Lichaun LCDA357H setup

- Pala2020

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

01 Feb 2021 22:30 #197339

by Pala2020

Replied by Pala2020 on topic Lichaun LCDA357H setup

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

01 Feb 2021 23:05 #197345

by tommylight

Replied by tommylight on topic Lichaun LCDA357H setup

@Pala2020,

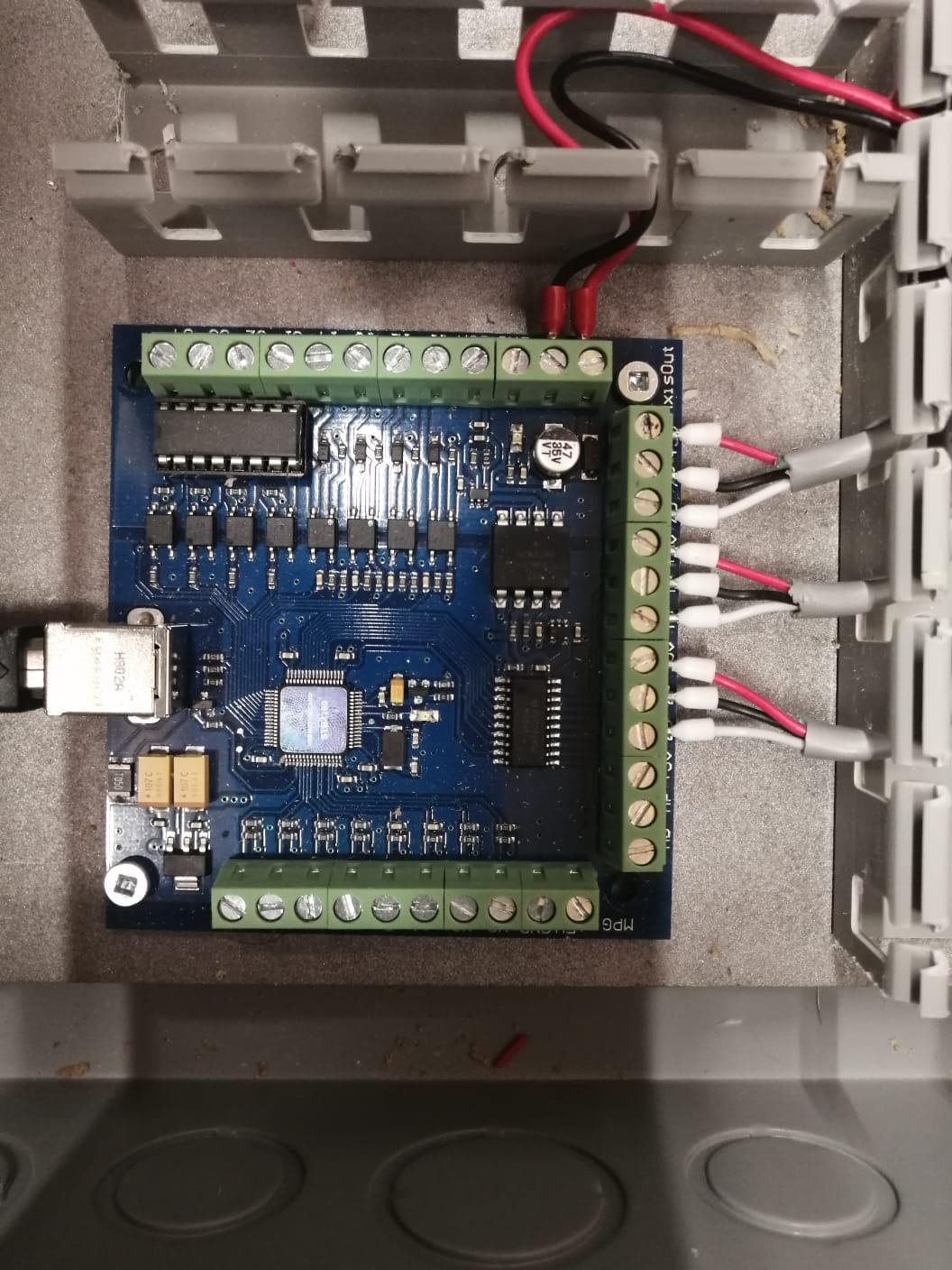

I am confused, that is a Mach3 control board so chances are it will not work with LinuxCNC.

