P0 ...

If you need to change the Z offset for all operations regardless of WCS you would probably want to change the tool-offset instead.

Please Log in or Create an account to join the conversation.

- Routerworks

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 12

Now I understand the difference between Axis' P0 and the others. Big help.

I just want to change the Z offset for the axis I am in. It seems that if I make a G54 offset change it affects the entire program. Moves the entire image.

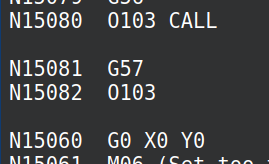

The difficulty I am having is moving from the end of the 4th position of the first subroutine back to the start (first) position of the second subroutine (o103) and repositioning the Z axis.

Freecad may have added some unnecessary moves and offsets.

For example I don't understand G0 X0 Y0 F70.

Also don't understand why it adds G92 offsets at the beginning of the next set of subroutine axis.

Getting there. Greatly appreciate your help.

Please Log in or Create an account to join the conversation.

- Routerworks

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 12

N15060 G0 X0 Y0 F70

N15061 M06 (Set too top of surface Z0.75)

N15062 G92 Z0.75 (Pocket surface top)

Don't understand the first line. F70 should only apply to G1?

Why the G92. This changes the origin position rather than just the offset from the present origin???

Please Log in or Create an account to join the conversation.

- Aciera

-

- Offline

- Administrator

-

- Posts: 4661

- Thank you received: 2078

eg line N3620

N3570 (Engrave)

N3571 O103 SUB

N3580 G0 X0 Y0 Z1.0

N3590 G0 Z0.0

N3591 M01

N3600 G0 X-0.7617 Y-1.2343

N3610 G0 Z0.8681

N3620 G1 X-0.7617 Y-1.2343 Z-0.0500

N3630 G1 X-0.7983 Y-1.2510 Z-0.0500 F70.0000 G92 affects all coordinate systems, this can be handy but it can also be a bit confusing.

linuxcnc.org/docs/html/gcode/g-code.html#gcode:g92

The difficulty I am having is moving from the end of the 4th position of the first subroutine back to the start (first) position of the second subroutine (o103) and repositioning the Z axis.

The first round (o100) is done with 'G92 Z0.75' while the second (o103) is done with 'G92 Z0.0'. It seems that there is no tool-length offset used (ie no G43). I don't know what your tool change work flow is but this would require that the tools used have exactly the same length OR the G92 offset is used to compensate for different tool-length, which would be a somewhat odd way of doing things.

Please Log in or Create an account to join the conversation.

- Routerworks

- Offline

- Premium Member

-

- Posts: 124

- Thank you received: 12

I manually move the head to a zero position and insert the new tool. Then I use G54 offset to give it the program height, then run.

Went back and tried to regenerate this, it seems to not be very good at it.

I think I am either going to have to split the operations into separate programs or learn how to assemble this myself. I haven't given up on learning how to take the code, create subroutines and write the code for multiple locations.

Don't think I need the G92s. When I enter the Z location it moves the entire 4 location layout on the screen. Have no idea why.

Anyhow, more to do and learn.

Almost there, I think

thanks

Please Log in or Create an account to join the conversation.