Lathe ID taper

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

17 Feb 2012 10:12 #17752

by Rick G

Lathe ID taper was created by Rick G

Here is a sub based on John Thorton's lathe id.

This untested sub should allow you to cut an inside diameter taper on the lathe.

It assumes you...

Have an existing undersze bore.

You know the depth of the taper and the difference between the large and the small diameter of the taper, and you have checked to make sure there is adequate tool clearance.

Rick G

This untested sub should allow you to cut an inside diameter taper on the lathe.

It assumes you...

Have an existing undersze bore.

You know the depth of the taper and the difference between the large and the small diameter of the taper, and you have checked to make sure there is adequate tool clearance.

Rick G

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

17 Feb 2012 13:13 #17757

by BigJohnT

Replied by BigJohnT on topic Re:Lathe ID taper

Dang your up early today... Thanks for sharing that Rick. I need to polish mine up a bit and post them again.

John

John

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

04 Jan 2013 18:13 #28364

by Rick G

Replied by Rick G on topic Re:Lathe ID taper

Here is an updated id taper sub for the lathe.

It works when you have an existing hole and you want to taper to a larger diameter and know the final diameter and the depth.

It uses a different method to calculate each pass to avoid excess Z air cutting movements.

Again not tested yet, only on a sim.

Rick G

It works when you have an existing hole and you want to taper to a larger diameter and know the final diameter and the depth.

It uses a different method to calculate each pass to avoid excess Z air cutting movements.

Again not tested yet, only on a sim.

Rick G

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

04 Jan 2013 20:45 #28371

by andypugh

Replied by andypugh on topic Re:Lathe ID taper

I bored an internal taper last night.

However, in my case I needed to set the angle (7/24 or 16.26 degrees) and I think this may be the more common situation.

(BT30 is 16.26 degrres and a 31.75 larger dimension)

However, in my case I needed to set the angle (7/24 or 16.26 degrees) and I think this may be the more common situation.

(BT30 is 16.26 degrres and a 31.75 larger dimension)

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

04 Jan 2013 20:57 #28374

by BigJohnT

Replied by BigJohnT on topic Re:Lathe ID taper

Andy, do you mean it is more common to use the angle of the taper instead of the two diameters? That's what my latest

Taper-OD

subroutine does.

John

John

Please Log in or Create an account to join the conversation.

- andypugh

-

- Offline

- Moderator

-

Less

More

- Posts: 19789

- Thank you received: 4605

04 Jan 2013 21:10 #28376

by andypugh

Replied by andypugh on topic Re:Lathe ID taper

I don't know. it is certainly more common for _me_ to care about the angle, but I guess it would typically depend on how the engineering drawing was dimensioned.Andy, do you mean it is more common to use the angle of the taper instead of the two diameters?

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

05 Jan 2013 16:54 #28394

by Rick G

Replied by Rick G on topic Re:Lathe ID taper

Interesting.

In this case I was working on a custom throttle body bore that needed a taper, I had the small diameter, the length and the large diameter.

What I wanted to avoid was excess Z moves cutting air part of the moves.