LinuxCNC compatible boards with ethernet are made by Mesa, there are several types of them, like 7i92 (similar to what you have), 7i96, 7i76E, etc.

Maybe there are other boards that do work with LinuxCNC through ethernet, but i am not aware of them.

Did you test that setup with Mach3?

I am confused, that is a Mach3 control board so chances are it will not work with LinuxCNC.

LinuxCNC compatible boards with ethernet are made by Mesa, there are several types of them, like 7i92 (similar to what you have), 7i96, 7i76E, etc.

Maybe there are other boards that do work with LinuxCNC through ethernet, but i am not aware of them.

Did you test that setup with Mach3?

Please Log in or Create an account to join the conversation.

- Pala2020

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

01 Feb 2021 23:42 #197349

by Pala2020

Replied by Pala2020 on topic Lichaun LCDA357H setup

thanks for answer.

my problem is the same of the other guys.

when i tray to move the stepper in close loop the driver send a alarm (3 flash)

i know this is a Linux forum.

But here is the only forum who have the answer i am looking for.

i don't know if the problem is the encoder wiring????or something more.

i really appreciate if you can help my to solve the problem.

Thank you very much for your help.

my problem is the same of the other guys.

when i tray to move the stepper in close loop the driver send a alarm (3 flash)

i know this is a Linux forum.

But here is the only forum who have the answer i am looking for.

i don't know if the problem is the encoder wiring????or something more.

i really appreciate if you can help my to solve the problem.

Thank you very much for your help.

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

02 Feb 2021 00:30 #197359

by tommylight

Replied by tommylight on topic Lichaun LCDA357H setup

That sounds like incorrect wiring of the encoder or motor wires are set for reverse spinning, so try swapping just 2 of the motor wires.when i tray to move the stepper in close loop the driver send a alarm (3 flash)

Please Log in or Create an account to join the conversation.

- Pala2020

- Offline

- New Member

-

Less

More

- Posts: 4

- Thank you received: 1

02 Feb 2021 01:19 #197366

by Pala2020

Replied by Pala2020 on topic Lichaun LCDA357H setup

You are right tommylight.

That was the problem..............Now everything is OK.

Thank for your Help..... I didn't realize the direction was the problem...... Now i can continue with my project

That was the problem..............Now everything is OK.

Thank for your Help..... I didn't realize the direction was the problem...... Now i can continue with my project

The following user(s) said Thank You: tommylight

Please Log in or Create an account to join the conversation.

- tommylight

-

- Away

- Moderator

-

Less

More

- Posts: 21164

- Thank you received: 7228

02 Feb 2021 09:52 #197397

by tommylight

Replied by tommylight on topic Lichaun LCDA357H setup

Nice, you are welcomed, always.

Please Log in or Create an account to join the conversation.

- tjtr33

-

- Offline

- Elite Member

-

Less

More

- Posts: 166

- Thank you received: 48

02 Aug 2021 06:16 - 03 Aug 2021 13:37 #216665

by tjtr33

Replied by tjtr33 on topic Lichaun LCDA357H setup

I got the 3 blink error just now (01AUG2021) after at least 1/2 hour runtime.

But i hooked up a thermometer on motor body and saw 57degC.

I'd like to reduce the current but thats a function of a windows .exe

so that will be done later.

Yesterday I ran for a few hours without problem.

I at least have to wait for the cores to cool down and add fans

( motors in test rig with no load nor attached to any heatsinking frame ).

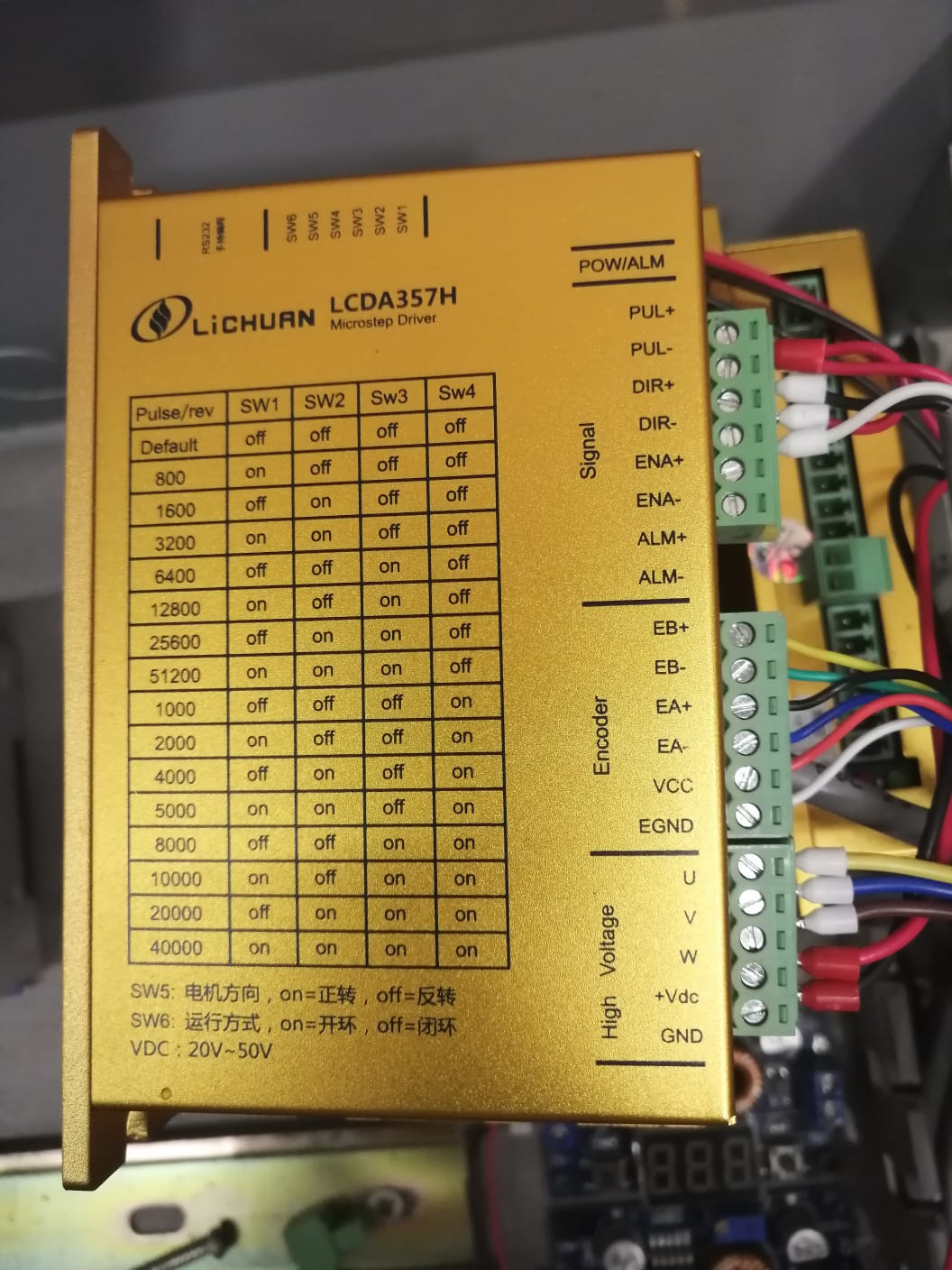

I have the swx6 set to closed loop stepping.

I use tie wraps on motor shaft and magic marker spots on motor to verify no lloss of steps.

(even with the swx6 set to closed loop.. )

tomp

ps using google translate

english open loop -> simplified chinese 开环

so you can tell sw6 ON (开环 ) means OPEN LOOP mode

and swx 6 OFF (闭环 ) means Closed loop ( 1st of 2 chars is different )

my swxs are all closed ( 1/4 uStep, motor direction normal?, closed loop,)

edit 4aug2021

I now have 2383mm/min with Gen Hesket & PCW's suggestion of 20000 for setup and hold terms.

My values were not small before, I had 50000 ! ( thats the default case for the allwincnc branch of lcnc for orange pi's. )

I also lowered the step and space from 5000 to 3000. I am not yet happy because the motors are at 55degC

with no load, and only 100 acceleration. The default 200 accell gets me the 3 blink err soon after first dir change.

This is now 21khz setp rate and 1588 rpm. Not as high as hoped for but stable. The test is _1000_ repeats of +/-80mm

motion at 2383 m/min. That test has now run 3 times w/o errors ( my ears ache !)