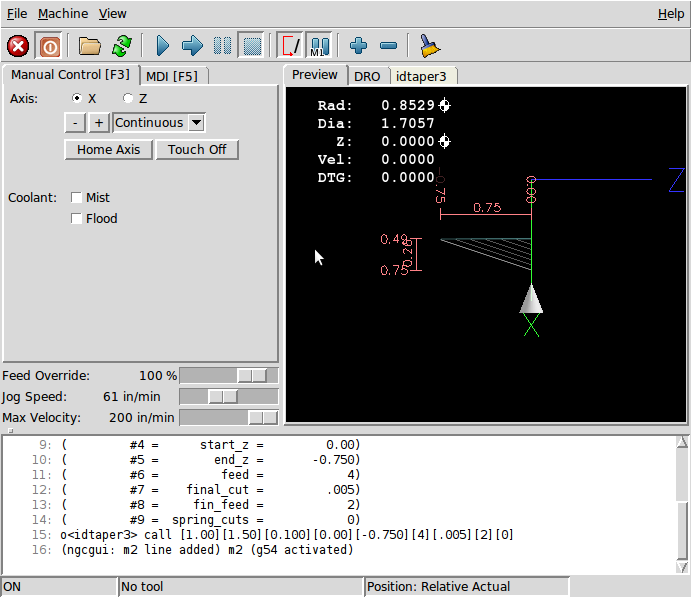

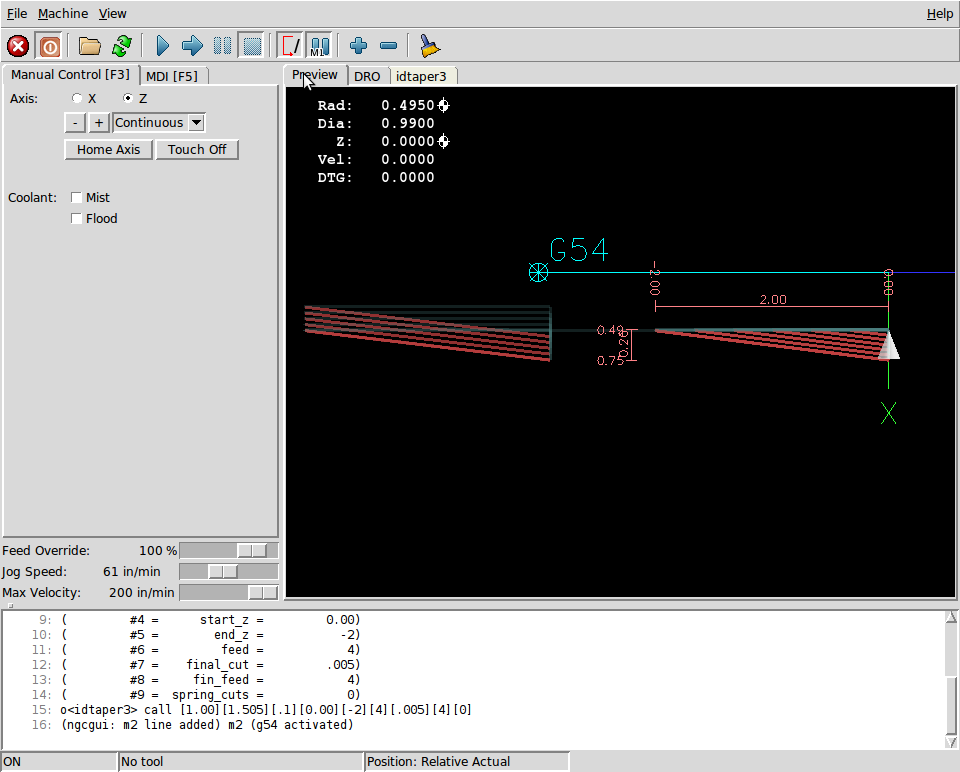

Below is a screen shot of two examples, on the left is the way I was cutting with full Z moves, on the right the newer sub.

The left took about 3 1/4 minutes the right 2 1/4 minutes at the same F4 cutting speed.

I can see the benefit and advantage of having different subs for tapers, ones that accept dimensions and ones that accept angles.

Rick G

In this case I was working on a custom throttle body bore that needed a taper, I had the small diameter, the length and the large diameter.

What I wanted to avoid was excess Z moves cutting air part of the moves.

Below is a screen shot of two examples, on the left is the way I was cutting with full Z moves, on the right the newer sub.

The left took about 3 1/4 minutes the right 2 1/4 minutes at the same F4 cutting speed.

I can see the benefit and advantage of having different subs for tapers, ones that accept dimensions and ones that accept angles.

Rick G

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

05 Jan 2013 20:27 #28397

by Rick G

Replied by Rick G on topic Re:Lathe ID taper

Morning John,

Looking at your od taper sub would your id taper look something like this?

(info: Taper OD, multi-pass)

o<taper-ida> sub

;#<diameter> = #1 (= 0.750 Stock Dia)

#<diameter> = #1 (= 0.750 Hole diam)

#<final-depth> = #2 (= 0.120 Taper Depth)

#<doc> = #3 (= 0.025 Depth of Cut)

#<angle> = #4 (= 45 Angle of Taper)

#<z-start> = #5 (= 0.000 Z Start)

#<feed> = #6 (= 2 Feed Rate)

#<tool> = #7 (= 1 Tool Number)

#<max-rpm> = #8 (= 2000 Max RPM)

#<sfm> = #9 (= 100 SFM)

#<coolant> = #10 (= 8 Flood=8, Off=9)

G7 G18 G40 G54 F#<feed>

G96 D#<max-rpm> S#<sfm>

T#<tool> M6 G43

G42 (start cutter comp)

M3 M#<coolant>

#<current-depth> = 0

o100 while [#<current-depth> LT #<final-depth>]

o110 if [[#<current-depth> + #<doc>]LT #<final-depth>]

#<current-depth> = [#<current-depth> + #<doc>]

o110 else

#<current-depth> = #<final-depth>

o110 endif

#<current-x> = [#<diameter> + [#<current-depth> * 2]]

G0 X#<current-x> Z[#<z-start> + .01]

G1 Z[#<z-start>]

;G1 X#<diameter> Z[#<z-start> + [#<current-depth> * TAN[90 - #<angle>]]]

G1 X#<diameter> Z[#<z-start> + [#<current-depth> * TAN[90 + #<angle>]]]

G1 X[#<diameter> - 0.01]

G0 Z[#<z-start> + .01]

o100 endwhile

M5 M9

G0 Z[#<z-start> + .1]

G40 G97

;G53 G0 X0.000 Z0.000

o<taper-ida> endsub

Looking at your od taper sub would your id taper look something like this?

(info: Taper OD, multi-pass)

o<taper-ida> sub

;#<diameter> = #1 (= 0.750 Stock Dia)

#<diameter> = #1 (= 0.750 Hole diam)

#<final-depth> = #2 (= 0.120 Taper Depth)

#<doc> = #3 (= 0.025 Depth of Cut)

#<angle> = #4 (= 45 Angle of Taper)

#<z-start> = #5 (= 0.000 Z Start)

#<feed> = #6 (= 2 Feed Rate)

#<tool> = #7 (= 1 Tool Number)

#<max-rpm> = #8 (= 2000 Max RPM)

#<sfm> = #9 (= 100 SFM)

#<coolant> = #10 (= 8 Flood=8, Off=9)

G7 G18 G40 G54 F#<feed>

G96 D#<max-rpm> S#<sfm>

T#<tool> M6 G43

G42 (start cutter comp)

M3 M#<coolant>

#<current-depth> = 0

o100 while [#<current-depth> LT #<final-depth>]

o110 if [[#<current-depth> + #<doc>]LT #<final-depth>]

#<current-depth> = [#<current-depth> + #<doc>]

o110 else

#<current-depth> = #<final-depth>

o110 endif

#<current-x> = [#<diameter> + [#<current-depth> * 2]]

G0 X#<current-x> Z[#<z-start> + .01]

G1 Z[#<z-start>]

;G1 X#<diameter> Z[#<z-start> + [#<current-depth> * TAN[90 - #<angle>]]]

G1 X#<diameter> Z[#<z-start> + [#<current-depth> * TAN[90 + #<angle>]]]

G1 X[#<diameter> - 0.01]

G0 Z[#<z-start> + .01]

o100 endwhile

M5 M9

G0 Z[#<z-start> + .1]

G40 G97

;G53 G0 X0.000 Z0.000

o<taper-ida> endsub

Please Log in or Create an account to join the conversation.

- BigJohnT

-

- Offline

- Administrator

-

Less

More

- Posts: 3990

- Thank you received: 994

05 Jan 2013 20:46 #28398

by BigJohnT

Replied by BigJohnT on topic Re:Lathe ID taper

Morning Rick,

Yep, it does look like that now with one exception

with one exception

(info: Taper ID, multi-pass)

John

Yep, it does look like that now

(info: Taper ID, multi-pass)

John

Please Log in or Create an account to join the conversation.

- Rick G

-

Topic Author

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 27

- Thank you received: 114

05 Jan 2013 21:03 #28399

by Rick G

Replied by Rick G on topic Re:Lathe ID taper

John,

That is pretty cool, I will add that to my sub directory if I need to work from the angle of the taper instead of the dimensions.

As I park my lathe at the tailstock end I need to comment out the ending G53 G0 move to avoid surprises.

Rick G

That is pretty cool, I will add that to my sub directory if I need to work from the angle of the taper instead of the dimensions.

As I park my lathe at the tailstock end I need to comment out the ending G53 G0 move to avoid surprises.

Rick G

Please Log in or Create an account to join the conversation.

Time to create page: 0.299 seconds