If i change my screws from 1.5pitch to 4, i can have 6m/min

But that's a Catch-22 , its easier to change that if I had a cnc machine

thx tomp

But i hooked up a thermometer on motor body and saw 57degC.

I'd like to reduce the current but thats a function of a windows .exe

so that will be done later.

Yesterday I ran for a few hours without problem.

I at least have to wait for the cores to cool down and add fans

( motors in test rig with no load nor attached to any heatsinking frame ).

I have the swx6 set to closed loop stepping.

I use tie wraps on motor shaft and magic marker spots on motor to verify no lloss of steps.

(even with the swx6 set to closed loop.. )

tomp

ps using google translate

english open loop -> simplified chinese 开环

so you can tell sw6 ON (开环 ) means OPEN LOOP mode

and swx 6 OFF (闭环 ) means Closed loop ( 1st of 2 chars is different )

my swxs are all closed ( 1/4 uStep, motor direction normal?, closed loop,)

edit 4aug2021

I now have 2383mm/min with Gen Hesket & PCW's suggestion of 20000 for setup and hold terms.

My values were not small before, I had 50000 ! ( thats the default case for the allwincnc branch of lcnc for orange pi's. )

I also lowered the step and space from 5000 to 3000. I am not yet happy because the motors are at 55degC

with no load, and only 100 acceleration. The default 200 accell gets me the 3 blink err soon after first dir change.

This is now 21khz setp rate and 1588 rpm. Not as high as hoped for but stable. The test is _1000_ repeats of +/-80mm

motion at 2383 m/min. That test has now run 3 times w/o errors ( my ears ache !)

If i change my screws from 1.5pitch to 4, i can have 6m/min

But that's a Catch-22 , its easier to change that if I had a cnc machine

thx tomp

Last edit: 03 Aug 2021 13:37 by tjtr33. Reason: typo, update

Please Log in or Create an account to join the conversation.

- Samuelx

- Offline

- Senior Member

-

Less

More

- Posts: 56

- Thank you received: 4

28 Jul 2022 08:25 - 28 Jul 2022 08:39 #248515

by Samuelx

Replied by Samuelx on topic Lichaun LCDA357H setup

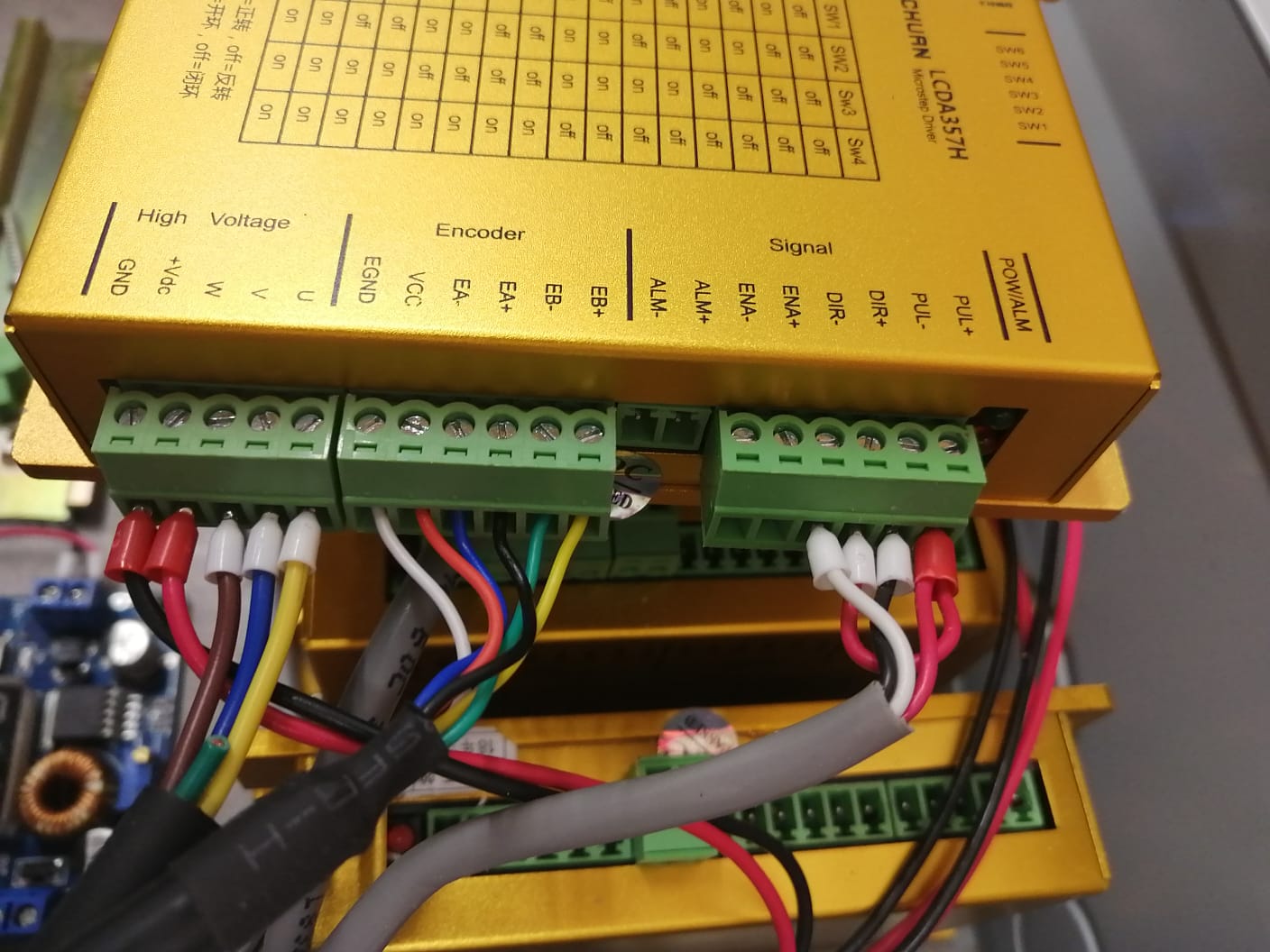

Attachments:

Last edit: 28 Jul 2022 08:39 by Samuelx.

Please Log in or Create an account to join the conversation.

- Todd Zuercher

-

- Away

- Platinum Member

-

Less

More

- Posts: 4693

- Thank you received: 1438

28 Jul 2022 15:12 - 28 Jul 2022 15:13 #248548

by Todd Zuercher

Replied by Todd Zuercher on topic Lichaun LCDA357H setup

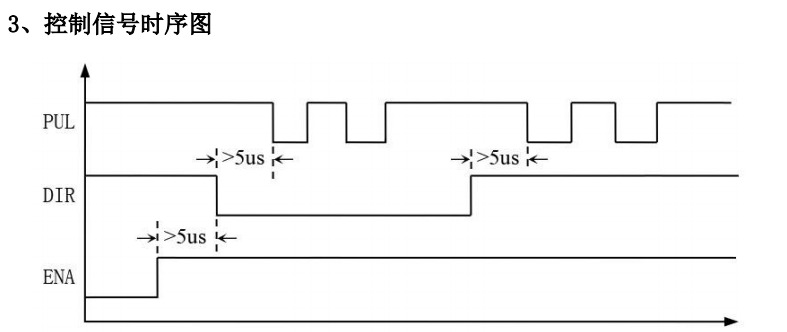

Just remember that the times listed in manuals are minimum times for detection. It is often a good practice to double them, when setting up an actual configuration. However the only meaningful time in that illustration is Direction Setup Time of 5us. (Also a setup time for Enable which Linuxcnc doesn't have a setting for.)

Last edit: 28 Jul 2022 15:13 by Todd Zuercher.

Please Log in or Create an account to join the conversation.

- Mariusz

-

- Visitor

-

23 Dec 2022 14:52 - 23 Dec 2022 20:24 #260154

by Mariusz

Replied by Mariusz on topic Lichaun LCDA357H setup

Anyone has a successfull connection with PC to setup encoder and maximum current? I can run this driver in open loop mode, but my servo take 2.1A @ 24V in holding mode and is inredible hot. I played with all bound rate and DriverNO without success. The same rs232 cabel I use with Ledshine controller and all work fine. I use LA052-040E 24V servo.

Last edit: 23 Dec 2022 20:24 by Mariusz.

Please Log in or Create an account to join the conversation.

Moderators: cmorley

Time to create page: 0.219 seconds